A powder feeder

A powder spreader and powder supply technology, applied in the field of additive manufacturing, can solve problems such as difficulty in improving the quality of powder spread, easy damage of the scraper, waste of powder, etc., achieve high-quality powder spread effect, reduce manufacturing cost, and improve structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

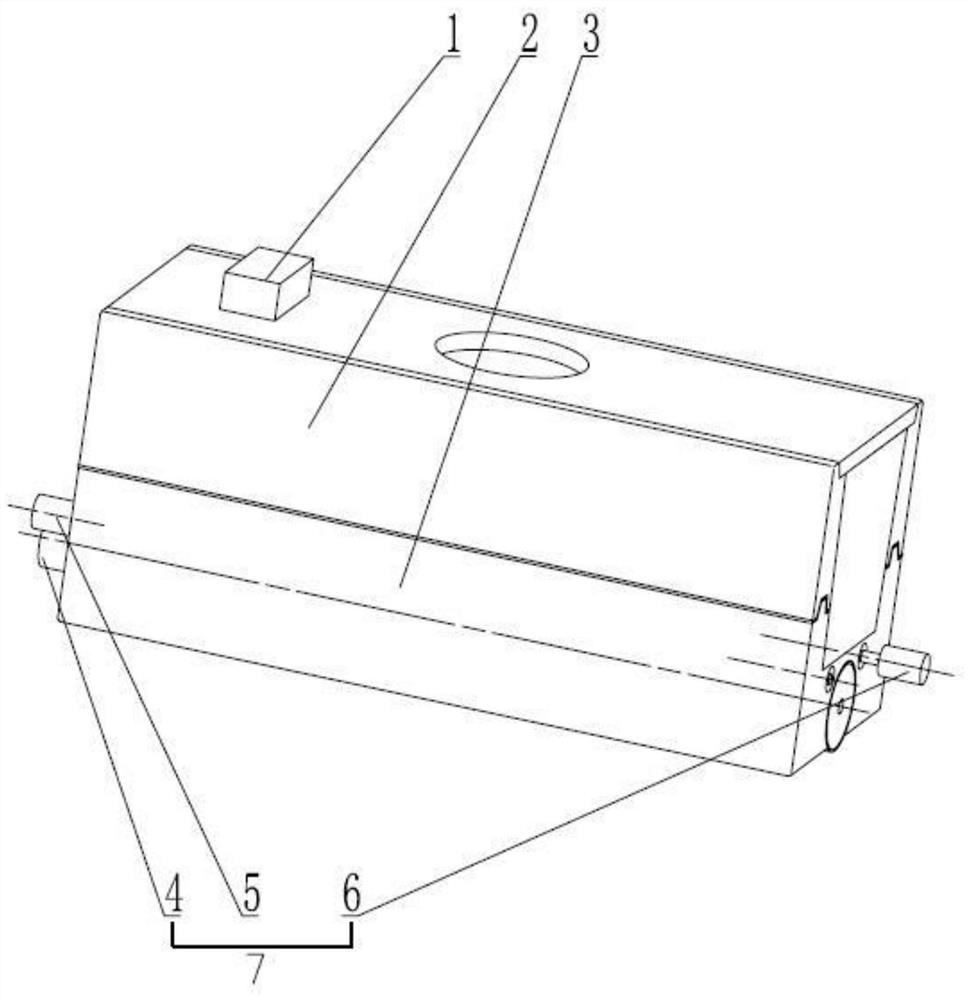

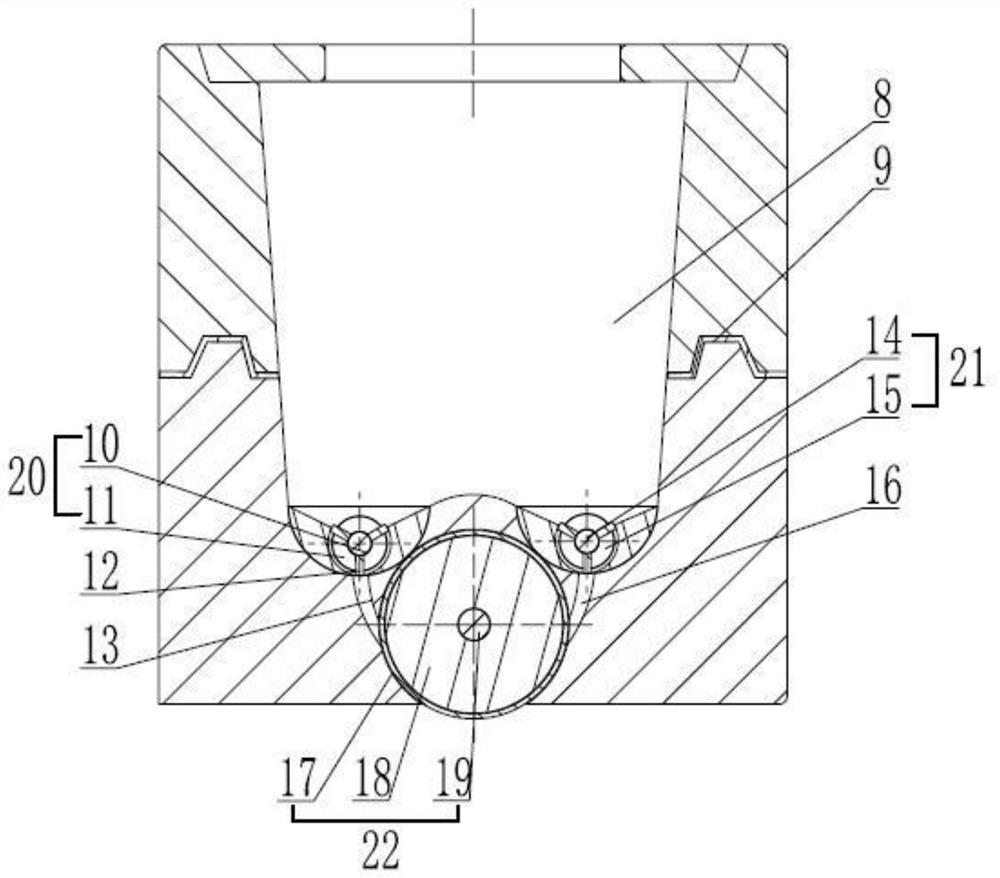

[0031] Refer figure 1 , figure 2 A method for dusting powder, a powder comprising a reservoir chamber 8, the first supply roller 20, the second supply roller 21, powder spreading roller 22, and a power level detector means 7, the first and second supply powder roller rotor structure; dusting the roller 22 is cylindrical.

[0032] The powder storage chamber 8 and the lower housing 23 constituting the upper casing, on the gasket 9 is provided between the lower case, both are connected together in a fitting manner, in order to ensure that the entire powder storage chamber 8 sealing effect, the ordinary polytetrafluoroethylene gasket 9; said first and second supply roller for the powder comprising first rotor 10 and the first powder storage tank 11, a second reservoir 14 and a second rotor for the powder powder grooves 15, the first, inner powder reservoir two semicircular groove, both provided in the bottom 8 inside powder reservoir chamber and higher than the dusting roller 22; said...

Embodiment 2

[0039] The difference between the present embodiment is only that the flour chalk set on the supply roller described in the embodiment of the present invention can set 6 pieces to send a powder blade according to the actual use, and the purpose is to adjust Powder supply at a single release can achieve a quantitative supply of powder more accurately.

[0040] The mode of operation and the remaining structure and the remaining structure of the present embodiment are in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com