Printing mechanism for sample container

A printing mechanism and sample container technology, which is applied in typewriters, printing devices, printing, etc., can solve the problems of inability to maximize efficiency, long waiting time, and reduced detection speed, so as to improve accuracy and detection efficiency, avoid mistaking or Cross-contamination, the effect of reducing the number of transfers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

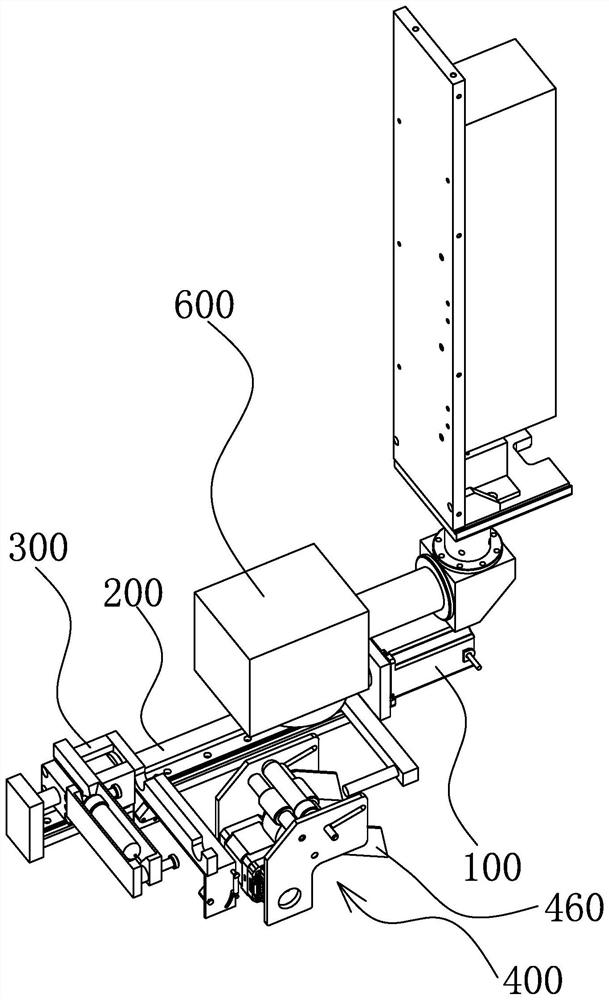

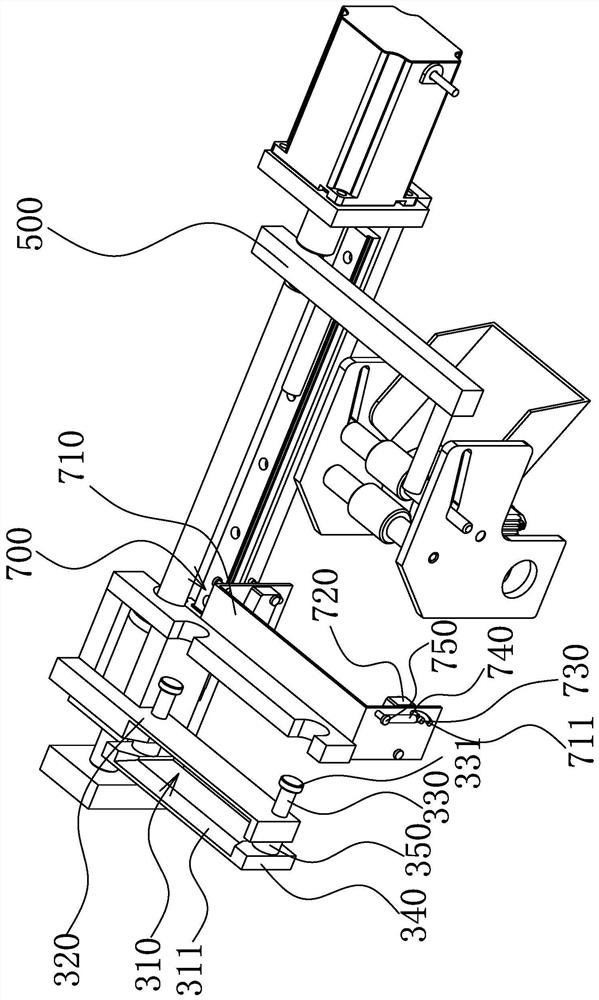

[0029] Such as Figure 1 to Figure 4 As shown, the printing mechanism of a kind of sample container provided by the present invention comprises:

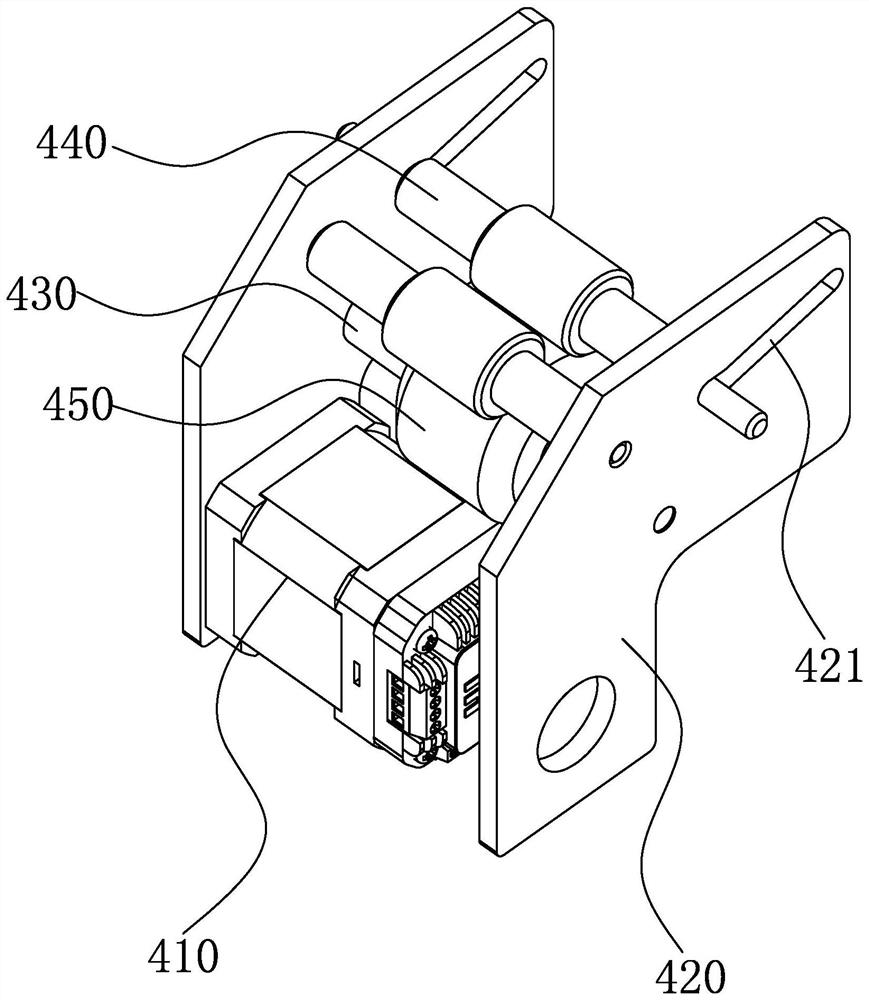

[0030] The translational motor 100 located at the discharge end is connected with a screw mandrel 200 at the output end, and a material receiving rack 300 is screwed on the screw mandrel 200, wherein the material receiving rack 300 is located at the material receiving end, and a material receiving tank 310 is arranged on it , and the two sides of the material receiving tank 310 are respectively provided with a fixed material receiving plate 320, and a movable material receiving plate 340 movably connected with the fixed material receiving plate 320 through the push rod 330;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com