Grounding of a filter by means of an electrically conductive conductor trace on the filter element

A technology of filter elements and strip conductors, which can be used in membrane filters, filtration separation, electrical components, etc., and can solve expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

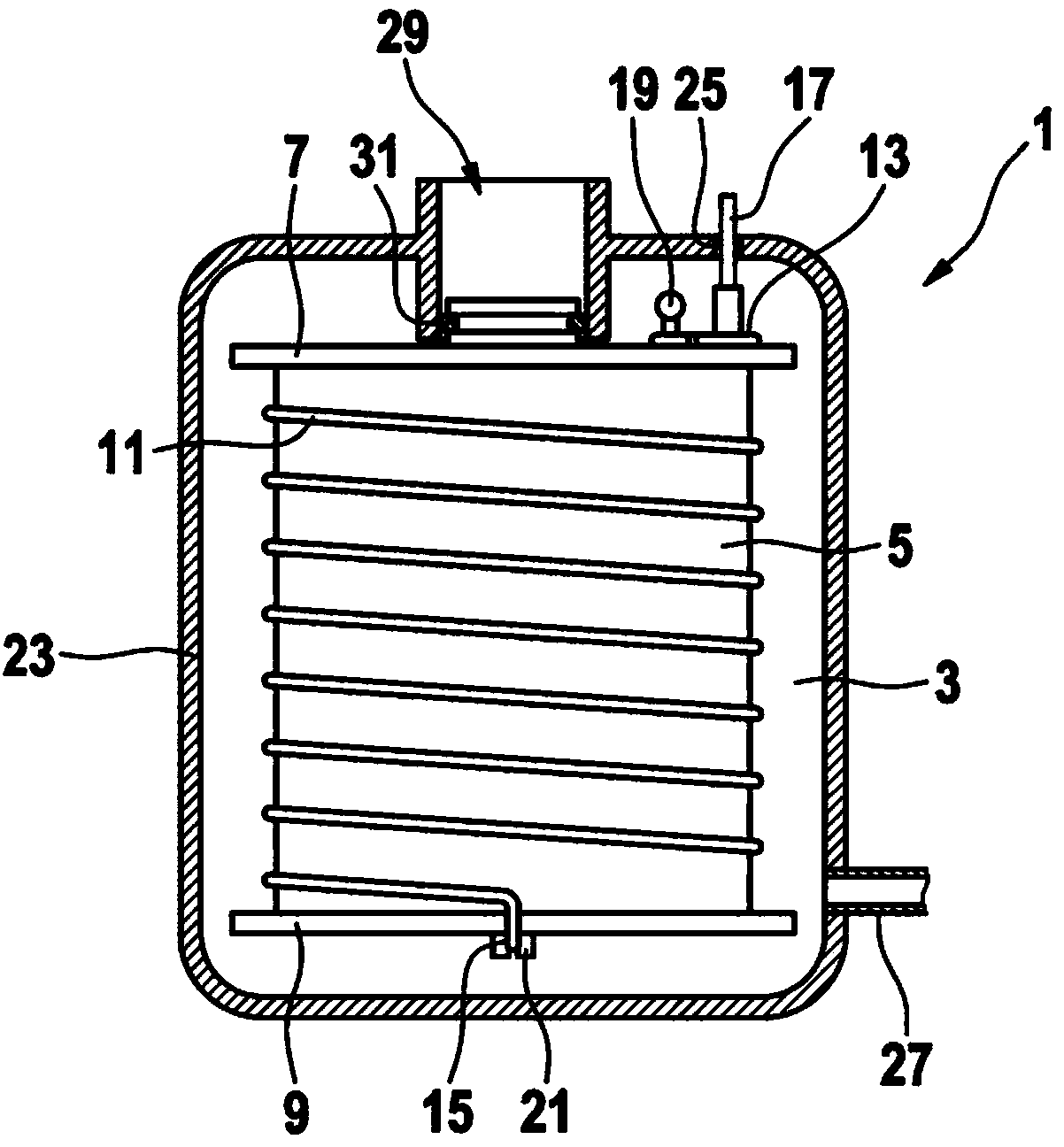

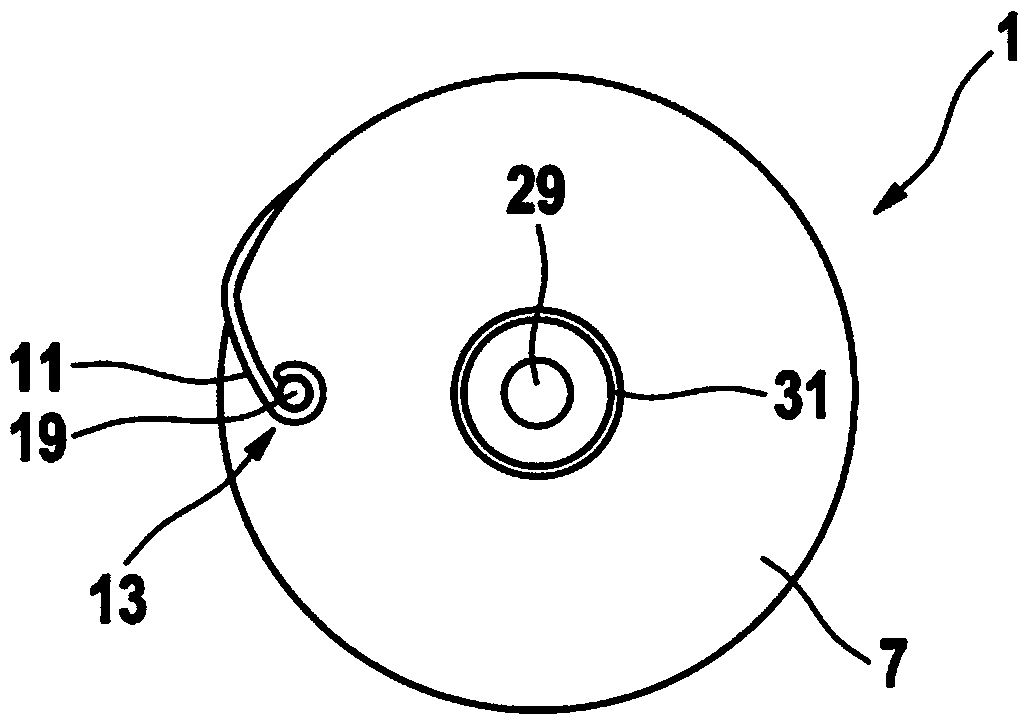

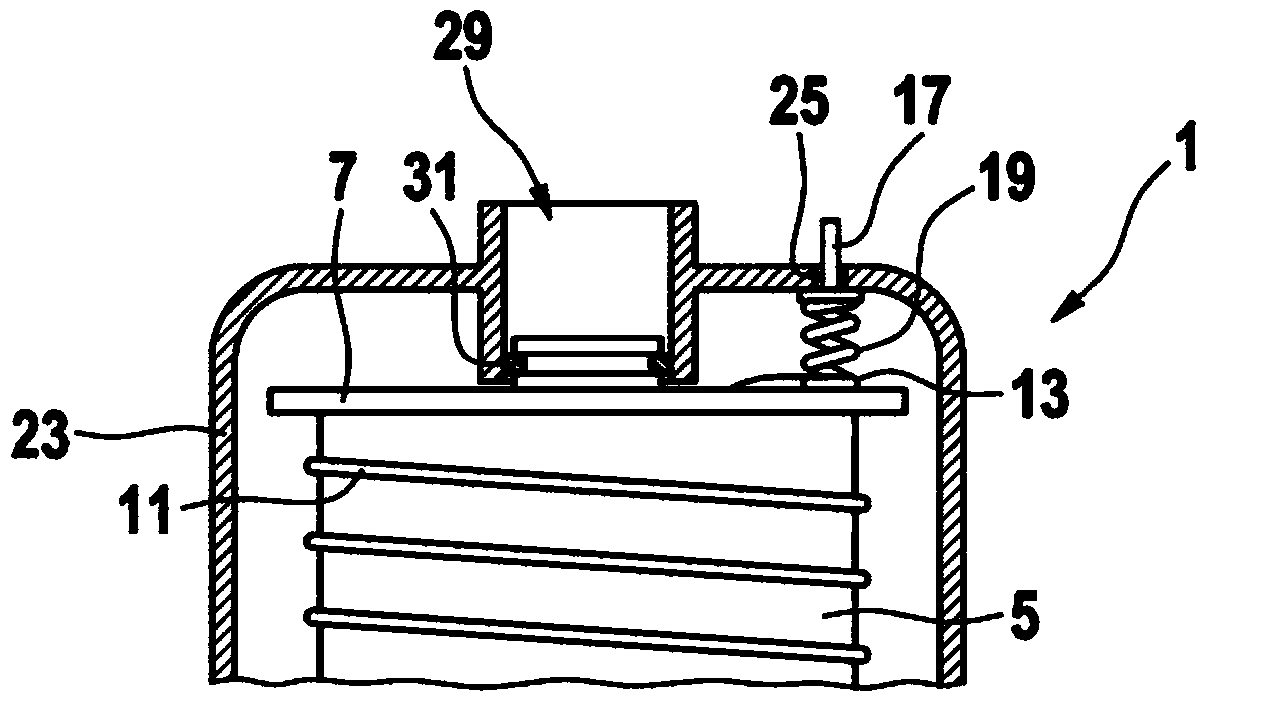

[0033] exist figure 1 A cross-section of a filter 1 , in particular a fuel filter, is shown in . The filter has a filter element 5 which is designed to remove unwanted particles from a liquid 3 , in particular fuel. The filter element 5 can here be, for example, a pleated filter paper, optionally with an internal support structure. The filter element 5 is arranged between the first end cap 7 and the second end cap 9 . The end caps 7 , 9 seal the filter element 5 in a fluid-tight manner against the liquid 3 in the interspace between the housing 23 and the filter element 5 . The liquid 3 thus has to pass through the filter element 5 before it can reach the cavity in the filter element 5 and be led there from there via the outlet 29 , possibly via a line. In the case of a fuel filter, the fuel is guided via the outlet 29 to the injection system of the internal combustion engine. The fuel filter can here be arranged, for example, in a fuel tank, in particular in a reservoir of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com