Bidirectional quantitative powder supplying and spreading device for additive manufacturing

A powder spreading device and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of large span of powder spreading scraper structure, reduced work efficiency, large molding area, etc., to improve the quality of powder spreading, improve sintering quality, reduce small dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

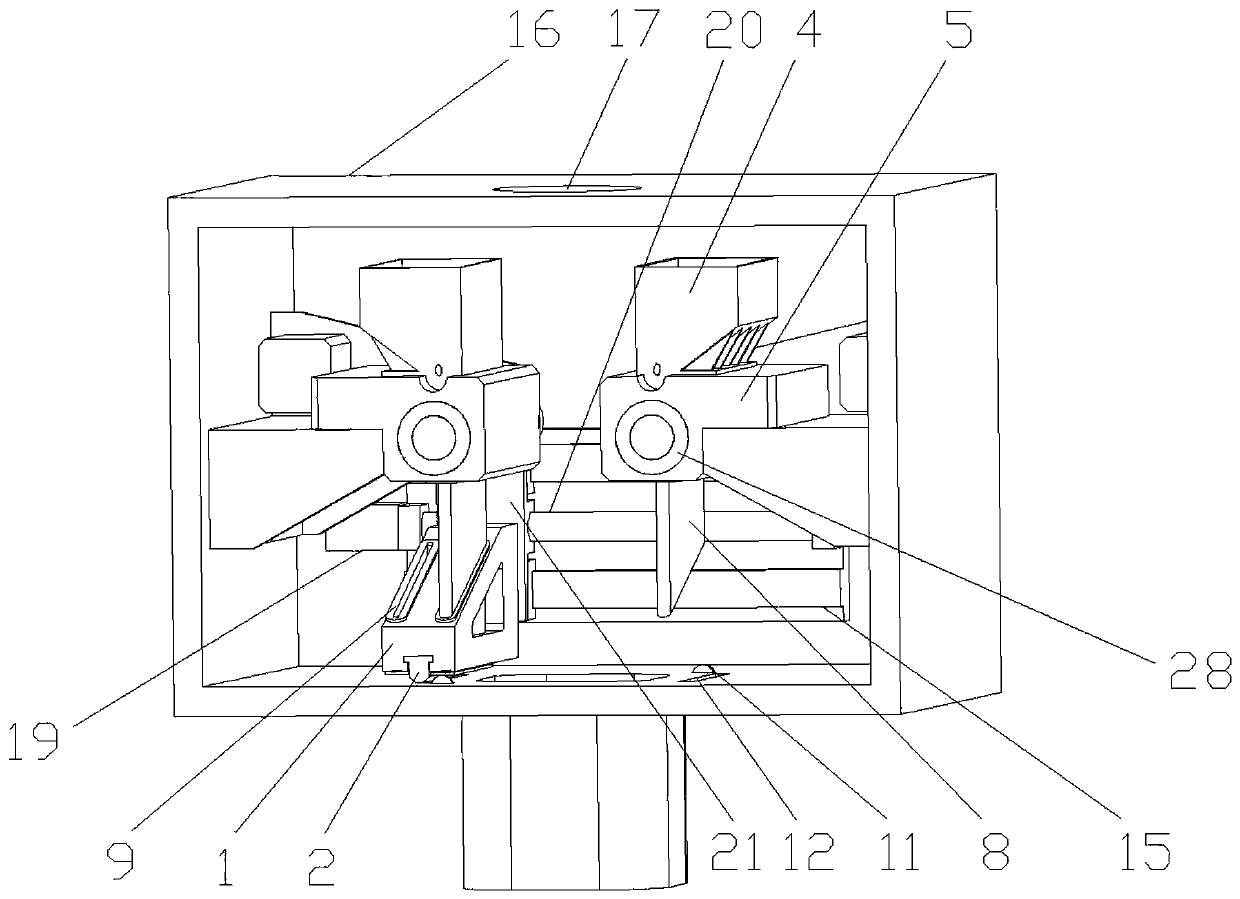

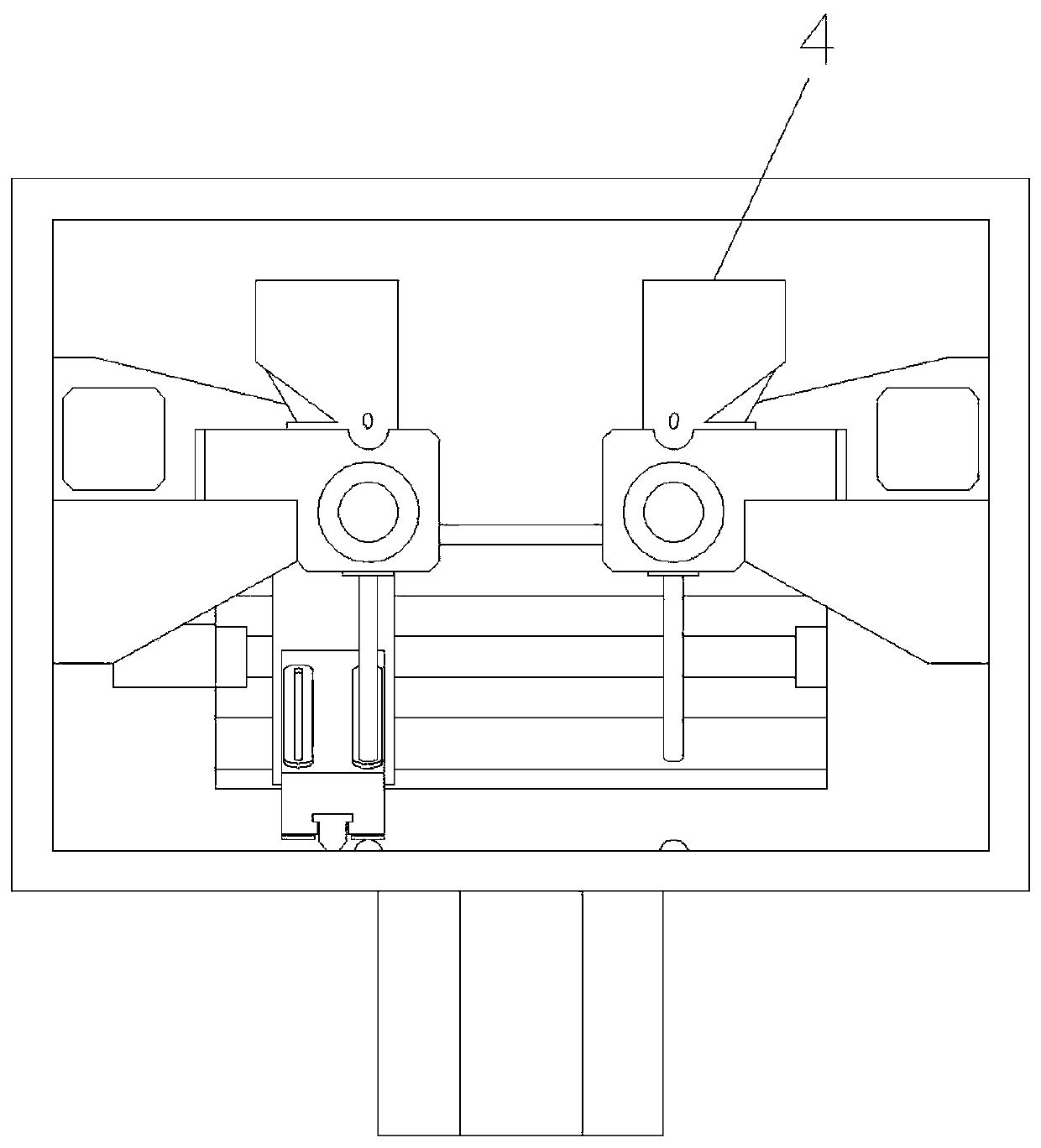

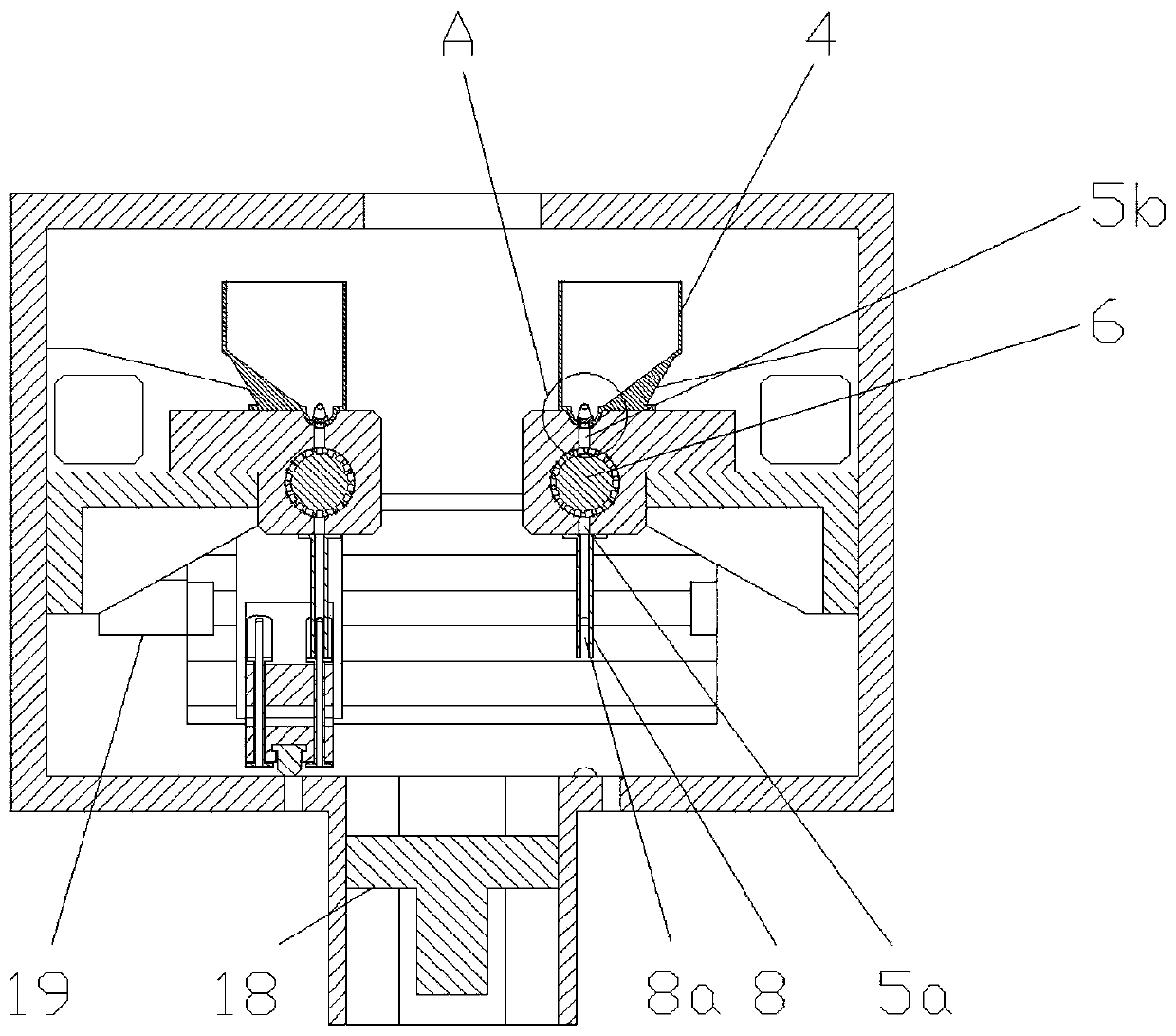

[0032] figure 1 It is a schematic diagram of the three-dimensional structure of the present invention; figure 2 It is a structural schematic diagram of the present invention; image 3 It is a schematic cross-sectional structure diagram of the present invention; Figure 4 for image 3 Schematic diagram of the enlarged structure at point A; Figure 5 It is a schematic diagram of the structure of the powder supply roller driving device; Image 6 A schematic diagram of the enlarged structure of the boss; Figure 7 It is a schematic diagram of the structure of the scraper mounting seat; Figure 8 It is a schematic diagram of the lining structure of the flow channel; Figure 9 It is a schematic diagram of the structure of the powder supply roller mounting seat; Figure 10 It is a schematic diagram of the powder supply roller structure; Figure 11 It is a schematic diagram of the structure of the powder supply box;

[0033] In this embodiment, the left, right, front and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com