Integrated production method of cable

A production method and cable technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as low production efficiency, affecting product quality, and missing packages, and achieve fast production speed, convenient operation, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be described below in conjunction with the examples.

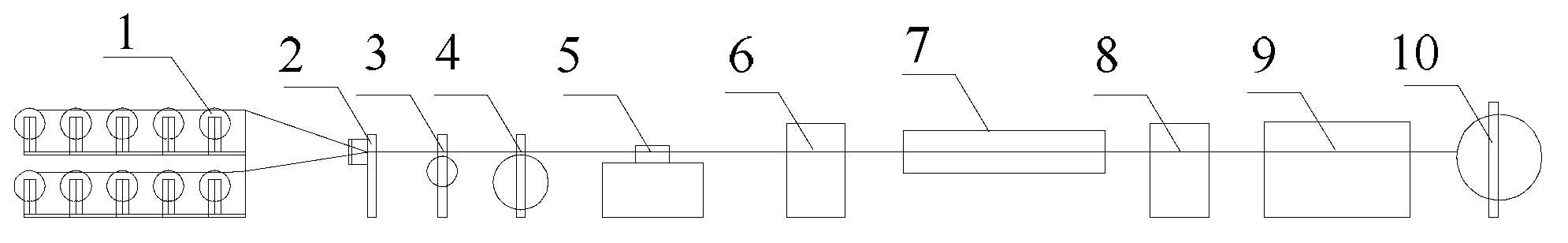

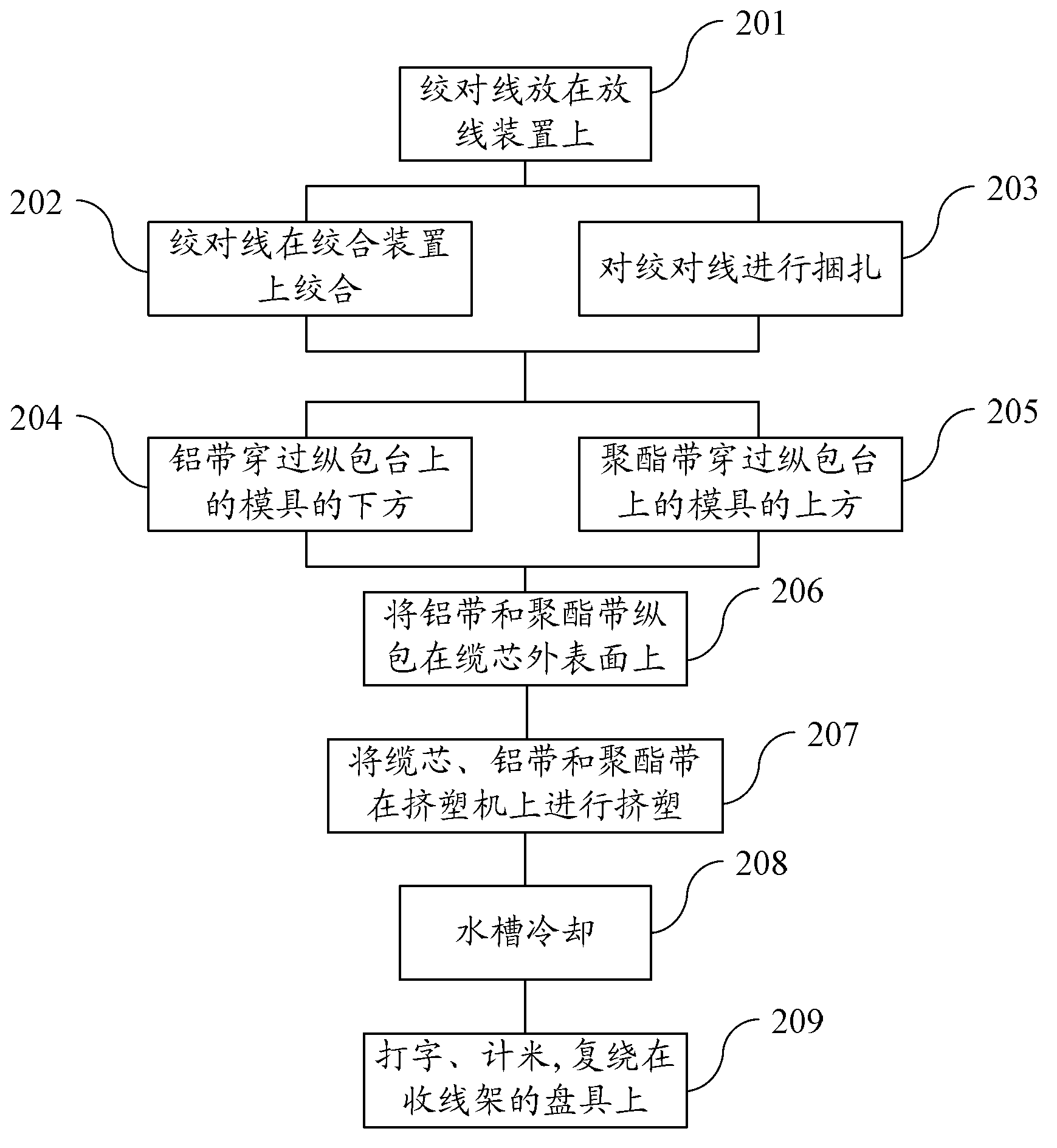

[0022] like figure 1 and 2 Shown are respectively a schematic diagram and a flow chart of the cable integrated production method of the present invention. This example is the integrated production of HYA 20×2×0.4 cables.

[0023] The steps of the HYA 20×2×0.4 cable integrated production method of this embodiment are as follows:

[0024] Step 201: arrange 20 pairs of twisted-pair wires in a certain order and place them on the pay-off device 1 .

[0025] Step 202: Arrange the twisted pairs released from the pay-off device 1 in a counterclockwise order, and after splitting, tying, and left-right twisting (SZ twisting) on the twisting device 2, a polyester-free tape is obtained cable core.

[0026] Step 203: While performing SZ twisting, the twisting device 2 bundles the twisted pair wires to fix the twisted pair wire structure.

[0027] Step 204: Place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com