Dehydrogenation process of hydrogen chloride synthesis gas

A technology for hydrogen chloride gas and synthesis gas, which is applied in chlorine/hydrogen chloride, hydrogen chloride preparation, chlorine/hydrogen chloride purification and other directions, can solve the problems of reduced hydrogen chloride purity, poor process recyclability, high energy consumption in dehydrogenation process, etc., and achieves low process consumption , Realize the effect of rational utilization of resources and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

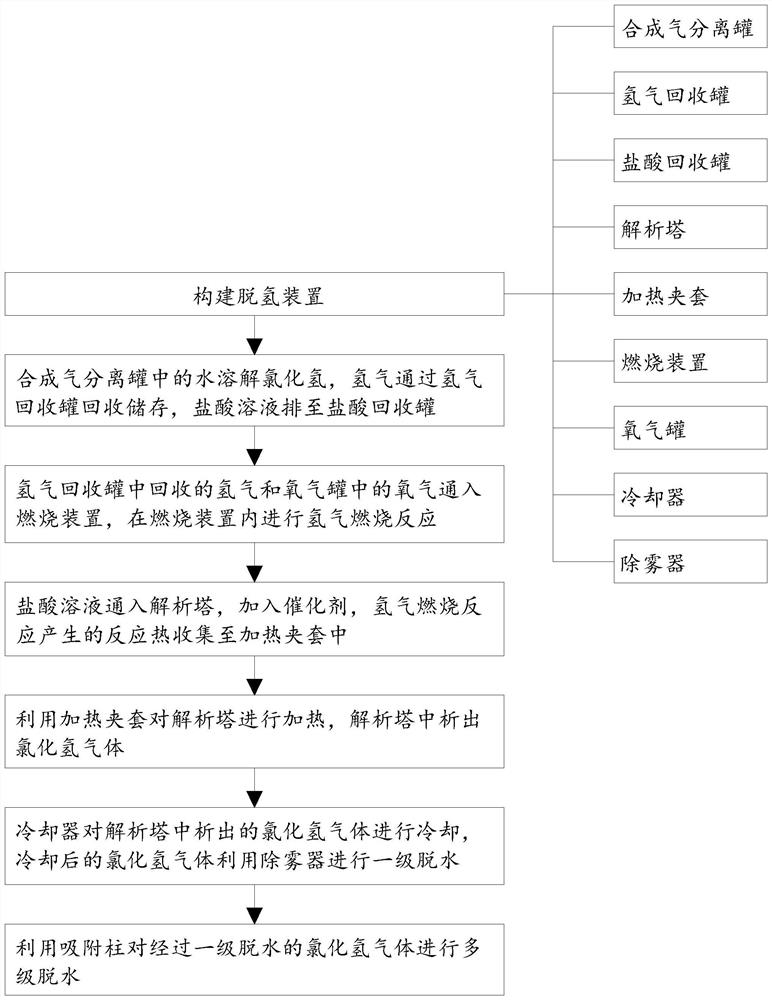

[0029] according to Figure 1-2 As shown, the present embodiment proposes a dehydrogenation process of hydrogen chloride synthesis gas, comprising the following steps:

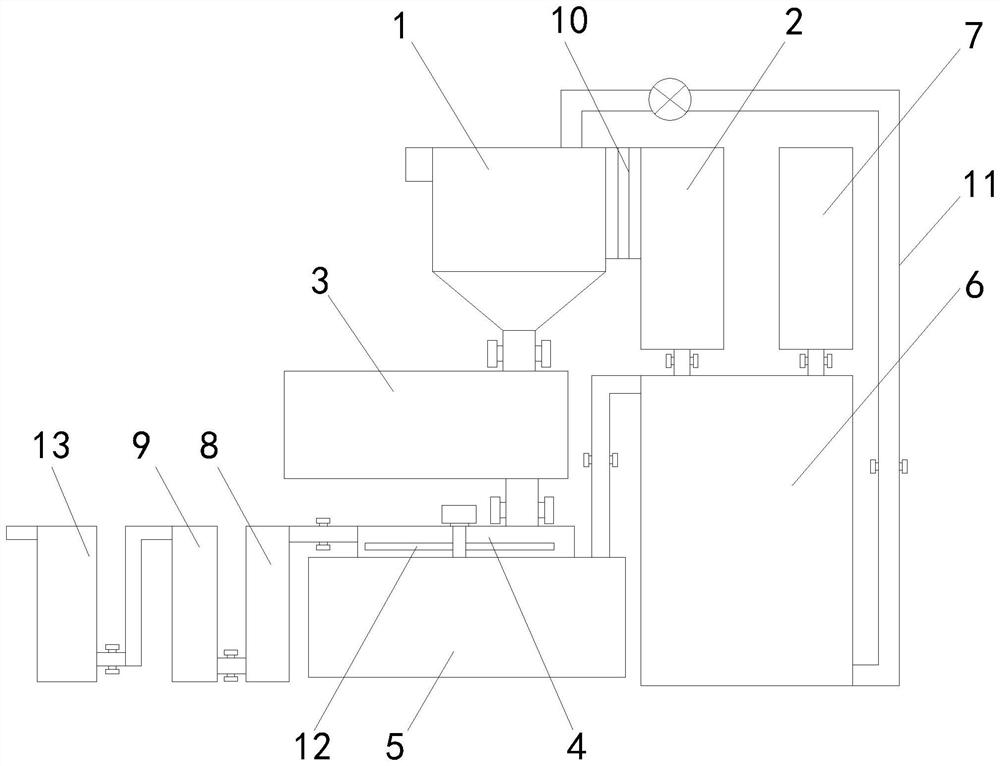

[0030] Step 1: Build a dehydrogenation device, which includes a synthesis gas separation tank 1, a hydrogen recovery tank 2, a hydrochloric acid recovery tank 3, an analysis tower 4, a heating jacket 5, a combustion device 6, an oxygen tank 7, a cooler 8 and a dehydrator Mist device 9, membrane separator 10 is also arranged between syngas separation tank 1 and hydrogen recovery tank 2, and the membrane material that membrane separator 10 adopts is polyimide macromolecular polymer film, in the present embodiment, heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com