Electric pruning shears

一种修枝剪、电动的技术,应用在切割工具、切割设备、园艺等方向,能够解决浪费时间和电量、修剪工作慢等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

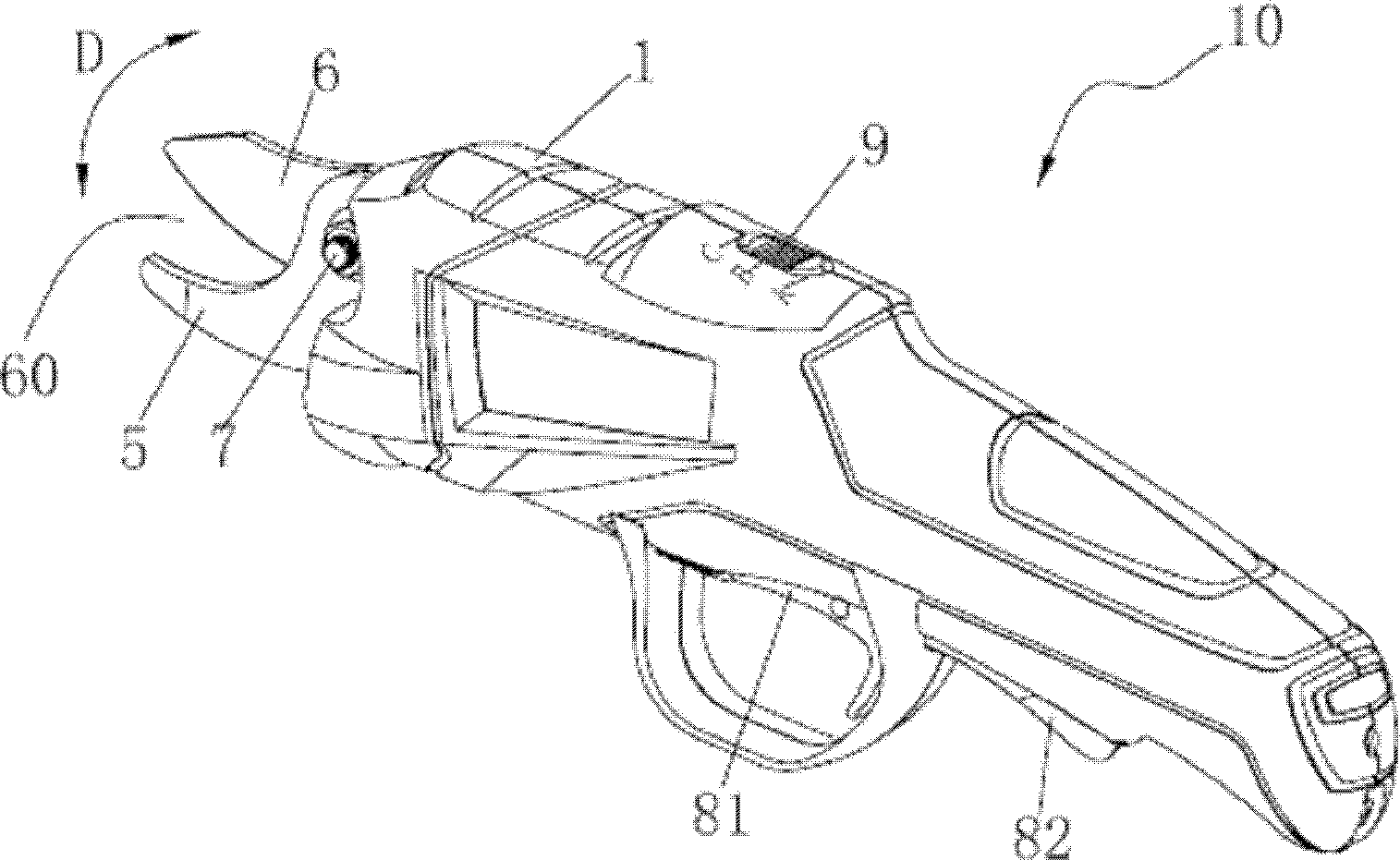

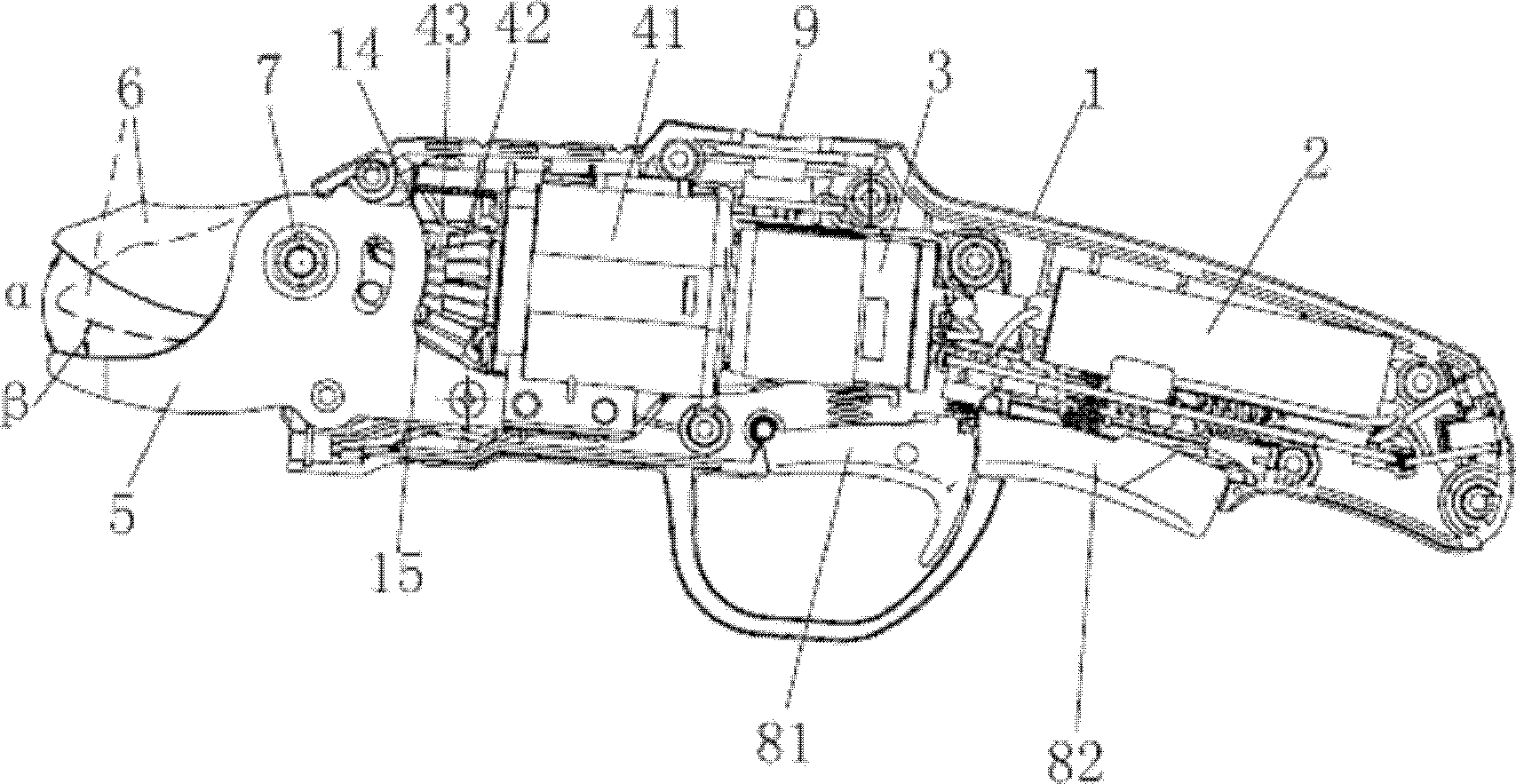

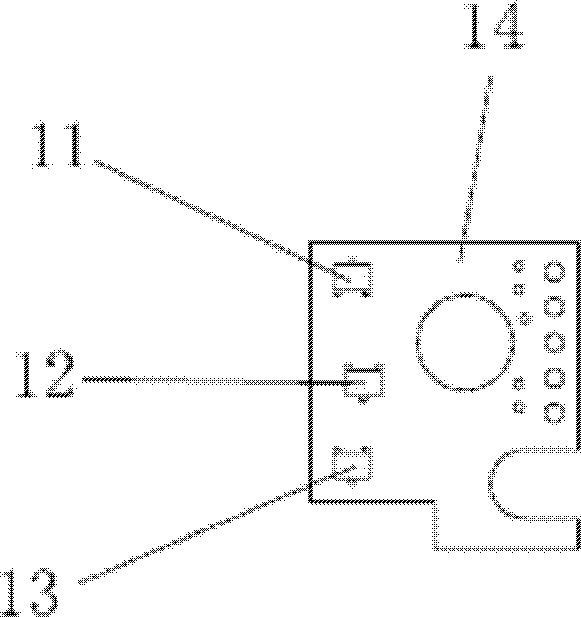

[0035] Such as figure 1 and figure 2 As shown, the electric pruning shears 10 include a housing 1, which is composed of two halves. exist figure 2 In , half of the casing is removed, which clearly shows the internal structure of the pruning shears 10 . The casing 1 is equipped with a battery 2, a motor 3, and a transmission device. The transmission device includes a reduction gear box 41 and a bevel gear transmission mechanism. The bevel gear transmission mechanism includes a driving gear 42 and a driven gear 43. The driven gear 43 is sector-shaped. A pair of blades 5 and 6 protrude from the casing 1 , wherein the fixed blade 5 is fixedly mounted on the casing 1 by bolts, and the movable blade 6 is pivotally connected to the fixed blade 5 by bolts 7 . One end of the movable blade 6 is fixedly connected with the driven gear 43, so it can swing back and forth in the direction of the arrow D under the drive of the motor 3 to realize the closing and opening of the knife edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com