630MPa high-strength seismic resistance index rebar and production method thereof

A 630mpa, high-strength technology, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problem that the production process is difficult to meet the 630MPa strength and seismic requirements, and the production cost is high, and achieves comprehensive performance. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

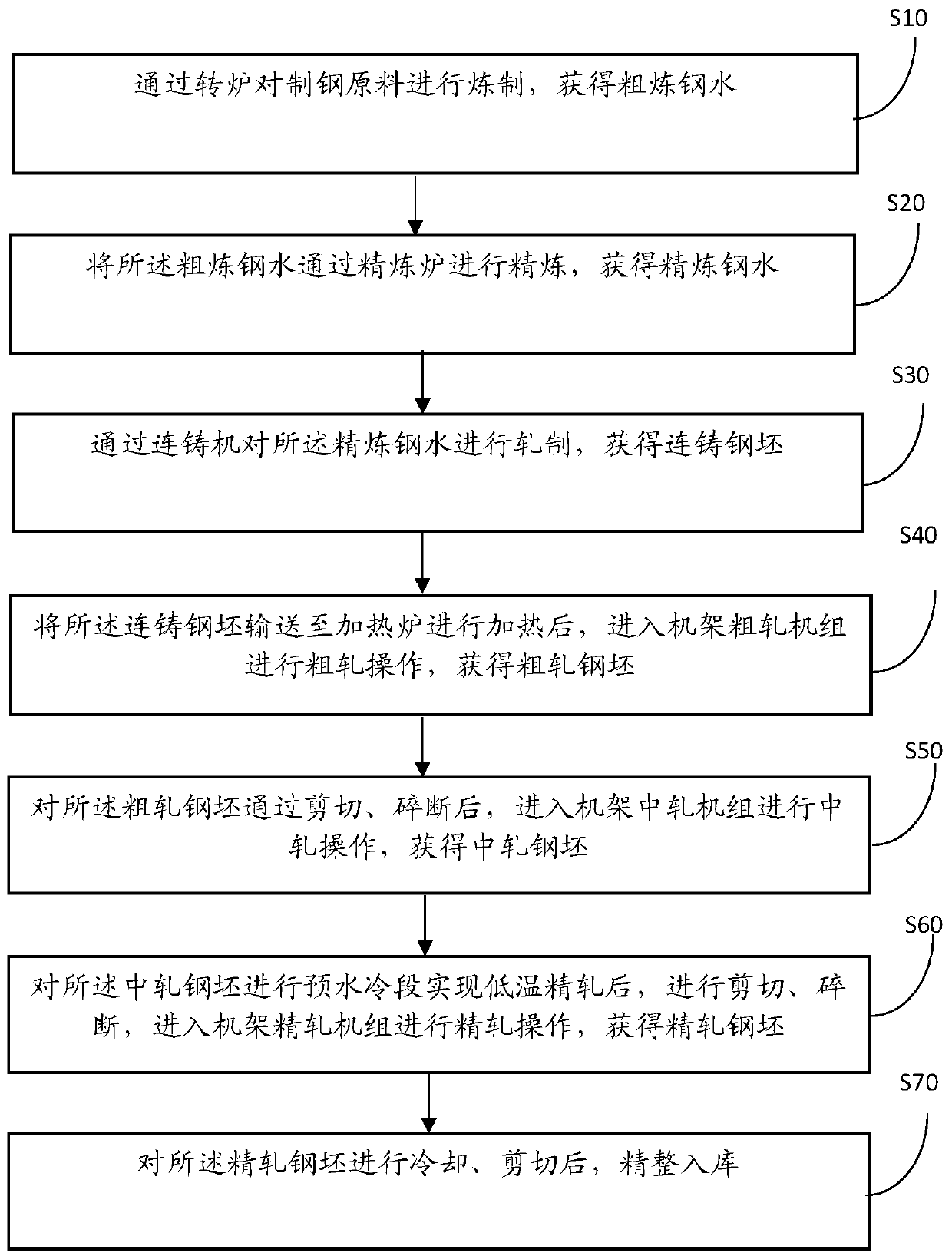

[0038] figure 1 It is a schematic flowchart of a method for producing 630MPa high-strength seismic index steel bars in an embodiment of the present invention. Such as figure 1 As shown, the embodiment of the present invention provides a method for producing 630MPa high-strength seismic index steel bars, the method comprising:

[0039] Step 10: Refining steelmaking raw materials through a converter to obtain crude molten steel.

[0040] Step 20: Refining the crude molten steel through a refining furnace to obtain refined molten steel.

[0041] Step 30: rolling the refined molten steel by a continuous casting machine to obtain a continuous casting billet.

[0042] Step 40: After the continuous casting billet is transported to the heating furnace for heating, it enters the rack rough rolling unit for rough rolling operation to obtain the rough rolled billet.

[0043] Further, before transporting the continuous casting billet to the heating furnace for heating, it includes: in...

Embodiment 2

[0061] The embodiment of the present invention provides a 630MPa high-strength anti-seismic index steel bar, which is suitable for the production method described in Example 1. The composition ratio of the 630MPa high-strength anti-seismic index steel bar is: C: 0.25-0.28%, Si: 0.50- 0.70%, Mn: 1.40-1.60%, S≤0.030%, P≤0.030%, V: 0.010-0.120%, Nb: 0.015-0.025%, N: 0.026-0.033%, and the rest are Fe and unavoidable impurities.

[0062] Further, the crystal grains in the 630MPa high-strength anti-seismic index steel bar are not larger than 4 μm.

[0063] Further, the strength of the 630MPa high-strength seismic index steel bar is 630MPa.

[0064]Specifically, the strength of the 630MPa high-strength seismic index steel bar of the embodiment of the present invention is 630MPa, which meets the requirements of high-strength steel bars, and its chemical composition is C: 0.25-0.28%, Si: 0.50-0.70%, Mn: 1.40-1.60%, S≤0.030%, P≤0.030%, V: 0.010-0.120%, Nb: 0.015-0.025%, N: 0.026-0.033%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com