A steel plate for high elastic armor and its manufacturing method

A manufacturing method and elastic technology, applied in the field of high elastic armor steel plate and its manufacturing, can solve the problems of high cost, difficult operation, poor weldability, etc., and achieve the effects of preventing self-cracking, wide adaptability, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

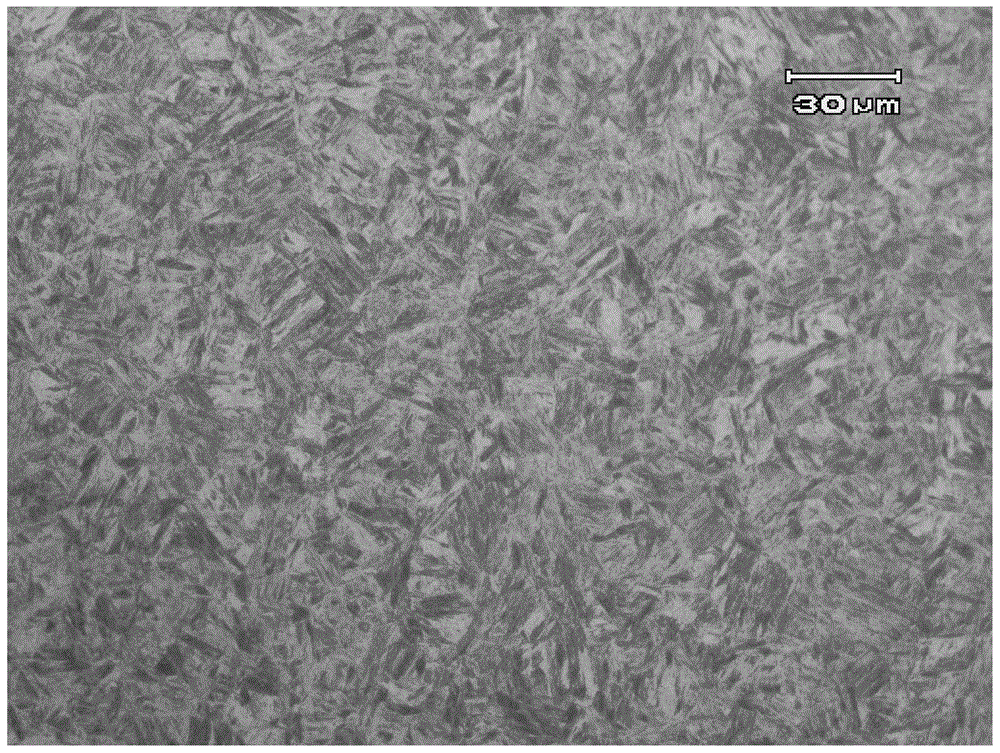

Image

Examples

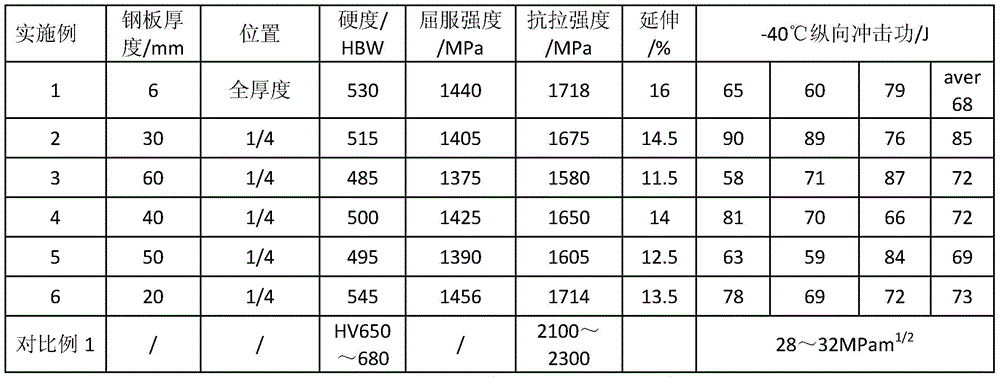

Embodiment 1

[0059] A steel plate for high-resistance armor, the chemical composition content by weight percentage is:

[0060] C: 0.21%, Si: 0.04%, Mn: 0.48%, P: 0.010%, S: 0.003%, Cr: 0.94%, Mo: 0.22%, Ti: 0.019%, Al: 0.029%, %, H: 0.00018 %, N: 0.0036%, CEV: 0.52%. The rest is Fe and inevitable impurities.

[0061] The manufacturing method includes the following steps:

[0062] 1) KR molten iron pretreatment: molten iron P=0.075%, sulfur content after pretreatment with KR molten iron is 0.003%.

[0063] 2) Converter smelting: the final component carbon of converter smelting is controlled at [C]=0.076%, S=0.007%, P=0.008%, and the final temperature is 1645°C.

[0064] 3) RH refining: the vacuum degree of RH refining is 87Pa, the treatment time is 15min, the pure degassing time is 12min, and then calcium oxide is added for calcium treatment. After calcium treatment, [Ca] is 16ppm;

[0065] 4) Slab continuous casting: the superheat of the continuous casting tundish is controlled at 15-20℃, and the ...

Embodiment 2

[0072] A steel plate for high-resistance armor, the chemical composition content by weight percentage is:

[0073] C: 0.25%, Si: 0.03%, Mn: 0.34%, P: 0.011%, S: 0.001%, Cr: 1.08%, Mo: 0.38%, Ti: 0.027%, Al: 0.049%, H: 0.00020%, N: 0.0032%, CEV: 0.60%, the rest is Fe and unavoidable impurities.

[0074] The steel plate manufacturing method includes the following steps:

[0075] 1) KR molten iron pretreatment: molten iron P=0.083%, sulfur content after pretreatment with KR molten iron is 0.002%.

[0076] 2) Converter smelting: the final carbon content of converter smelting is controlled at [C] = 0.092%, S = 0.005%, P = 0.007%, and the final temperature is 1642°C;

[0077] 3) RH refining: the vacuum degree of RH refining is 80Pa, the treatment time is 18min, the pure degassing time is 13min, and then calcium oxide is added for calcium treatment, after calcium treatment [Ca]=22ppm;

[0078] 4) Slab continuous casting: the superheat of the tundish of continuous casting is controlled at 16-22...

Embodiment 3

[0086] A steel plate for high-resistance armor, the chemical composition content by weight percentage is:

[0087] C: 0.28%, Si: 0.06%, Mn: 0.28%, P: 0.009%, S: 0.003%, Cr: 1.27%, Mo: 0.31%, Ti: 0.035%, Al: 0.035%, H: 0.00017%, N: 0.0031%, CEV: 0.64%, the rest is Fe and unavoidable impurities.

[0088] The production method of steel plate is as follows:

[0089] 1) KR molten iron pretreatment: molten iron P=0.068%, the sulfur content after pretreatment with KR molten iron is equal to 0.002%.

[0090] 2) Converter smelting: the final component carbon of converter smelting is controlled at [C]=0.09%, S=0.004%, P=0.007%, and the final temperature is 1657℃;

[0091] 3) RH refining: the vacuum degree of RH refining is 91Pa, the treatment time is 16min, the pure degassing time is 10min, after calcium treatment [Ca]=19ppm;

[0092] 4) Slab continuous casting: the superheat of the tundish of continuous casting is controlled at 14-20℃, and the temperature fluctuates 8℃ throughout the process;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com