Automatic break point memory returning system for cloth spreader and control method

A technology of automatic return and breakpoint memory, which is applied in general control systems, program control, electrical program control, etc., can solve the problems of reducing production efficiency, increasing labor intensity, and low degree of automation, so as to improve production efficiency and reduce operation Intensive, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

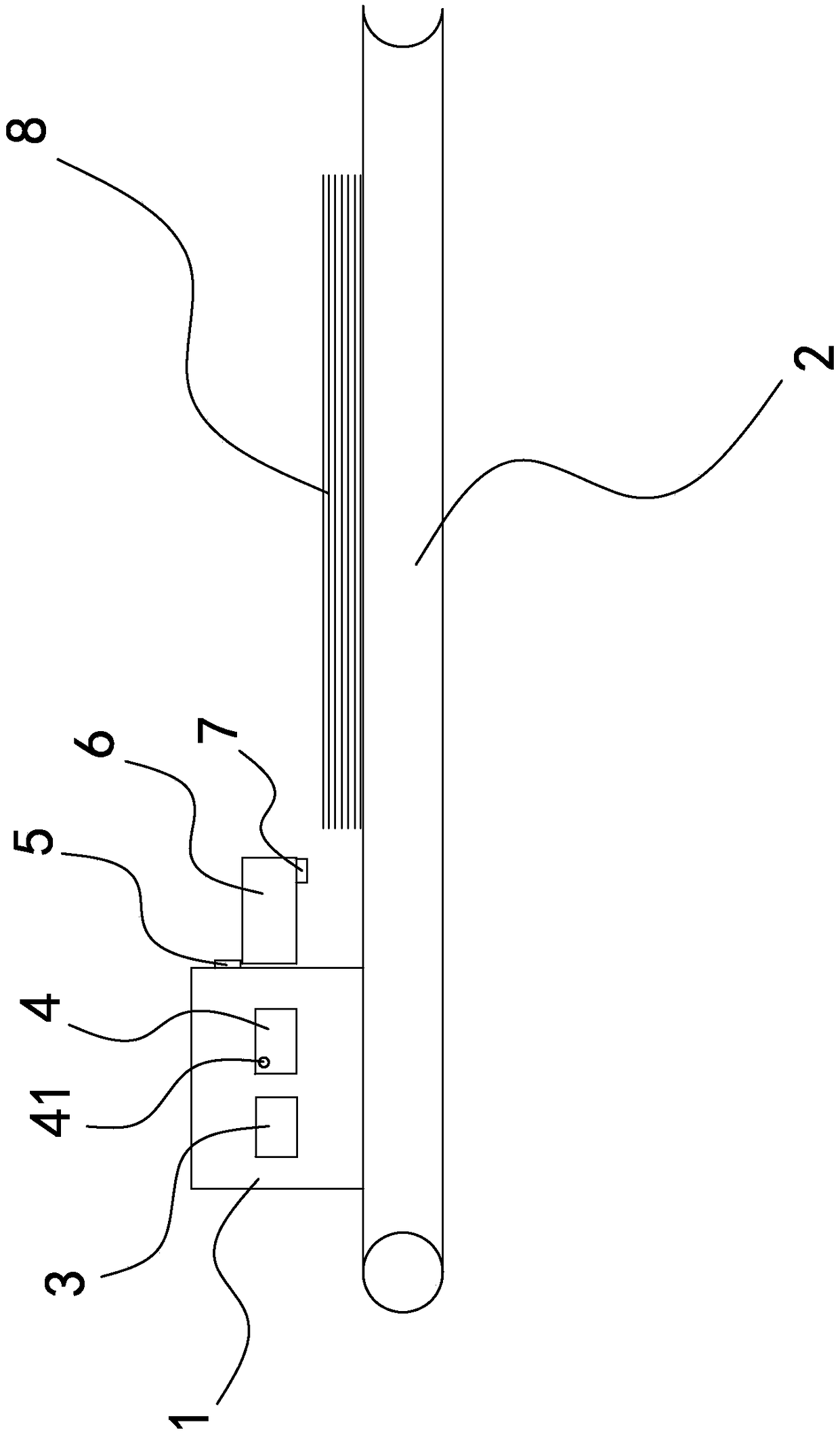

[0033] like figure 1As shown, the breakpoint memory automatic return system used on the cloth spreading machine is applied to the cloth spreading machine. The cloth spreading machine includes a frame 1, a cloth bed 2, a cloth spreading device 6 and a control cabinet 3. The control cabinet 3 is installed in the The controller on the frame 1 and in the control cabinet 3 is a processing module based on PLC, and a touch screen 4 and a reset switch 5 are installed on the frame 1, and the touch screen 4 is used for input and output. The touch screen 4 is provided with a breakpoint button 41, and the reset switch 5 is a proximity switch and is in contact with and away from the spreading device 6. The cloth spreading device 6 can move back and forth at both ends of the cloth bed 2; certainly the cloth spreading device 6 can also include a cloth feeding structure and a cloth clamping structure, the cloth clamping structure is fixed on the other end of the cloth bed 2, and the cloth fee...

Embodiment 2

[0046] The spreading machine includes a frame 1, a cloth bed 2, a spreading device 6 and a control cabinet 3. The control cabinet 3 is installed on the frame 1 and the controller in the control cabinet 3 is a processing module based on PLC. A touch screen 4 and a reset switch 5 are installed, and the touch screen 4 is used for input and output. The reset switch 5 is a proximity switch and is in contact with and away from the spreading device 6 .

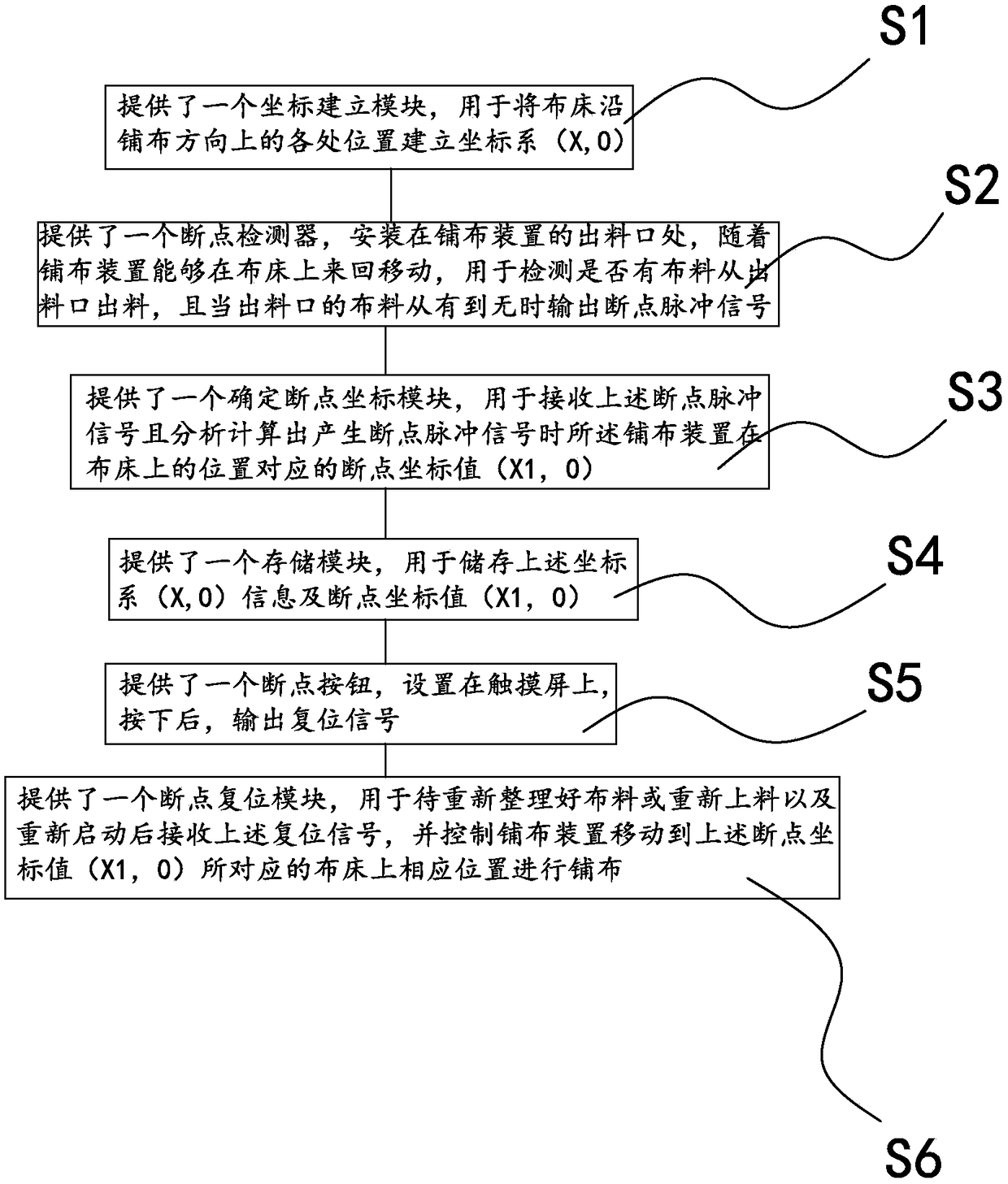

[0047] like figure 2 As shown, the automatic return control method includes the following steps:

[0048] S1. A coordinate establishment module is provided, which is used to establish a coordinate system (X, 0) for various positions of the cloth bed 2 along the cloth spreading direction;

[0049] S2, a breakpoint detector 7 is provided, installed at the outlet of the cloth spreading device 6, along with the cloth spreading device 6 can move back and forth on the cloth bed 2, for detecting whether there is cloth 8 coming out of the...

Embodiment 3

[0060] The difference between this embodiment and Embodiment 2 is that the specific method for determining the breakpoint coordinate module is: an encoder is installed on the motor shaft of the spreading device 6, and the stroke of the moving of the spreading device 6 after the encoder rotates one circle is S1, the rotation angle of the encoder is Q, since the spreading device 6 touches the reset switch 5 after a back and forth, the timing of the controller will also be cleared, so there are only two situations in the operation, one is the breakpoint pulse signal appears In the process that the spreading device 6 is gradually moving away from the initial position, the distance between the breakpoint and the initial position is S=S1*Q / 360; the other is that the breakpoint pulse signal appears when the spreading device 6 is gradually approaching the initial position. , the distance from the breakpoint to the initial position at this time is S=2*D-S1*Q / 360; where D is the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com