Method for preparing light high-strength composite trench cover

A preparation method and technology for ditch cover, which can be used in construction, road, special pavement and other directions, and can solve the problems of easy breakage and high construction labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

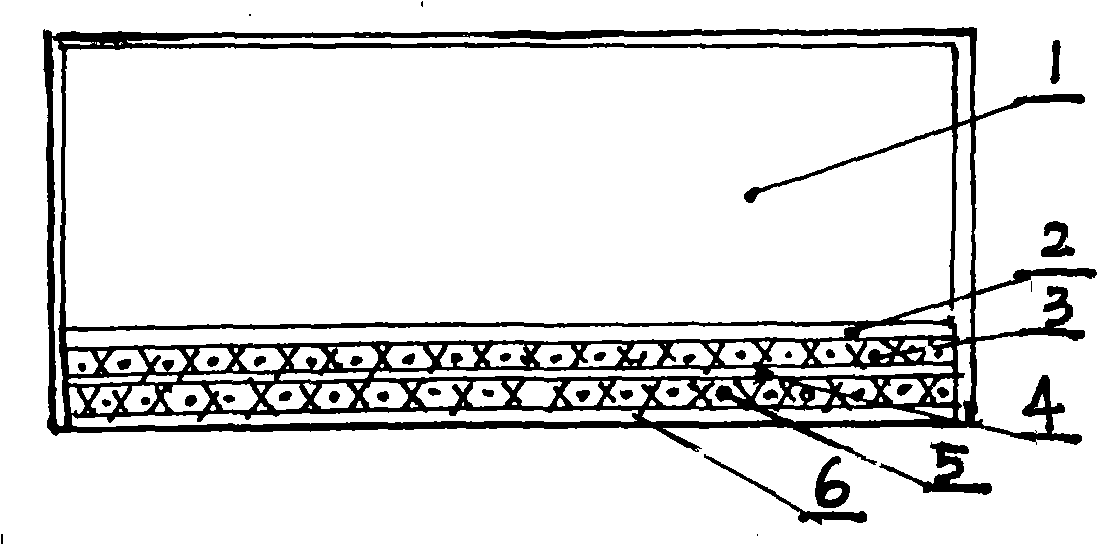

[0011] The preparation method of the light-weight and high-strength composite trench cover plate of the present invention takes low-alkali and high-strength sulfoaluminate cement as the main raw material, adds light-weight filling materials and reinforcing agents in a scientific reinforcement method, and uses the polymer polymerization technology, It is a multi-layer lightweight and high-strength composite trench cover formed in a mold at one time. It is widely used in power plant substations, railways, trenches, shafts and other parts of indoor and outdoor non-motor vehicles. It is not only energy-saving, environmentally friendly, pollution-free, but also resistant to acid and alkali , fire and other performance. The composite trench cover plate is composed of a variety of lightweight composite materials and multiple layers. The surface layer 2 and the bottom surface layer 6 of the cover plate 1 are both cement mortar layers, and steel mesh is provided in the cement mortar lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com