Powder sieving device of 3D printing device

A 3D printing and powder sieving technology, which is applied in coating devices, 3D object support structures, additive manufacturing, etc., can solve problems such as uneven powder feeding and product quality impact, and achieve the effect of uniform powder spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

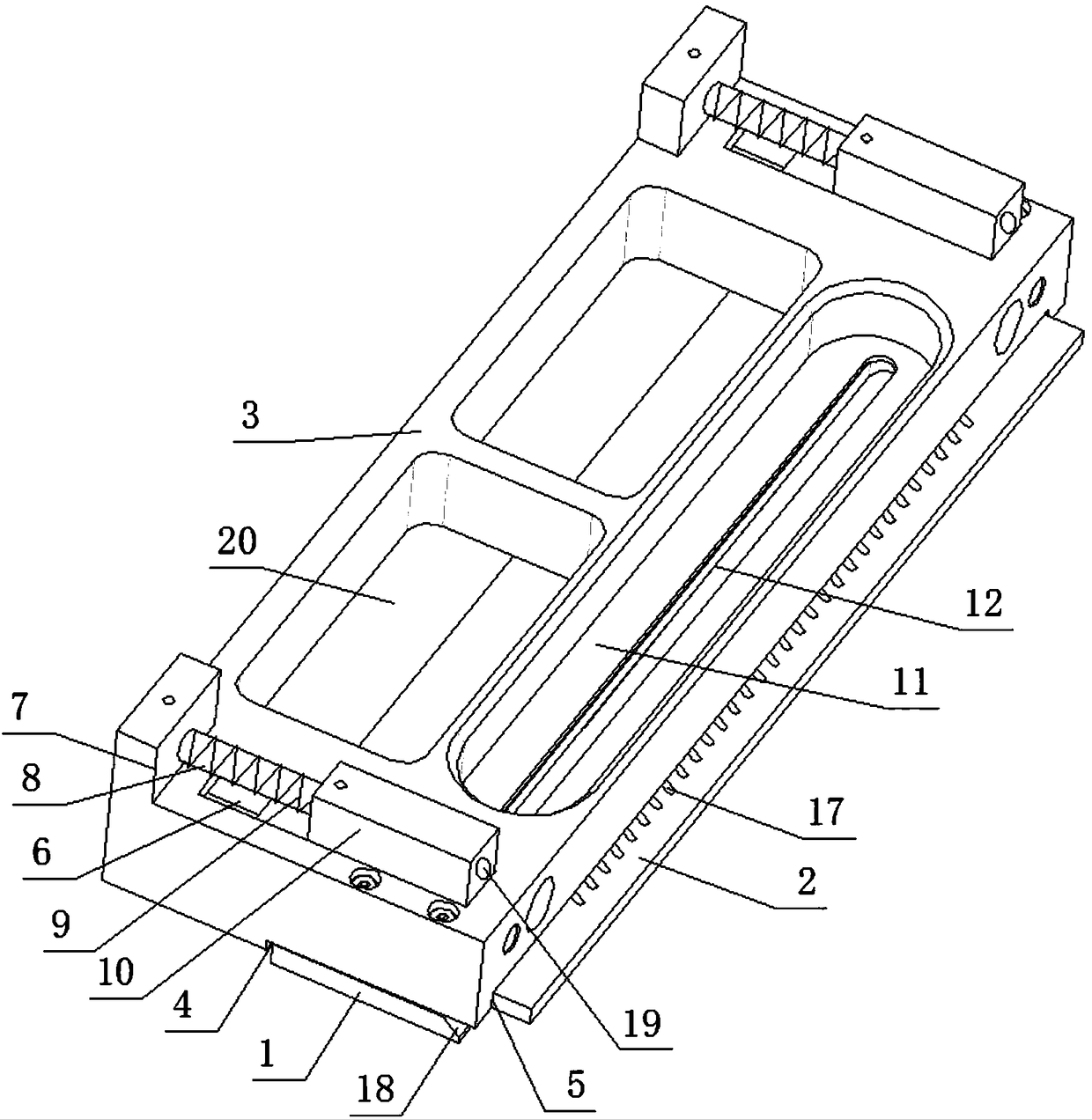

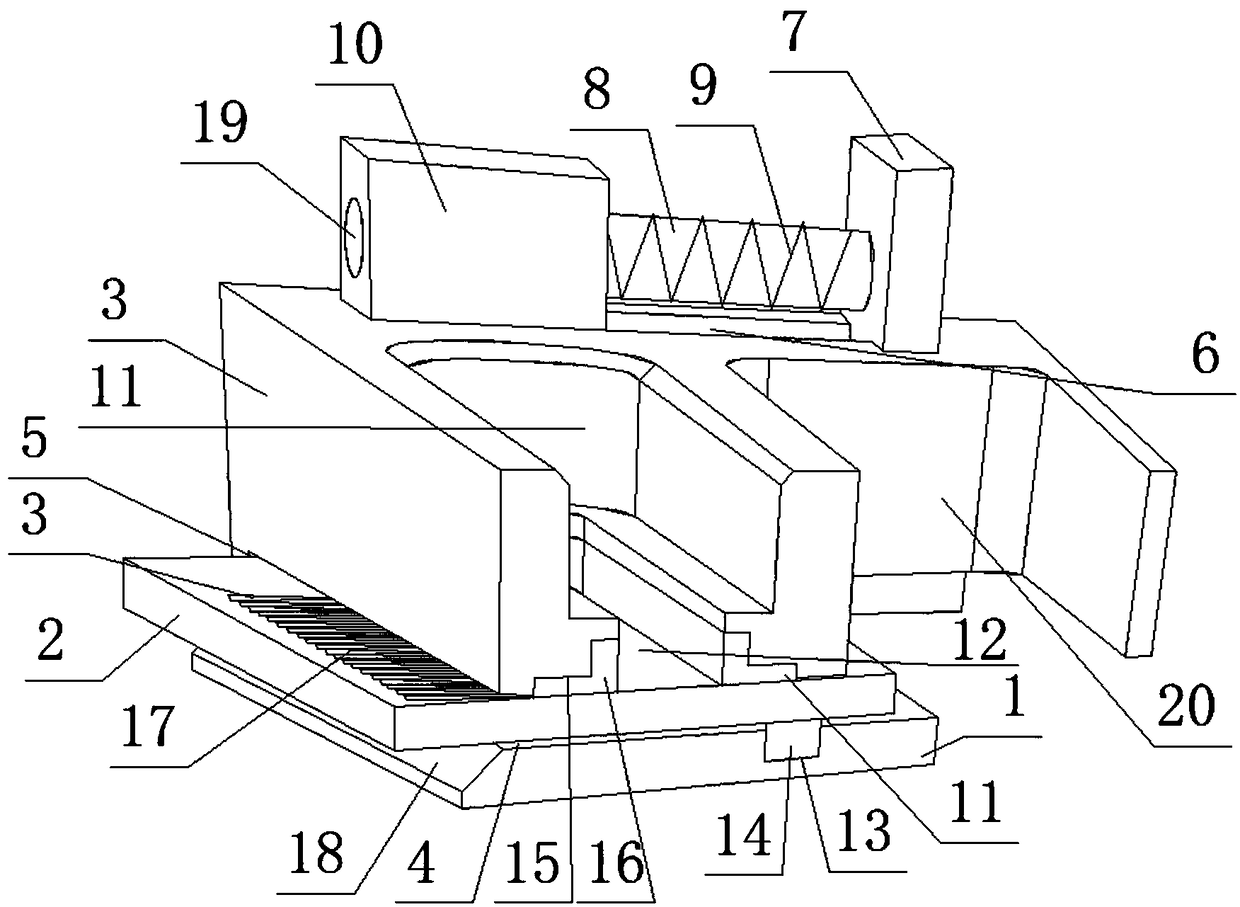

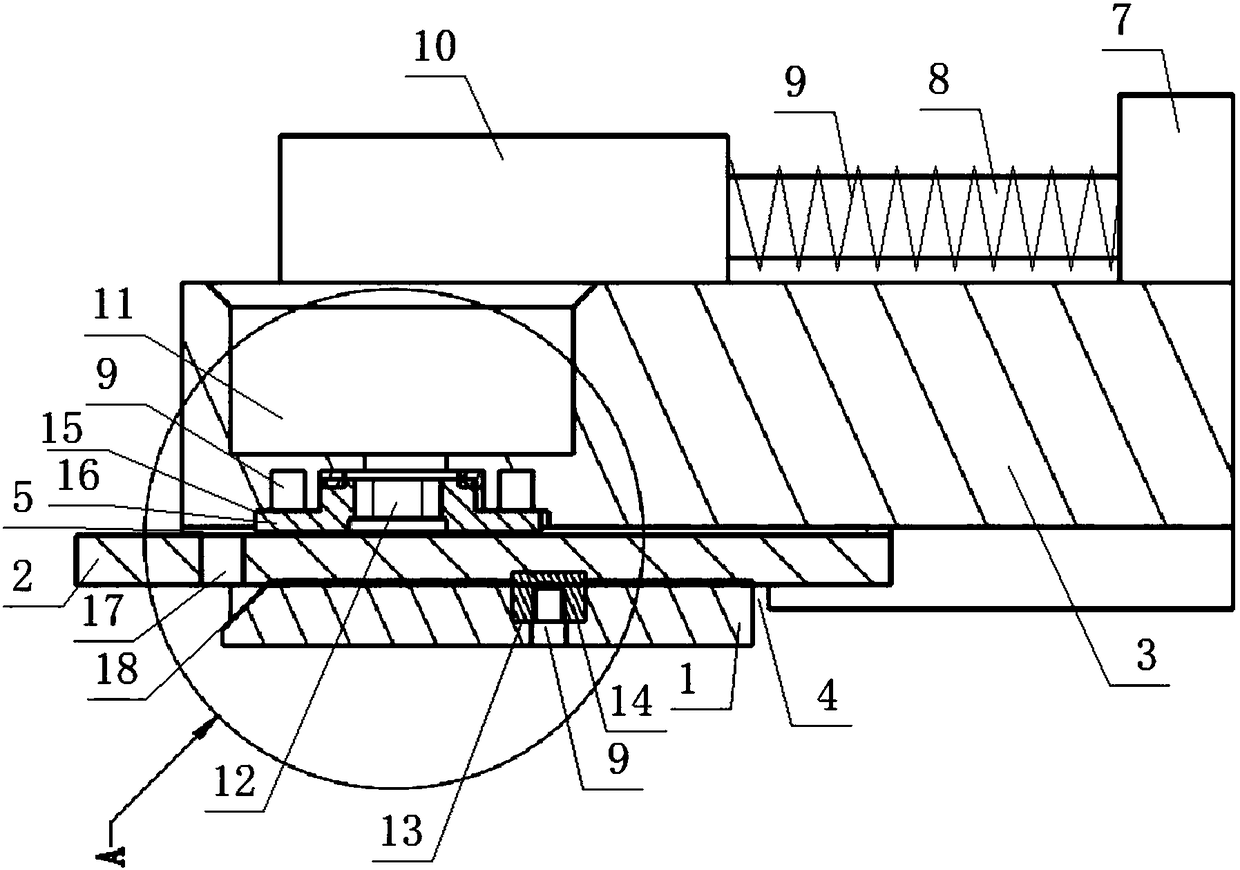

[0016] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Figure 1-4 A specific embodiment of the present invention is shown: a powder sieving device for a 3D printing device, including a support plate 1, a sieve plate 2, a powder outlet plate 3 and a linkage device, and the lower end of the powder outlet plate 3 is sequentially provided with Horizontal rectangular groove 4 and longitudinal rectangular groove 5, the support plate 1 is arranged in the horizontal rectangular groove 4, the sieve plate 2 is arranged in the longitudinal rectangular groove 5, the two ends of the powder outlet plate 3 are A chute 6 and a block 7 are provided, the block 7 is provided with a slide bar 8, the slide bar 8 is provided with a spring 9 and a slide block 10, and the bottom end of the slide block 10 is in phase with the sieve plate 2 connected, the powder outlet plate 3 is provided with a powder storage gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com