Non-crosslinked polyolefin composition for cables

A non-crosslinked, polyolefin technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as insufficient heat resistance, and achieve good compatibility, no environmental pollution, and excellent processability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

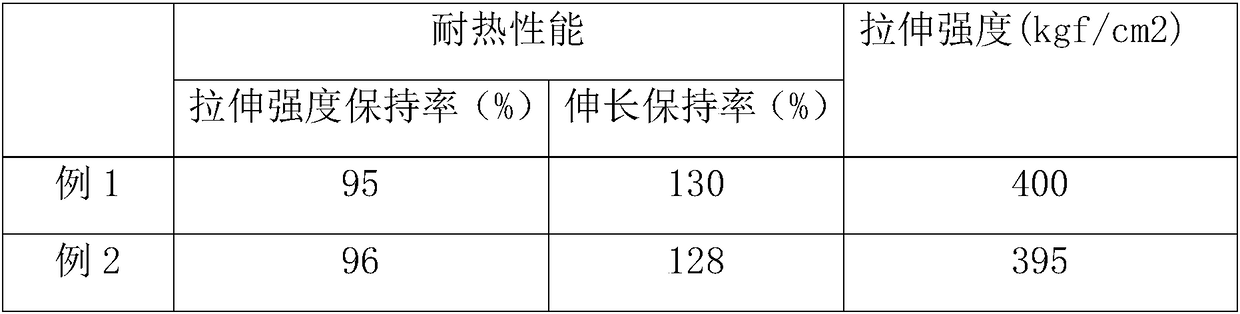

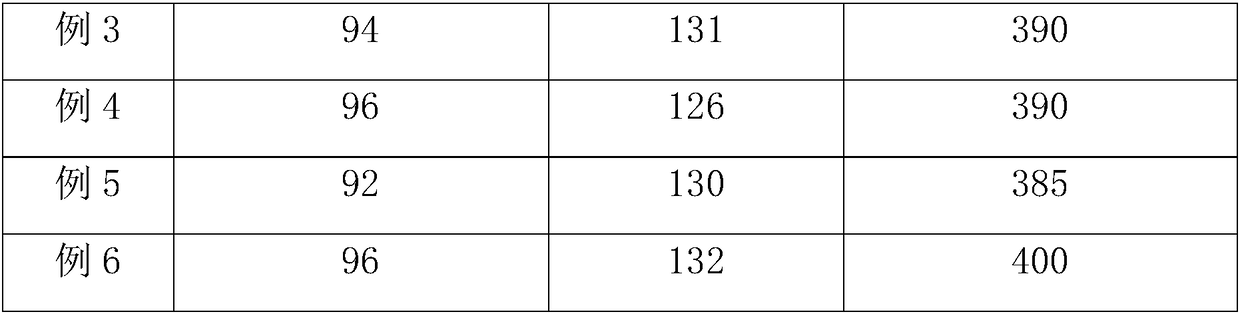

Examples

Embodiment 1

[0021] In the non-crosslinked polyolefin composition for cables of this embodiment, the raw materials include the following components in parts by weight:

[0022] 30 parts of ethylene-vinyl acetate copolymer, 10 parts of polyethylene, 10 parts of maleic anhydride, 5 parts of octene, 1 part of N,N-dimethylformamide, 1 part of dimethyl sulfoxide, triphenyl phosphate 1 part, 1 part of dimethyl acetal, 1 part of N,N-diethylcinnamic amide, 2 parts of ultrafine zinc borate, 1 part of initiator; stir the above mixed material at a stirring speed of 150r / min for 5 minutes , and then melted and plasticized in the twin-screw extruder and carried out grafting reaction, and then extruded from the die head, the barrel temperature of the twin-screw extruder is 120 ° C, the die head temperature is 130 ° C, and the screw speed is 40r / min.

Embodiment 2

[0024] In the non-crosslinked polyolefin composition for cables of this embodiment, the raw materials include the following components in parts by weight:

[0025] 40 parts of ethylene-vinyl acetate copolymer, 20 parts of polyethylene, 20 parts of maleic anhydride, 10 parts of octene, 4 parts of N,N-dimethylformamide, 4 parts of dimethyl sulfoxide, triphenyl phosphate 4 parts, 4 parts of dimethyl acetal, 3 parts of N,N-diethylcinnamic amide, 6 parts of ultrafine zinc borate, 5 parts of initiator; stir the above mixed material at a stirring speed of 200r / min for 10 minutes , and then melted and plasticized in the twin-screw extruder and carried out grafting reaction, and then extruded from the die head, the barrel temperature of the twin-screw extruder is 160 ° C, the die head temperature is 140 ° C, and the screw speed is 70r / min.

Embodiment 3

[0027] In the non-crosslinked polyolefin composition for cables of this embodiment, the raw materials include the following components in parts by weight:

[0028] 30 parts of ethylene-vinyl acetate copolymer, 20 parts of polyethylene, 10 parts of maleic anhydride, 10 parts of octene, 1 part of N,N-dimethylformamide, 4 parts of dimethyl sulfoxide, triphenyl phosphate 1 part, 4 parts of dimethyl acetal, 1 part of N,N-diethylcinnamic amide, 6 parts of ultrafine zinc borate, 1 part of initiator; stir the above mixed material at a stirring speed of 200r / min for 5 minutes , and then melted and plasticized in the twin-screw extruder and carried out grafting reaction, and then extruded from the die head, the barrel temperature of the twin-screw extruder is 160 ° C, the die head temperature is 130 ° C, and the screw speed is 70r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com