Method for preparing anisotropic nanocrystalline rare-earth permanent magnet block material

An anisotropic, rare-earth permanent magnet technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of limited cooling capacity of copper molds, large difference in crystallization temperature, weak amorphous formation ability, etc., to achieve Good comprehensive permanent magnetic properties and mechanical strength, simple production process, and low process consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

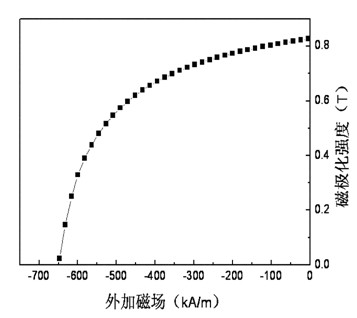

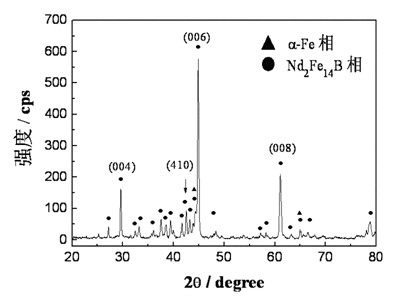

Embodiment 1

[0021] Using Nd, Pr, Fe, Y, Cr, Co, Si, Zr and B with a purity of 99.9wt% as raw materials, according to Nd 9 PR 1.5 Fe 61 Y 0.5 Cr 0.5 co 9 Si 1 Zr 2 B 15.5 ratio, put it into the magnetic levitation melting furnace, and evacuate to 10 -5 Pa, then pass through 1.1×10 5The high-purity argon gas of Pa is smelted 6 times under the protection of argon gas to ensure the ingot with uniform composition. In order to ensure that the composition of the ingot basically meets the design composition, attention must be paid to the loss of alloying elements during the smelting process. Next, put the alloy ingot into a quartz glass tube with a small hole (0.7 mm in diameter) at the bottom, and place it in a vacuum spray-casting furnace with a DC electric field and a DC magnetic field device. The inner cavity of the quartz tube is 1.5mm (thickness) × 25mm (width) × 25mm (length) water-cooled copper mold. Vacuum until the vacuum degree in the spray casting furnace cavity is 10 -5 Pa...

Embodiment 2

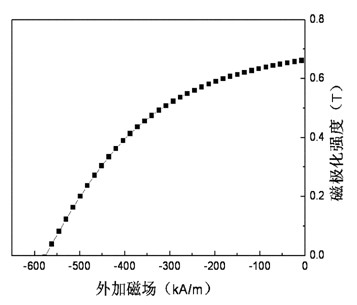

[0023] Using Nd, Dy, Fe, Co, Cr, Zr, Ti, Ga, B and C with a purity of 99.9wt% as raw materials, according to Nd 11 Dy 1 Fe 55 co 12 Cr 1 Zr 1 Ti 0.5 Ga 0.5 B 17.5 C 0.5 ratio, put it into the magnetic levitation melting furnace, and evacuate to 10 -5 Pa, then pass through 1.1×10 5 The high-purity argon gas of Pa is smelted 6 times under the protection of argon gas to ensure the ingot with uniform composition. In order to ensure that the composition of the ingot basically meets the design composition, attention must be paid to the loss of alloying elements during the smelting process. Next, put the alloy ingot into a quartz glass tube with a small hole (0.7 mm in diameter) at the bottom, and place it in a vacuum spray casting furnace with a DC electric field and a DC magnetic field device, and place a water-cooled copper mold at the lower end of the quartz tube , the inner diameter of the copper mold cavity is 2mm, and the length is 50mm. Vacuum until the vacuum degr...

Embodiment 3

[0025] Using Nd, La, Dy, Fe, Co, Zr, Ti, Mo and B with a purity of 99.9wt% as raw materials, according to (Nd 0.9 La 0.1 ) 12 Dy 1 Fe 63 co 10 Zr 1 Ti 2 Mo 1 B 10 ratio, put it into the magnetic levitation melting furnace, and evacuate to 10 -5 Pa, then pass through 1.1×10 5 The high-purity argon gas of Pa is smelted 6 times under the protection of argon gas to ensure the ingot with uniform composition. In order to ensure that the composition of the ingot basically meets the design composition, attention must be paid to the loss of alloying elements during the smelting process. Next, put the alloy ingot into a quartz glass tube with a small hole (0.7 mm in diameter) at the bottom, and place it in a vacuum spray casting furnace with a DC electric field and a DC magnetic field device, and place a water-cooled copper mold at the lower end of the quartz tube , the inner diameter of the copper mold cavity is 1.5mm, and the length is 50mm. Vacuum until the vacuum degree i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com