A kind of laser sintering equipment

A laser sintering and equipment technology, applied in the field of additive manufacturing, can solve the problems of air holes, poor sealing effect, and difficulty in scraping of parts, and achieve the effect of improving efficiency, improving the quality of powder laying, and feeding powder uniformly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

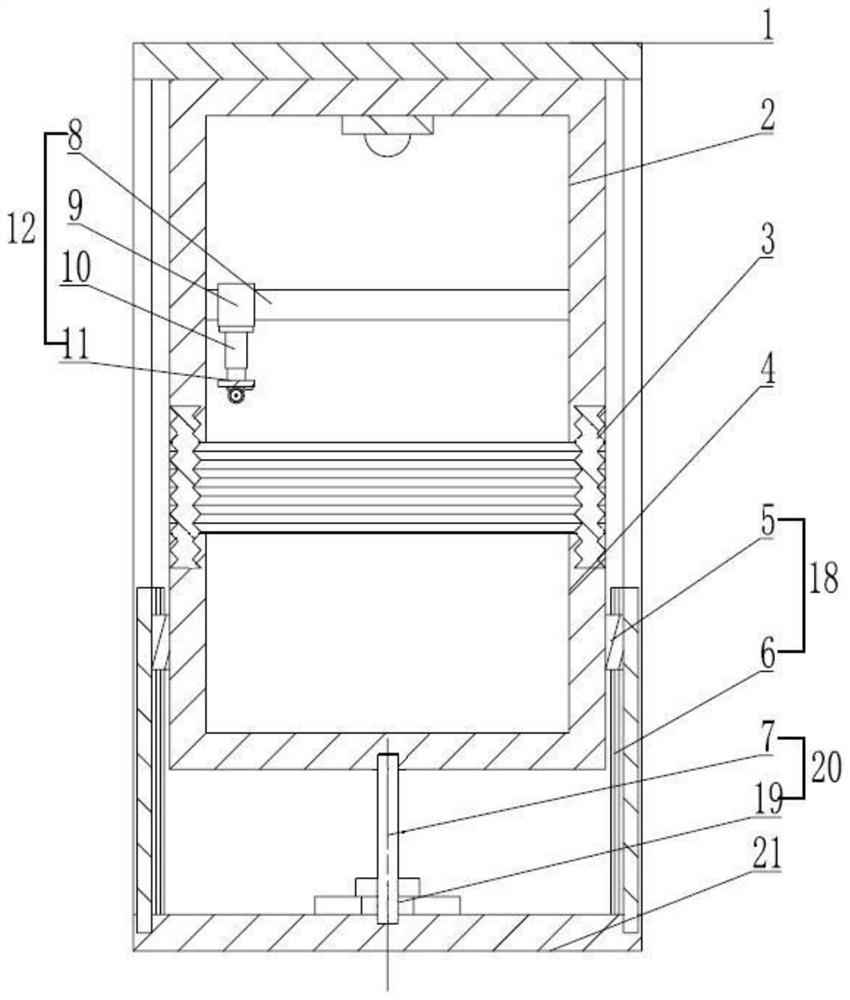

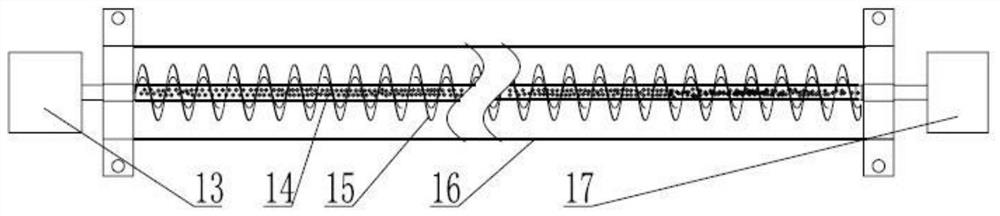

[0033] Embodiment 1: refer to figure 1 with figure 2 , a laser sintering printer, including a frame 1, an upper cylinder body 2, a lower cylinder body 4, a powder spreading mechanism 12, an orientation guide rail 18, a screw nut pair 20 and a telescopic structure 3.

[0034] In this embodiment, the upper and lower cylinder bodies are fixedly connected with the telescopic structure 3 through fitting, so that the entire molding cylinder is a closed space; the screw nut pair 20 is located at the center of the outer bottom of the lower cylinder body 4, It is consistent with the Z-axis direction of the cylinder body; the lower cylinder body 4 is provided with a directional guide rail 18 that supports the cylinder body and cooperates with the lead screw and nut pair 20 to make the lower cylinder body 4 move up and down.

[0035]The directional guide rail 18 includes a slider 5 and a static guide rail 6, and the static guide rail 6 is fixed on the lower mounting plate 21 of the fra...

Embodiment 3

[0049] The difference between this embodiment and Example 1 is that the diameter of the powder outlet hole on the powder outlet sieve is 70um. The purpose of this design is to adapt to the particle size of the powder. If the particle size of the powder is below 70um, the powder outlet sieve Powders with a diameter greater than 70um will be filtered, because in 3D printing, powders whose diameter does not meet the requirements will reduce the printing quality.

[0050] The working mode and other structures and connection modes of this embodiment are the same as those in Embodiment 1.

Embodiment 4

[0052] The difference between this embodiment and embodiment 1 is only that the diameter of the powder outlet hole on the powder outlet sieve is 120um, and its purpose is consistent with that described in embodiment 3, that is, if the particle size of the powder is below 120um, the powder outlet sieve will Filter powders with a diameter greater than 120um, because in 3D printing, powders whose diameter does not meet the requirements will reduce the printing quality.

[0053] The working mode and other structures and connection modes of this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com