A laser sintering 3D printer

A 3D printer and laser sintering technology, used in the field of material manufacturing, can solve the problems of inability to completely avoid powder entry, complex structure, etc., to ensure the quality of powder coating, prevent a large number of accumulations, and be easy to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

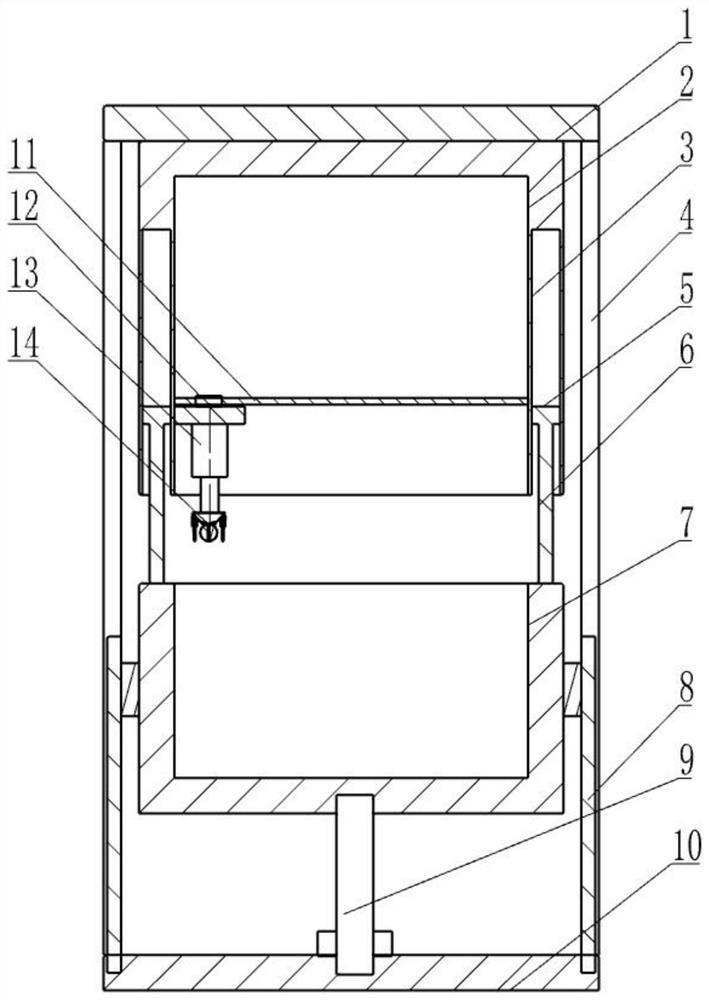

[0027] see figure 1 , a laser sintering 3D printer, including a frame, an upper cylinder body 2 and a lower cylinder body 7, the top of the side wall of the lower cylinder body 7 is connected with an insert plate 6 with a thickness smaller than that of the lower cylinder body, and the insert plate The thickness of the upper end is increased to form an outer edge 5, which is closely matched with the inner wall of the groove 3 of the upper cylinder body. The lower cylinder body 7 and the insert plate 6 are integrally formed; the upper and lower cylinder bodies are rectangular, and the insert plate is a rectangle corresponding to the upper and lower cylinder bodies; matching groove 3; the frame is composed of an upper top surface 1, a lower bottom surface 10, a column 4 and a crossbeam, the column is 4, the upper top surface 1 is fixedly connected with the top surface of the upper cylinder body 2, and the lower bottom surface 10 The column 4 is connected to the upper top surface...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the upper top surface of the frame is formed by extending the upper cylinder top surface, and the two are on the same plane. All the other structures and working methods are the same as those in Example 1. Compared with Embodiment 1, this embodiment further reduces the complexity of the structure, reduces the weight, and reduces the cost.

Embodiment 3

[0036] The only difference between this embodiment and the embodiment 1 is that a seal is added between the outer edge and the groove to achieve a further sealing effect. All the other structures and working methods are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com