Detachable tool rest on numerically-controlled machine tool

A CNC machine tool and detachable technology, applied in the field of machinery, can solve problems such as time and energy spent on operators, reduced production efficiency of enterprises, bending deformation of tools, etc., so as to achieve unaffected machining accuracy, fast replacement speed, and tool change efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

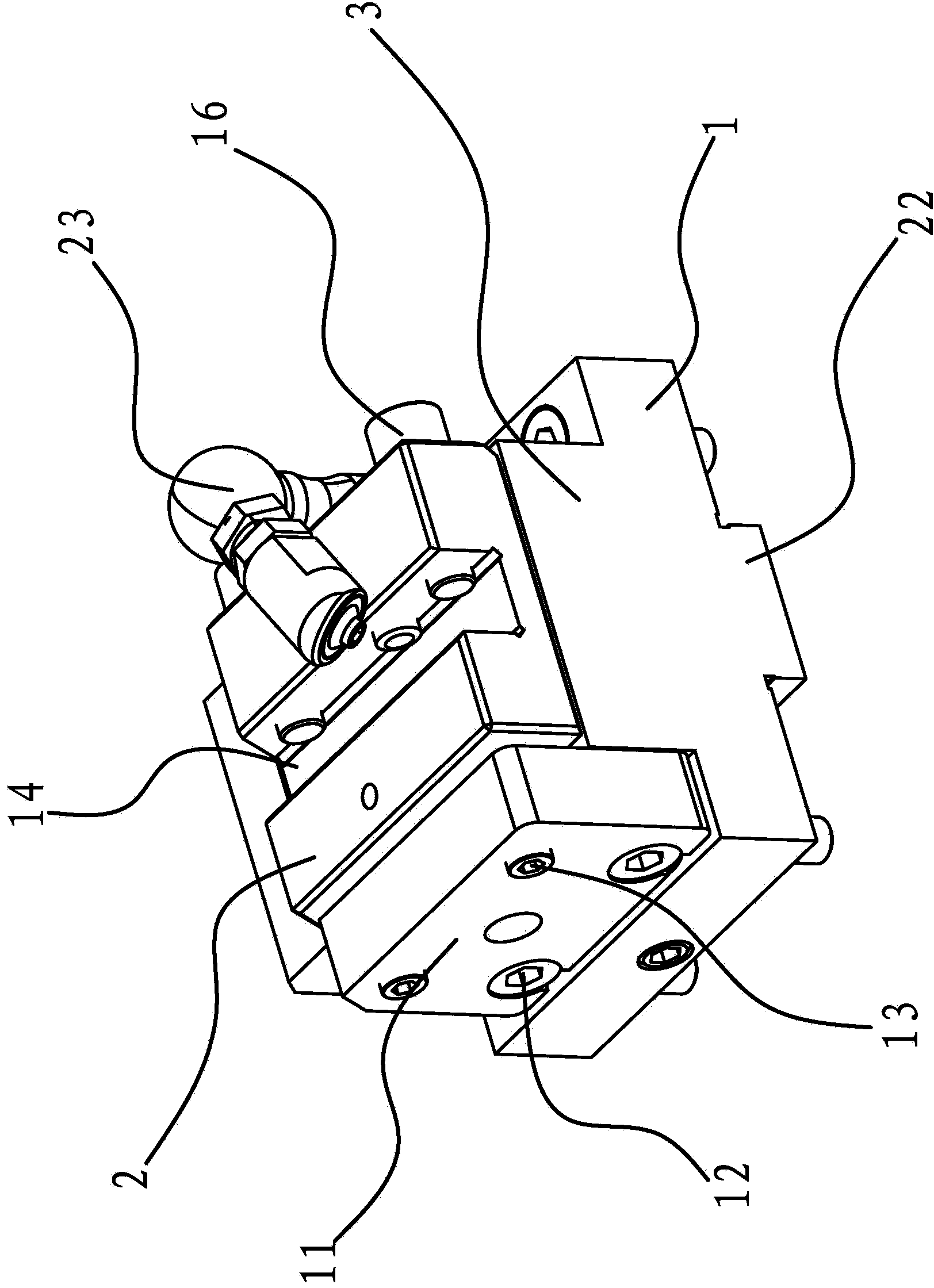

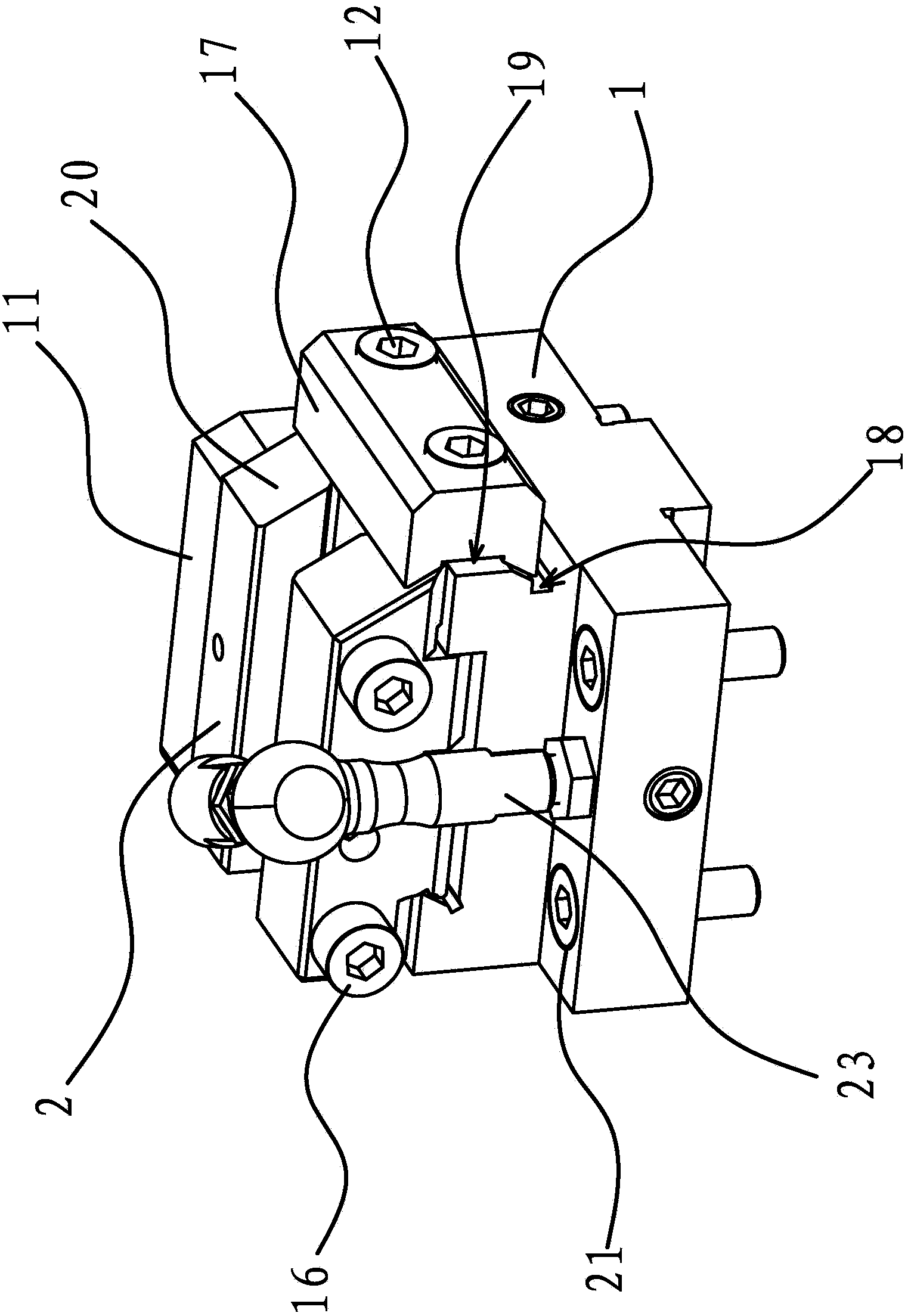

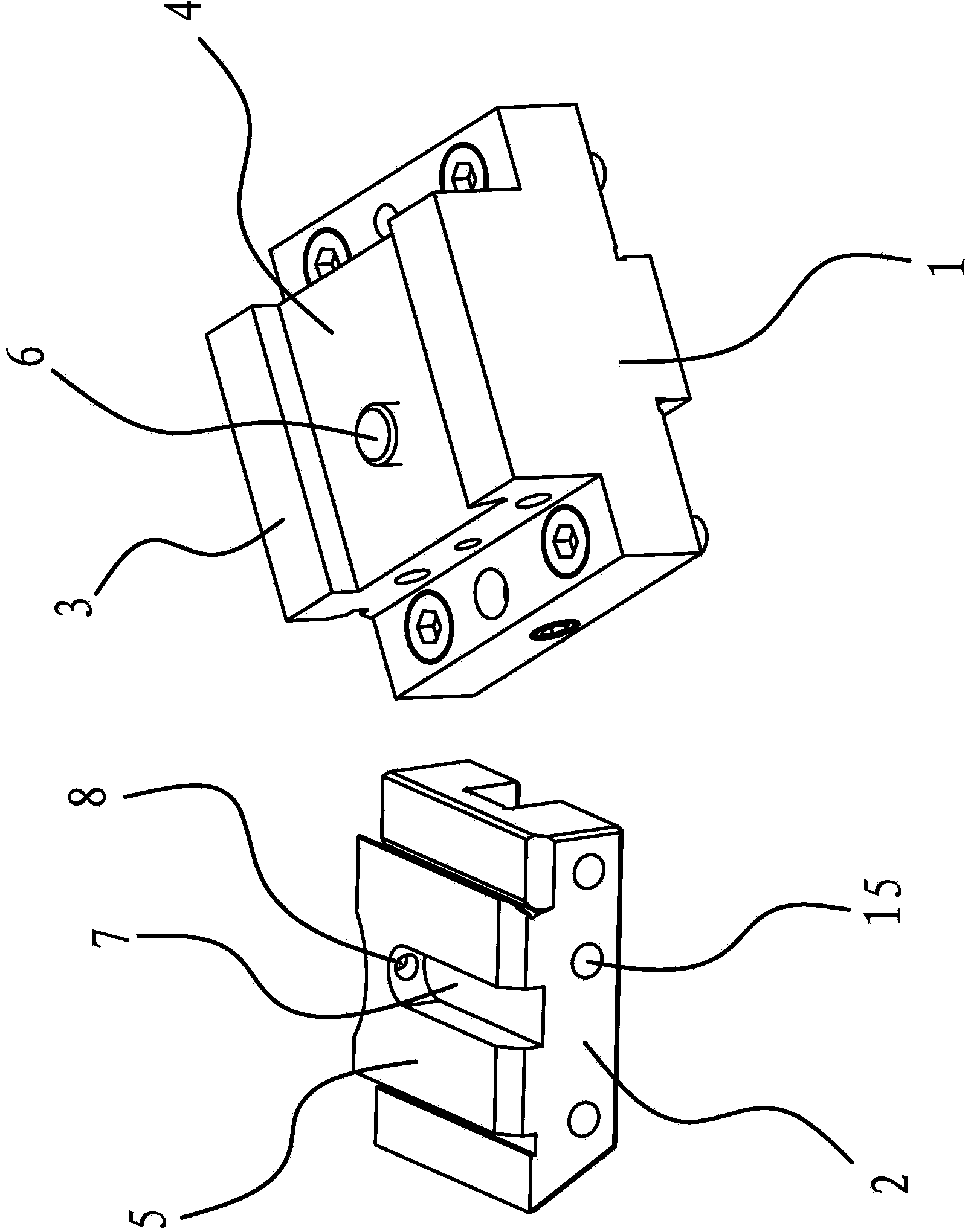

[0038] Such as Figure 1-Figure 6 As shown, a detachable tool rest used on a CNC machine tool, the CNC machine tool has a turret, the detachable tool rest includes a base 1 for fixing on the turret and a tool rest connected to the base 1 The main body 2 and the base 1 have a positioning boss 3 , and the positioning boss 3 is provided with a slot 4 passing through its side, and the base 1 of the tool holder body 2 has a snap-in portion 5 that can be snapped into the slot 4 .

[0039] Such as figure 1 As shown, the side of the positioning boss 3 perpendicular to the card slot 4 is fixedly connected with the baffle 11 through the fastening screws 12, and the side of the baffle 11 is pressed against the side of the tool holder body 2 by several fastening studs 13 . The knife rest body 2 is block-shaped, and the surface of the knife rest body 2 is provided with a tool mounting groove 14, and the other side where the knife rest body 2 is connected with the baffle plate 11 has seve...

Embodiment 2

[0050] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the blocking member in this embodiment includes a bar that protrudes upwards from the bottom of one end of the slot 4, and the corresponding end of the engaging part 5 has a When the tool rest body 2 is clipped onto the base 1 until the notch on it abuts against the bar at the bottom of the slot 4, the tool post body 2 is clipped to the specified position on the base 1.

Embodiment 3

[0052] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: there are several connecting holes 1 distributed on the surface of the knife holder body 2 in this embodiment, and a number of connecting holes 2 are correspondingly distributed on the base 1, and the fixing parts include Pass through the connecting hole one and pass through the latch in the connecting hole two. After the tool holder body 2 is clamped with the base 1 , the bolt is used to pass through the connection hole and penetrate into the connection hole 2, so that the tool holder body 2 and the base 1 are fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com