Multi-zone array selective melting manufacturing equipment and process

A technology of selective melting and manufacturing equipment, which is applied in the direction of manufacturing tools, processing and manufacturing, and additive manufacturing. It can solve the problems of high comprehensive processing cost, low processing efficiency, and long powder spreading time, so as to achieve stable powder spreading effect and improve processing efficiency. , the effect of spreading powder evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

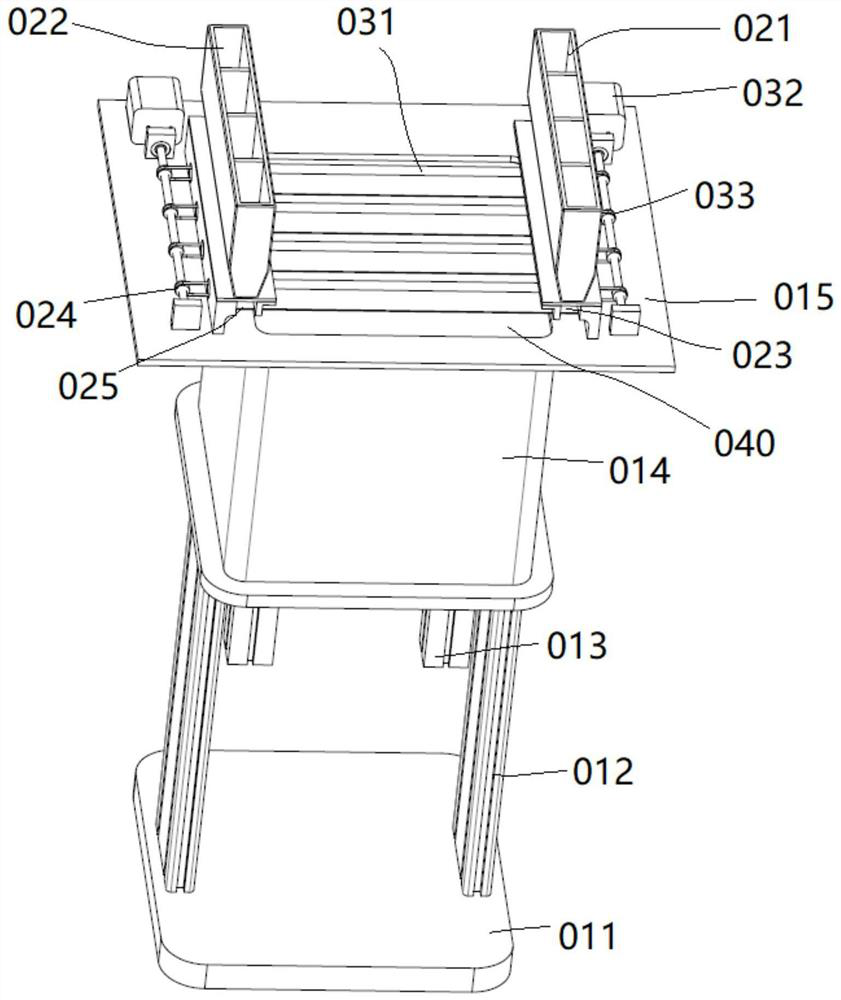

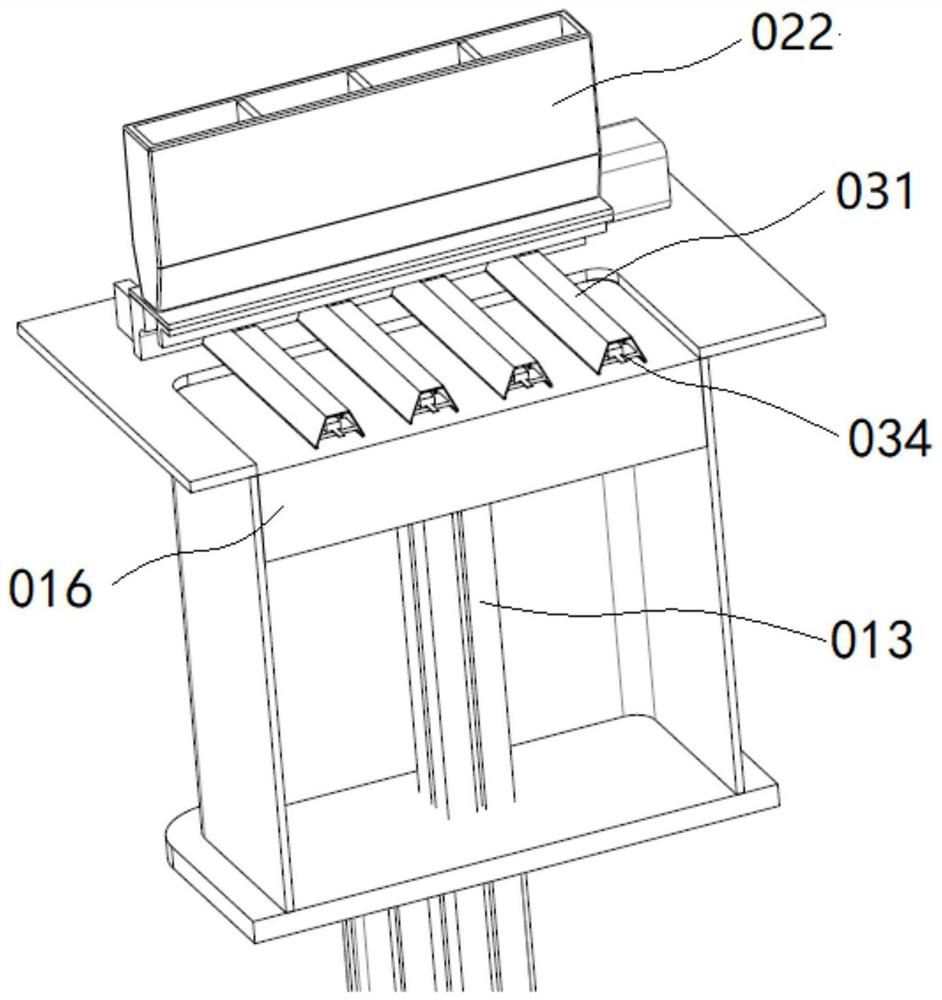

[0025] Such as figure 1 , as shown in 2, the multi-partition array type selective melting manufacturing equipment of the present invention includes a base 011, a support 012, a lifting guide rail 013, a forming bin 014, a forming platform 015, a forming bottom plate 016, a powder bin 1 021, and a powder bin 2 022, the first discharge port 023, the second discharge port 024, the sliding base of the silo 025, the powder spreading grid 031, the scraper drive motor 032, the scraper drive mechanism 033, the small scraper 034, and the powder forming area 040.

[0026] The base 011 in the equipment of the present invention is the basic load-bearing structure of the whole set of devices, ensuring that the whole device does not shake during operation, the support 012 is installed on the base 011, the forming chamber 014 is installed on the support 012, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com