Relay capable of reducing contact jitter

A contact vibration and relay technology, applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of unfavorable moving reeds working efficiently, hindering normal breakpoint action, increasing the probability of contact bonding, etc., to achieve effective Conducive to miniaturization design, reduce vibration phenomenon, avoid the effect of arc reignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

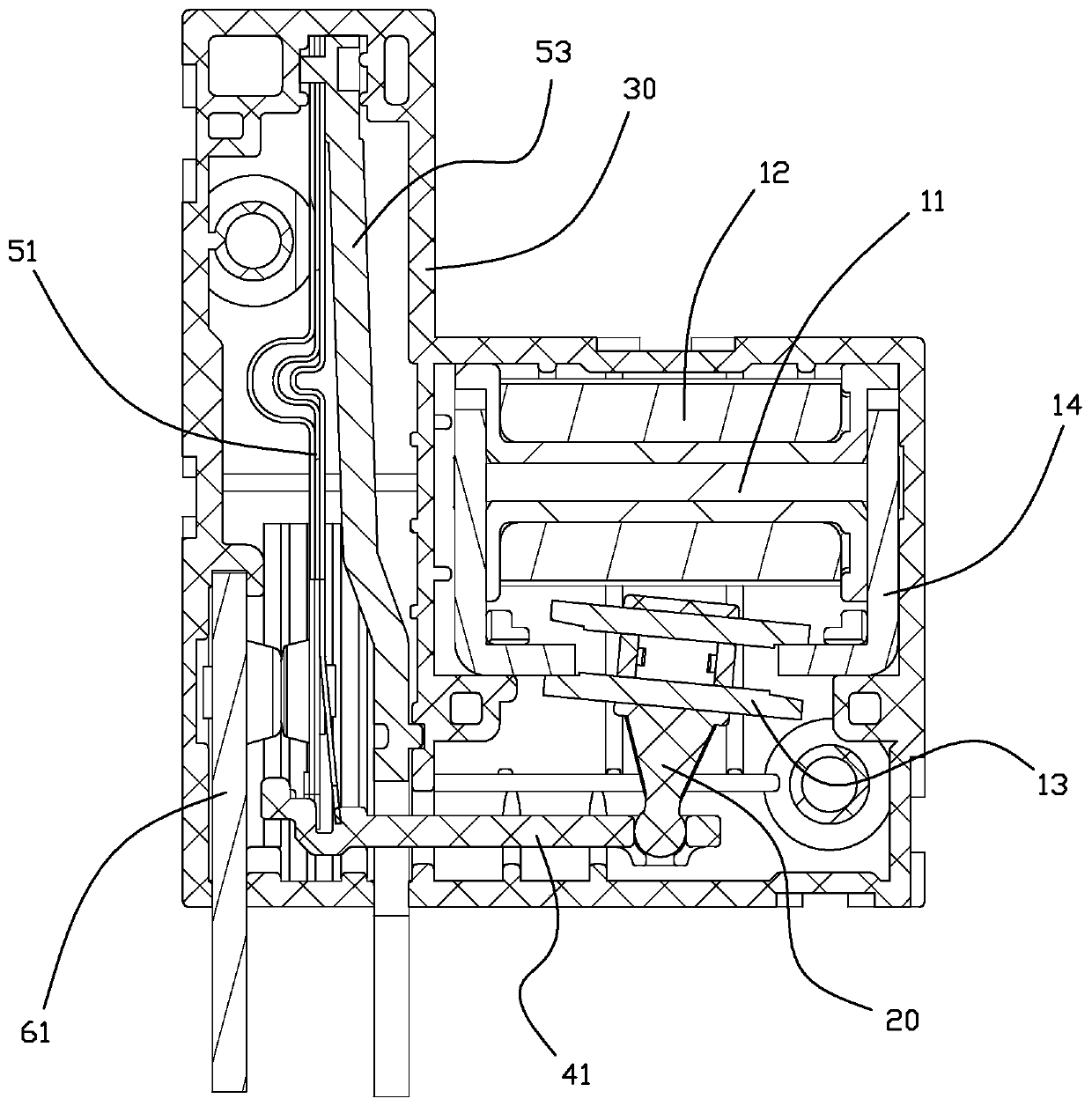

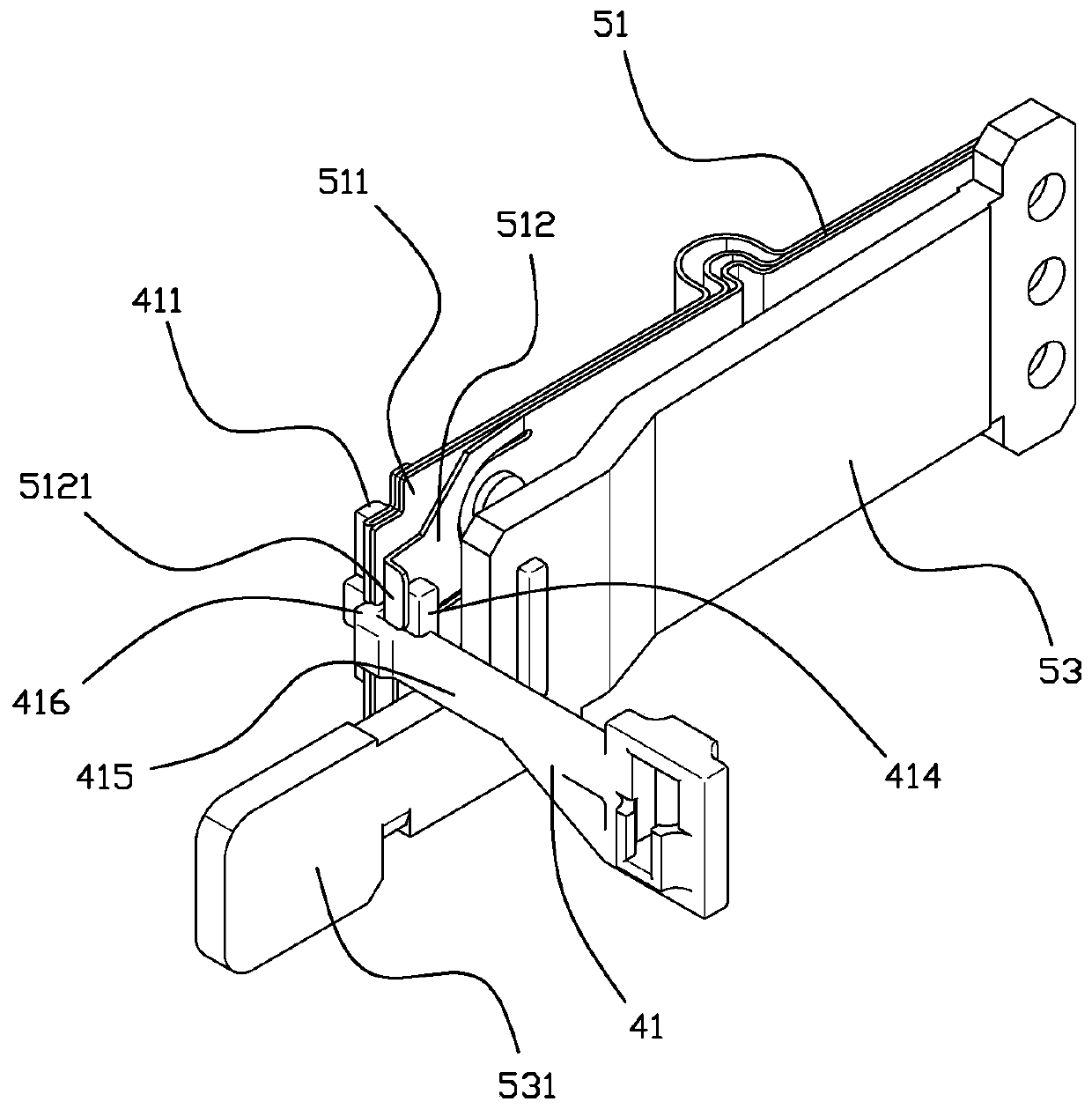

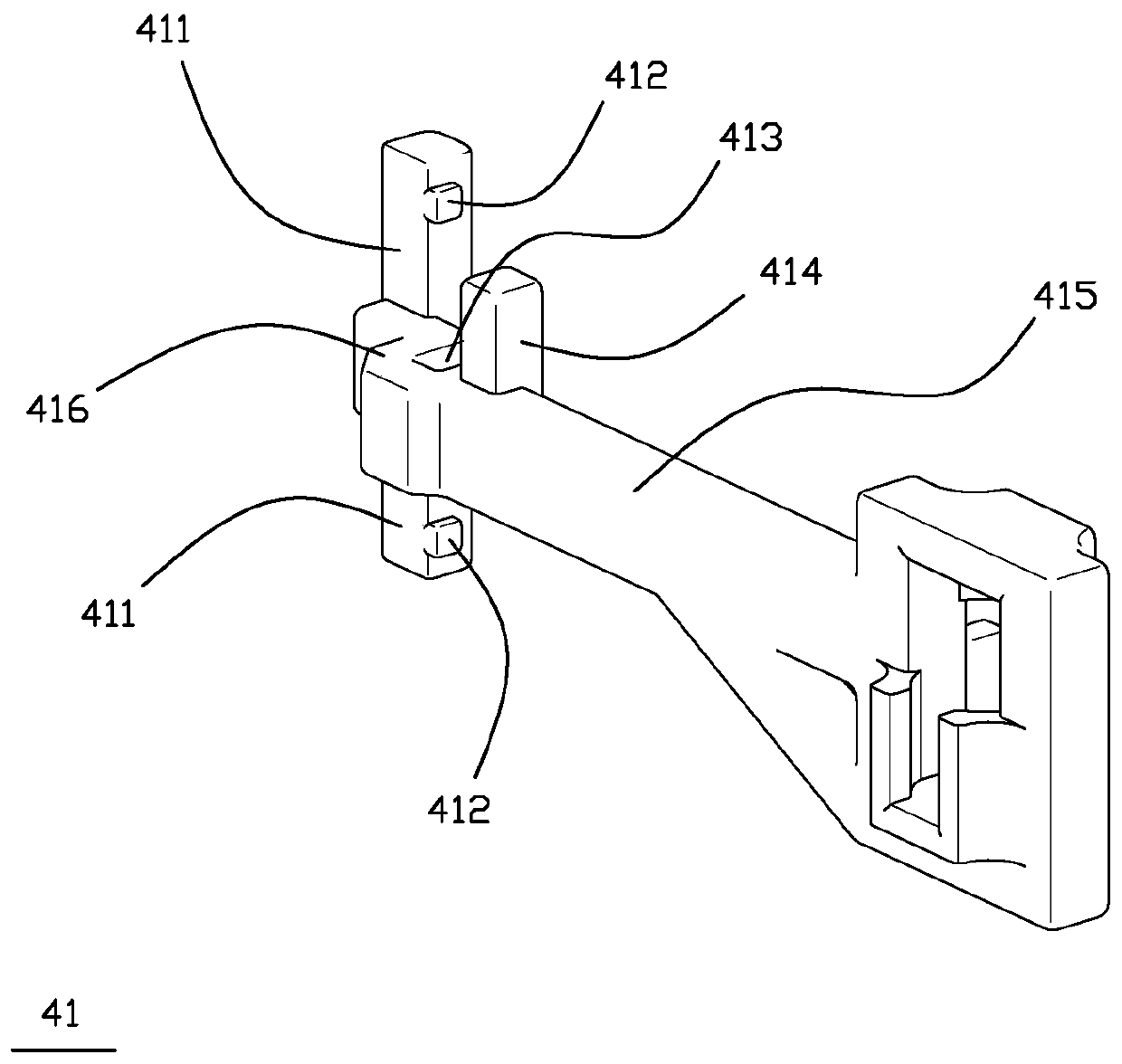

[0042] In order to solve the problems existing in the prior art, such as the large jitter of the moving spring part and the interference between the push-pull rod and the lead-out piece of the moving spring, the present invention provides a relay with reduced contact jitter, such as Figure 1 to Figure 6As shown, the relay described in this embodiment includes a magnetic circuit system, a contact system, a push member 20 and a base 30; the magnetic circuit system is composed of an iron core 11, a coil 12, an armature 13 and a yoke 14, and the contact system is provided with Push-pull rod 41, moving spring part, static spring part. The moving spring part includes a moving reed 51, a moving contact 52 and a moving spring lead-out piece 53, and the static spring part includes a static reed 61 and a static contact 62, and the moving reed 51 and the static reed 61 are respectively arranged on matching Position; the root of the movable reed 51 is fixed, and the movable contact 52 is...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that the width of the slot 413 is different, such as Figure 9 , Figure 10 As shown, in this embodiment, the connection between the slot 413 and the counter force reed 512 is clearance fit, that is, when the counter force reed 512 is set in the slot 413, the width of the slot 413 is equal to that of the blocking surface 4132 and There is a certain gap in the counter force reed 512, so that gap installation is realized. At the same time, in order to ensure that the rebound distance is within the preset effect, a micro gap is set between the blocking surface 4132 of the slot 413 and the reaction force spring 512, which is convenient for assembly while ensuring that the rebound is reduced.

[0059]During specific implementation, the maximum amplitude of the counterforce reed 512 in an unrestricted state is affected by the performance of the magnetic circuit system, the work efficiency of the push-pull rod 41, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com