Mixed pulping and papermaking process

A papermaking process and a mixed pulping technology, applied in the field of papermaking production, can solve the problems of increased load of the first motor, long discarding time of waste paper, damage of the first motor and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

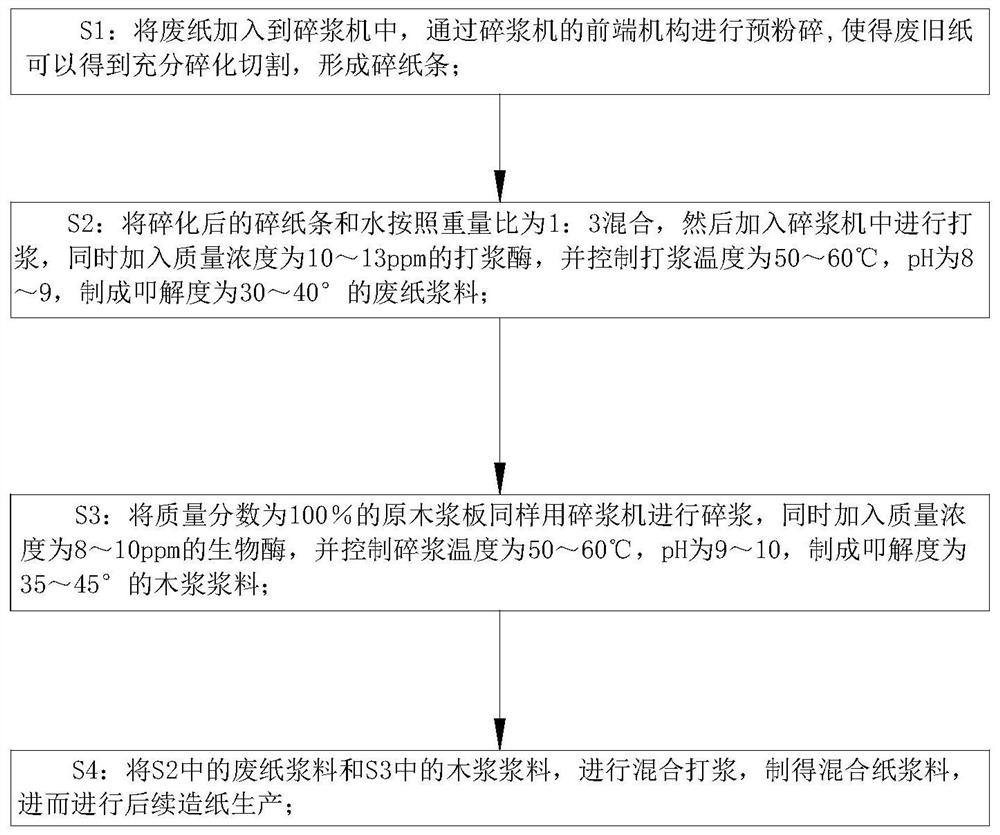

Method used

Image

Examples

Embodiment approach

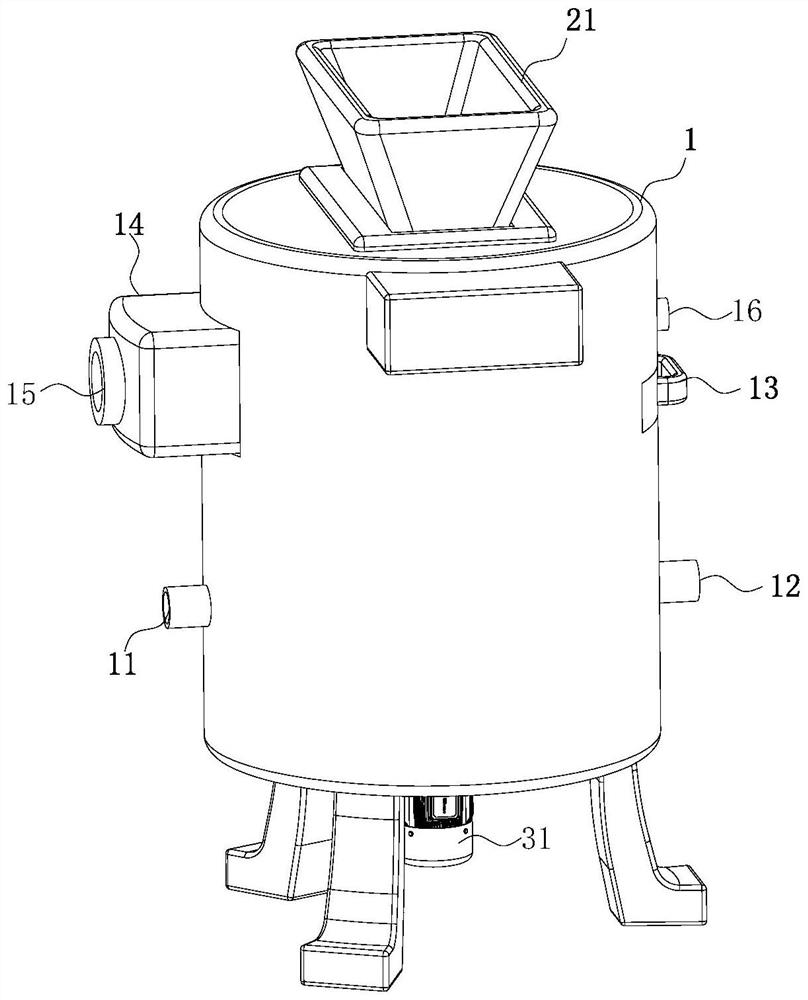

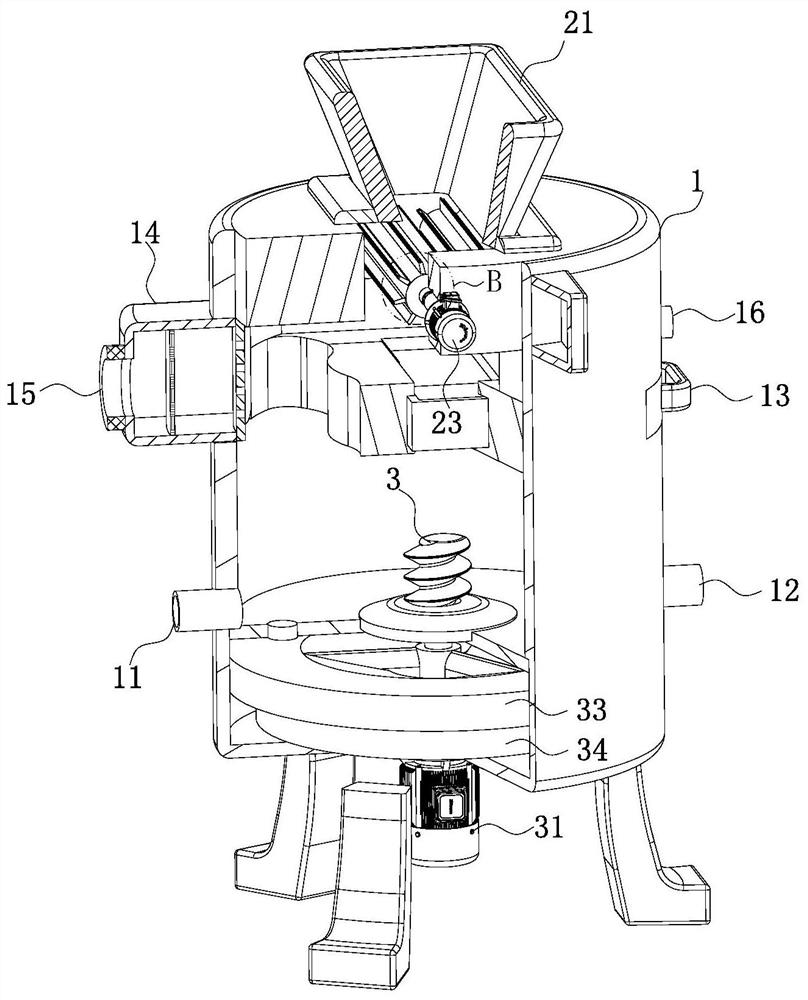

[0037] As an embodiment of the present invention, the upper wall of the crushing tank 1 is provided with a guide groove directly below the pre-shredding tank; the inside of the guide groove is slidingly connected with a waste collection box 13; The outer arc of the tank 1 is provided with a powder hole directly above the waste pipe 11; the inside of the powder hole is fixed with a coarse filter; the outer arc of the slurry tank 1 is fixed at the position of the powder hole. A powder box 14 is connected; the inner surface of the powder box 14 is fixedly connected with an upright fine filter; the left side of the powder box 14 is fixedly connected with an air outlet pipe 15; the slurry tank 1 The outer arc surface of the waste material collection box 13 is fixedly connected with an air inlet pipe 16; the upper wall of the slurry tank 1 is provided with a material guide hole near the position of the powder box 14; during work, through the air inlet pipe 16, the Air is blown into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com