Method for the manufacture of knitted fabrics with intarsias and decorative stitches

A decorative thread and pattern technology, applied in the directions of knitting, weft knitting, warp knitting, etc., can solve the problem that only one carriage direction is possible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

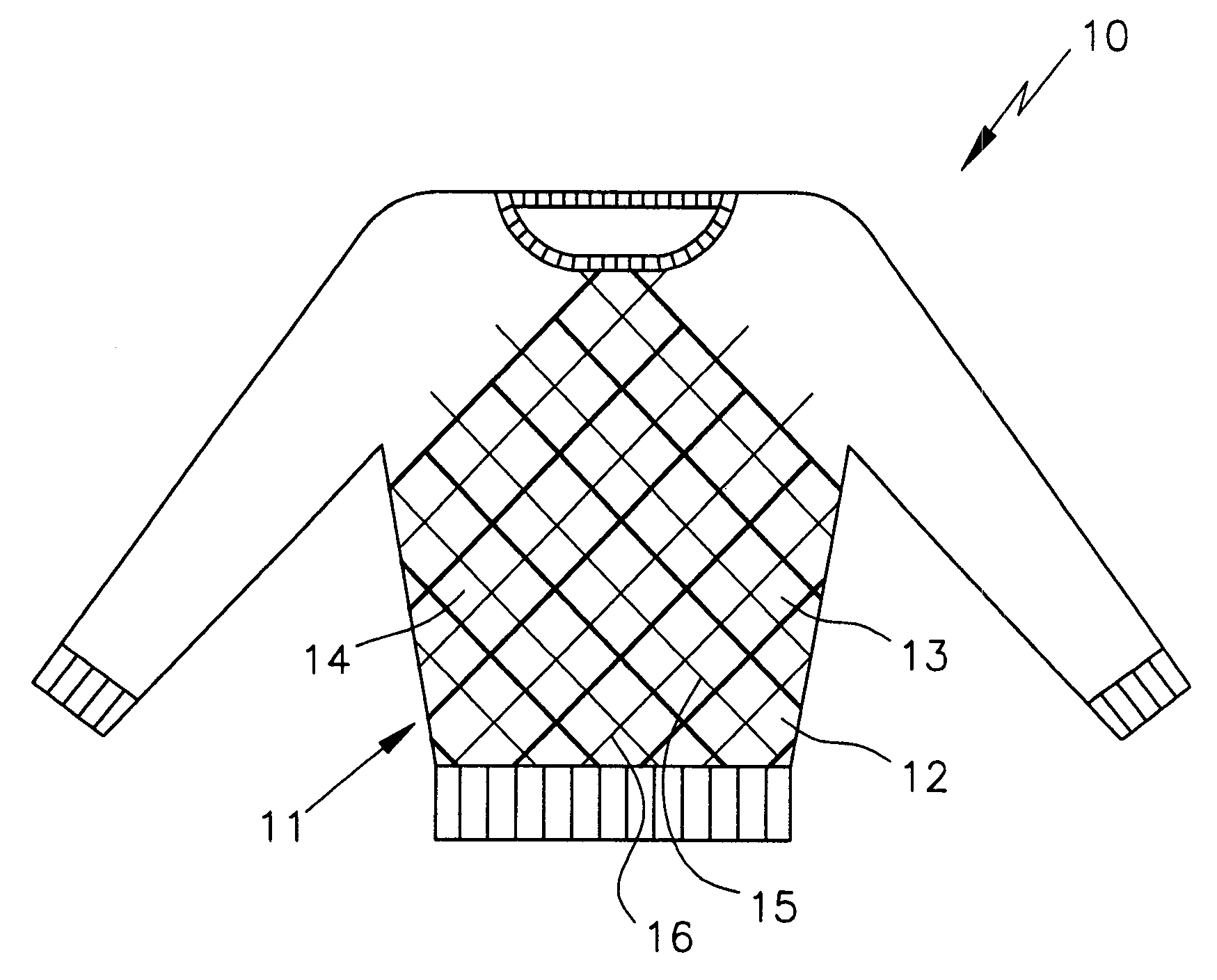

[0018] figure 1 Shown is a pullover 10 which is provided with argyle patterns on its body part. The lozenge consists of a plurality of lozenges 12 , 13 , 14 over which decorative stitching 15 , 16 runs in a contrasting colour.

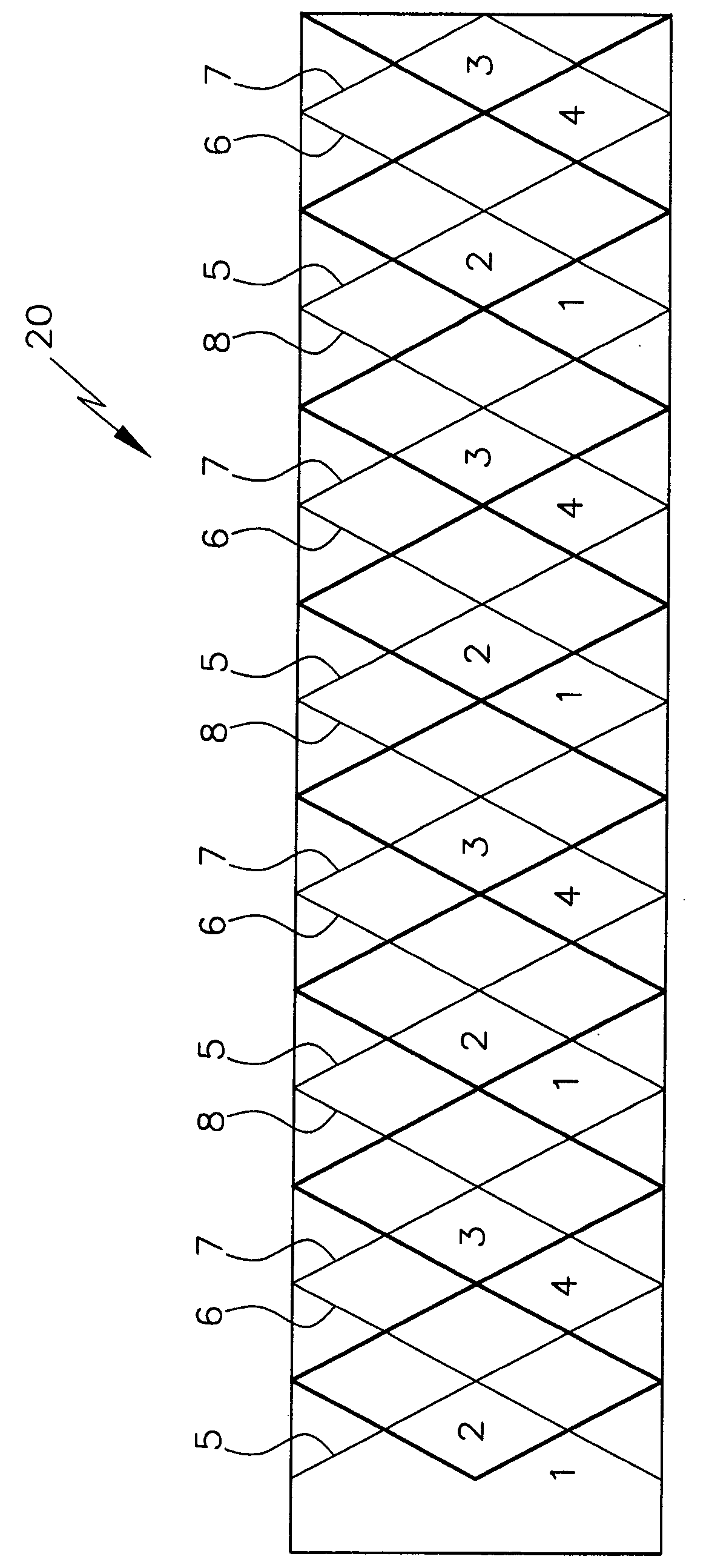

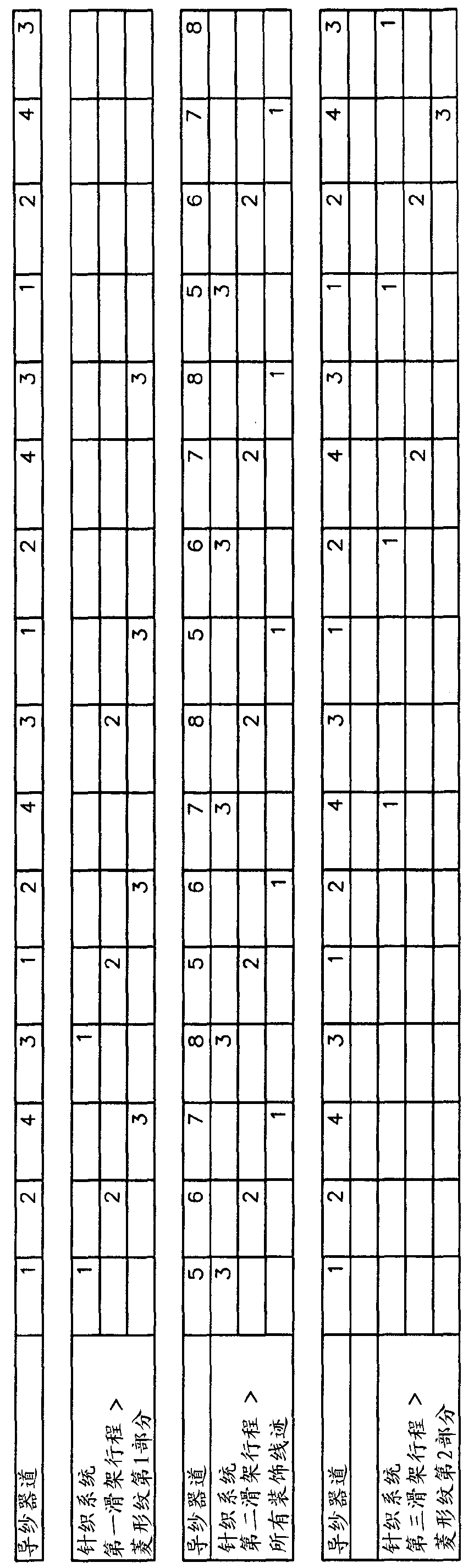

[0019] figure 2 Shown is a lozenge 20 which, in the example shown, is formed by sixteen differently colored lozenges, on which decorative stitches likewise run in sixteen different colors. A total of 32 different yarn guides (which are necessary to make the pattern) are in figure 2 In the example shown in , it is distributed over eight different thread carrier tracks 1 to 8, wherein each thread carrier track carries four thread carriers accordingly. figure 2 The relationship of the thread guide tracks 1 to 8 with respect to the formation of the respective diamonds and decorative stitches is illustrated. The yarn guide rails 1 to 4 carry the yarn guides for forming the diamond pattern. Which yarn feeder of the yarn feeder track is used to form w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com