Spherical hinge structure with automatic gap compensation function

An automatic compensation, ball joint technology, applied in the direction of transmission control, components with teeth, belt/chain/gear, etc., can solve the problem of ball joint seat unable to move synchronously, affecting the driver's feel, delay, etc., to achieve compensation Clearance, improved comfort, and the effect of avoiding empty travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

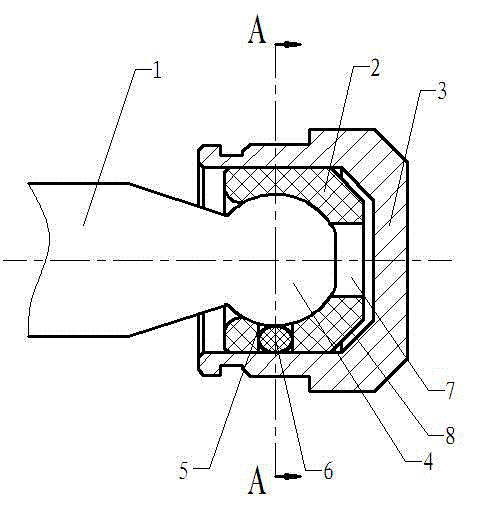

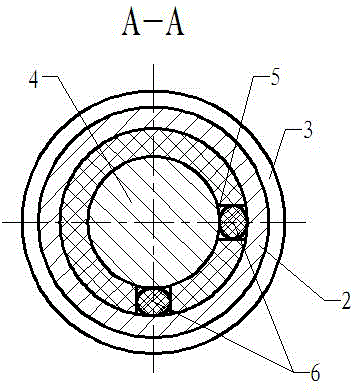

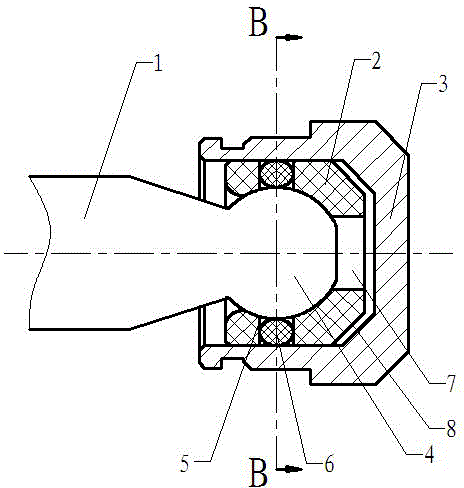

[0018] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

[0019] figure 1 , figure 2 The structure of the first embodiment of the present invention is given, such as figure 1 , figure 2 As shown, a ball joint structure for automatically compensating the gap includes a shift shaft 1, a ball joint bushing 2 and a ball joint seat 3, and one end of the shift shaft 1 is provided with a ball head 4 with a diameter of twelve millimeters, The ball head 4 is housed in the ball joint bushing 2 and forms a spherical pair with the inner cavity of the ball joint bushing 2, and the ball joint bushing 2 is housed in the ball joint seat 3; there are two through holes I5 on the ball joint bushing , in each through hole I5 there is an elastic small ball 6 made of rubber with a diameter of three millimeters. The axis of the shaft 1, the line co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com