Automatic feeding roller way accurate in positioning

A technology of automatic feeding and precise positioning, applied to conveyor objects, transportation and packaging, etc., can solve the problems of high cost, complex structure and process, and high requirements for equipment installation accuracy, and achieve low production cost, high degree of automation and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

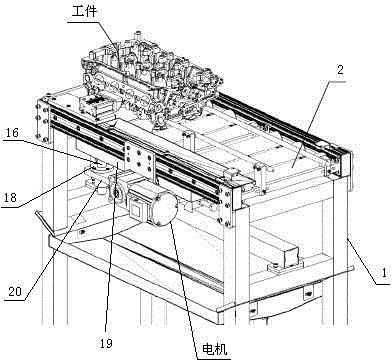

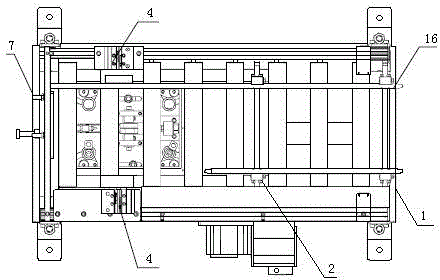

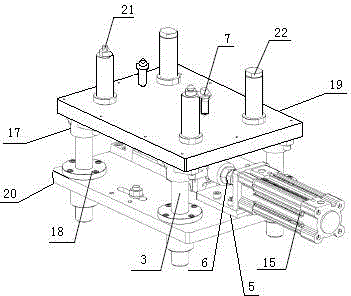

[0013] The present invention is further analyzed below in conjunction with accompanying drawing: a kind of precise positioning automatic feeding roller table is guided by frame 1, cylinder 2, substrate guide optical axis 3, pusher cylinder 4, cylinder mounting seat 5, floating joint 6, close to Switch 7, slider 8, linear guide rail 9, hydraulic buffer 10, rotating shaft 11, fixed seat 12, cylindrical roller bearing 13, wedge 14, lifting cylinder 15, roller guide optical axis 16, substrate guide optical axis fixed seat 17. Linear bearing 18, upper base plate 19, lower base plate 20, positioning pin 21 and positioning support 22; roller 2 is arranged on the upper part of frame 1; pusher cylinder 4 is arranged on both sides of roller 2; roller 2 is arranged on the roller table Guided on the optical axis 16; the linear guide rail 9 is arranged on the lower base plate 20; the lower base plate 20 is fixedly installed with the cylinder mounting seat 5; the lifting cylinder 15 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com