A method of smelting weathering steel

A technology of weathering steel and molten steel, which is applied in the field of steelmaking, can solve the problems of high production cost of weathering steel and reduce production cost, and achieve the effect of reducing raw material cost, solving high production cost, reducing cost and process consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

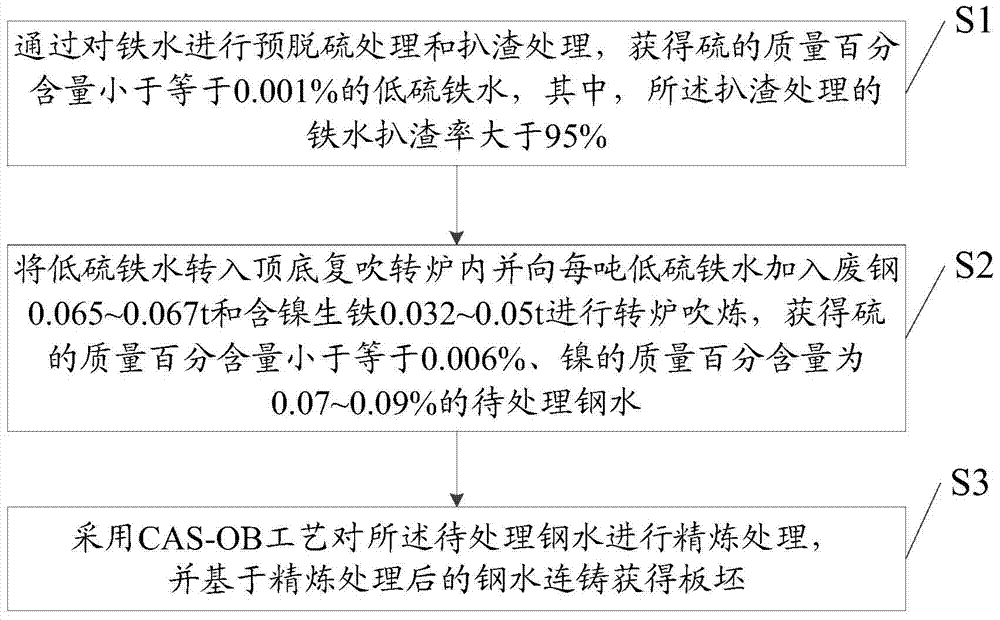

[0028] Please refer to figure 1 , the embodiment of the present application provides a method of smelting weathering steel, the method comprising:

[0029] Step S1: performing pre-desulfurization treatment and slag removal treatment on the molten iron to obtain low-sulfur molten iron with a mass percentage of sulfur less than or equal to 0.001%, wherein the slag removal rate of the molten iron in the slag removal treatment is greater than 95%;

[0030] Step S2: transfer the low-sulfur molten iron into the top-bottom combined blowing converter, and add 0.065-0.067t of scrap steel and 0.032-0.05t of nickel-containing pig iron to each ton of the low-sulfur molten iron for converter blowing to obtain the mass of sulfur The molten steel to be treated with a percentage content less than or equal to 0.006% and a mass percentage content of nickel of 0.07-0.09%;

[0031] Step S3: Refining the molten steel to be treated by using CAS-OB (Composition Adjustment by Sealed Argon Bubbling–O...

example 1

[0047] 1) The molten iron is pretreated by KR desulfurization to obtain molten iron with an S content of 0.0002%;

[0048] 2) Then transfer the above-mentioned desulfurized molten iron into a top-bottom combined blowing converter for blowing, add 20t of scrap steel and 15t of low-nickel pig iron for converter blowing. At the end of the converter blowing, the steel is tapped with a sliding plate to stop the slag. When tapping the steel, argon gas is blown at the bottom of two channels to stir, and the flow rate of each bottom blow is controlled at 300NL / min. 208Kg, add 1600kg of aluminum and iron when the tapping amount is 2 / 5;

[0049] 3) After tapping, increase the bottom blowing argon to 600NL / min (each channel), turn off the bottom blowing argon after stirring for 3-5 minutes, take a molten steel sample to analyze [S] content is 0.0042%, [Ni] content 0.089%;

[0050] 4) After the molten steel with [S] content of 0.0042% and [Ni] content of 0.089% is transferred to the CAS...

example 2

[0053] 1) The molten iron is pretreated by KR desulfurization to obtain molten iron with an S content of 0.00001%;

[0054] 2) Then, before transferring the above-mentioned desulfurized molten iron into the top-bottom combined blowing converter for blowing, add 25t of scrap steel and 10t of low-nickel pig iron. At the end of the converter smelting, the steel is tapped with a sliding plate to stop the slag. When tapping the steel, argon is blown from the bottom of two channels to stir, and the flow rate of each bottom blow is controlled at 300NL / min. When the steel output is 1 / 5, 980Kg of small-grained lime and 328Kg of fluorite are added. , Add 1500kg of aluminum and iron when the tapping amount is 2 / 5;

[0055] 3) After tapping, increase the bottom blowing argon to 800NL / min (each channel), turn off the bottom blowing argon after stirring for 3-5 minutes, take a molten steel sample to analyze [S] content is 0.0046%, [Ni] content 0.073%;

[0056] 4) After the molten steel wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com