Direct-acting rigidity-controllable magneto-rheological fluid damper

A magnetorheological fluid and shock absorber technology, which is applied in the fields of precision machinery and mechanical vibration, can solve problems such as errors and differences, and achieve the effects of vibration reduction frequency bandwidth, low energy consumption, and good control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

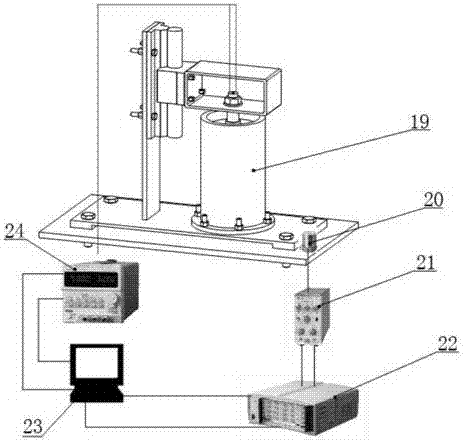

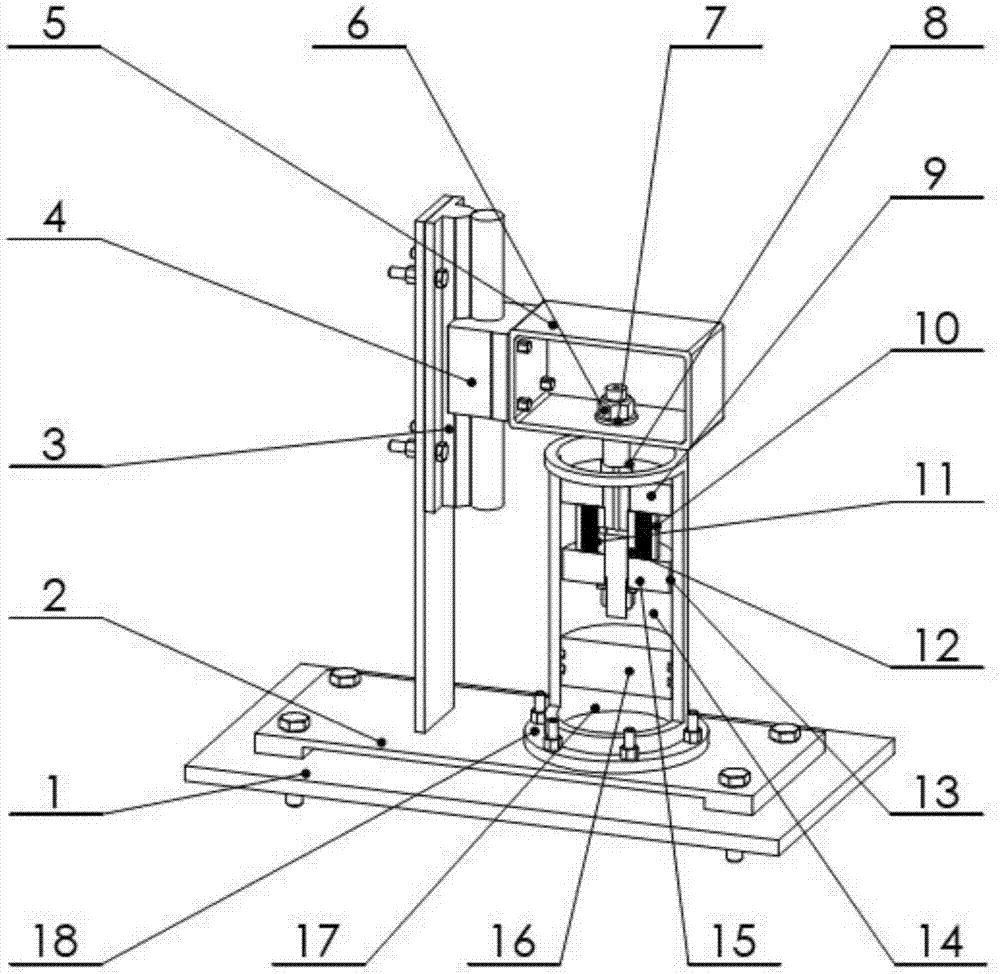

[0030] Such as figure 1 As shown, the magneto-rheological fluid shock absorber with controllable stiffness of the present invention is characterized in that it includes a controlled object and a magnetorheological fluid shock absorber installed on the controlled object, wherein:

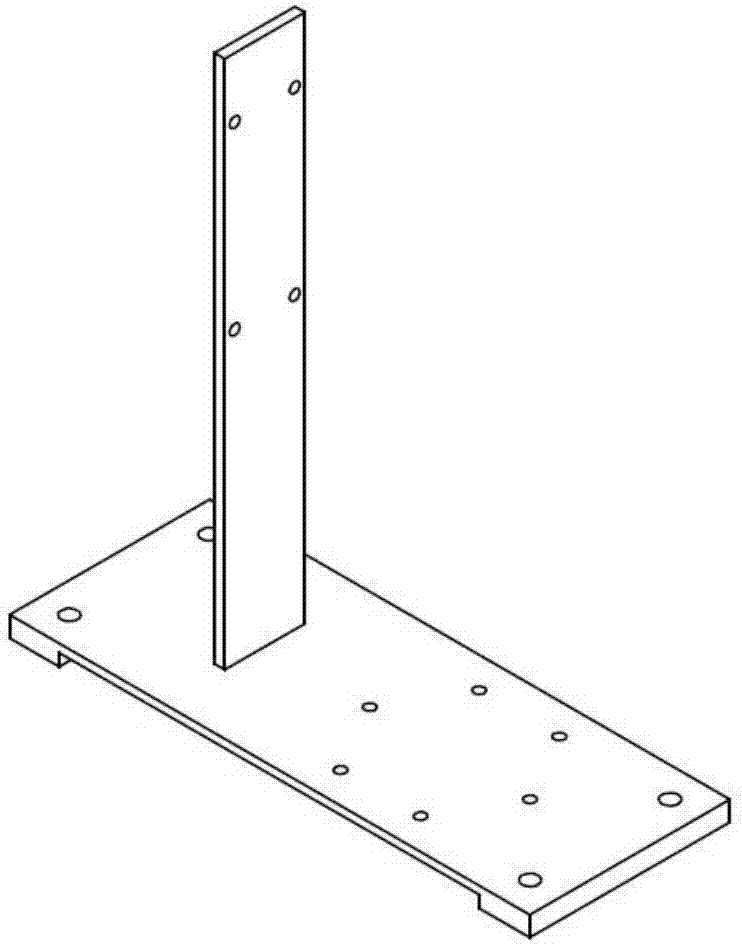

[0031]The controlled object 1 is the vibration control object. The magneto-rheological fluid damper consists of a support plate 2, a slide rail 3, a slider 4, a connecting plate 5, a lock nut 6, an elastic washer 7, a piston rod 8, and an upper piston 9 , outer sleeve 10, excitation coil 11, inner sleeve 12, damping channel 13, magnetorheological fluid 14, lower end piston 15, floating piston 16, nitrogen chamber 17 and working cylinder 18. Both the side plate of the support plate 2 and the slide rail 3 are processed with M5 threaded holes, and the slide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com