Sliding surface pull-type landslide model test device

A landslide model test and sliding surface pulling technology, which is applied in soil material testing, material inspection, etc., can solve the problems of overall instability and damage, and achieve the effect of simple operation, simple overall structure, and clear layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

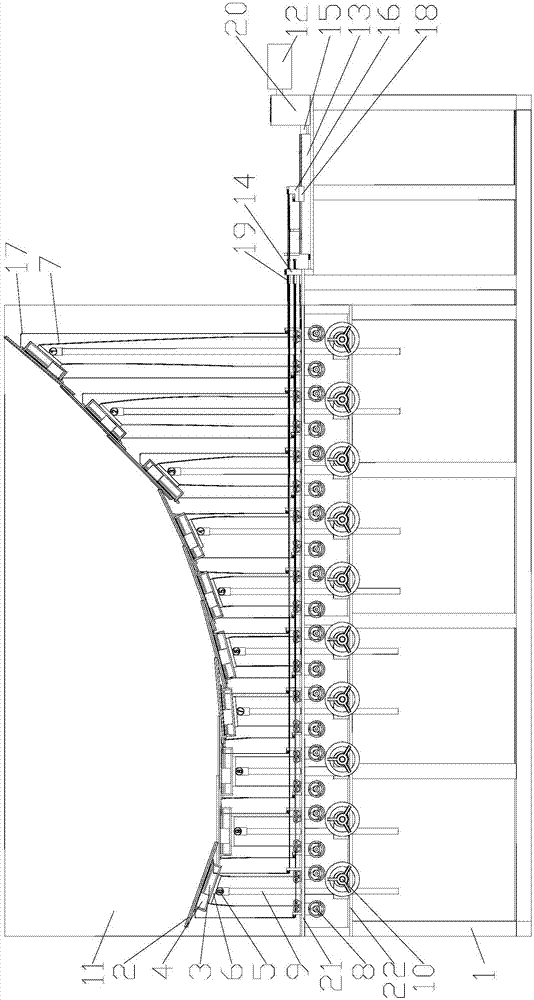

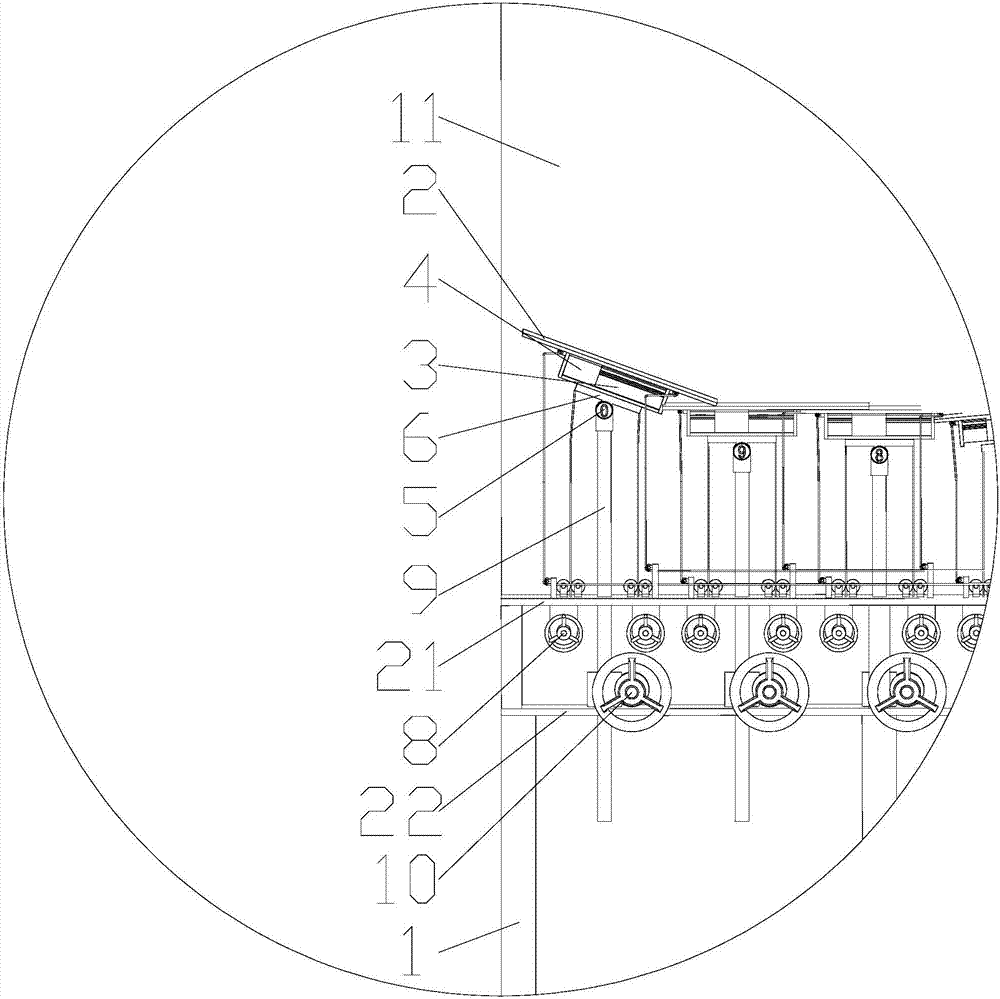

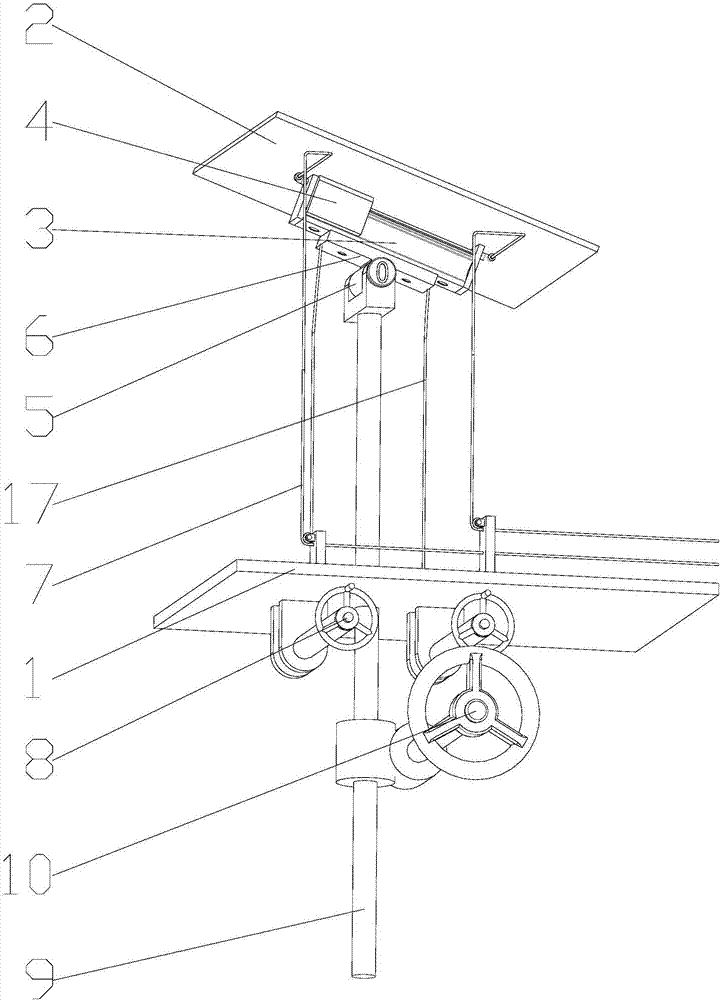

[0027] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a sliding surface pulling type landslide model test device includes an outer frame 1, and a lifting unit and a power module arranged on the outer frame 1; And lifting mechanism, guide rail slide block comprises guide rail 3 and the slide block 4 that moves in guide rail 3, and the upper end of slide block 4 is fixedly connected with described slide plate 2; The connecting plate 6, the connecting plate 6 is fixedly connected to the guide rail 3; the adjustment mechanism includes the pipelines 7 respectively arranged on the connecting plates 6 on both sides of the hinge rod 5, each pipeline 7 is connected with a movable pulley below, and the movable pulley is connected There is an adjustment handwheel 8; the lifting mechanism includes a cooperatingly connected worm wheel and a worm 9, and the worm wheel is provided with a lifting handwheel 10 for adjustment; the hinged rod 5 is hinged to the upper end of the ...

Embodiment 2

[0033] This embodiment is a further improvement on the basis of Embodiment 1, and the difference from Embodiment 1 is:

[0034] Preferably, a protective gearbox 20 is arranged outside the reduction gear set. Setting the gear set in the gearbox can prevent the gear set from being touched by mistake, resulting in structural damage or affecting the accuracy. Setting the gear set in the gearbox can also prevent people from being injured by mistake and improve safety.

[0035] Preferably, a dust shield 21 is provided below the slide plate 2, a lifting mechanism mounting plate 22 is arranged below the dust shield 21, the transparent plate 11 is arranged on the dust shield 21, and the dust shield 21 and the lifting mechanism mounting plate 22 are all fixed on the outer frame 1. The use of the dust shield can effectively reduce the impact of dust generated during the experiment on the lifting mechanism. The lifting mechanism mounting plate can facilitate the fixing of the lifting mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com