Automatic cloth laying machine and automatic cloth finishing device thereof

A cloth spreading machine and cloth unscrambling technology, which is applied in the direction of thin material handling, transportation and packaging, and spreading thin soft materials, etc., can solve the problems of shrinking area for effective use of cloth, affecting quality, and non-straightness, etc., so as to improve paving The effect of improving cloth quality and improving spreading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

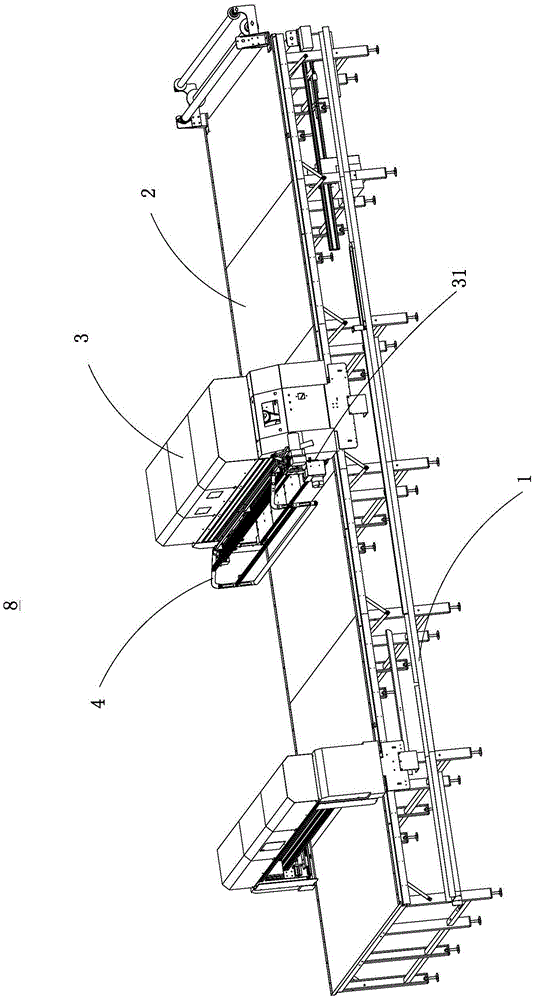

[0021] Please also refer to Figure 1 ~ Figure 3 The automatic spreading machine 8 of the present invention comprises a support 1, a spreading table 2, a traveling mechanism 3 and an automatic cloth arrangement device 4, the traveling mechanism 3 moves back and forth along the length direction of the spreading machine 8 to spread the cloth, and the automatic arrangement The cloth device 4 is installed and fixed on the knife rest 31 of the traveling mechanism 3 .

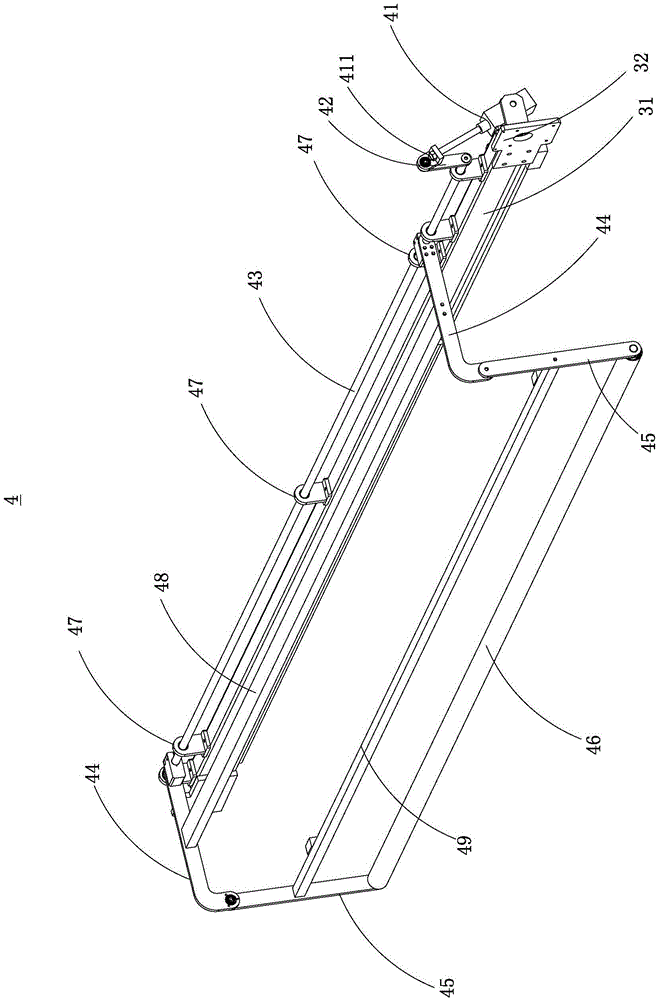

[0022] The automatic cloth arranging device 4 includes a driving member 41, a driving connecting arm 42, a rotating shaft 43, a first swing arm 44, a second swing arm 45 and a cloth arranging member 46, and one end of the driving connecting arm 42 is fixedly sleeved on the One end of the rotating shaft 43, the rotating shaft 43 is supported on the tool rest 31 by a plurality of supporting seats 47 arranged on the tool rest 31, and the rotating shaft 43 is connected to the supporting seats 47, and the One end of the ...

Embodiment 2

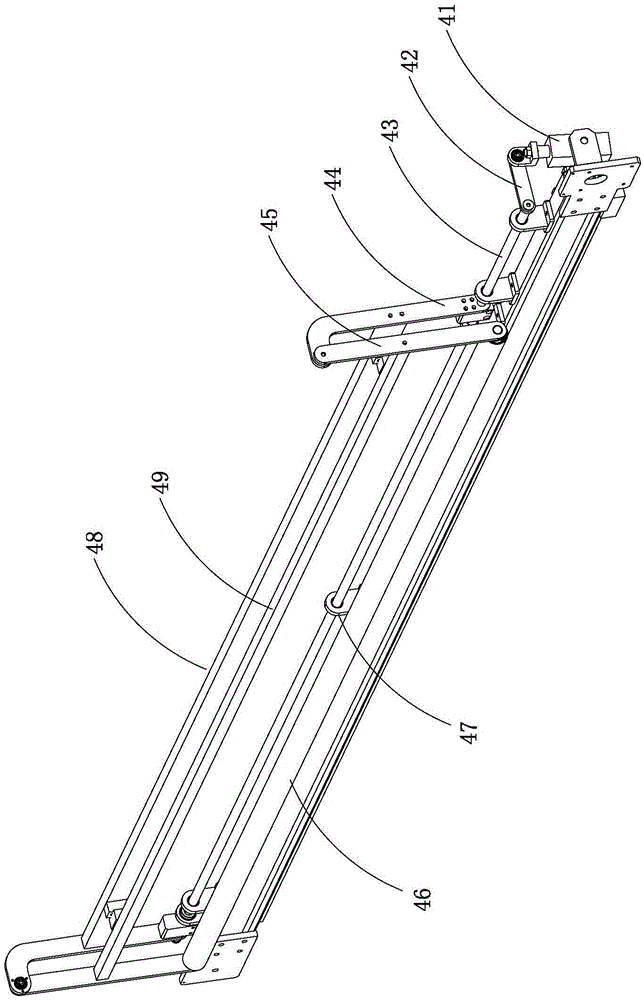

[0026] see Figure 4 The difference between this embodiment and Embodiment 1 is that the first swing arm 44' is arranged in the middle of the rotating shaft 43', the cloth arranging member 6' is a two-stage drum structure, and the two drum structures are used to arrange the cloth. The member is movably connected to the end of the second swing arm 45' connected to the cloth-arranging member 6'. During the cloth-arranging process, the cloth-arranging roller rolls; in addition, in order to provide a larger and more balanced driving force, the The driving member 41' adopts two air cylinders, and the two air cylinders are distributed at both ends of the rotating shaft 43'. Correspondingly, there are also two driving connecting arms 42'. In this embodiment, since the single swing arm structure is adopted, the support rod structure in the double swing arm structure is omitted, but there are higher requirements on the rigidity of the first and second swing arms.

[0027] The automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com