Method for extracting alkaloid by utilizing waste water and sludge of tobaccos

A technology for wastewater sludge and alkaloids, which is applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problem of not having too many alkaloids in the tailings, so as to improve the utilization value, Low relative safety, less loss of alkaloids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

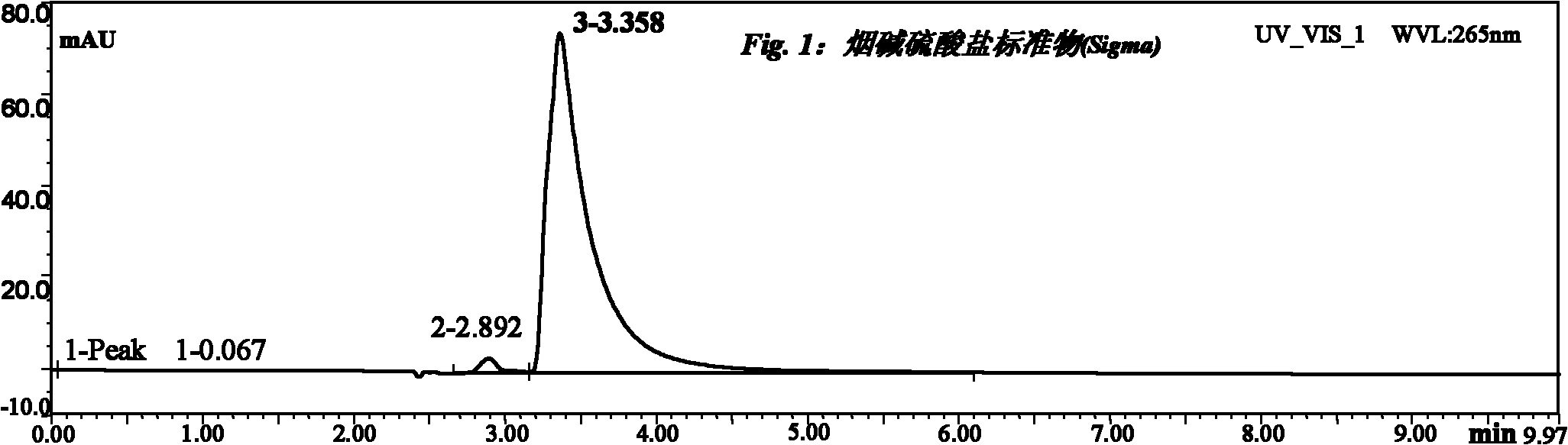

[0034] The "method for extracting alkaloids from tobacco flake wastewater sludge" provided by the present invention adopts the same principle of base activation and calcium base replacement for the two sludges to increase the extraction rate of the sludge. Its specific implementation is as follows:

[0035]"Sludge I": starting from the homogeneous pool of paper-making tobacco flake wastewater, the waste water was treated according to the "solid-liquid enrichment and separation method of paper-making tobacco flake wastewater" (application number 201010029028.X) published by the same inventor. Enrichment separation was performed and the resulting sludge solids were denoted as "Sludge I". The technological process of the method is: waste water→grid slag blocking→coagulation enrichment→sedimentation→sludge filter press→sludge I.

[0036] "Sludge II": starting from the sludge thickening tank of the current physicochemical-biochemical treatment facilities, the sludge is pretreated ...

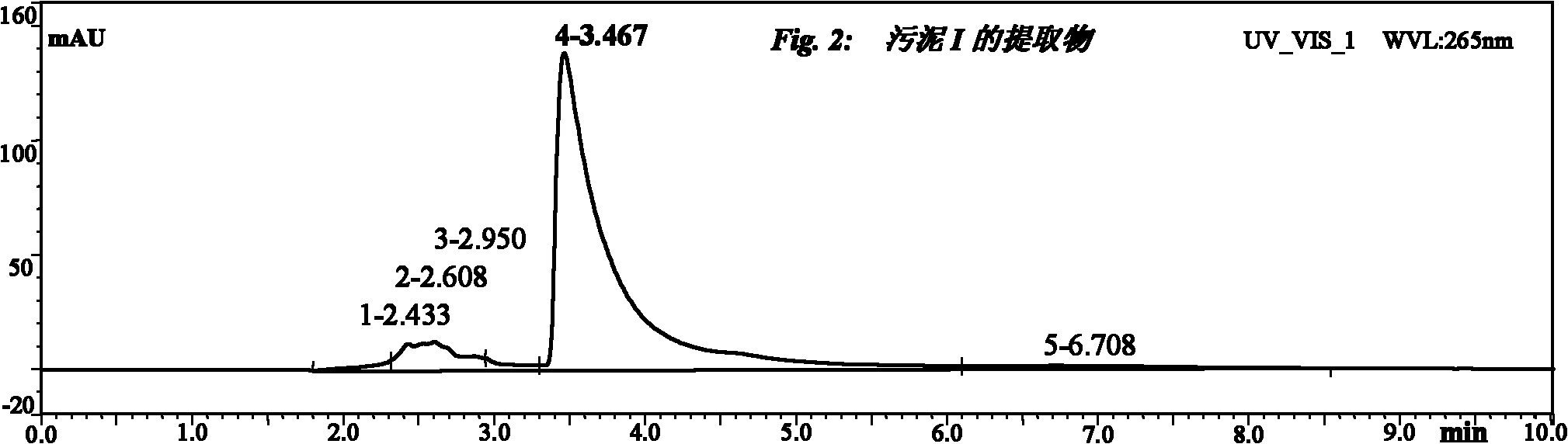

Embodiment 1

[0044] Take 45kg of comprehensive wastewater from the homogeneous tank of the sewage treatment station of Hubei Xinye Tobacco Sheet Development Co., Ltd., and the wastewater is sent as a sample by Wuhan Green Environmental Protection Facility Operation Co., Ltd., and the amount of preparation is carried out in the laboratory (referring to the amount of pure alkaloid obtained is 1g-100g level) extraction test. Firstly, according to the "solid-liquid enrichment and separation method for papermaking tobacco flake wastewater" (application number 201010029028.X), the waste water was enriched and separated, and 1500 g of wet sludge of sludge I was obtained. The solid-liquid enrichment separation process is as follows:

[0045] Wastewater 45kg → pass through 50 mesh standard sieve → coagulation sedimentation → sludge suction filtration → obtain sludge I wet mud 1500g.

[0046] The coagulation agent used in the process of coagulation and sedimentation is prepared in advance according...

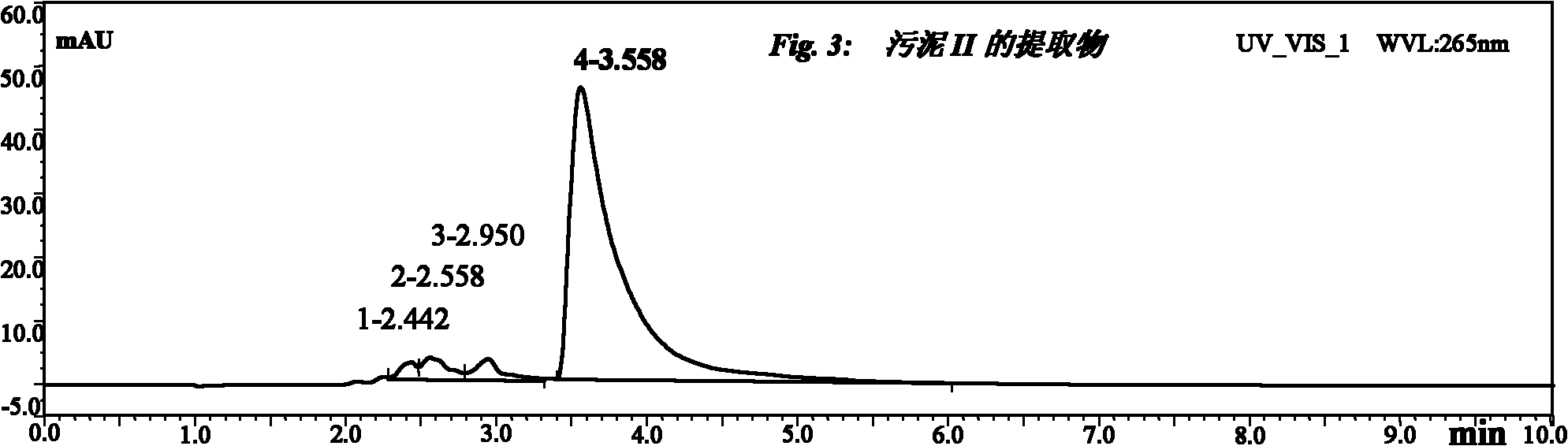

Embodiment 2

[0058] Take 10kg of sludge from the sludge concentration tank of the sewage treatment station of Hubei Xinye Tobacco Sheet Development Co., Ltd., and the sludge is sent as a sample by the Environmental Monitoring Station of Hanyang District, Wuhan City, and is pretreated and alkaloid extracted in the laboratory. First measure the dry sludge content of the sludge to be 8%, add AR grade Ca(OH) 2 160 g of powder was pretreated to obtain 4 kg of wet sludge of sludge II. Its preprocessing flow is as follows:

[0059] Sludge 10kg→adding pretreatment agent→coagulation concentration→sludge suction filtration→obtain 4kg of sludge II wet sludge.

[0060] After 4 kg of the obtained wet sludge was dried in an oven at 80-90° C. in stages, it was pulverized until all of it passed through a 180-mesh standard sieve, and 1000 g of dry sludge powder of sludge II was obtained. Divide the dry mud powder into 8 equal parts, each 125g, and carry out 8 cycles of "extraction-elution" operation resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com