Pop can flatting machine

A technology for pop-top cans and flattening machines, which is applied to presses, manufacturing tools, etc., can solve the problems of not easy to top-bottom cans, small volume compression, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

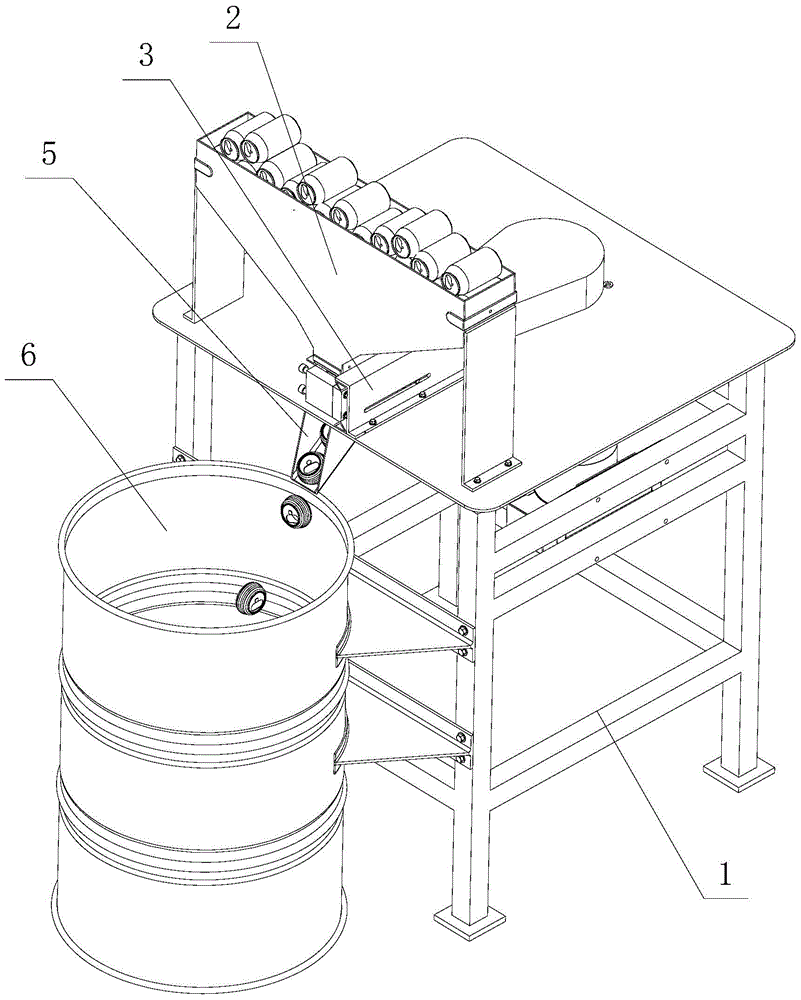

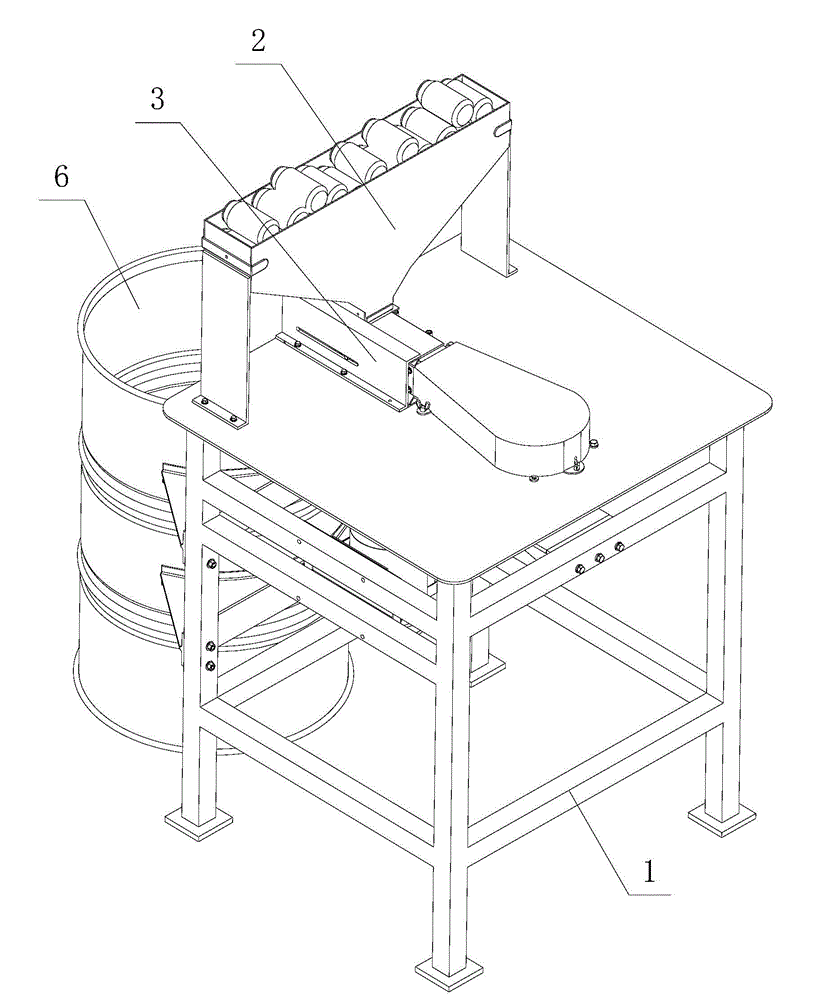

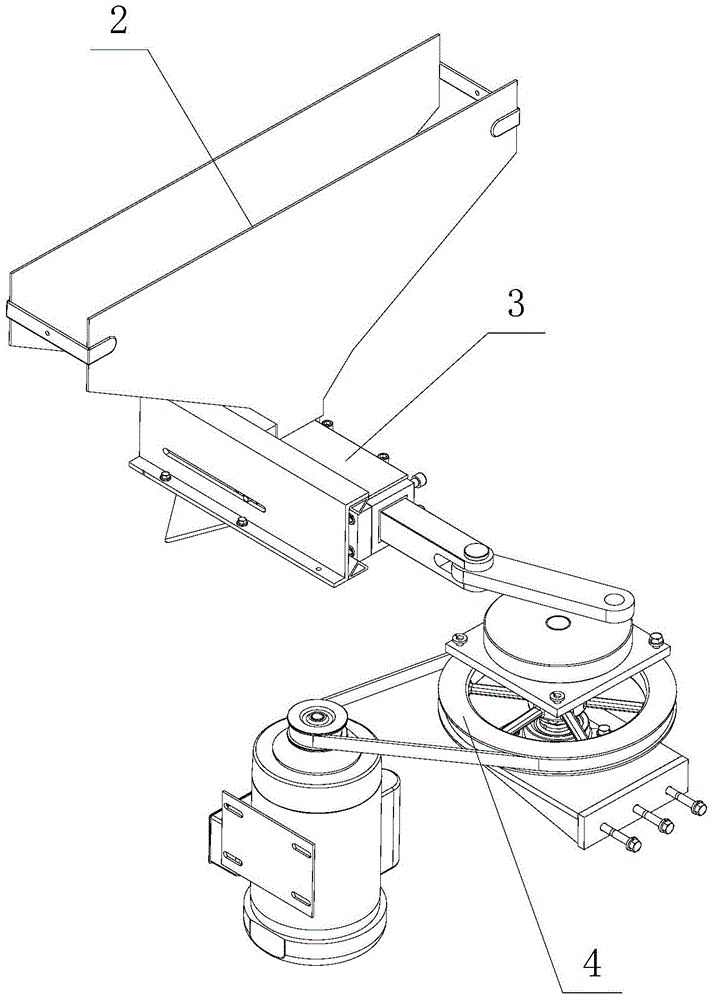

[0028] refer to Figure 1 to Figure 5 , the present invention provides a can flattening machine, which includes a frame 1, a hopper 2, a pressing mechanism 3 and a driving mechanism 4;

[0029] The frame 1 is used to support and install other components, which includes a bracket and a bracket platform installed on the bracket; the hopper 2 is fixed on the frame 1 and is used to place pop cans, and the bottom of the hopper 2 is provided with a discharge that is easy to pull the cans out of In the present embodiment, a photoelectric sensor is also provided on the discharge port for detecting pop cans, and when no pop cans are detected, it will be fed back to the host computer to stop the driving mechanism and avoid empty travel; A pressing chamber is formed on the top, and the pressing chamber is located directly below the discharge port of the hopper 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com