Thread processing device of high-consistency nuts

A thread processing and consistency technology, applied in the direction of tangent device, metal processing equipment, tangential feeding device, etc., can solve the problems of uncertain nut direction, poor installation effect and stability, poor consistency of plane a1, etc., to achieve the same Improve the axiality, ensure high efficiency, and improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solutions and advantages of the present application clearer, the technical solutions in the embodiments will be clearly and completely described below in conjunction with the drawings in the embodiments.

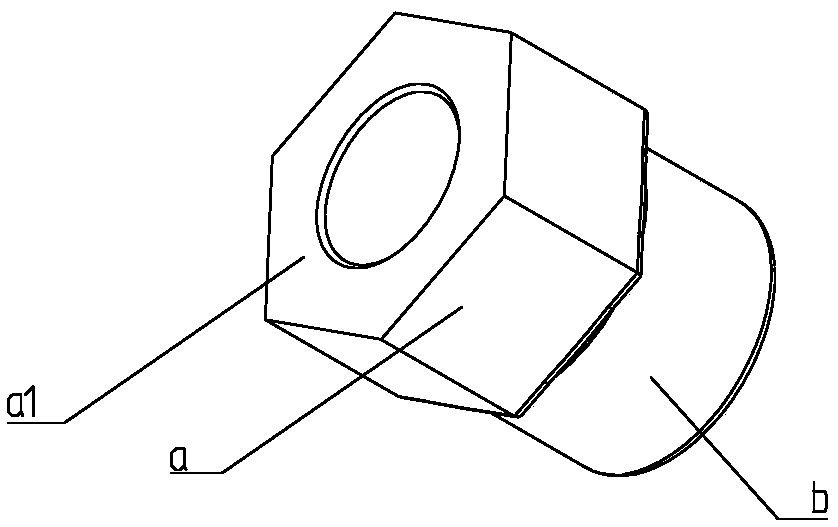

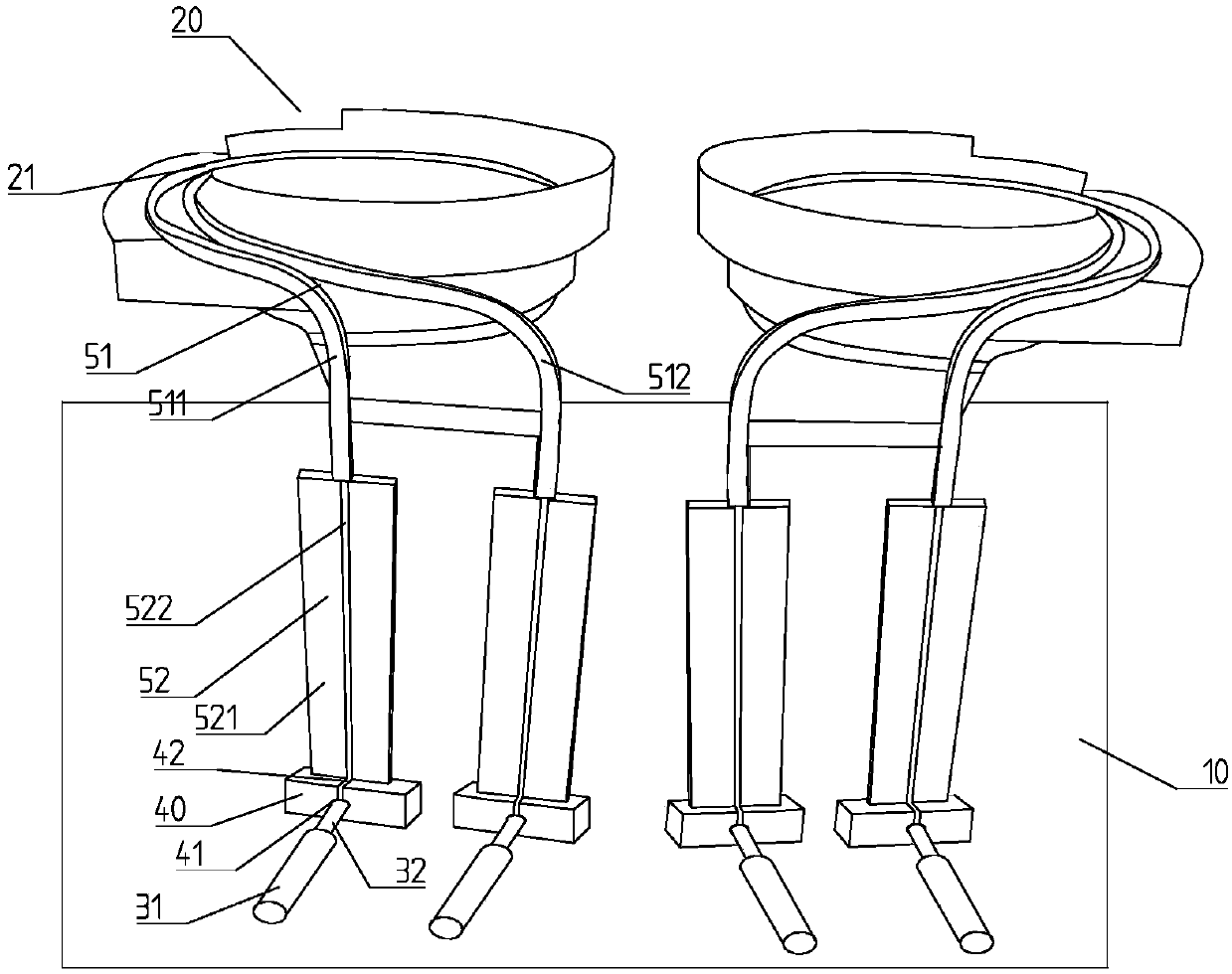

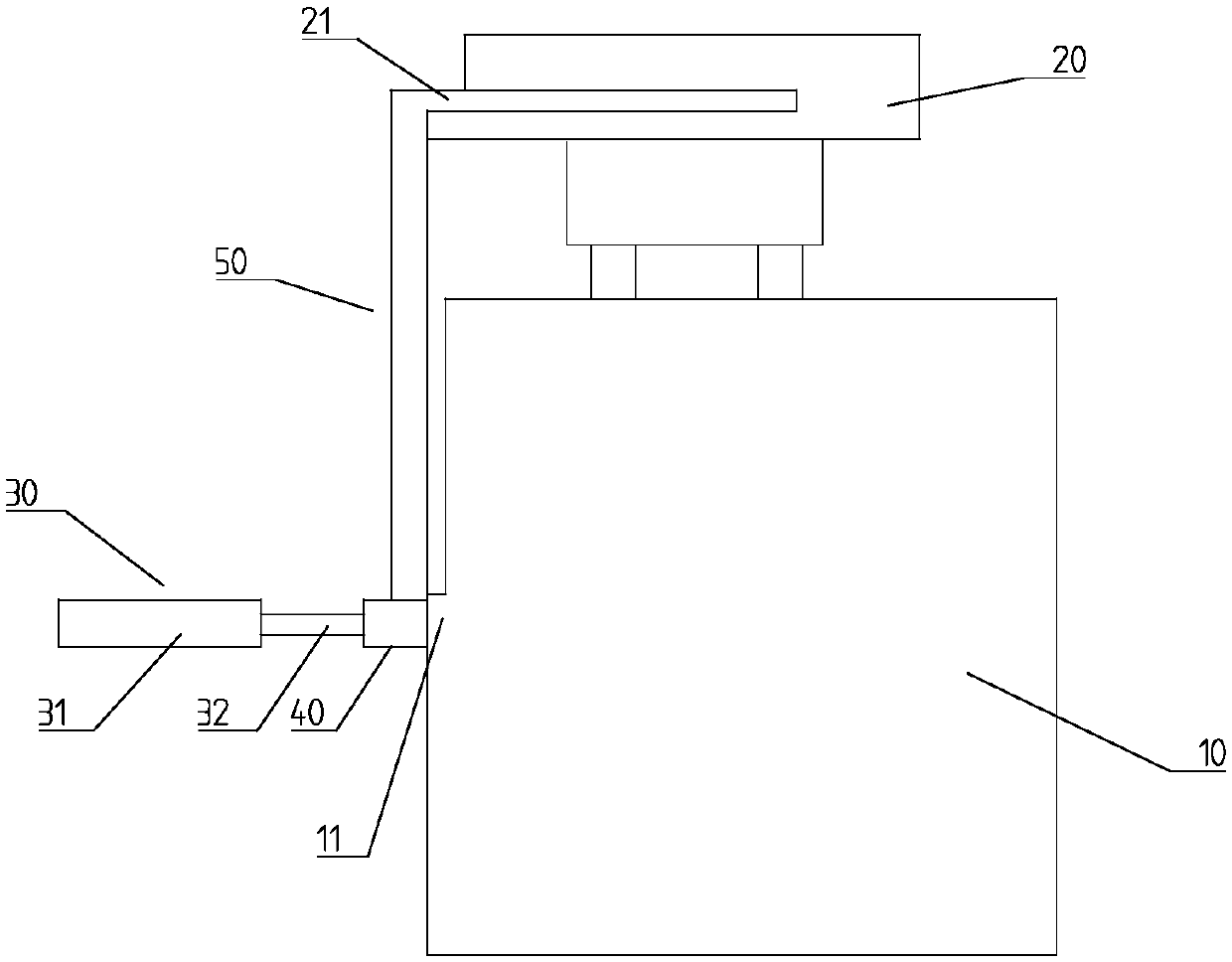

[0020] A high-consistency nut thread processing device, comprising a screening nut vibrating plate 20 and a nut tapping machine 10, the discharge port 21 of the screening nut vibrating plate 20 communicates with a nut guiding passage 51, and the outlet of the nut guiding passage 51 is located at the nut tapping machine. At the entrance 11 of the threading machine, a pusher mechanism 30 is provided at the entrance 11 of the nut tapping machine. The pusher mechanism 30 includes a drive mechanism 31 and a push rod 32 connected to the power output end of the drive mechanism 31. The push rod 32 guides the nut into the passage 51 The nut of export is pushed in the nut tapping machine 10; figure 1 The direction of the nuts is screened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com