3D printer and powder spreading mechanism therefor

A 3D printer and powder spreading technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve problems such as affecting the powder spreading effect and smoothing the movement of powder components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

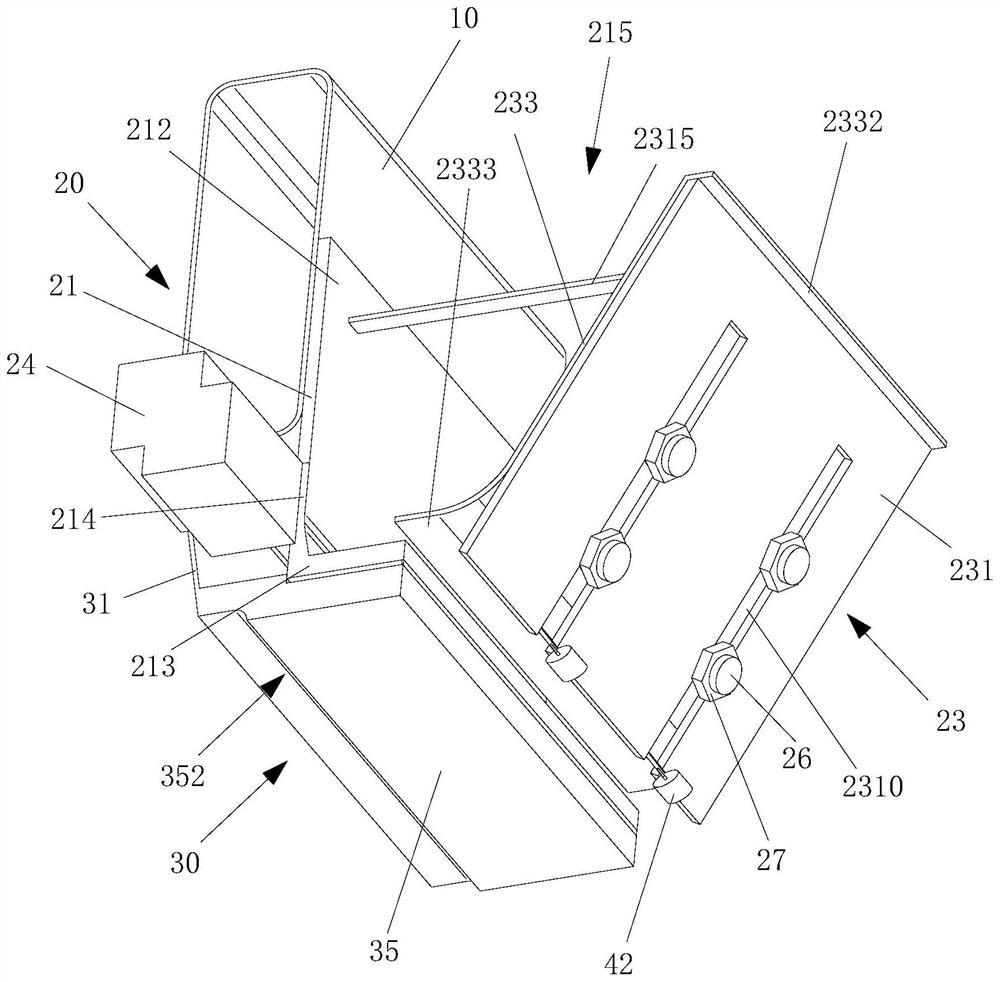

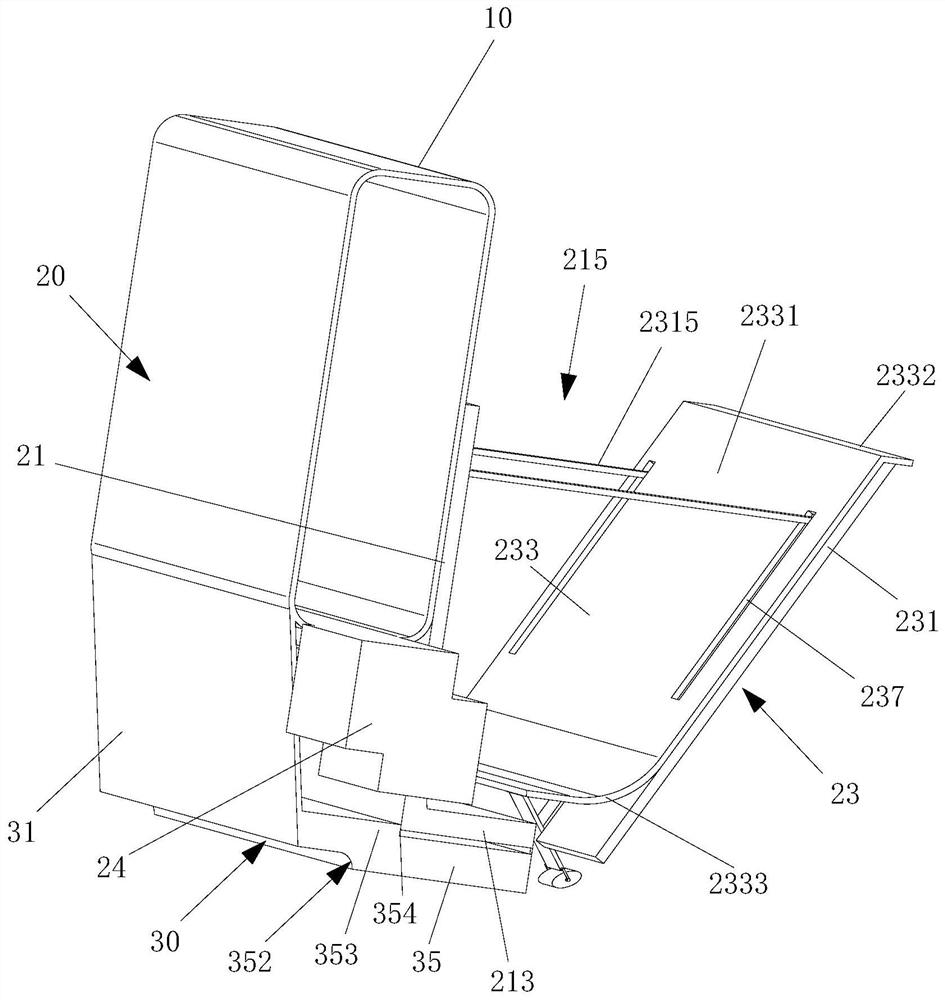

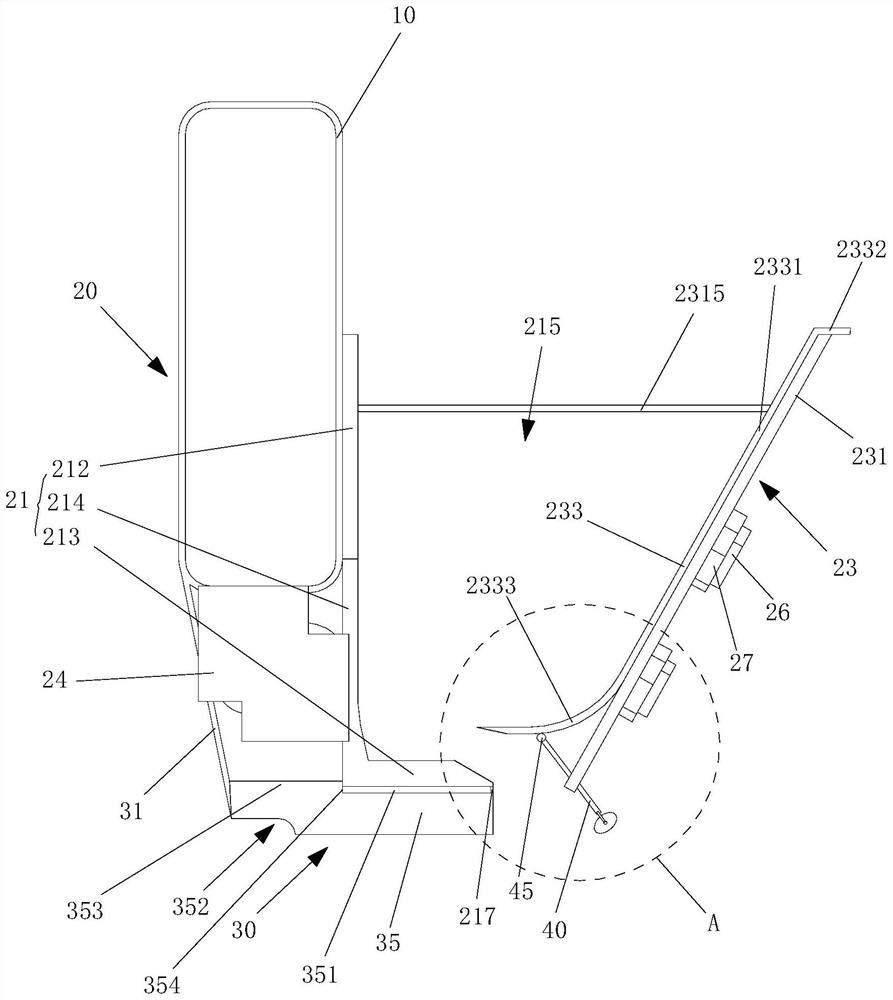

[0019] see Figure 1 to Figure 4 , a powder spreading mechanism of a 3D printer, comprising a square steel frame 10, a powder outlet component 20 and a powder spreading component 30, the powder outlet component 20 including a vibrating plate 21, a guide plate structure 23, a vibrating motor 24 and a vibrating cam (not shown in the figure) ), the top of the vibrating plate 21 is fixed on the square steel frame 10, the bottom of the vibrating plate 21 is formed with a flexible vibrating plate part 214, the guide plate structure 23 is obliquely arranged relative to the vibrating plate 21, between the vibrating plate 21 and the guiding plate structure 23 A powder outlet space 215 is formed, the vibrating motor 24 is installed on the bottom of the square steel frame 10 through a connecting frame (not shown), the vibrating cam is installed on the output shaft of the vibrating motor 24 and is held against the flexible vibrating plate portion 214, The powder spreading assembly 30 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com