Powder laying device with convenient replacement function for 3D printer

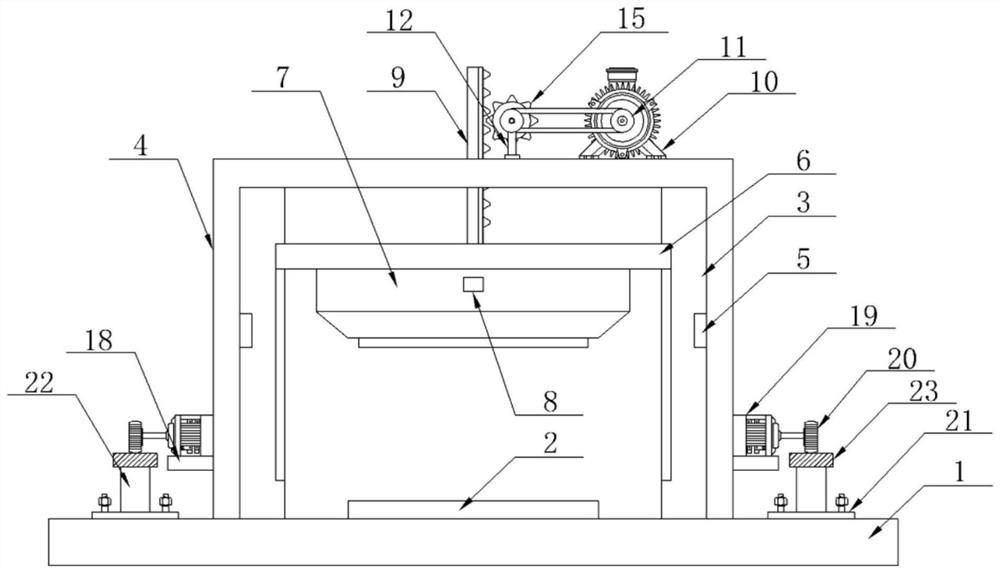

A technology of 3D printer and powder spreading device, which is applied in coating device, 3D object support structure, additive manufacturing, etc., can solve the problems of uneven scattering, inability to guarantee the average powder material on the printing platform, and difficulty in replacing powder spreading mechanism. To achieve the effect of spreading powder evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

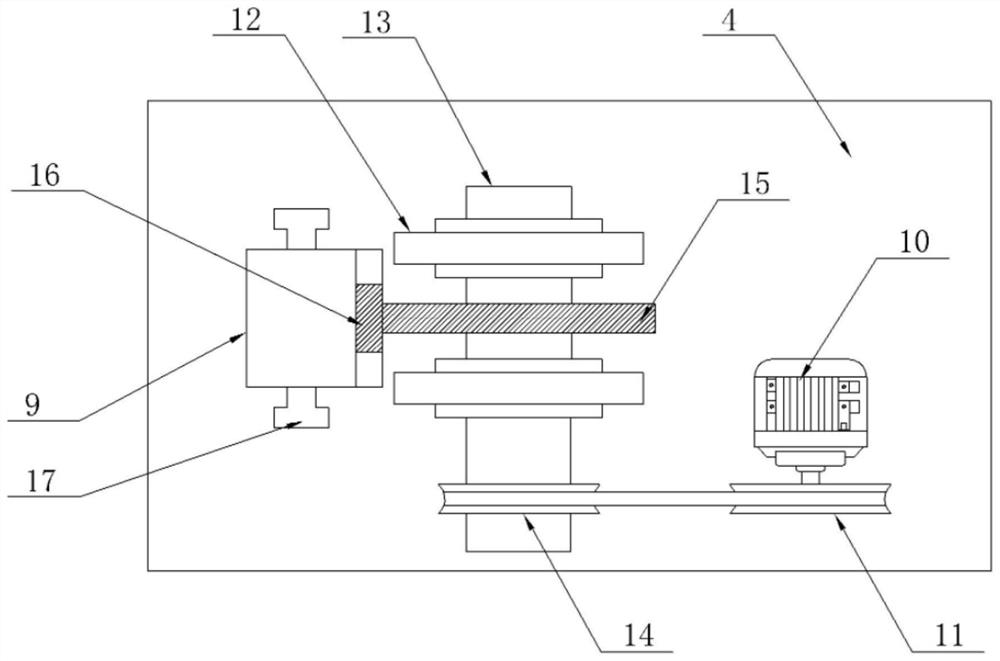

Embodiment 1

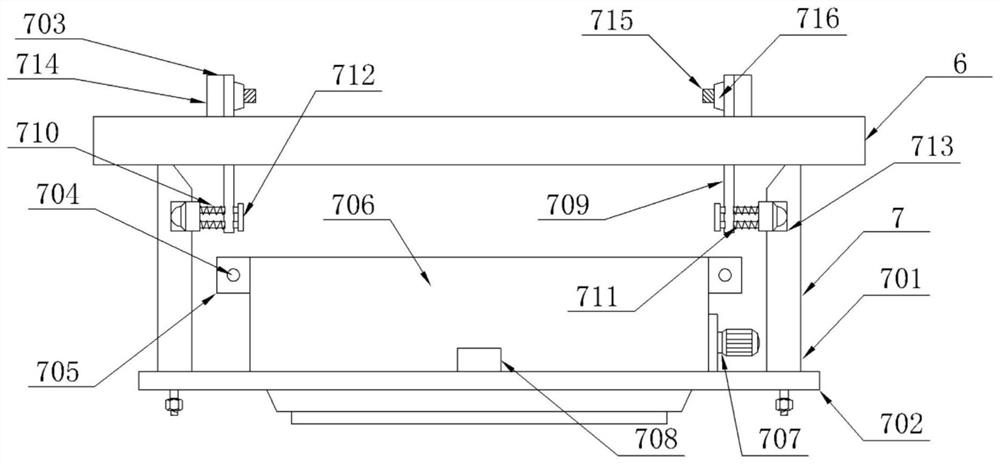

[0026] see Figure 3-5The powder spreading assembly 7 includes a mounting frame 701 installed at the bottom of the lifting plate 6. The mounting frame 701 is fixed by the self-locking assemblies 703 installed on the left and right sides of the outer wall of the bottom of the lifting plate 6. During installation, it only needs to be inserted upward for fixing The bottom of the installation frame 701 is provided with a bottom reinforcement plate 702, the bottom outer wall of the bottom reinforcement plate 702 is provided with screw holes at four corners, the inner thread of the screw hole is provided with a fixing bolt, and the bottom of the installation frame 701 is provided with a screw hole matched with the fixing bolt, The casing 706 is fastened. The middle of the rear inner wall of the installation frame 701 is provided with two sets of left and right screws 704. The outer wall of the screw 704 is movably provided with a mounting block 705. Each threaded sleeve is provided ...

Embodiment 2

[0028] Please refer to Figure 3-5 The powder spreading assembly 7 includes a mounting frame 701 installed at the bottom of the lifting plate 6. The mounting frame 701 is fixed by the self-locking assemblies 703 installed on the left and right sides of the outer wall of the bottom of the lifting plate 6. During installation, it only needs to be inserted upward for fixing The bottom of the installation frame 701 is provided with a bottom reinforcement plate 702, the bottom outer wall of the bottom reinforcement plate 702 is provided with screw holes at four corners, the inner thread of the screw hole is provided with a fixing bolt, and the bottom of the installation frame 701 is provided with a screw hole matched with the fixing bolt, The bottom reinforcement plate 702 is provided with a clamping slot matched with the bottom of the casing 706, the casing 706 is installed in the clamping slot of the bottom reinforcement plate 702, and the bottom of the connection between the righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com