Tail vane refitting structure for refitting manned helicopter into aviation fire extinguishing device

A technology of fire extinguishing device and helicopter, which is applied to rotorcraft, motor vehicles, fire rescue and other directions, can solve the problems of unfavorable automatic flight and fire extinguishing, unfavorable maintenance and repair, slow response speed, etc., and achieves advantages of automatic flight and fire extinguishing, simple structure, Responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments of the specification, but the protection scope of the present invention is not limited to the following specific embodiments.

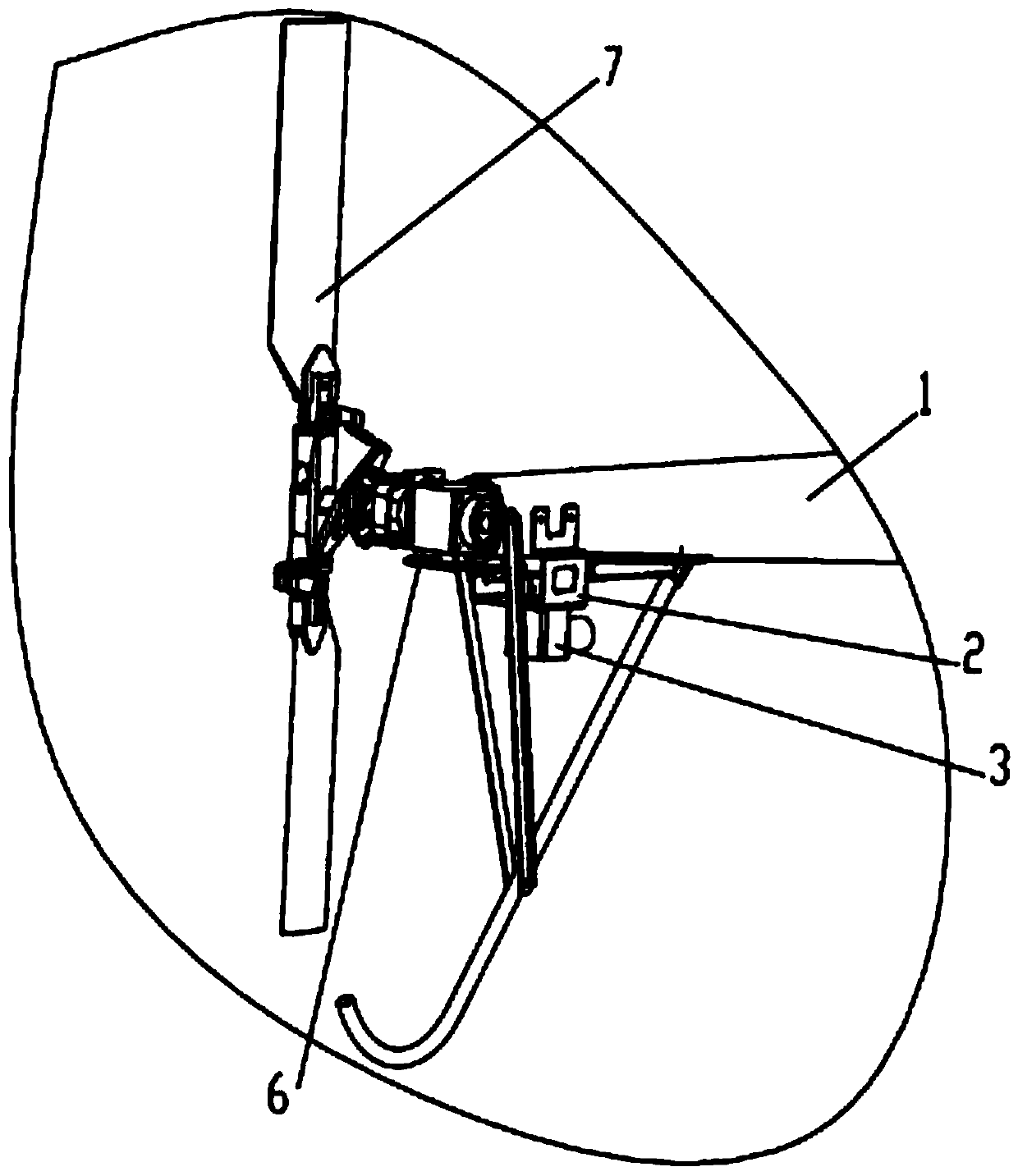

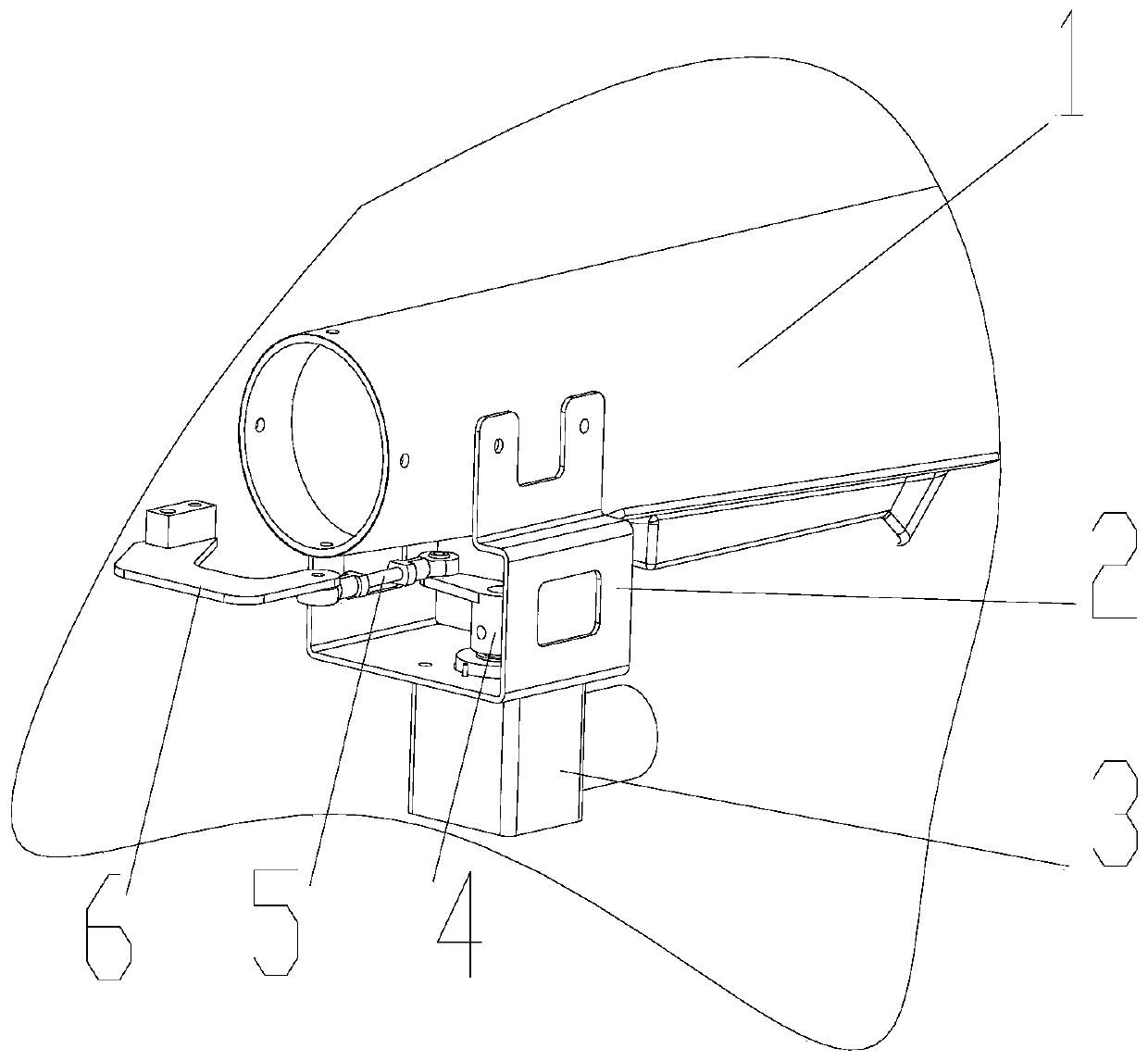

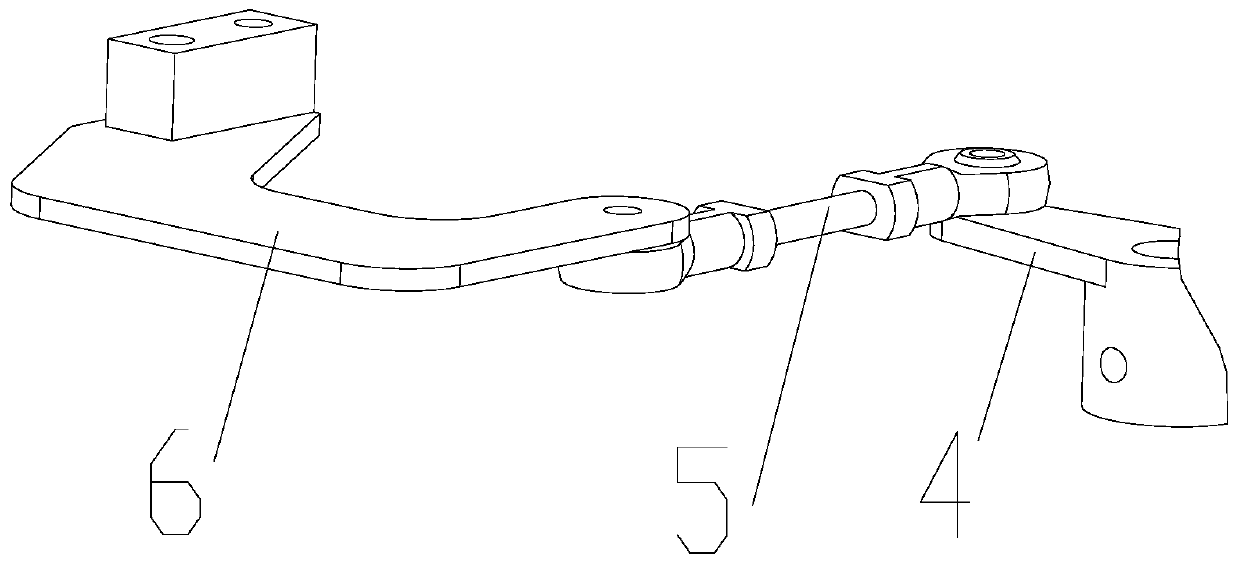

[0025] See Figure 1 ~ Figure 3 The manned helicopter of the present invention is converted into a tail rudder modification structure of an aviation fire extinguishing device, including a steering gear 3, a steering gear mounting seat 2, a steering gear rocker arm 4, and a rigid connecting rod 5. Both ends of the rigid connecting rod 5 are provided with rods End bearing, the steering gear 3 is installed outside the helicopter through the steering gear mounting seat 2 and is located vertically below the end of the helicopter tail beam 1. One end of the steering gear rocker arm 4 is fixedly connected to the output shaft of the steering gear 3. The other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com