Patents

Literature

33results about How to "Reduce process consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

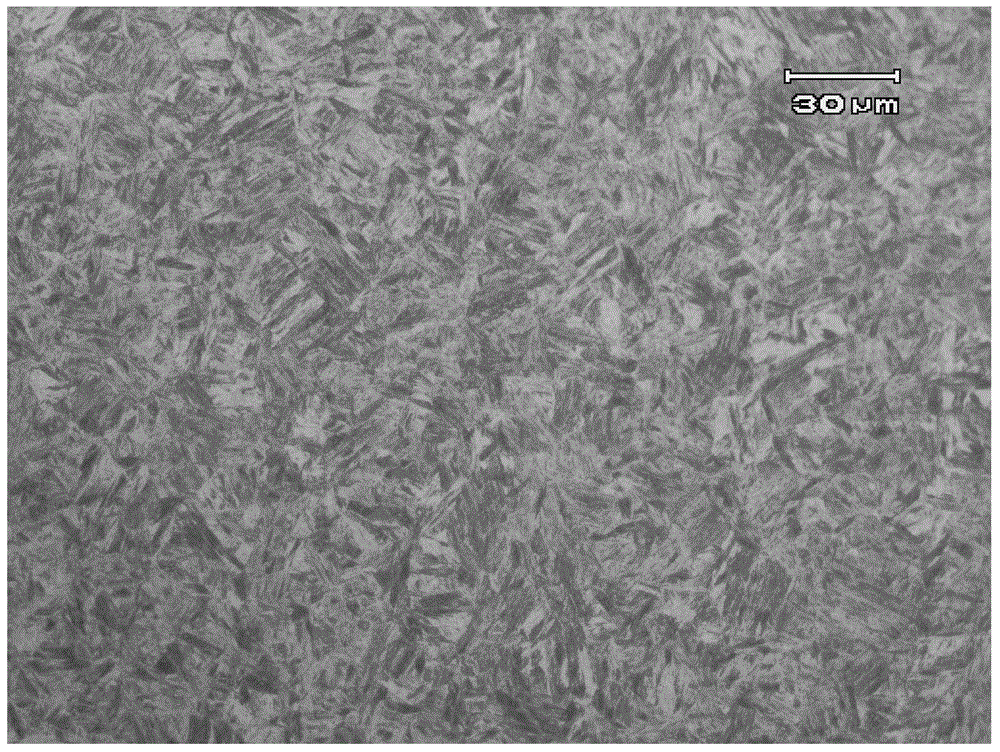

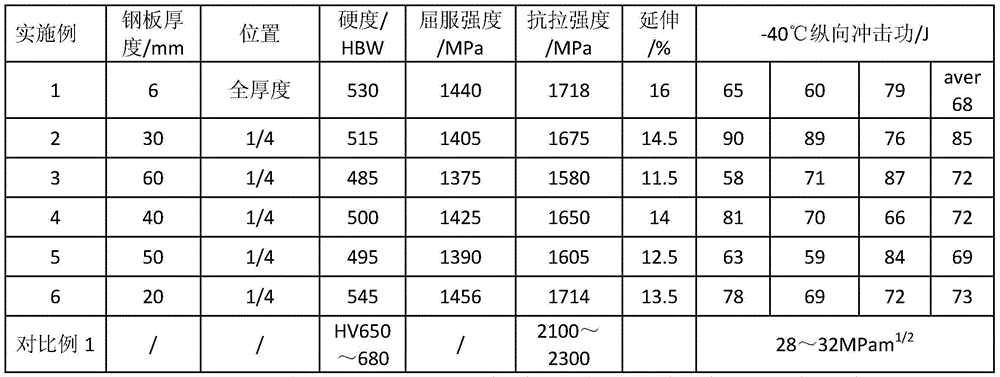

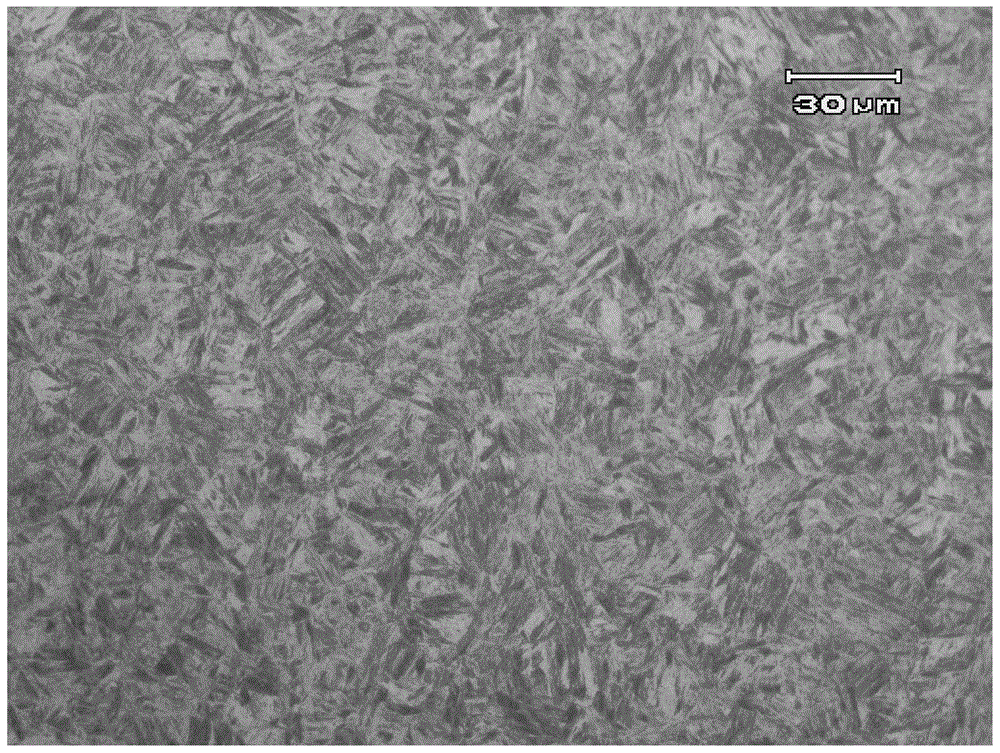

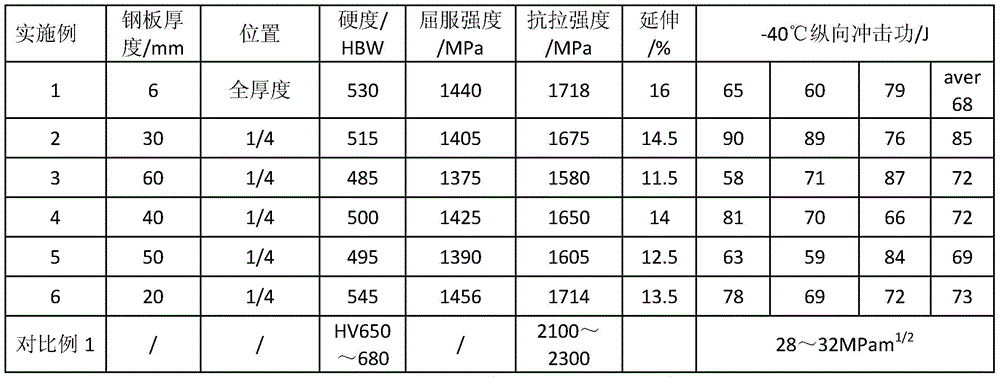

Armor steel plate with high anti-bullet property and manufacturing method of armor steel plate

The invention relates to an armor steel plate with a high anti-bullet property and a manufacturing method of the armor steel plate. The armor steel plate comprises chemical components in percentage by weight as follows: 0.20%-0.28% of carbon, smaller than or equal to 0.10% of silicon, 0.20%-0.50% of manganese, smaller than or equal to 0.012% of phosphorus, smaller than or equal to 0.003% of sulfur, 0.90%-1.30% of chromium, 0.20%-0.40% of molybdenum, 0.015%-0.035% of titanium, 0.020%-0.050% of aluminum, smaller than or equal to 0.00020% of hydrogen, smaller than or equal to 0.0040% of nitrogen, smaller than or equal to 0.65% of carbon equivalent and the balance of iron and inevitable impurities. The hardness of armor steel with the high anti-bullet property reaches 480-550 HBW, the shock absorption energy at the temperature of subzero 40 DEG C is larger than or equal to 20 J, and the armor steel plate has penetration resistance, can prevent armor steel from cracking, breaking or stripping and has the characteristics of low cost, stable quality, simplified process and easiness in large-scale industrial production.

Owner:SHANDONG IRON & STEEL CO LTD

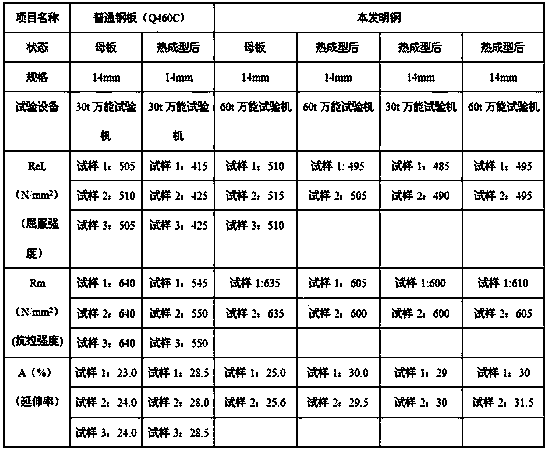

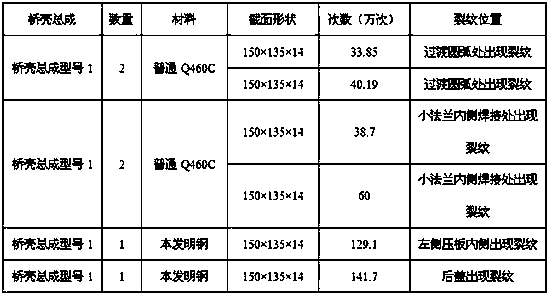

Steel plate for punching-welding axle housing and manufacturing method thereof

The invention relates to a 600MPa steel plate which is used for punching and welding an axle housing after being heated and is good in hot punching formability and a manufacturing method of the steel plate. Nb, V and other elements which guarantee the high temperature performance of steel are added, the content of C, Si and other elements which influence punching performance is lowered, Ti, Al and other nitrogen fixation elements are in cooperation, the steel plate is fundamentally guaranteed to have the good formability, meanwhile, high-temperature strength is improved, low-temperature toughness is excellent, welding performance is improved, fatigue strength is obviously improved, and the fatigue life of the component is prolonged by more than 50%. The steel plate can be widely applied to the production of medium plate rolling pieces in large structures of hot forming, a large air blower, a vibrating screen and the like under a high temperature condition, and the steel for the medium plate rolling pieces requires for high-temperature strength.

Owner:JIGANG GRP

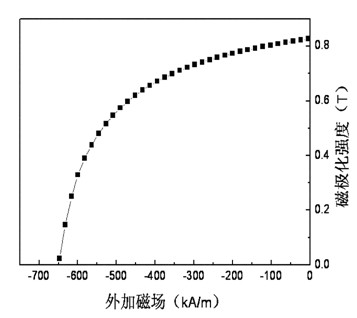

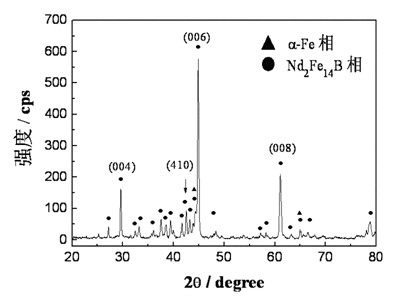

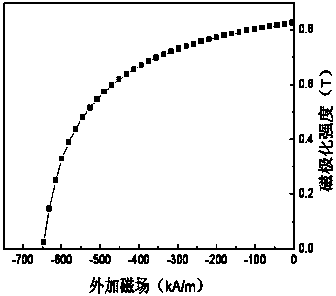

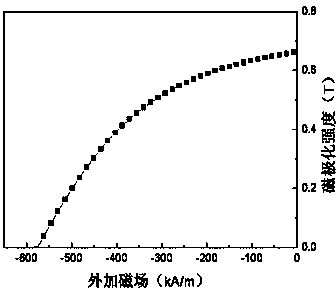

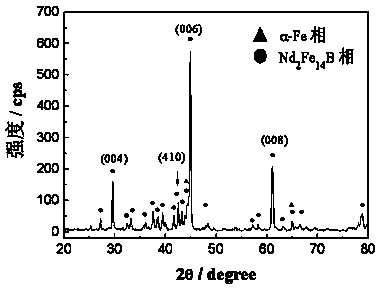

Method for preparing anisotropic nanocrystalline rare-earth permanent magnet block material

InactiveCN102543341AHigh densityImprove permanent magnet performanceInorganic material magnetismInductances/transformers/magnets manufactureRare earthElectric field

The invention discloses a method for preparing an anisotropic nanocrystalline rare-earth permanent magnet block material, which includes: firstly, preparing an alloy ingot by the vacuum smelting process; secondly, melting the alloy ingot and injecting an external direct-current electric field to the melt to realize direct-current inoculation process; thirdly, preparing an anisotropic nanocrystalline rare-earth permanent magnet material by the rapid copper mould solidification process under action of an external direct-current magnetic field; and finally processing the material in heat properly according to specific conditions. The anisotropic nanocrystalline rare-earth permanent magnet block material prepared by the method has the advantages of evident magnetic anisotropy, high density and fine comprehensive permanent magnetic performance. The method is simple in procedure, convenient in operation and low in processing consumption.

Owner:FUZHOU UNIV

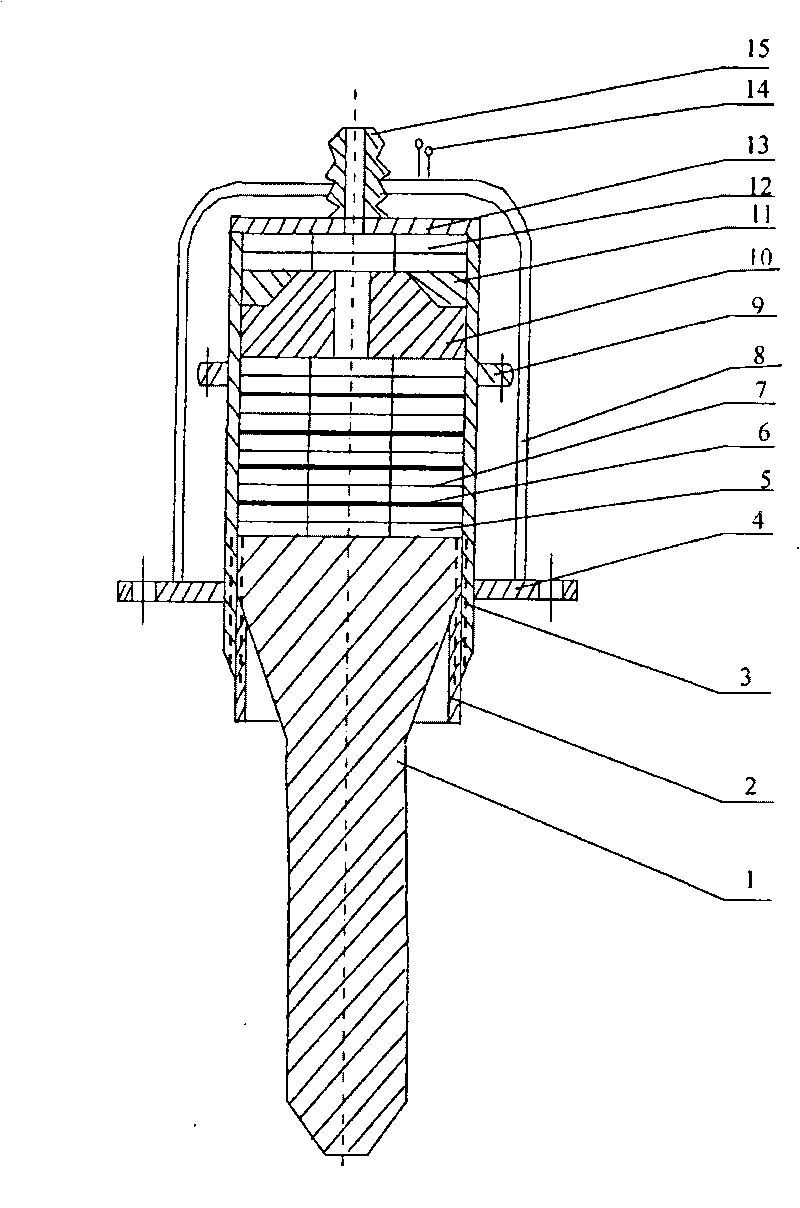

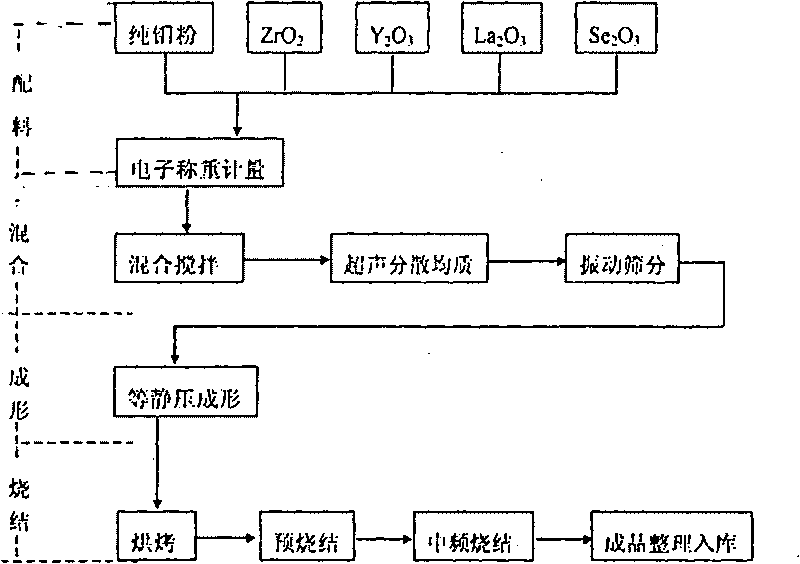

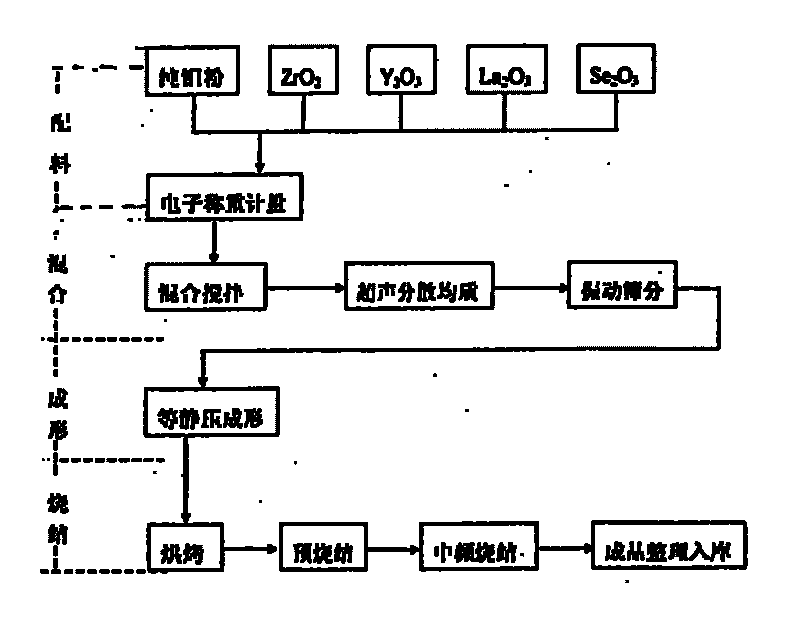

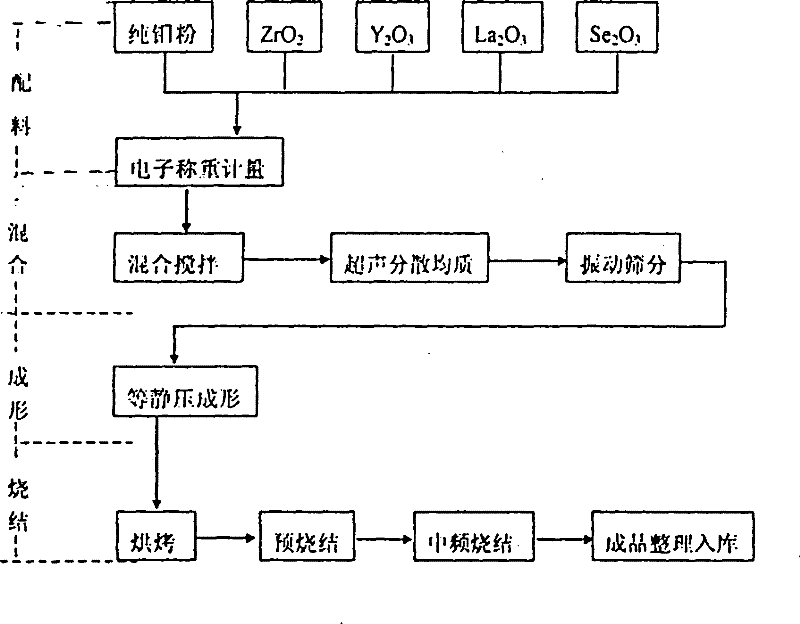

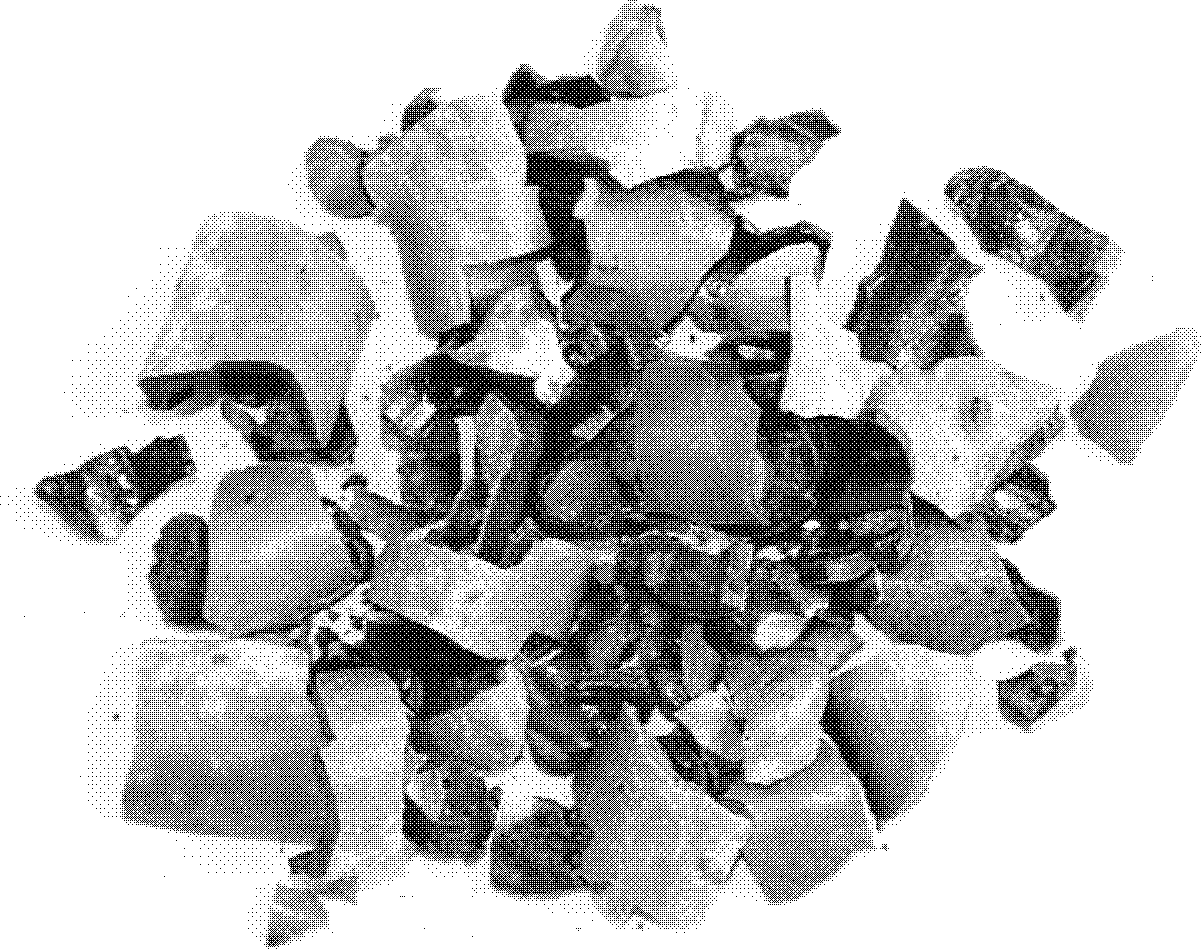

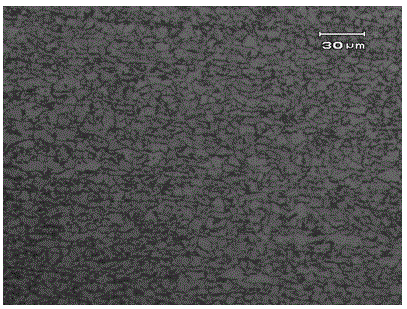

Molybdenum-base rare earth powder metallurgy forming plug and manufacturing method thereof

ActiveCN101722308ARaise the recrystallization temperatureHigh tensile strengthMandrelsMetal rolling arrangementsChemical industryAviation

The invention relates to a seamless steel tube, in particular to a molybdenum-base rare earth powder metallurgy forming plug used by a high nickel-chromium stainless steel seamless pipe and a manufacturing method thereof. The manufacturing method of the molybdenum-base rare earth powder metallurgy forming plug comprises the following steps of: simultaneously mixing four rare earth oxides of ZrO2, Y2O3, La2O3 and SC2O3 in pure molybdenum powder; mixing molybdenum-base material to prepare powder by using an ultrasound characteristic; packaging the powder into a vane mixing blender, dispersing mixed molybdenum-base rare earth powder by primary refining; dispersing homogenized molybdenum-base rare earth powder by ultrasound refining through an ultrasound transducer; screening by a 180-mesh equalizing screen in accordance with a configured Tyler standard in a 'vibrating screen classifier' to obtain screen under flow, namely blended qualified molybdenum-base rare earth powder; and manufacturing the molybdenum plug by an isostaticmoulding mold, demolding and cleaning, and finishing the manufacturing in a configured hydrogen atmosphere roaster, a hydrogen atmosphere pre-sintering furnace and a hydrogen atmosphere horizontal intermediate frequency furnace. The molybdenum-base rare earth powder metallurgy forming plug and the manufacturing method thereof can be widely applied to chemical industry, metallurgy, machinery, aviation, national defense and other industrial departments.

Owner:四平市北威钼业有限公司

Preparation method of low-carbon acid-resistant pipeline steel

ActiveCN103667875AAvoid elevationReduce one RH decarburization treatment operationManufacturing convertersSmelting processMaterials science

The invention discloses a preparation method of low-carbon acid-resistant pipeline steel. The preparation method comprises the steps of performing slag-skimming treatment on molten iron after pre-desulfurization to obtain the molten iron with the sulfur content of not more than 0.001%; smelting the molten iron with the sulfur content of not more than 0.001% by a dephosphorization converter to obtain semi-molten iron with C of not less than 3.3%, P of not more than 0.040% and T of not less than 1320 DEG C; smelting the semi-molten iron by a decarbonization furnace to obtain molten steel with the C content of 0.015%-0.025%; performing heating, desulfurization and component adjustment treatment on the molten steel by an LF (ladle furnace), and then controlling the carbon pick-up in the molten steel to be not more than 50ppm; performing deep degassing treatment on the molten steel with the carbon pick-up of not more than 50ppm by an RH refining process, and then performing continuous casting to obtain a plate blank. The preparation method of low-carbon acid-resistant pipeline steel, provided by the invention, has the advantages that the production consumption is reduced and the production cost is saved by optimizing a smelting process.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

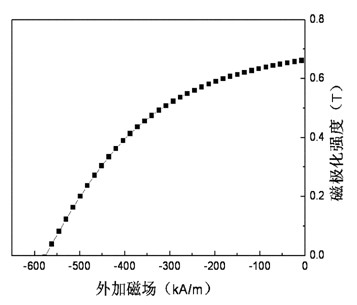

Method for preparing high-performance biphase rare-earth permanent magnet material using hydrogenation heat treatment process

InactiveCN1545107AFine nanostructureRegular nanostructureInductances/transformers/magnets manufactureMagnetic materialsAdhesion processHydrogen

The invention discloses a preparing method of high-performance double-phase, rare-earth, permanent magnetic material by hydrogenation thermal treatment. Firstly, it adopts vacuum welting method to prepare alloy; secondly, adopts fast quenching method or mechanical alloying method to prepare prealloy powder; then, places the prealloy powder in a hydrogen processing device, vacuumize the device and charges in hydrogen for hydrogen absorption and dehydrogenation reactions at 600-1000 deg.C; and finally, adopts adhesion process, cold press process, and thermal press or thermal stress process to prepare an alloyed magnet. It has better synthetic permanent magnetic performance, and its producing device and process are simple, and the consumption of process is low.

Owner:ZHEJIANG UNIV

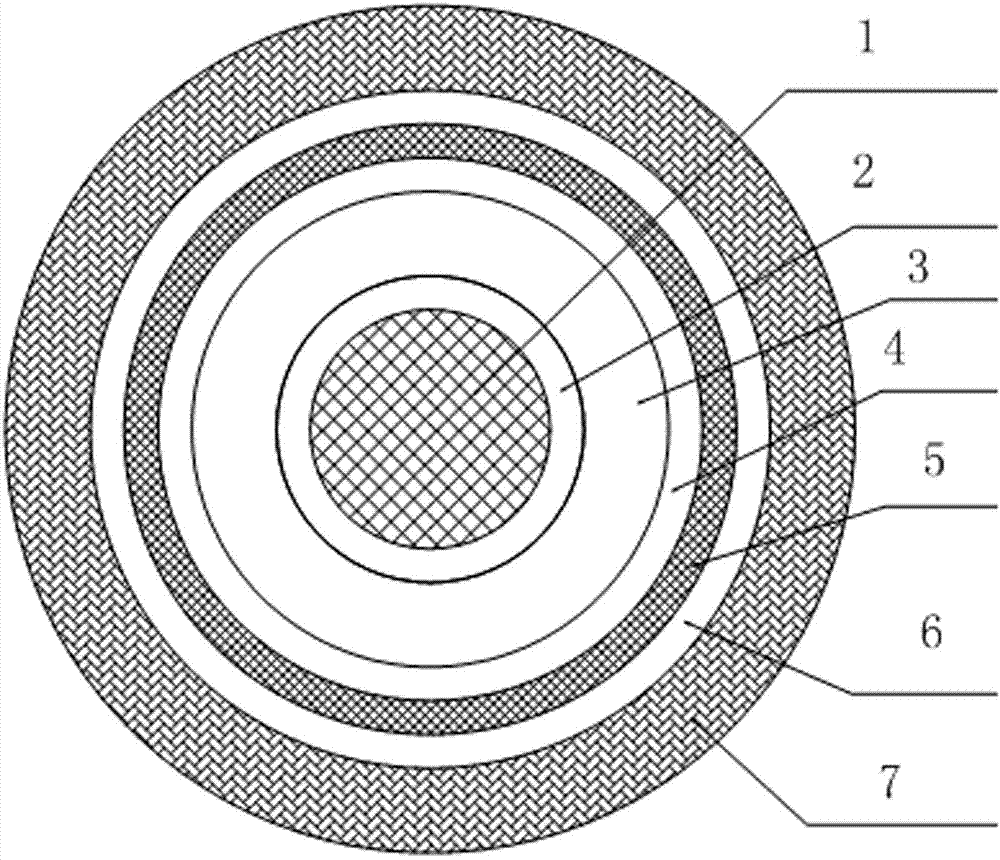

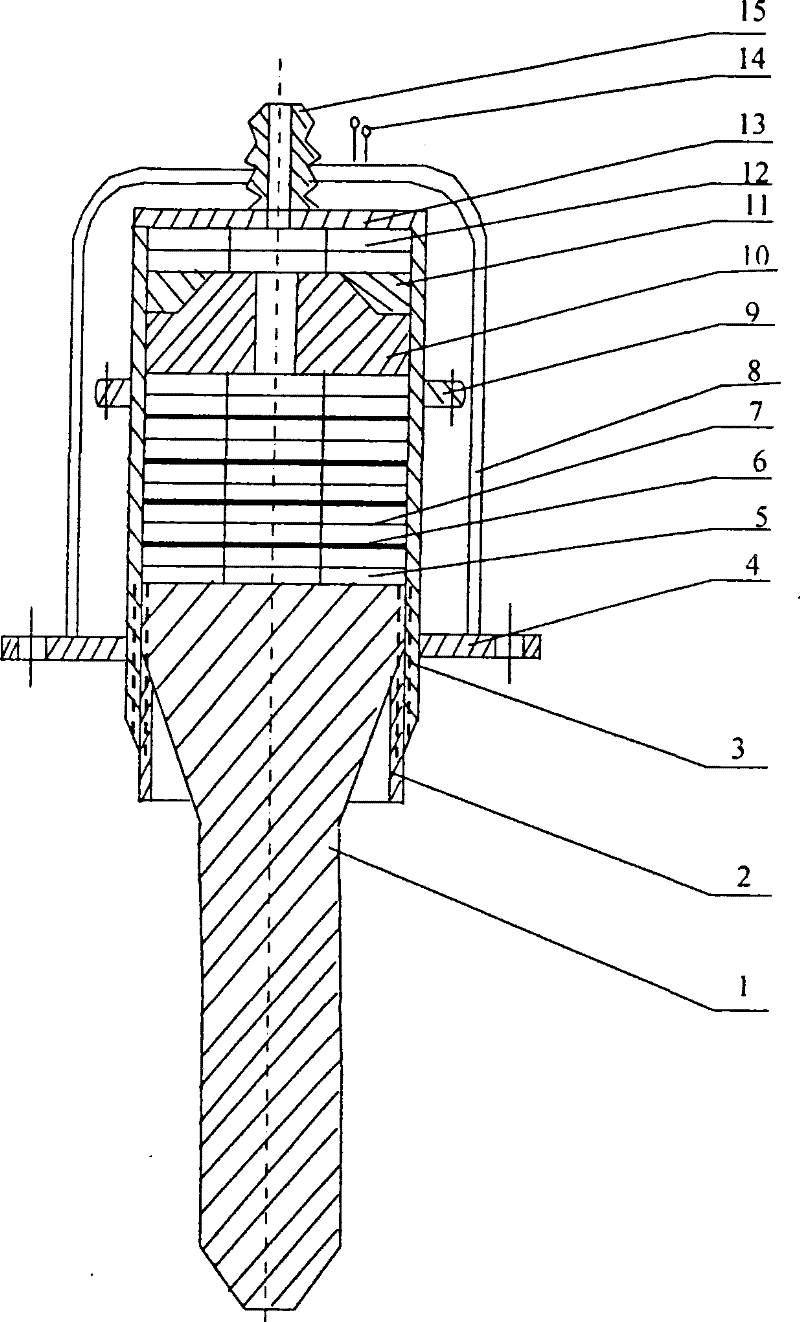

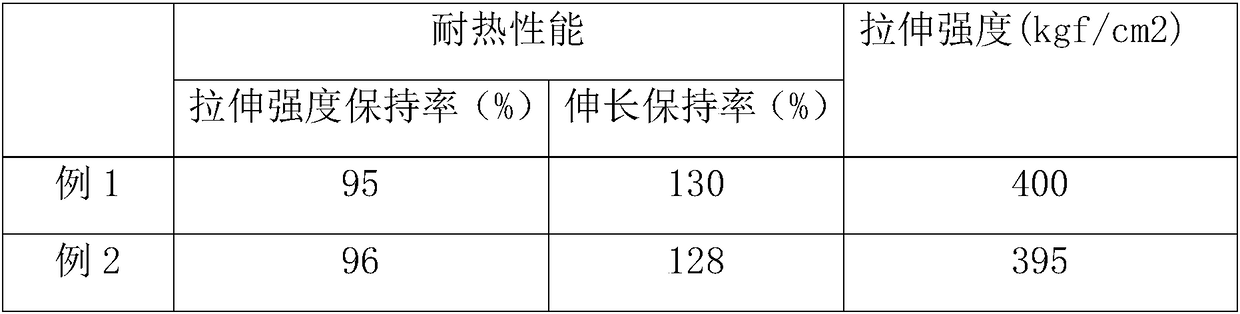

Non-crosslinking polyethylene insulating high-voltage cable

InactiveCN103093875ASimple manufacturing processImprove mechanical propertiesFlexible cablesFlexible conductorsPolyesterManufacturing cost reduction

The invention relates to a non-crosslinking polyethylene insulating high-voltage cable. The cable comprises a conductor, an inner semiconductive shielding layer wrapped outside the conductor, an insulating layer wrapped outside the inner semiconductive shielding layer, an outer semiconductive shielding layer wrapped outside the insulating layer, a metal woven shielding layer wrapped outside the outer semiconductive shielding layer, a polyester film wrapped outside the metal woven shielding layer, and an outer sheath layer wrapped outside the polyester film. The insulating layer is made of high-purity polyethylene and high-purity polyethylene grafted modified elastic bodies. The non-crosslinking polyethylene insulating high-voltage flexible cable utilizes the high-purity polyethylene grafted modified elastic bodies as the insulating layer. Accordingly, the non-crosslinking polyethylene insulating high-voltage cable not only has an excellent physical machinery and electric property and good flexibility, but also can simplify the manufacturing process of the cable, reduce process consumption and lower manufacturing cost.

Owner:王震

Preparation method of low-carbon acid-resistant pipeline steel

ActiveCN103667875BAvoid elevationReduce one RH decarburization treatment operationManufacturing convertersSmelting processLadle furnace

The invention discloses a preparation method of low-carbon acid-resistant pipeline steel. The preparation method comprises the steps of performing slag-skimming treatment on molten iron after pre-desulfurization to obtain the molten iron with the sulfur content of not more than 0.001%; smelting the molten iron with the sulfur content of not more than 0.001% by a dephosphorization converter to obtain semi-molten iron with C of not less than 3.3%, P of not more than 0.040% and T of not less than 1320 DEG C; smelting the semi-molten iron by a decarbonization furnace to obtain molten steel with the C content of 0.015%-0.025%; performing heating, desulfurization and component adjustment treatment on the molten steel by an LF (ladle furnace), and then controlling the carbon pick-up in the molten steel to be not more than 50ppm; performing deep degassing treatment on the molten steel with the carbon pick-up of not more than 50ppm by an RH refining process, and then performing continuous casting to obtain a plate blank. The preparation method of low-carbon acid-resistant pipeline steel, provided by the invention, has the advantages that the production consumption is reduced and the production cost is saved by optimizing a smelting process.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

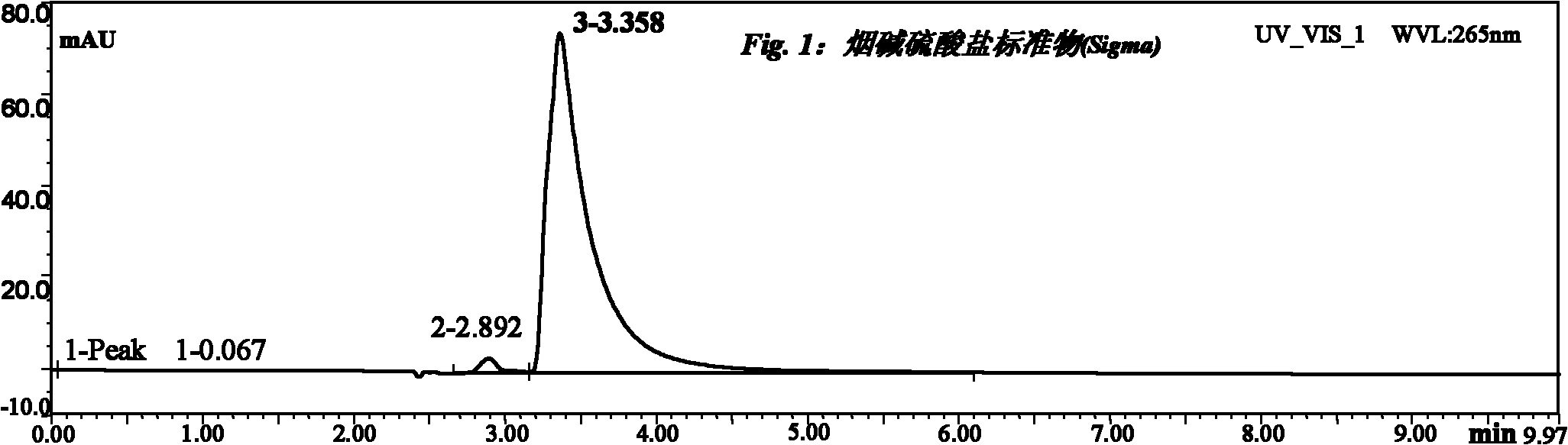

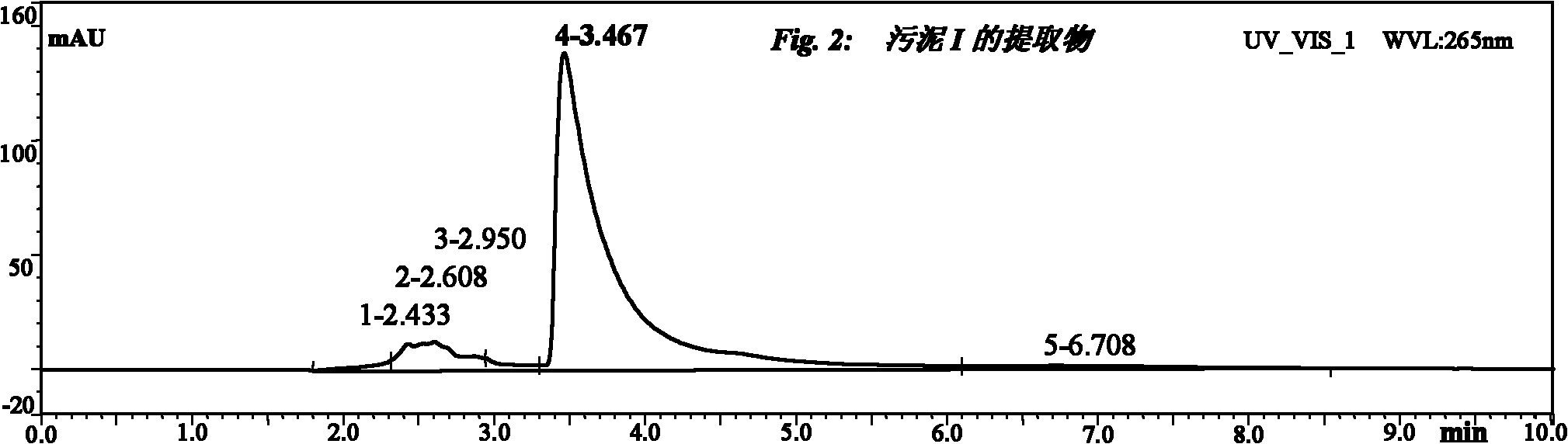

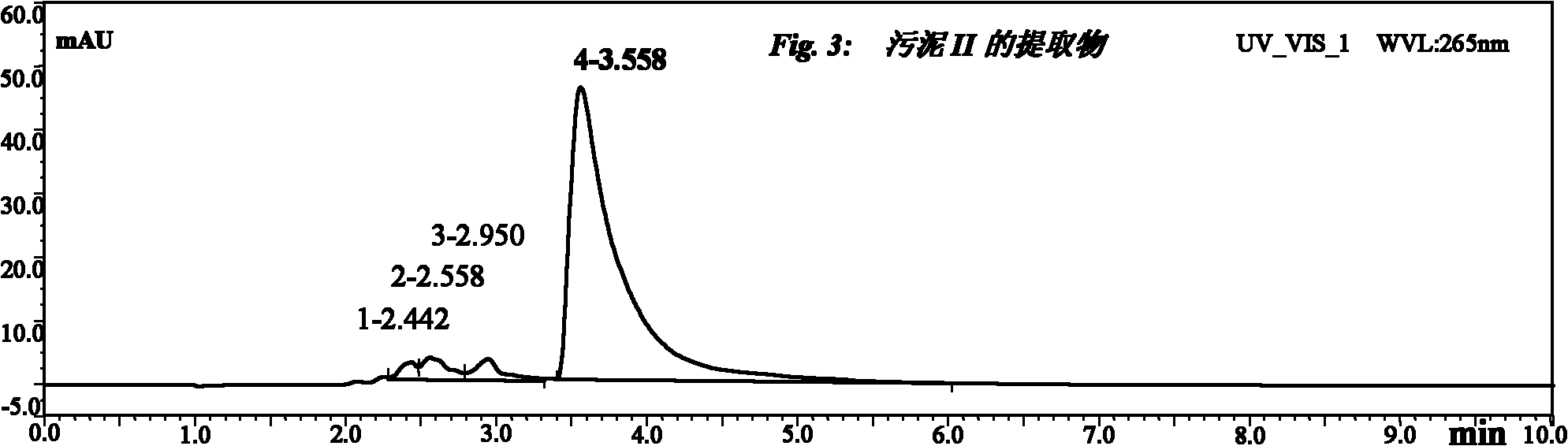

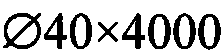

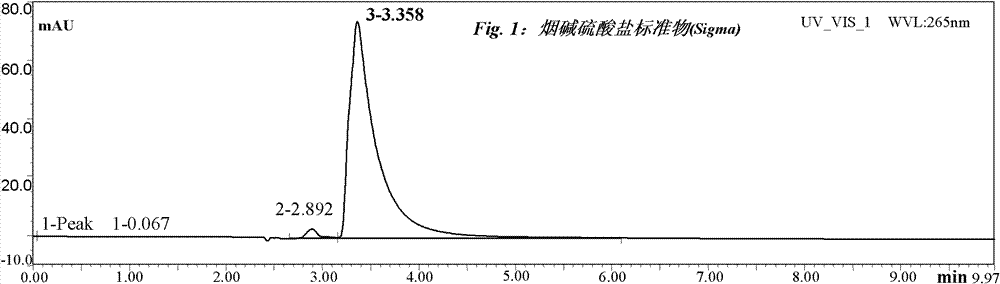

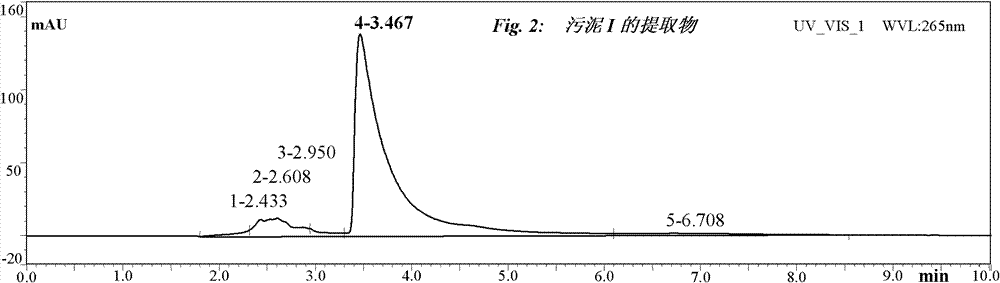

Method for extracting alkaloid by utilizing waste water and sludge of tobaccos

InactiveCN102093336AImprove use valueReduce lossOrganic chemistrySludge treatmentProcess lossNornicotine

The invention relates to a method for extracting alkaloid by utilizing waste water and sludge of tobaccos, which can ensure that waste water and sludge of the tobacco industry, particularly waste water and sludge of tobacco sheets can be reasonably utilized. According to basic group activation and calcium group replacement principles, a pretreating agent is added to sludge, and the alkaloid extraction is realized through a positive-reverse cycling extraction process of alternately carrying out solvent extraction and dilute acid elution. The method mainly comprises the following steps of: pretreating sludge; drying and pulverizing; extracting the solvent; and eluting with dilute sulphuric acid, wherein the alkaloid extraction ratio is 1-3 percent of the dry weight of the sludge; and measured by a high performance liquid chromatography (HPLC), the main ingredient (occupies 80 percent) of the extractive is nicotine sulfate, and the rest alkaloid ingredients are all nicotine homologues and derivatives, which can be alkaloids such as isonicotine, nornicotine, and the like. The solvent used in the method of the invention has no color, taste and toxicity, low flammability, relative safety, no influence on environment, extremely low process loss rate and recycling capability.

Owner:WUHAN DANYAXIANG TECH DEV

Method for preparing biphase rare-earth permanent magnet material using hydrogenation heat treatment process

InactiveCN1242427CFine nanostructureRegular nanostructureInductances/transformers/magnets manufactureMagnetic materialsAdhesion processHydrogen

Owner:ZHEJIANG UNIV

Application of a diamond-like film on the impeller

InactiveCN102261347ANo deformationMeet the normal working environmentPump componentsPumpsImpellerDiamond-like carbon

The invention relates to a fan, in particular to the application of a diamond-like film on an impeller. The diamond-like carbon film is used as a coating, which is plated on the flow channel of the impeller. The present invention adopts the omni-directional plasma injection method on the inner wall of the irregular shape such as the impeller, and coats the diamond-like film on the inner wall of the irregular shape, so that the inner surface of the irregular shape can be uniformly realized, and avoids the influence of some conventional surface heat treatment on the shape of the product, etc. Restriction, and the uniform coating of DLC film inside the impeller flow channel can effectively improve the service life and efficiency of the impeller while avoiding the problem of regular online cleaning.

Owner:SHENYANG BLOWER WORKS GROUP CORP +1

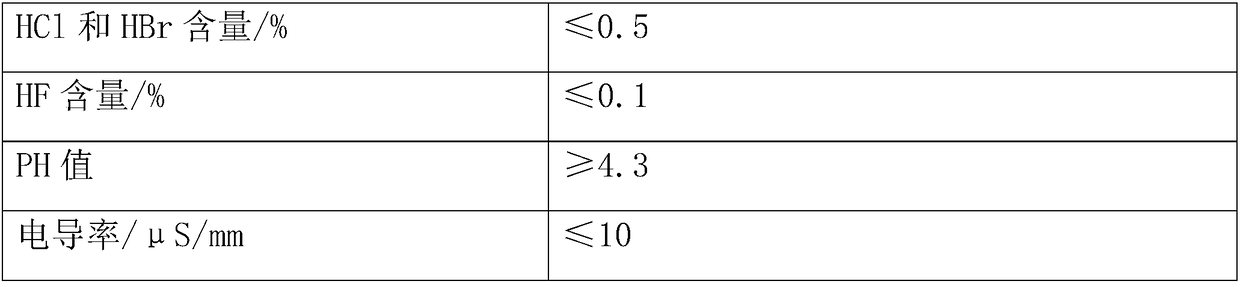

Method for preparing monofluo-rodicloroethane

ActiveCN101250086ALow costHigh purityPreparation by halogen halide additionHydrogen fluorideUltraviolet lights

The invention discloses a preparation method of monofluo-rodicloroethane, which comprises 1, processing addition reaction on acetylene and hydrogen chloride or hydrogen fluoride at the mol ratio of 1.5-2.5:1, in the presence of catalyst, to prepare vinyl chloride or fluoride, 2, processing addition reaction on the vinyl chloride or fluoride at the mol ratio of 1:3-5 or on the fluoride or vinyl chloride at the mol ratio of 1:3-5, in the presence of catalyst to prepare monofluo-chloroethane, 3, reacting the monofluo-chloroethane and chlorine at the mol ratio of 4-6:1, in the catalysis of catalyst or ultraviolet light to generate monofluo-rodicloroethane. The invention can avoid using vinylidene chloride and 1, 1, 1-methyl chloroform as basic materials, thereby reducing material cost of the whole process and improving the purity of monofluo-rodicloroethane (HCFC 141b).

Owner:CHANGSHU 3F FLUOROCHEM IND CO LTD

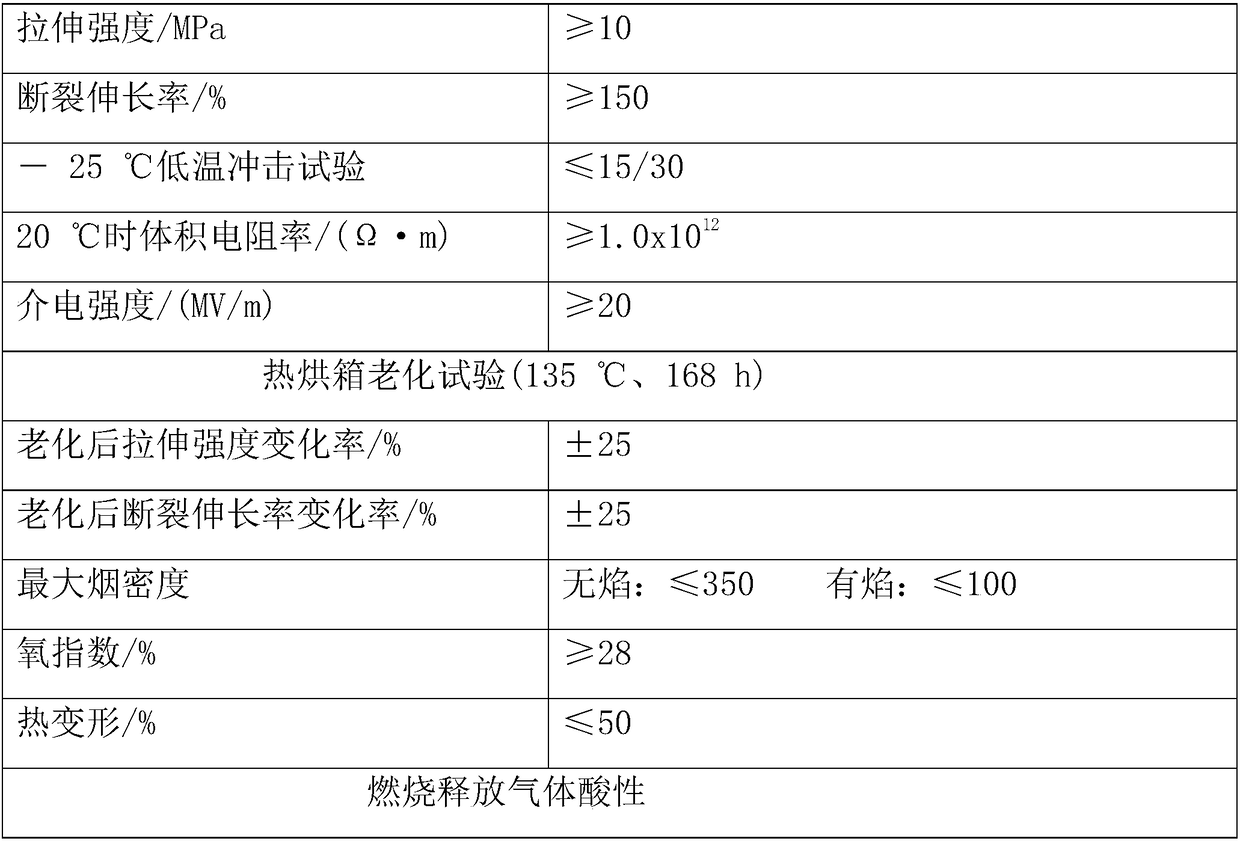

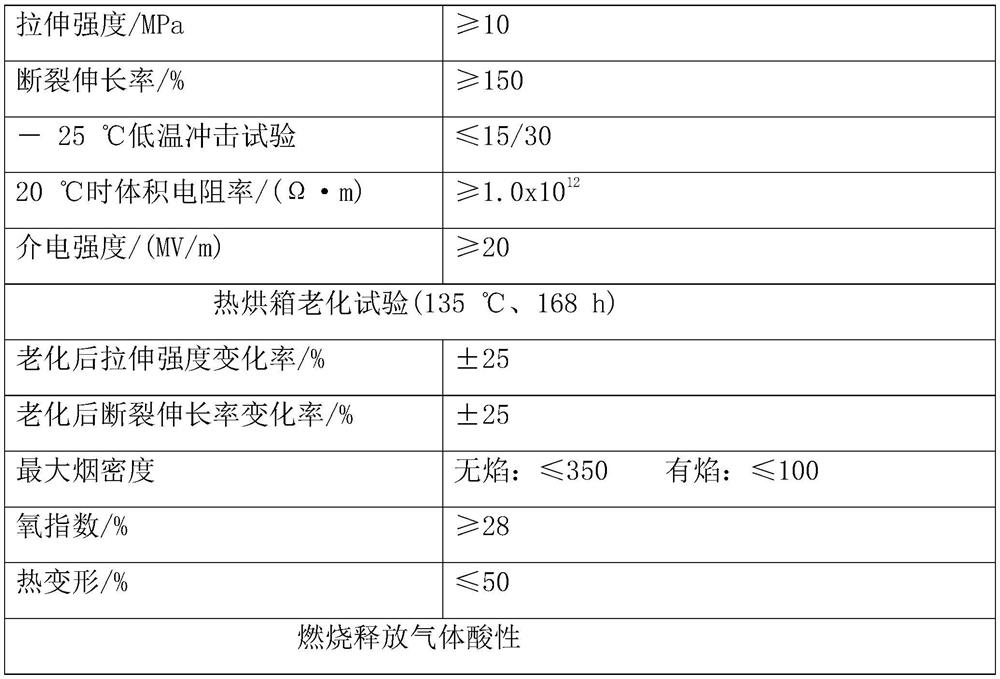

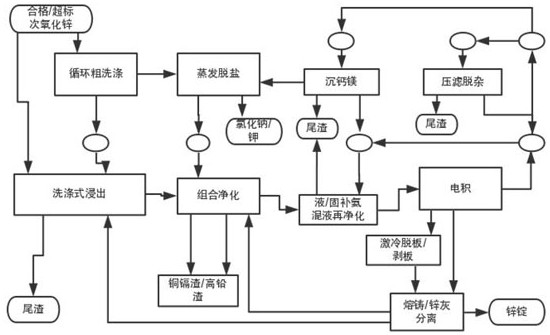

Heat-resistant halogen-free low-smoke flame-retardant non-crosslinked polyolefin composition for cable

ActiveCN108690257ANo pollution in the processImprove heat resistancePlastic/resin/waxes insulatorsManufacturing cost reductionLinear low-density polyethylene

The invention discloses a heat-resistant halogen-free low-smoke flame-retardant non-crosslinked polyolefin composition for a cable. The composition is characterized in that raw materials of the compound are prepared from the following ingredients of 40 to 60 parts of vinyl-vinyl acetate copolymer, 20 to 40 parts of LLDPE (linear low density polyethylene), 160 to 180 parts of inorganic hydroxides,6 to 20 parts of solvents, 1 to 5 parts of synergists and 0.5 to 1.5 parts of stabilizing agents. The heat resistance of the material can be improved; the work temperature can reach a value being 90 DEG C or above; the process consumption is reduced; the production cost is reduced; excellent mechanical performance and processing performance are realized; the recovery can be realized; no pollutionis caused on the environment.

Owner:海南六八鸿昌兴科技股份有限公司

A steel plate for high elastic armor and its manufacturing method

The invention relates to an armor steel plate with a high anti-bullet property and a manufacturing method of the armor steel plate. The armor steel plate comprises chemical components in percentage by weight as follows: 0.20%-0.28% of carbon, smaller than or equal to 0.10% of silicon, 0.20%-0.50% of manganese, smaller than or equal to 0.012% of phosphorus, smaller than or equal to 0.003% of sulfur, 0.90%-1.30% of chromium, 0.20%-0.40% of molybdenum, 0.015%-0.035% of titanium, 0.020%-0.050% of aluminum, smaller than or equal to 0.00020% of hydrogen, smaller than or equal to 0.0040% of nitrogen, smaller than or equal to 0.65% of carbon equivalent and the balance of iron and inevitable impurities. The hardness of armor steel with the high anti-bullet property reaches 480-550 HBW, the shock absorption energy at the temperature of subzero 40 DEG C is larger than or equal to 20 J, and the armor steel plate has penetration resistance, can prevent armor steel from cracking, breaking or stripping and has the characteristics of low cost, stable quality, simplified process and easiness in large-scale industrial production.

Owner:SHANDONG IRON & STEEL CO LTD

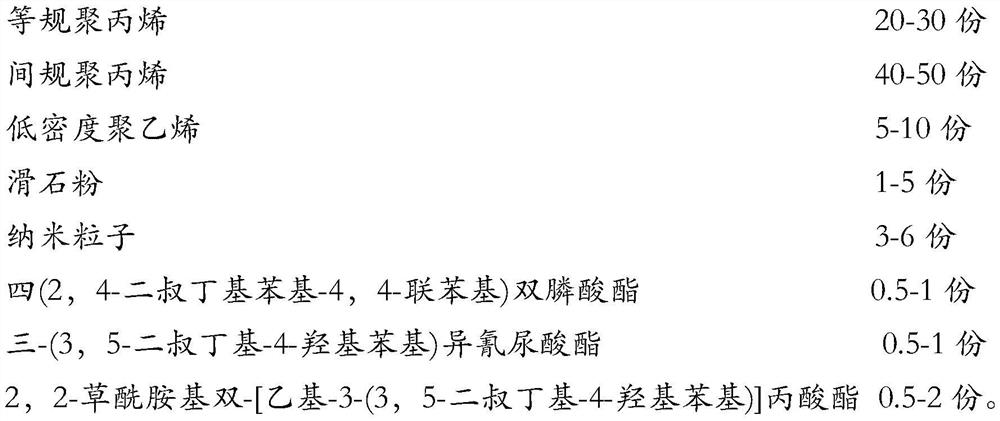

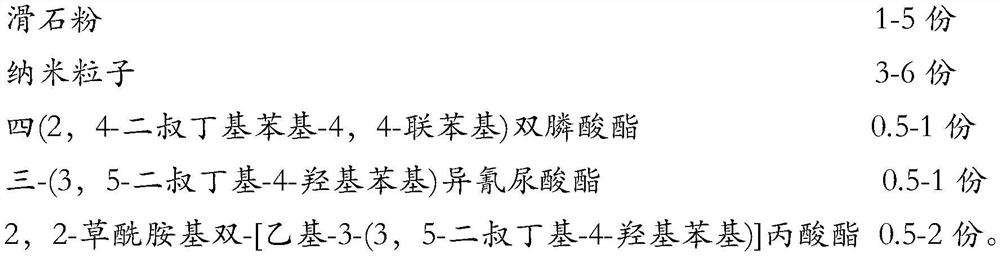

Non-crosslinked polypropylene material and cable

ActiveCN112646266AHigh glass transition temperatureGood flexibilityPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a non-crosslinked polypropylene material and a cable, and belongs to the technical field of cables, and the non-crosslinked polypropylene material comprises the following raw materials by weight: 20-30 parts of isotactic polypropylene, 40-50 parts of syndiotactic polypropylene, 5-10 parts of low density polyethylene, 1-5 parts of talcum powder, 3-6 parts of nanoparticles, 0.5-1 part of tetra (2, 4-di-tert-butylphenyl-4, 4-biphenyl) bisphosphonate, 0.5-1 part of tris- (3, 5-di-tert-butyl-4-hydroxyphenyl) isocyanurate and 0.5-2 parts of 2, 2-oxamido bis-[ethyl-3-(3, 5-di-tert-butyl-4-hydroxyphenyl) ] propionate. The cable material still has ultrahigh flexibility and toughness at the temperature of -30 DEG C and lower, therefore, the cold resistance, weather resistance and low-temperature impact resistance of the cable material are improved, the application range is wide, the practicability is high, and the oxidation resistance of the cable material is improved by using multiple antioxidants.

Owner:杭州龙源电力有限公司 +2

Heat-resistant, halogen-free, low-smoke, flame-retardant non-crosslinked polyolefin composition for cables

ActiveCN108690257BNo pollution in the processImprove heat resistancePlastic/resin/waxes insulatorsLinear low-density polyethyleneManufacturing cost reduction

The invention discloses a heat-resistant, halogen-free, low-smoke, and flame-retardant non-crosslinked polyolefin composition for cables, which is characterized in that: the raw materials of the composition include the following components in parts by weight: ethylene-vinyl acetate copolymer 40-60 parts of compound, 20-40 parts of linear low density polyethylene (LLDPE), 160-180 parts of inorganic hydroxide, 6-20 parts of phase solvent, 1-5 parts of synergist, 0.5-1.5 parts of stabilizer; It can improve the heat resistance of the material, and its working temperature can be as high as above 90°C. At the same time, it can reduce process consumption and manufacturing cost, and has excellent mechanical properties and processing properties. It can be recycled and has no pollution to the environment.

Owner:海南六八鸿昌兴科技股份有限公司

Molybdenum-base rare earth powder metallurgy forming plug and manufacturing method thereof

The invention relates to a seamless steel tube, in particular to a molybdenum-base rare earth powder metallurgy forming plug used by a high nickel-chromium stainless steel seamless pipe and a manufacturing method thereof. The manufacturing method of the molybdenum-base rare earth powder metallurgy forming plug comprises the following steps of: simultaneously mixing four rare earth oxides of ZrO2,Y2O3, La2O3 and SC2O3 in pure molybdenum powder; mixing molybdenum-base material to prepare powder by using an ultrasound characteristic; packaging the powder into a vane mixing blender, dispersing mixed molybdenum-base rare earth powder by primary refining; dispersing homogenized molybdenum-base rare earth powder by ultrasound refining through an ultrasound transducer; screening by a 180-mesh equalizing screen in accordance with a configured Tyler standard in a 'vibrating screen classifier' to obtain screen under flow, namely blended qualified molybdenum-base rare earth powder; and manufacturing the molybdenum plug by an isostaticmoulding mold, demolding and cleaning, and finishing the manufacturing in a configured hydrogen atmosphere roaster, a hydrogen atmosphere pre-sintering furnace and a hydrogen atmosphere horizontal intermediate frequency furnace. The molybdenum-base rare earth powder metallurgy forming plug and the manufacturing method thereof can be widely applied to chemical industry, metallurgy, machinery, aviation, national defense and other industrial departments.

Owner:四平市北威钼业有限公司

Low-silicon-aluminum-killed-steel-casting-slag-based refining agent and preparation method thereof

InactiveCN102876839BReduce consumptionReduce steelmaking costsProcess efficiency improvementAlkalinitySlag

The invention relates to a product obtained by comprehensively utilizing casting slag and a preparation method for the product. The product comprises the following components in percentage by weight: 86 to 96 percent of low-silicon-aluminum killed steel casting slag with the particle size of less than or equal to 5mm, 1 to 6 percent of fluorite, 3 to 8 percent of aluminum powder, and an inorganic binder which accounts for 2 to 4 percent of the total weight of the raw materials. The preparation method for the product comprises the following steps of: crushing the low-silicon-aluminum killed steel casting slag; uniformly mixing the materials; adding the inorganic binder and stirring uniformly; pelletizing and controlling the alkalinity of pellets to be 5.0 to 6.0; roasting; and taking out of a furnace for later use. The invention provides a low-silicon-aluminum-killed-steel-casting-slag-based refining agent and a preparation method thereof. The continuous casting slag of low-carbon low-silicon-aluminum killed steel can be comprehensively utilized, and the refining agent prepared from the continuous casting slag of the low-carbon low-silicon-aluminum killed steel is applied to a ladle furnace (LF), so that the slagging speed of the LF is high, the time of the formation of reducing white slag can be shortened, the desulfurization rate can be increased, the environmental pollution is reduced, and the production cost is reduced.

Owner:武汉钢铁有限公司

Steel plate for punching-welding axle housing and manufacturing method thereof

InactiveCN103422020BGood formabilityImprove high temperature strengthAxle unitsHot stampingStructural engineering

The invention relates to a 600MPa grade hot stamping steel plate with excellent performance for stamping and welding axle housing after heating and its manufacturing method. By adding elements such as Nb and V to ensure the high temperature performance of the steel, the influence of C and Si on stamping is reduced. The element content of the performance, through the combination of Ti, Al and other nitrogen-fixing elements, fundamentally ensures that the steel plate has good formability, while the high-temperature strength is improved, the low-temperature toughness is excellent, the welding performance is improved, the fatigue strength is significantly improved, and the fatigue life of the component is extended. above 50. It can be widely used in the production of medium and heavy plate rolling pieces that require high temperature strength for large structural steels that operate under high temperature conditions such as hot forming, large blowers, and vibrating screens.

Owner:JIGANG GRP

A steel plate for marine energy equipment and its preparation process

The invention relates to a steel plate used for ocean energy equipment and a preparation process of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.07-0.11% of carbon, 0.10-0.30% of silicon, 1.20-1.30% of manganese, less than or equal to 0.015% of phosphorus, less than or equal to 0.010% of sulfur, 0.05-0.08% of vanadium, 0.010-0.030% of titanium, 0.020-0.045% of aluminum, 0.35-0.45% of copper, 0.25-0.40% of nickel, 0.45-0.65% of chromium, 0.05-0.15% of zirconium, and the balance of iron and unavoidable impurities. The Ceq (carbon equivalent) is less than or equal to 0.45%, and the anti-corrosion factor (I) is more than or equal to 6.0. The steel plate produced by the preparation process disclosed by the invention has the yield strength of more than 500MPa, can endure a low temperature environment of 60 DEG C below zero, meets the requirements for 25-100kJ / cm of high welding heat input, is high in corrosion resistance which is 2.05 times that of a plain carbon steel, and is good in direct cutting performance in a normal temperature environment.

Owner:JIGANG GRP

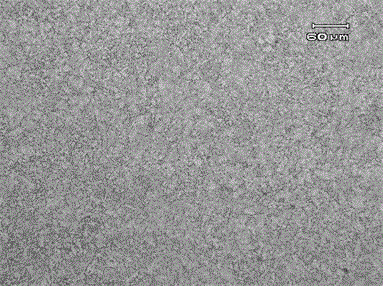

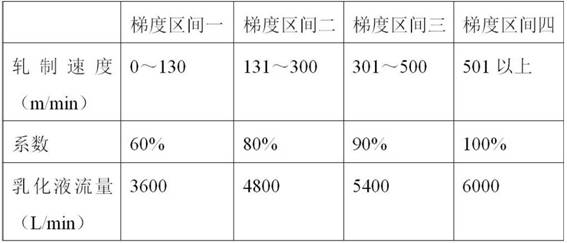

The Method of Dynamically Adjusting the Flow of Emulsion in Continuous Cold Rolling Mill

ActiveCN111872131BResolve overflowReduce development costsWork cooling devicesMass flow control deviceMotor speedEmulsion

The invention discloses a method for dynamically adjusting the emulsified liquid flow rate of a cold tandem rolling mill, and relates to the technical field of metallurgy. It includes using the principle of heat balance, deriving through formulas, constructing the rolling speed and emulsion flow function, and using the constructed rolling speed and emulsion flow function to control the emulsion flow according to the rolling speed. The present invention realizes the function of dynamic adjustment of the emulsion following the rolling speed by deriving the relationship between the flow rate of the emulsion and the rotational speed of the main motor of the rolling mill, and better solves the problems of the emulsion overflow and the inaccurate measurement of the thickness gauge existing in the original system , the development cost is low, the operation and maintenance are convenient, the process consumption is significantly reduced, the yield and product quality have been qualitatively improved, and economic benefits have been brought to the cold rolling production and operation.

Owner:广西钢铁集团有限公司 +1

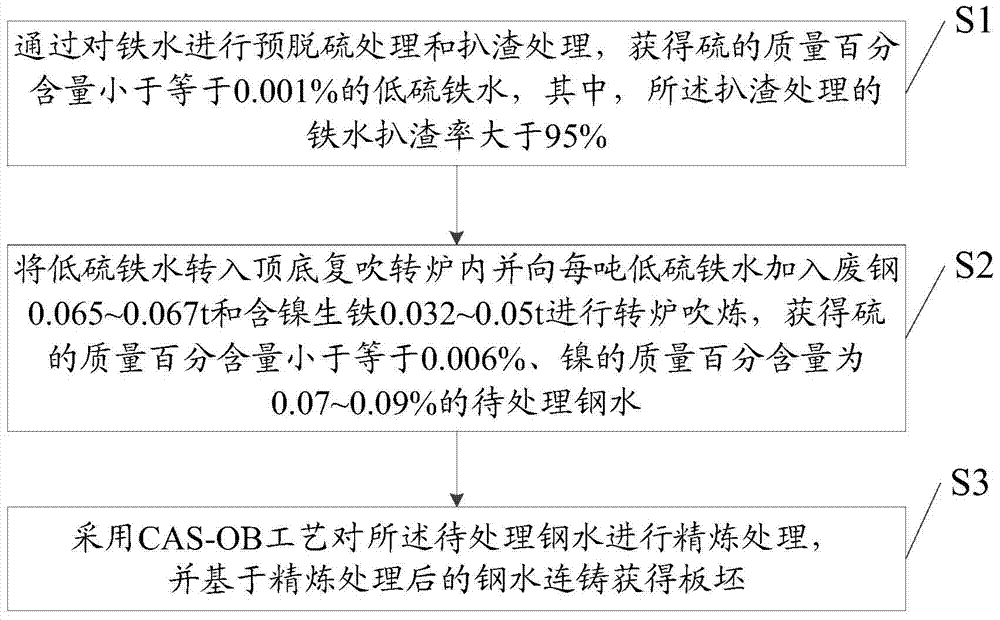

A method of smelting weathering steel

ActiveCN105256094BSolve technical problems with high production costsLow costManufacturing convertersProcess efficiency improvementSulfurMolten steel

The invention discloses a method for smelting weathering resistant steel. The method comprises the steps that pre-desulfuration processing and drossing processing are carried out on molten iron, and low-sulphur molten iron with the sulphur mass percentage composition smaller than or equal to 0.001% is obtained, wherein the drossing rate of the molten iron on which drossing processing is carried out is larger than 95%; the low-sulphur molten iron is shifted into a top-bottom combined blowing converter, 0.065-0.067 t of scrap steel and 0.032-0.05 t of nickel containing pig iron are added in each ton of low-sulphur molten iron, converter smelting is carried out, and to-be-processed molten steel with the sulphur mass percentage composition smaller than or equal to 0.06% and the nickel mass percentage composition of 0.07-0.09% is obtained; and refining processing is carried out on the to-be-processed molten steel through the CAS-OB technology, and a plate blank is obtained on the basis of continuous casting of the molten steel on which refining processing is carried out. According to the technical scheme, the content of the nickel component in the molten steel is adjusted through the nickel containing pig iron, the pre-desulfuration of the molten iron is carried out before refining, the CAS-OB technology is adopted during refining, and the cost of raw materials and production consumption are reduced; and the technical problem that in the prior art, the production cost of the weathering resistant steel is high is solved, and the production cost is reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

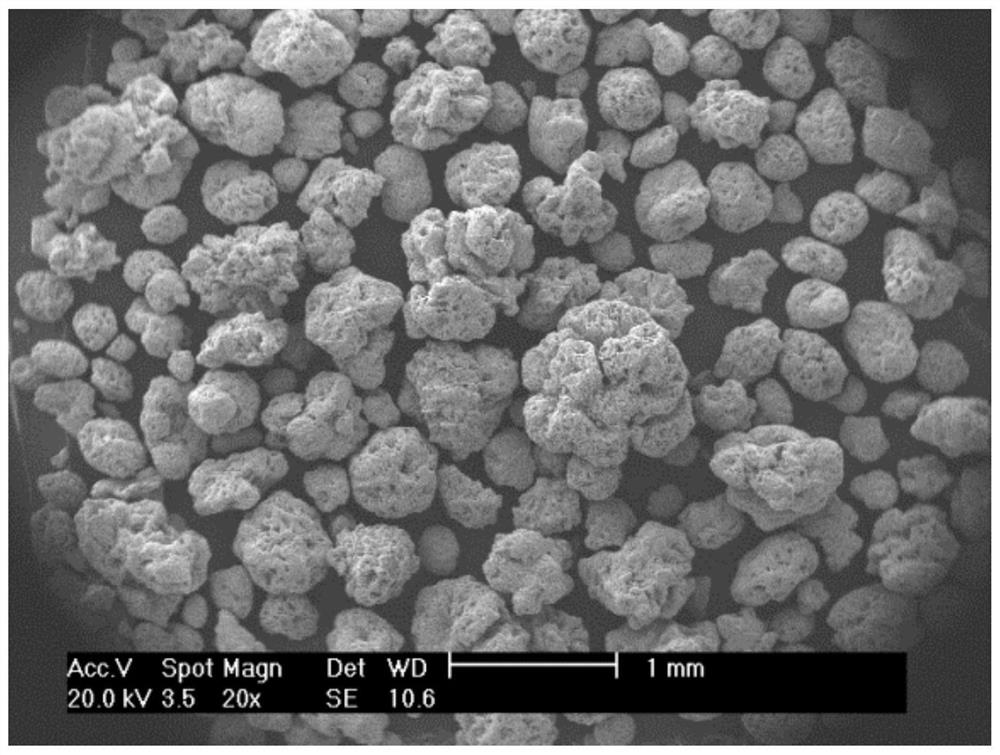

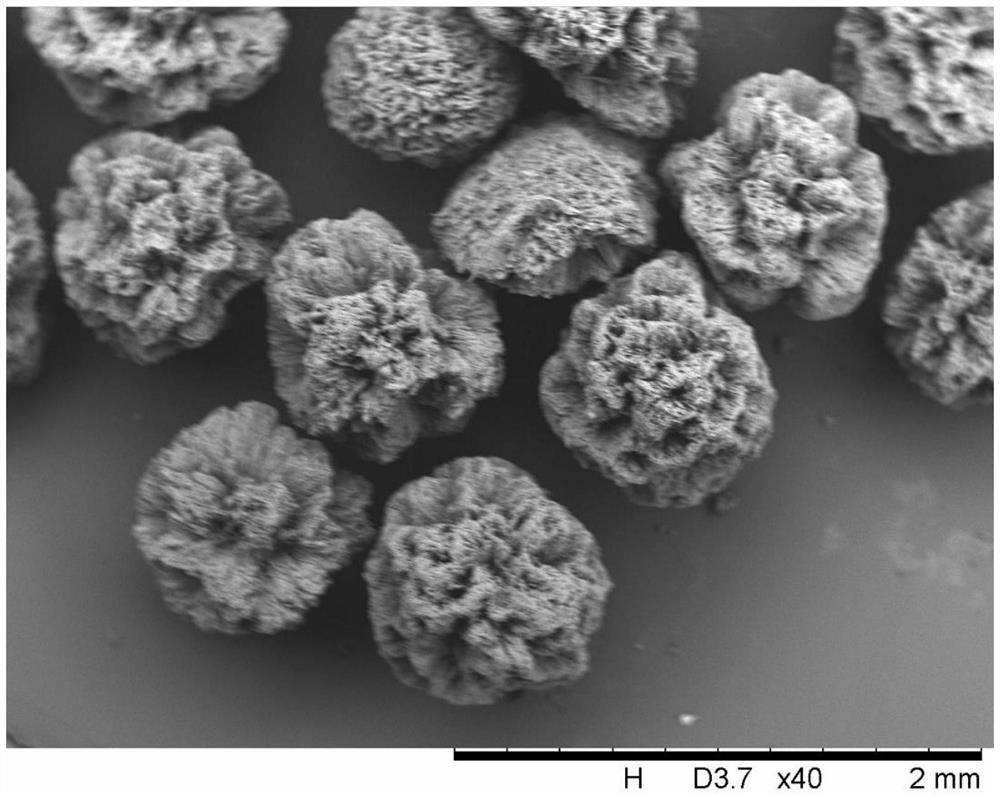

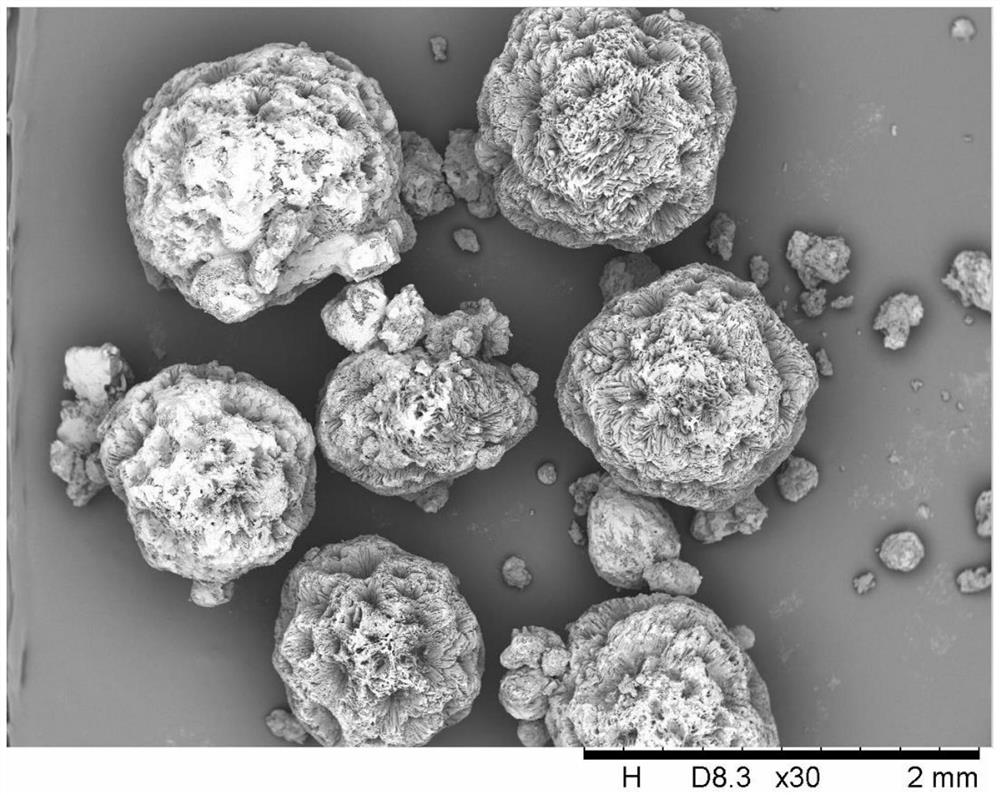

Preparation method of sodium percarbonate

ActiveCN112758897AIncrease dosageReduce consumptionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhysical chemistrySupersaturation

The invention provides a preparation method of stable sodium percarbonate. The stable sodium percarbonate is prepared by reacting and crystallizing sodium carbonate decahydrate, mother liquor and hydrogen peroxide solution. A three-flow feeding mode is adopted, the supersaturation degree of a system is adjusted and controlled through the slurry flow speed and the sodium chloride content, the number of crystal nucleuses is controlled, and therefore the sodium percarbonate spherical particles with different granularities are prepared. The sodium percarbonate product prepared by the method is round and uniform in particle size, the active oxygen content is higher than 14.5%, the thermal stability is higher than 95%, the wet stability is higher than 78%, and particles of 40 meshes or more account for 98.5% of the total particle number.

Owner:TIANJIN UNIV

Method for preparing anisotropic nanocrystalline rare-earth permanent magnet block material

InactiveCN102543341BHigh densityImprove permanent magnet performanceInorganic material magnetismInductances/transformers/magnets manufactureRare earthElectric field

The invention discloses a method for preparing an anisotropic nanocrystalline rare-earth permanent magnet block material, which includes: firstly, preparing an alloy ingot by the vacuum smelting process; secondly, melting the alloy ingot and injecting an external direct-current electric field to the melt to realize direct-current inoculation process; thirdly, preparing an anisotropic nanocrystalline rare-earth permanent magnet material by the rapid copper mould solidification process under action of an external direct-current magnetic field; and finally processing the material in heat properly according to specific conditions. The anisotropic nanocrystalline rare-earth permanent magnet block material prepared by the method has the advantages of evident magnetic anisotropy, high density and fine comprehensive permanent magnetic performance. The method is simple in procedure, convenient in operation and low in processing consumption.

Owner:FUZHOU UNIV

Method for preparing monofluo-rodicloroethane

ActiveCN101250086BLow costHigh purityPreparation by halogen halide additionHydrogen fluorideUltraviolet lights

The invention discloses a preparation method of monofluo-rodicloroethane, which comprises 1, processing addition reaction on acetylene and hydrogen chloride or hydrogen fluoride at the mol ratio of 1.5-2.5:1, in the presence of catalyst, to prepare vinyl chloride or fluoride, 2, processing addition reaction on the vinyl chloride or fluoride at the mol ratio of 1:3-5 or on the fluoride or vinyl chloride at the mol ratio of 1:3-5, in the presence of catalyst to prepare monofluo-chloroethane, 3, reacting the monofluo-chloroethane and chlorine at the mol ratio of 4-6:1, in the catalysis of catalyst or ultraviolet light to generate monofluo-rodicloroethane. The invention can avoid using vinylidene chloride and 1, 1, 1-methyl chloroform as basic materials, thereby reducing material cost of the whole process and improving the purity of monofluo-rodicloroethane (HCFC 141b).

Owner:CHANGSHU 3F FLUOROCHEM IND CO LTD

Method for extracting alkaloid by utilizing waste water and sludge of tobaccos

InactiveCN102093336BImprove use valueReduce lossSludge treatmentOrganic chemistryProcess lossNornicotine

Owner:WUHAN DANYAXIANG TECH DEV

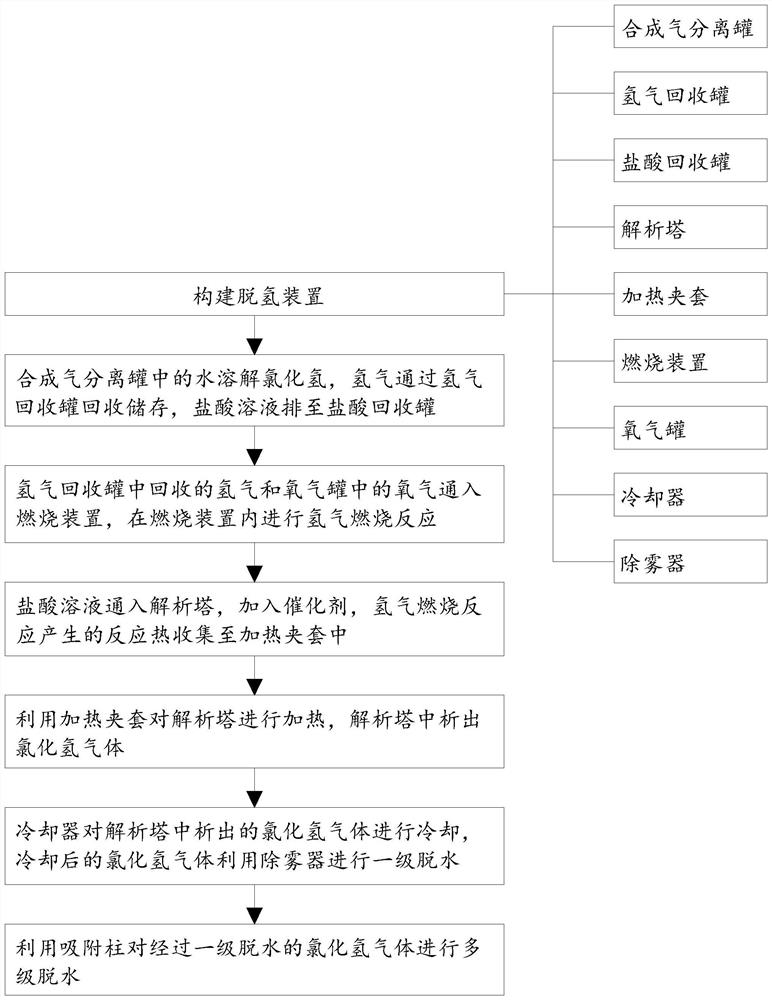

Dehydrogenation process of hydrogen chloride synthesis gas

PendingCN114436215ARealize rational useTake advantage ofChlorine/hydrogen-chloride purificationHydrogen chloride preparationPtru catalystOxygen tank

The invention discloses a dehydrogenation process of hydrogen chloride synthesis gas, which relates to the technical field of synthesis gas dehydrogenation, and comprises the following steps: constructing a dehydrogenation device, dissolving hydrogen chloride in water in a synthesis gas separation tank, introducing hydrogen recovered in a hydrogen recovery tank and oxygen in an oxygen tank into a combustion device, introducing a hydrochloric acid solution into a desorption tower, and adding a catalyst, the method comprises the following steps: collecting reaction heat generated by hydrogen combustion reaction into a heating jacket, heating a desorption tower by using the heating jacket, cooling hydrogen chloride gas separated out from the desorption tower by using a cooler, performing primary dehydration by using a demister, and performing multi-stage dehydration on the hydrogen chloride gas subjected to primary dehydration by using an adsorption column; hydrogen chloride gas and hydrogen are separated by using the synthesis gas separation tank, and heat released by reaction of the separated hydrogen and oxygen is used as a heat source in a hydrogen chloride solution desorption process, so that reasonable utilization of resources can be effectively realized; and the product water generated by the reaction of the hydrogen and the oxygen can be used as the dissolving water when the hydrogen chloride dissolving gas is dissolved in the synthesis gas separation tank.

Owner:HWASU

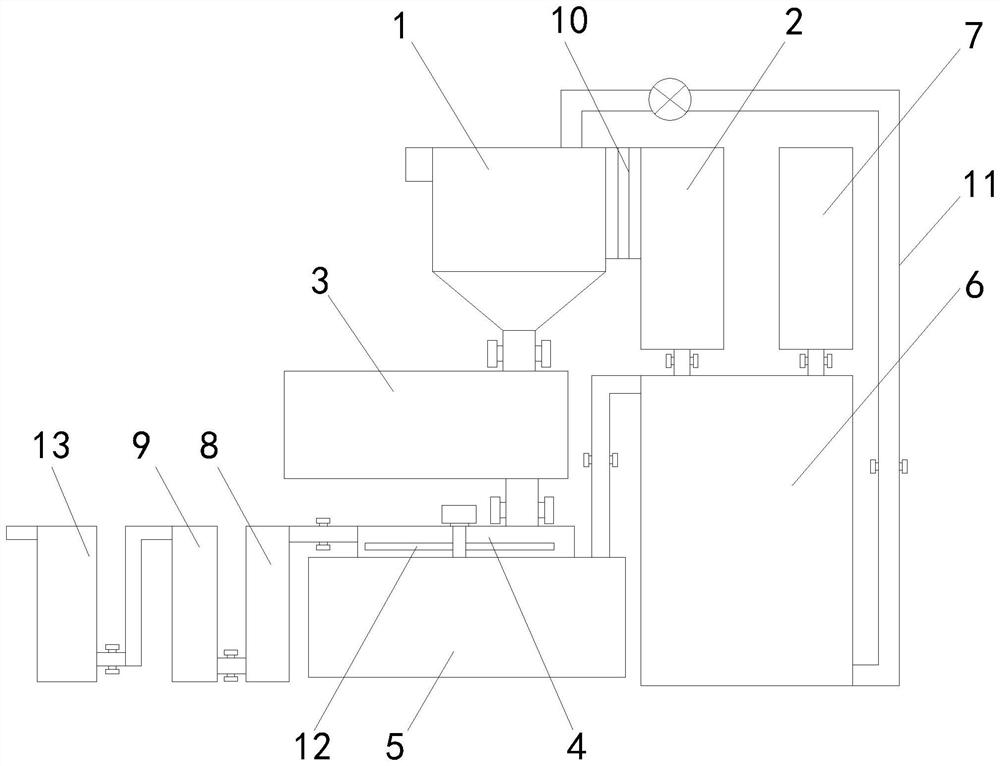

Combined long-term stable operation ammonium chloride method zinc electrolysis process flow

InactiveCN112853399AGuarantee basic qualityCompact and flexible layoutElectrolysis componentsPhotography auxillary processesElectrolysisHydrazine compound

The invention provides a combined long-term stable operation ammonium chloride method zinc electrolysis process flow. The flow comprises leaching, purification, an electrolysis main flow and an ultra-impurity raw material circulation coarse washing, excessive calcium and magnesium precipitation and oxidation impurity filtration auxiliary flow, and the two flows are arranged and connected in parallel, can work independently and do not influence each other. According to the flow, the stability of the quality of an electrolyte is controlled through the cooperation of main and auxiliary flows and through the whole flow, temperature control, compact parallel-series layout, multiple working sections, synchronization / asynchronism and multiple means, the multi-element interference brought by complex raw materials is solved, especially the problem of long-period stable and efficient operation of ammonium chloride method zinc electrolysis is solved, and the flow has positive environmental protection and economic significance in treatment of high-fluorine-chlorine and high-impurity zinc-containing raw materials through an ammonia method, and environmental protection and resource recycling of secondary zinc resources such as zinc-containing steel, metallurgical smoke and the like.

Owner:彭勃 +1

A stepwise moistening process

ActiveCN106423355BEasy to separateImprove antioxidant capacityGrain millingChemical qualityMicrowave

The invention discloses a stepwise moistening process, which belongs to the technical field of wheat flour processing. Ultrasonic wave, microwave, freezing and functional wheatenizing solution are combined to carry out stepwise moistening of wheat grains three times, which improves the bond between bran and wheat germ. Separation increases the degree of evacuation and penetration between the structure of wheat grain epidermis, seed coat, germ, endosperm and macromolecular nutrients, accelerates the water penetration speed, shortens the total process time of moistening wheat to 6-12h, and flour is powdered The rate is 78.5‑79.5%, which improves the anti-oxidation and nutritional value of flour, improves the appearance quality, physical and chemical quality and food safety of wheat flour, reduces the consumption of subsequent milling and other processes, reduces production costs, and provides benefits for wheat tempering Craft explores a new path.

Owner:宁夏鑫德粮油工贸有限公司

Non-crosslinked polyolefin composition for cables

InactiveCN108794691ASimple manufacturing processGood compatibilityPlastic/resin/waxes insulatorsManufacturing cost reductionPolyolefin

The invention discloses a non-crosslinked polyolefin composition for cables. The non-crosslinked polyolefin composition is prepared from, by weight, 30-40 parts of an ethylene-vinyl acetate copolymer,10-20 parts of polyethylene, 10-20 parts of maleic anhydride, 5-10 parts of octylene, 1-4 parts of N,N-dimethylformamide, 1-4 parts of dimethyl sulfoxide, 1-4 parts of triphenyl phosphate, 1-4 partsof dimethylacetal, 1-3 parts of N,N-diethyl cinnamamide, 2-6 parts of ultrafine zinc borate and 1-5 parts of an initiator. The composition is prepared by steps: stirring the materials for 5-10min at astirring speed of 150-200r / min; performing melt plasticization in a double-screw extruder, carrying out grafting reaction, and performing extrusion molding through a die head, wherein a barrel temperature of the double-screw extruder is 120-160 DEG C, the die head temperature is 130-140 DEG C, and a screw rod rotating speed is 40-70r / min. High mixture compatibility, high softness and excellent heat resistance and physical, mechanical and electrical performances are achieved, a cable manufacturing process can be simplified, process consumption and manufacturing cost are reduced, and excellentprocessability is realized while environmental pollution is avoided.

Owner:CHONGQING UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com