Large-thickness titanium alloy narrow-gap laser welding device and method based on automatic powder laying

A laser welding and titanium alloy technology, which is applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of metal powder waste and unsatisfactory weld formation, so as to improve utilization rate and save space , the effect of reducing the volume of the box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

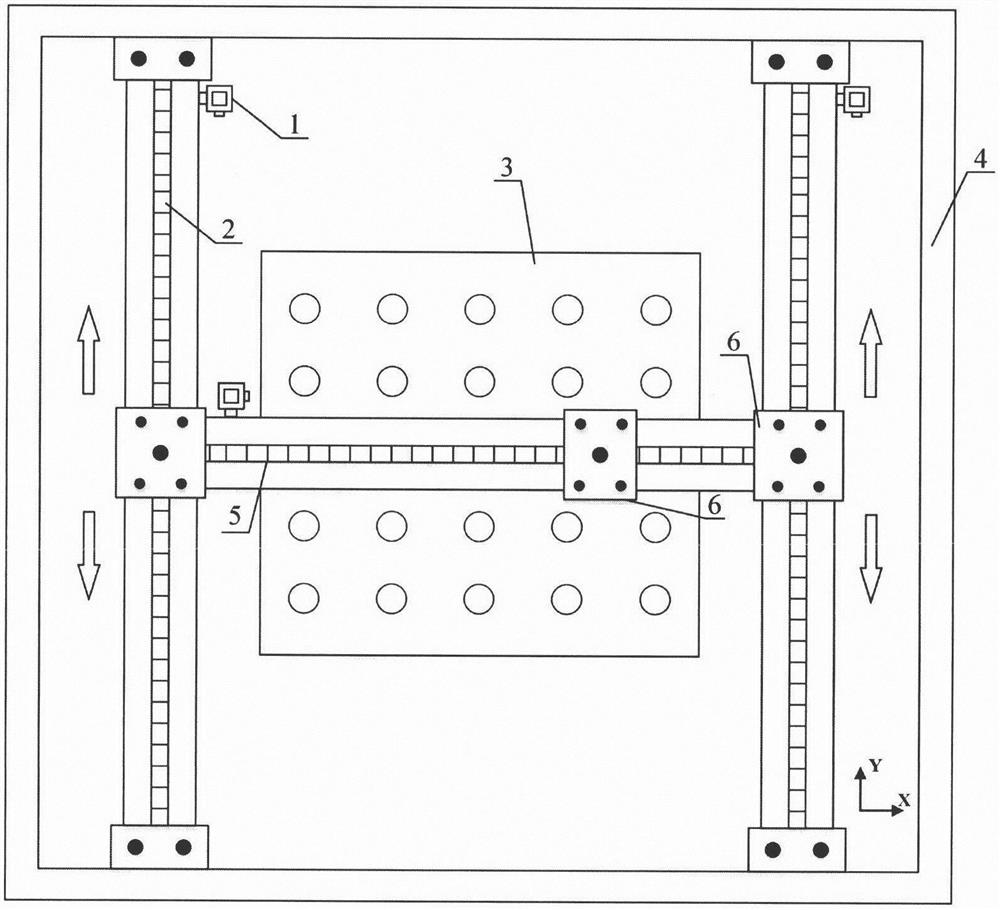

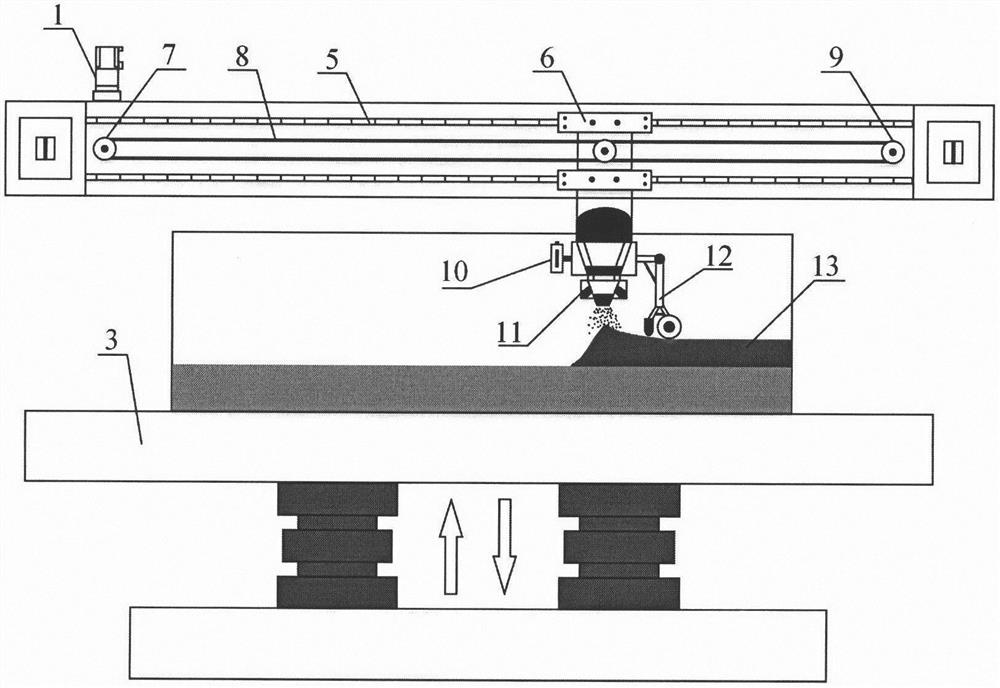

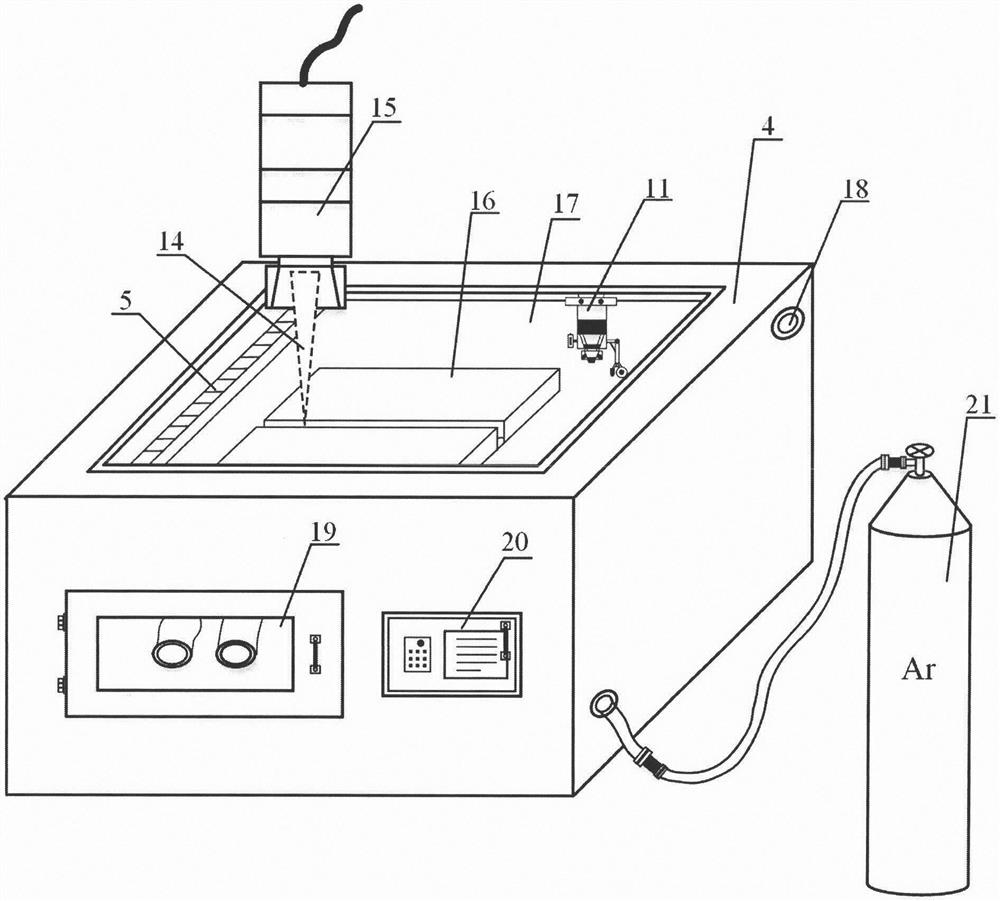

[0024] The following is a specific description of a large-thickness titanium alloy narrow-gap laser welding device and method based on automatic powder spreading in the present invention.

[0025] Carry out laser welding experiments based on automatic powder feeding and powder spreading for large-thickness TC4 titanium alloy plates. The size of the titanium alloy plate is 100×50×20mm, and the plate is processed with a U-shaped groove. The groove gap is 5mm and 2mm is reserved. blunt edge. Fix two titanium alloy plates on the lifting and clamping platform without gap. Open the valve of the argon gas cylinder, and increase the gas flow to 25L / min. After the argon gas fills the entire box, reduce the gas flow to 5L / min, and keep the gas flow constant throughout the welding process. The experimental equipment used includes YLS10000 continuous fiber laser and KUKA60 robot, and the maximum average power output by the laser can reach 10000W.

[0026] Import the CAD model of the spl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com