Steel plate for punching-welding axle housing and manufacturing method thereof

A manufacturing method and technology of punching and welding bridges, which are applied to high-performance steel plates formed by 600MPa hot stamping and their manufacturing fields, can solve the problems of difficulty in meeting strength and low strength levels, and achieve unique process path control, improved molten steel cleanliness, The effect of deoxidation degree control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

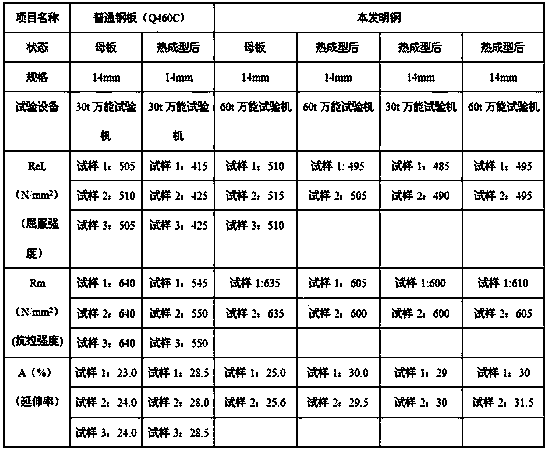

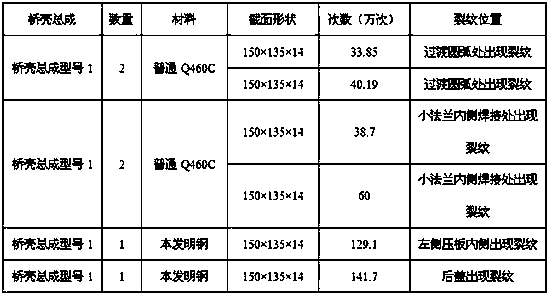

Examples

Embodiment 1

[0049] C: 0.16%, Si: 0.04%, Mn: 1.48%, P: 0.010%, S: 0.003%, Nb: 0.027%, V: 0.039%, Ti: 0.019%, Al: 0.029%, CEV: 0.41%. The rest is Fe and unavoidable impurities.

[0050] The production method of steel plate is as follows:

[0051] 1) The temperature of the molten iron after pretreatment with KR is 1355°C, and the [S] in the treated molten iron is 0.001%.

[0052] 2) The carbon composition at the end point of converter smelting is controlled at [C]=0.074%, Si=0.0045%, S=0.009%, P=0.012%, and the end point temperature is 1640°C; the tapping time of double-block slag is 4.7 minutes, and the tapping process is guaranteed The ladle is stirred with argon blowing throughout.

[0053] 3) In the deoxidation alloying process, the amount of high-carbon ferromanganese, aluminum manganese, ferro-niobium, and ferro-vanadium alloys is converted according to the actual tapping amount and alloy composition, and the alloy is added before 4 / 5 of the tapping; blowing argon at the CAS station ...

Embodiment 2

[0062] C: 0.17%, Si: 0.03%, Mn: 1.54%, P: 0.012%, S: 0.004%, Nb: 0.036%, V: 0.043%, Ti: 0.024%, Al: 0.032%, CEV: 0.44%. The rest is Fe and unavoidable impurities.

[0063] The production method of steel plate is as follows:

[0064] 1) The temperature of the molten iron after pretreatment with KR is 1371°C, and [S] in the treated molten iron is 0.003%.

[0065] 2) The carbon composition at the end point of converter smelting is controlled at [C]=0.10%, Si=0.0005%, S=0.010%, P=0.0086%, and the end point temperature is 1642°C; the tapping time of double-block slag is 4.8 minutes, and the tapping process is guaranteed The ladle is stirred with argon blowing throughout.

[0066] 3) In the deoxidation alloying process, the amount of high-carbon ferromanganese, aluminum manganese, ferro-niobium, and ferro-vanadium alloys is converted according to the actual tapping amount and alloy composition, and the alloy is added before 4 / 5 of the tapping; blowing argon at the CAS station Fee...

Embodiment 3

[0075] C: 0.18%, Si: 0.04%, Mn: 1.58%, P: 0.008%, S: 0.001%, Nb: 0.042%, V: 0.046%, Ti: 0.026%, Al: 0.035%, CEV: 0.45%. The rest is Fe and unavoidable impurities.

[0076] The production method of steel plate is as follows:

[0077] 1) The temperature of the molten iron after pretreatment with KR is 1367°C, and [S]=0.002% in the treated molten iron.

[0078] 2) The carbon composition at the end point of converter smelting is controlled at [C]=0.061%, Si=0.003%, S=0.008%, P=0.010%, and the end point temperature is 1650°C; the tapping time of double-block slag is 4.7 minutes, and the tapping process is guaranteed The ladle is stirred with argon blowing throughout.

[0079] 3) In the deoxidation alloying process, the amount of high-carbon ferromanganese, aluminum manganese, ferro-niobium, and ferro-vanadium alloys is converted according to the actual tapping amount and alloy composition, and the alloy is added before 4 / 5 of the tapping; blowing argon at the CAS station Feed th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com