Fast mortar-spreading device for building brick wall

A fast, lime-sand technology, applied in the field of installations of fast-spreading lime-sand mortar for building brick walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

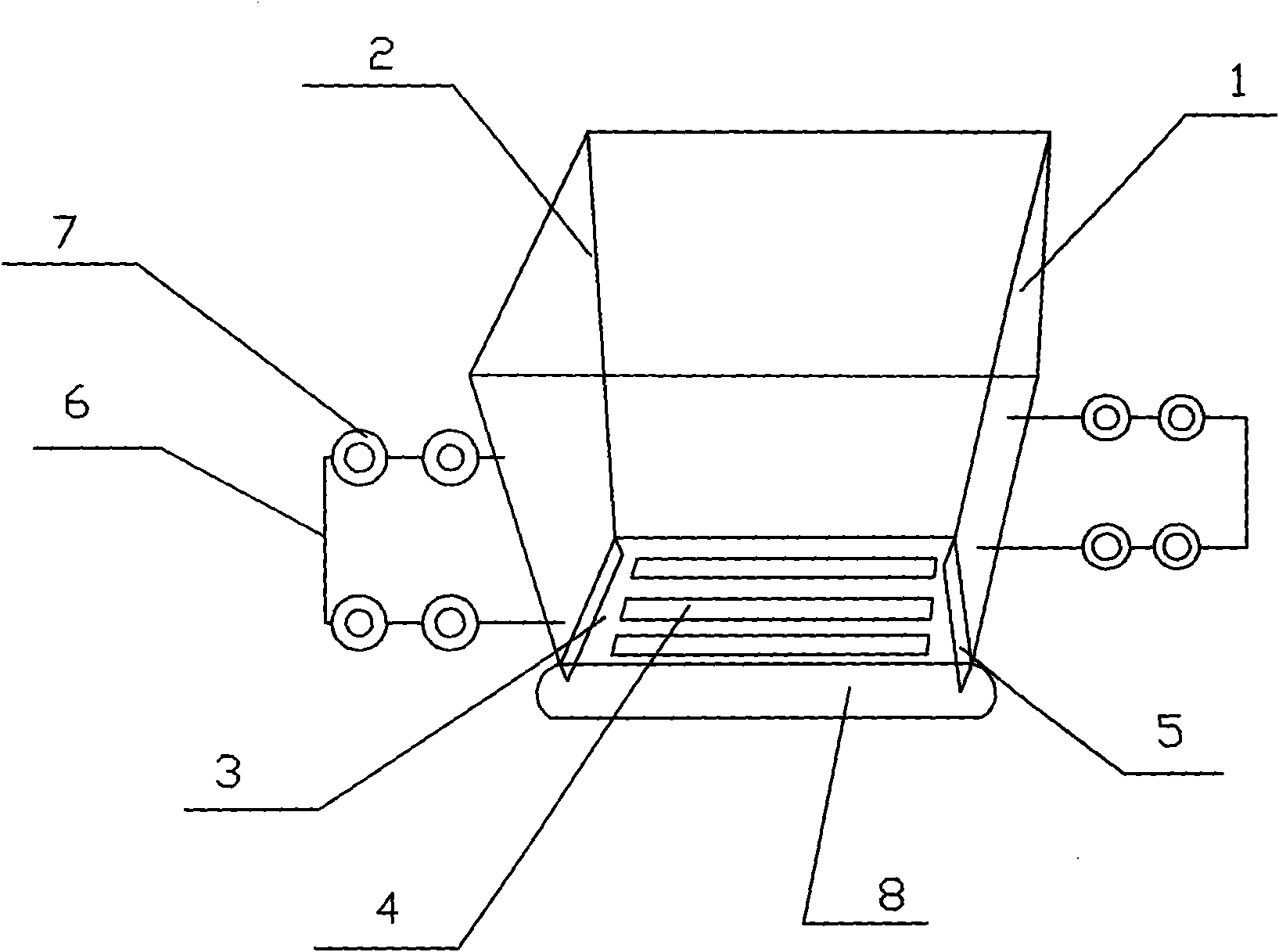

[0013] Such as figure 1 As shown, make a hopper 1 with thick 0.3 centimeter iron plate, the hopper upper end 2 is long 50 centimeters, wide 30 centimetres; Lime mortar.

[0014] At the hopper lower end, the bottom plane of the hopper is provided with 3 long 30 wide 3 centimeters strip gray mortar outlets 4, so that the mortar that leaks down becomes three strips when moving.

[0015] On the front and rear sides of the hopper, near the lower end of the hopper, a plastering iron bar 5 with a width of 4 cm and a length of 24 cm is respectively welded along the hopper width direction. A strip of gray mortar is extruded and flattened.

[0016] Respectively install a "U" type mount 6 of fixed wheels in the front and rear of the hopper, and the "U" type mount is used as a handle simultaneously to pull the hopper forward and backward.

[0017] 4 vibrating wheels 7 are installed on each " U " type mounting seat, and each vibrating wheel is a gear, and each gear has a diameter of 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com