Plastic-wood composite board and preparation method thereof

A composite board and plastic wood technology, applied in the field of polymer material processing and molding, can solve the problems of long molding time, low extrusion molding strength, and high equipment investment, and achieve the effects of increasing annual output, increasing strength, and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

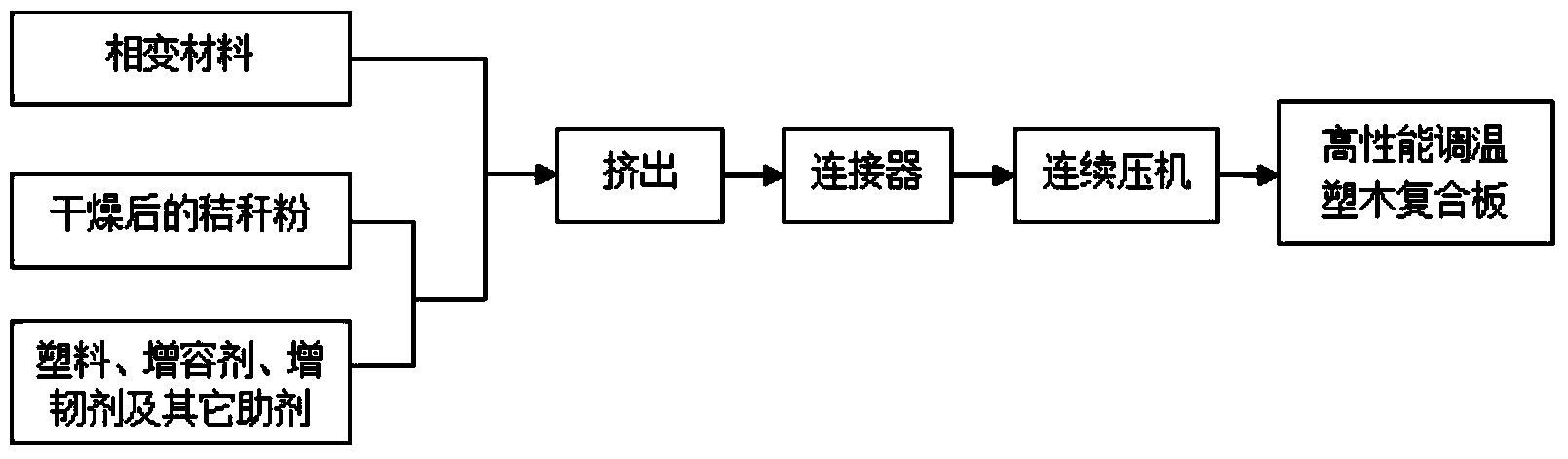

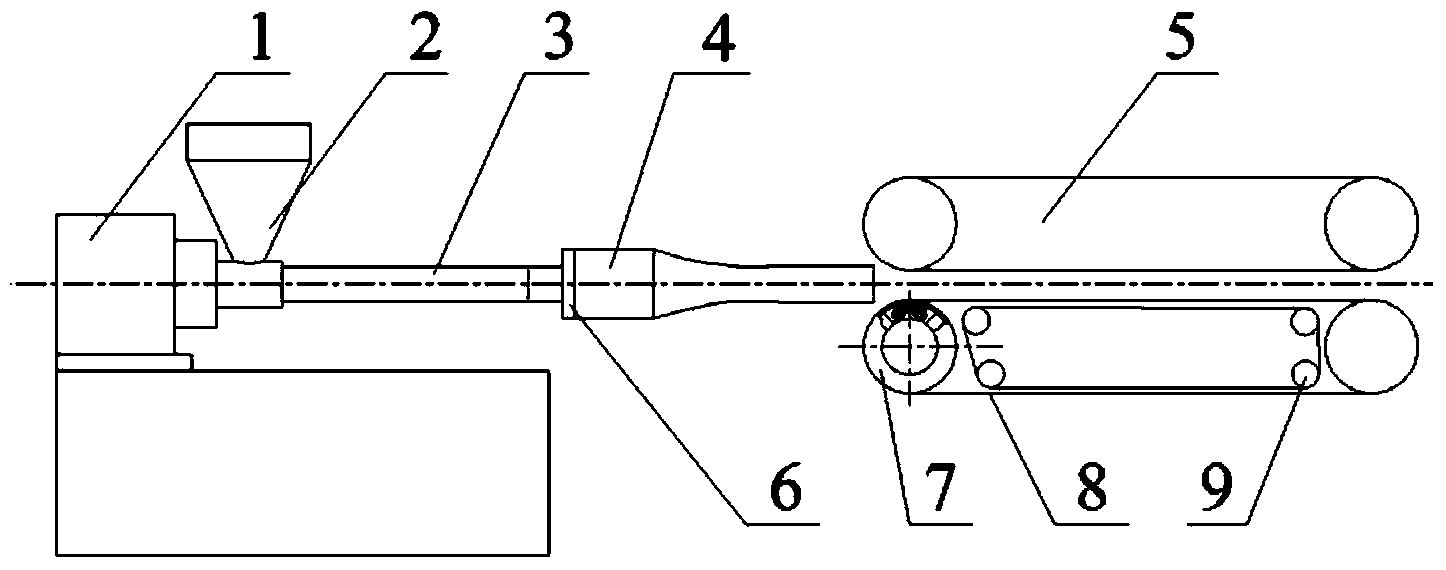

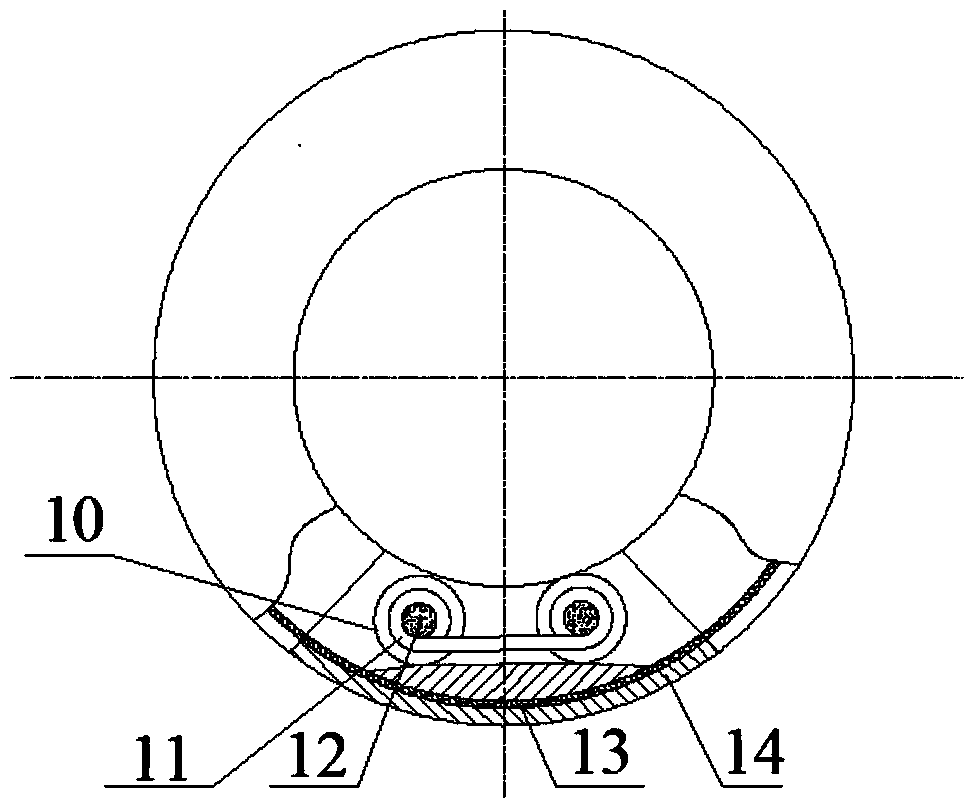

Method used

Image

Examples

Embodiment 1

[0053] The plastic-wood composite board of the present invention is composed of the following mass percentages: wood fiber (straw powder): 20%; plastic matrix: 40%, which can be a mixture of HDPE and PP, with a large amount of HDPE; phase change material: 30 %; Compatibilizer (silane): 4%; Toughening agent (SBS): 5%; Diffusing agent: 0.5%; Lubricant: 0.5%.

Embodiment 2

[0055] The plastic-wood composite board of the present invention is composed of the following mass percentages: wood fiber (straw powder): 20%; plastic matrix: 40%, which can be a mixture of HDPE and PP; phase change material: 30%; compatibilization Agent (titanate): 4%; Toughening agent (SBS): 5%; Diffusing agent: 0.5%; Lubricant: 0.5%.

Embodiment 3

[0057] The plastic-wood composite board of the present invention is composed of the following mass percentages: wood fiber (straw powder): 20%; plastic matrix: 40%, which can be a mixture of HDPE and PP; phase change material: 30%; compatibilization Agent (PP-g-MAH): 2%; Toughening agent (SBS): 7%; Diffusing agent: 0.5%; Lubricant: 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com