Powder supplying and spreading device

A powder spreader and powder supply technology, which is applied in the field of additive manufacturing, can solve the problems of difficulty in improving the quality of powder spreading, achieving the effect of powder spreading, and difficult to meet the ideal effect when using it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

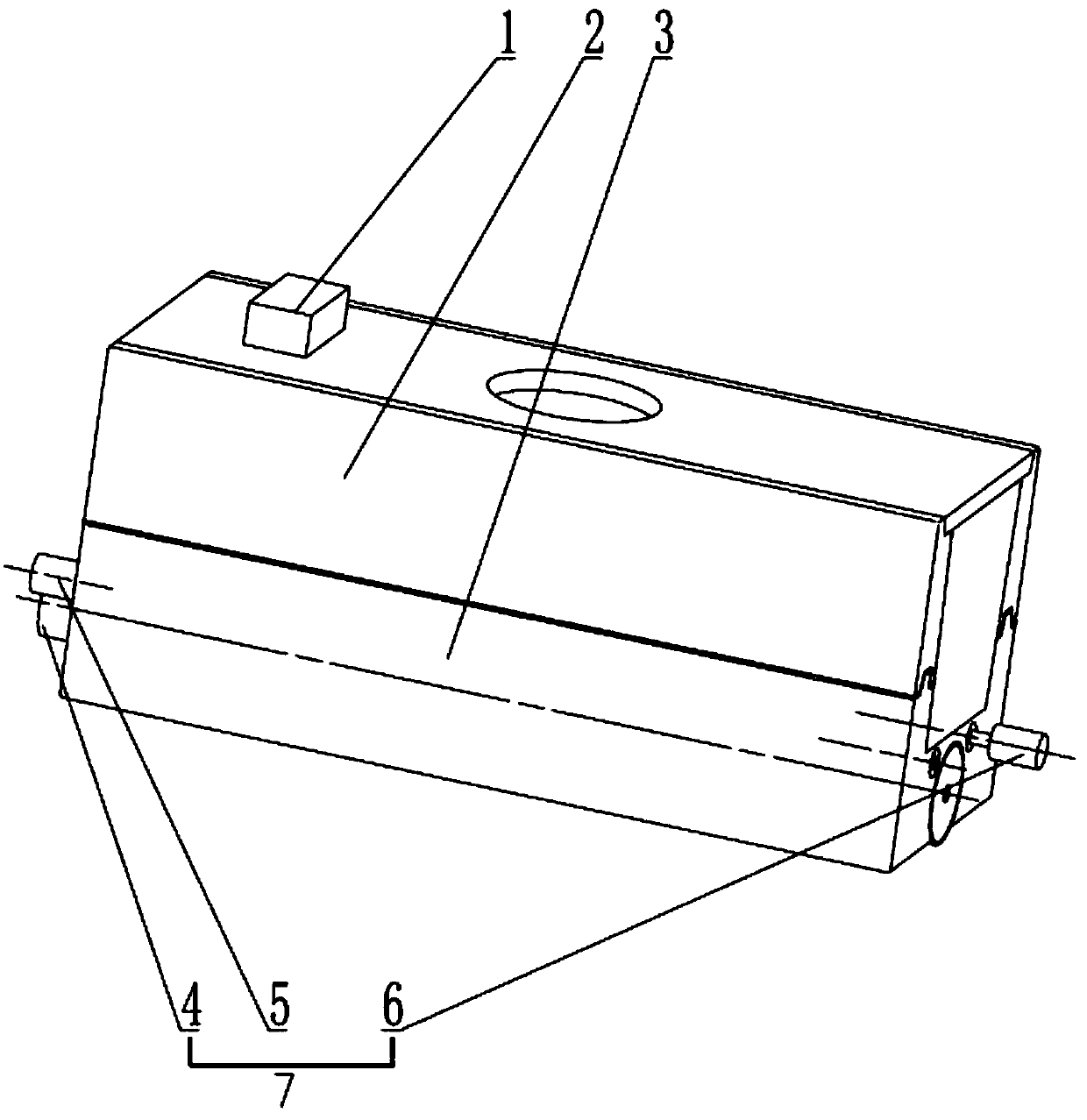

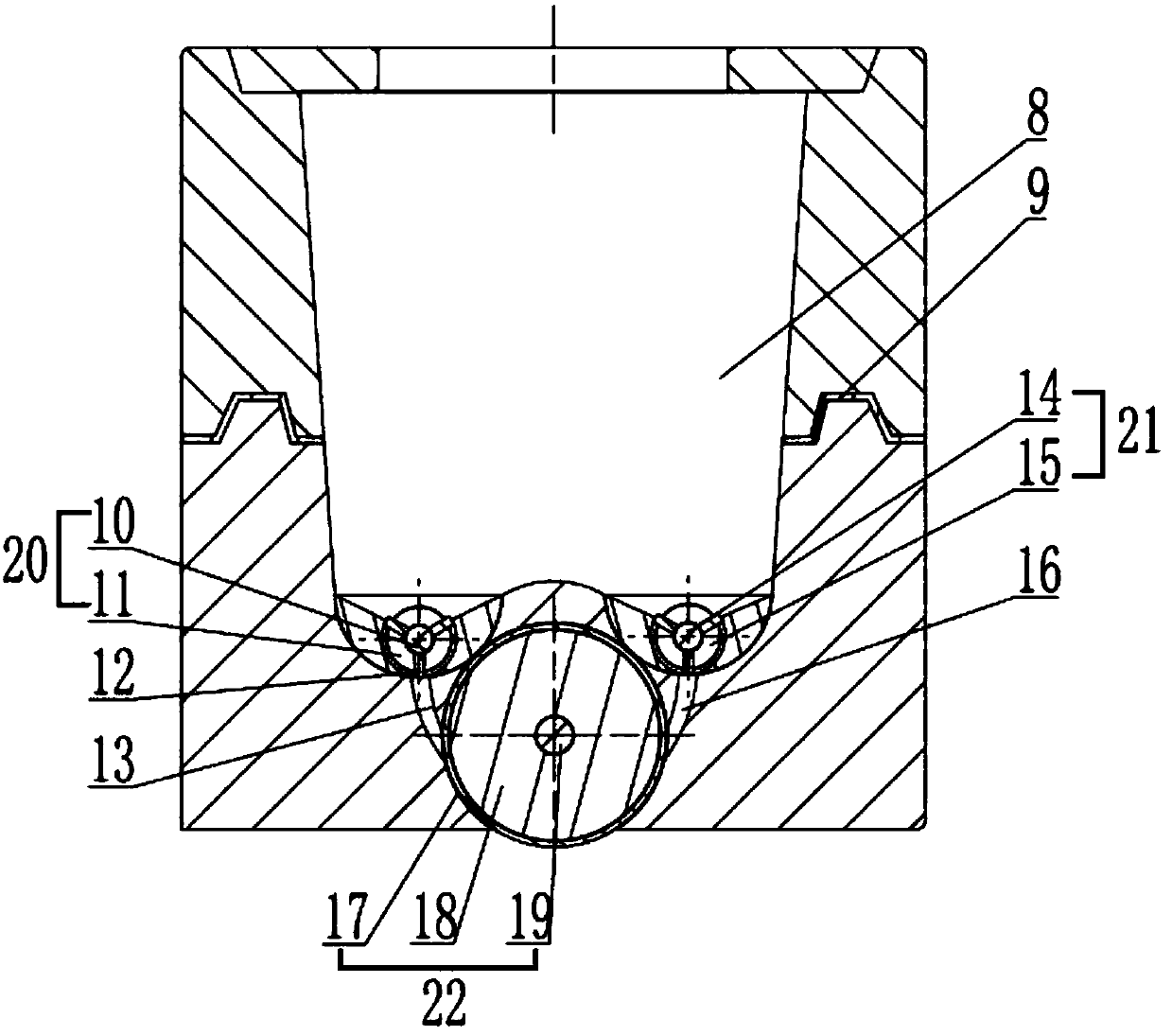

[0031] refer to figure 1 , figure 2 , a kind of powder supply powder spreader, comprises powder storage room 8, first powder supply roller 20, second powder supply roller 21, powder spread roller 22, level detector 1 and power unit 7, described first, two supply The powder roller has a rotor structure; the powder spreading roller 22 is cylindrical.

[0032] The powder storage chamber 8 is composed of an upper box body 2 and a lower box body 3, and a sealing gasket 9 is arranged between the upper and lower box bodies, and the two are connected together in a fitting manner to ensure that the entire powder storage chamber 8 The sealing effect, the sealing gasket 8 adopts ordinary polytetrafluoroethylene; the first and second powder supply rollers respectively include the first powder supply rotor 10 and the first powder storage tank 11, the second powder supply rotor 14 and the second powder storage tank Powder tank 15, the inside of the first and second powder storage tanks i...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the powder feeding blades provided on the powder supply roller described in the embodiment of the present invention can be provided with 6 powder feeding blades according to the actual use situation. The purpose of doing this is to adjust The powder supply amount during a single powder spreading can realize quantitative powder supply more accurately.

[0040] The working mode and other structures and connection modes of this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com