Device for printing three-dimensional product layer by layer

A layer-by-layer printing, three-dimensional technology, used in the improvement of process efficiency, additive processing of solid materials and liquid materials, additive manufacturing, etc., can solve problems such as large thickness and uneven powder material laying, and achieve good continuity. , The structure is simple and reasonable, and the quality of the molded product is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

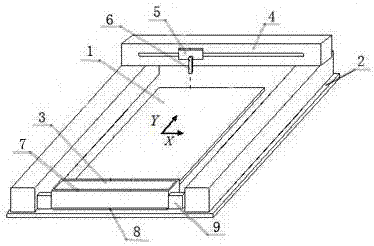

[0025] like figure 1 A device for layer-by-layer printing of three-dimensional products is shown, including a casting mold platform 1, a powder spreading device 3, a printing head 6 and a frame platform 2, the casting mold platform 1 is set on the frame platform 2, and the frame platform 2 is on the casting mold platform. One end of 1 is provided with a powder spreading device 3, and the rack platform 2 is provided with a sliding guide rail 4 at the other end opposite to the powder spreading device 3. The sliding guide rail 4 is provided with a printing head 6 through a sliding fixed seat 5. A feeding port 7 is provided at the position, and a discharging port 8 is provided at the lower end position of the powder spreading device 3 which is matched with the feeding port 7 .

[0026] In this embodiment, the mold platform 1 can move vertically up and down, the powder spreading device 3 drives the sliding guide 4 to move along the Y-axis direction through the motor 9, and the powd...

Embodiment 2

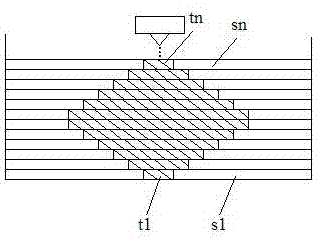

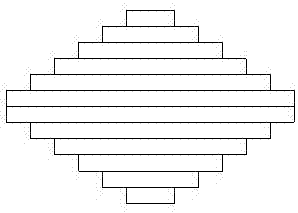

[0028] like figure 2 and image 3 A method for using a device for layer-by-layer printing of a three-dimensional product is shown, including the following contents:

[0029] At the beginning of printing, the powder spreading device 3 filled with particulate material is firstly located, and the powder spreading device 3 is located at the initial edge of the mold platform 1;

[0030] Open the discharge port 8 and lay a layer of granular material;

[0031] At the same time, the powder spreading device 3 is driven to the opposite edge of the mould platform 1 at a constant speed, so that the mould platform 1 is covered by a uniform layer of granular material;

[0032] After the material is conveyed, the powder spreading device 3 is reset, and the feeding port 7 is opened for charging;

[0033] The print head 6 moves to a prescribed area on the mold platform 1 along a prescribed path through the movement of the sliding guide 4 , sprays the adhesive, and then returns to the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com