The Method of Dynamically Adjusting the Flow of Emulsion in Continuous Cold Rolling Mill

A technology of dynamic adjustment for tandem cold rolling mills, applied in the field of metallurgy, can solve problems such as inaccurate control of emulsion flow in tandem cold rolling mills, complex maintenance of the control system, and impact on product quality, so as to solve emulsion overflow, reduce process consumption, and avoid The effect of emulsion reflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

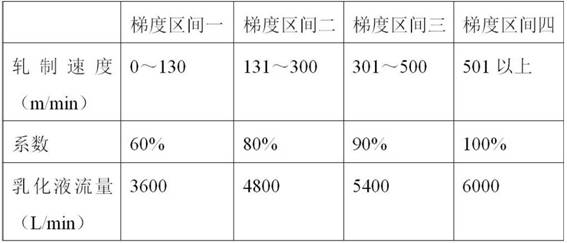

[0061] This embodiment takes the five-stand tandem cold rolling mill production line in the production workshop of Guangxi Iron and Steel Group Co., Ltd. as an example, and introduces in detail the method and effect of how to dynamically adjust the flow rate of the emulsion in the tandem cold rolling mill.

[0062] It includes the following steps:

[0063] A. Using the principle of heat balance, the function of rolling speed and emulsion flow is constructed through formula derivation; among them, the specific formula derivation process is as follows:

[0064] ① The calculation formula of the emulsion flow value f of the emulsion required by the system is:

[0065] Formula 1);

[0066] Among them, f——the flow rate of emulsion, L / min;

[0067] Δt——The temperature rise of the emulsion, °C;

[0068] Cs ——Specific heat of steel, heal / kg·℃;

[0069] r s - specific gravity of steel, kg / m3;

[0070] Q——heat generated by power consumption, kcal / min;

[0071] ②The formula for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com