Shearing device for automatically distinguishing positions of capacitor pins of electronic components

A technology for electronic components and cutting devices, applied in the field of electronic components, can solve the problems of too short pin cutting, economic loss, unfavorable use, etc., and achieve consistent cutting length, high degree of automation, and automatic replacement. bit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

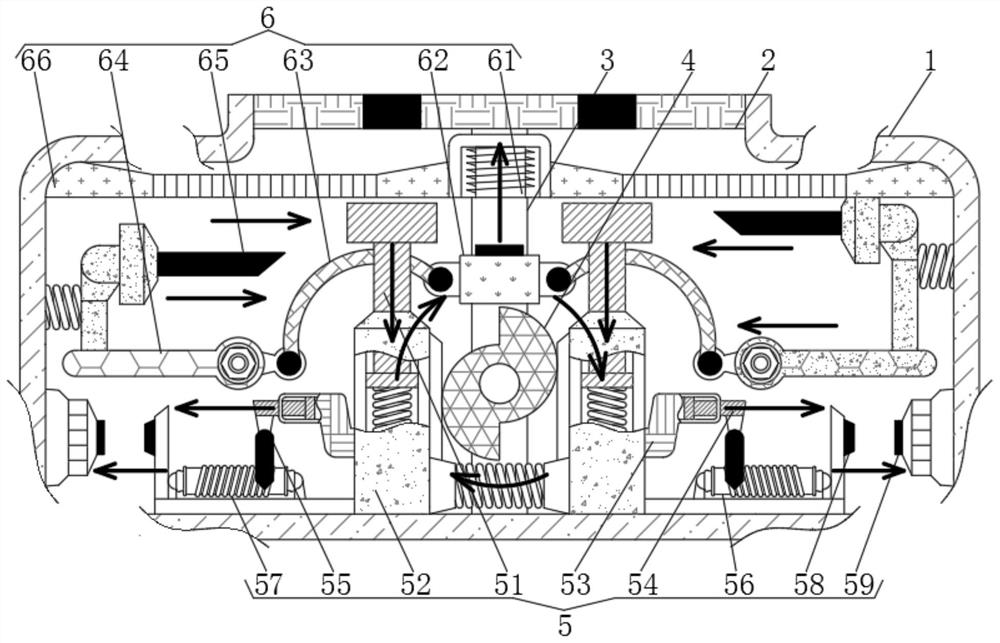

[0022] see Figure 1-3 , a shearing device for automatically identifying the position of capacitor pins of electronic components, including a housing 1, a placement table 2, a support rod 3, a rotary block 4, a driving mechanism 5 and a shearing mechanism 6.

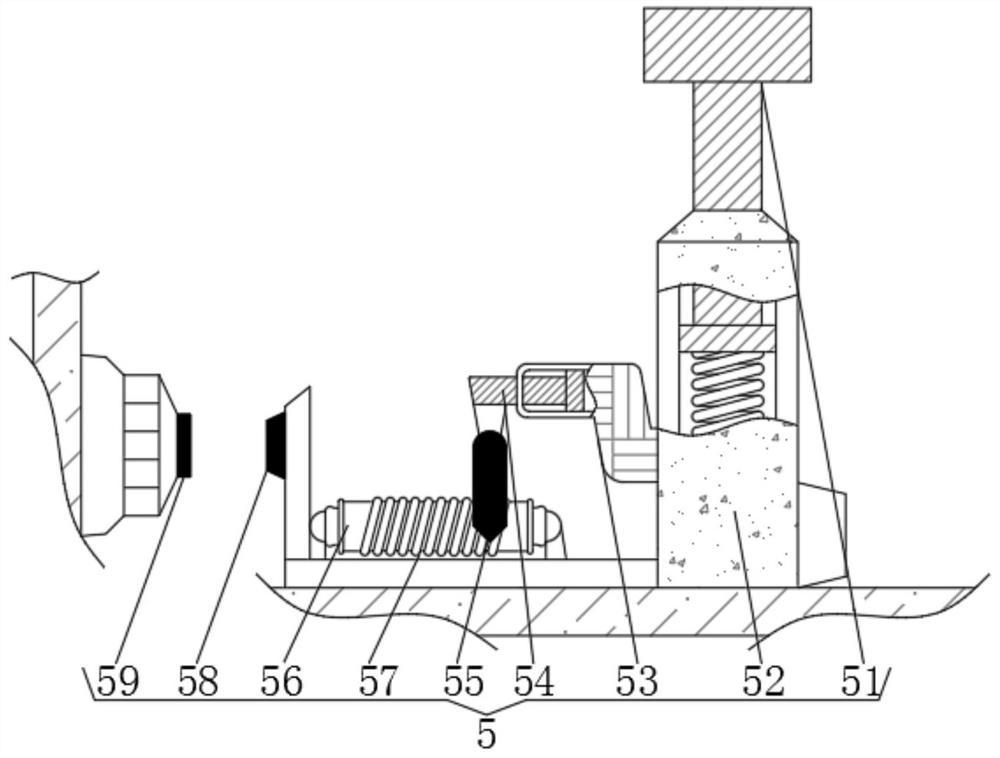

[0023] The drive mechanism 5 includes a pressure rod 51, the outer side of the pressure rod 51 is sleeved with an outer tube 52, the outer side of the outer tube 52 is welded with a side tube 53, the inside of the side tube 53 is movably connected with a piston 54, and the bottom of the piston 54 is welded with a Metal sliding piece 55, the rear side of metal sliding piece 55 is provided with insulating tube 56, and the outer side of insulating tube 56 is wound with resistance coil 57, and the outer side of insulating tube 56 is provided with extruding rod 58, and extruding rod 58 is far away from insulating tube 56 One side of is provided with button 59.

[0024] There are two pressure rods 51 with the same specificati...

Embodiment 2

[0027] see Figure 1-3 , a shearing device for automatically identifying the position of capacitor pins of electronic components, including a housing 1, a placement table 2, a support rod 3, a rotary block 4, a driving mechanism 5 and a shearing mechanism 6.

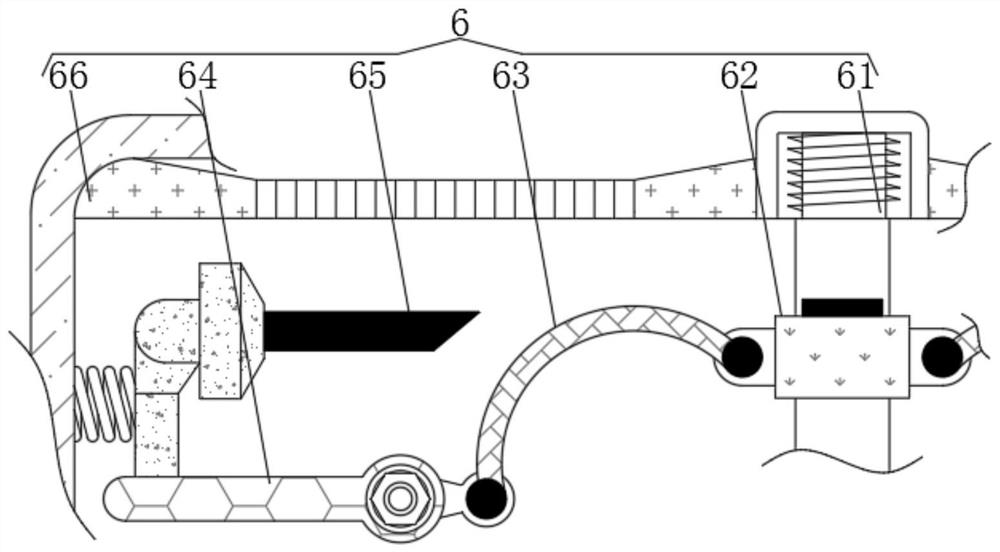

[0028] Also includes a shearing mechanism 6, the shearing mechanism 6 includes an electromagnet 61, a cover block 62 is slidably connected to the bottom of the electromagnet 61, and both sides of the cover block 62 are rotatably connected with a rotating rod 63, and the rotating rod 63 is away from the sleeve block One side of 62 is slidably connected with moving bar 64, and the top of moving bar 64 is provided with cutter 65, and the both sides of electromagnet 61 are connected with connecting frame 66, and electromagnet 61 is electrically connected with left side resistance coil 57, simultaneously It is electrically connected with the button 59, and the inside of the cover block 62 is provided with a through hole, and ...

Embodiment 3

[0031] see Figure 1-3 , a shearing device for automatically identifying the position of capacitor pins of electronic components, including a housing 1, a placement table 2, a support rod 3, a rotary block 4, a driving mechanism 5 and a shearing mechanism 6.

[0032] The drive mechanism 5 includes a pressure rod 51, the outer side of the pressure rod 51 is sleeved with an outer tube 52, the outer side of the outer tube 52 is welded with a side tube 53, the inside of the side tube 53 is movably connected with a piston 54, and the bottom of the piston 54 is welded with a Metal sliding piece 55, the rear side of metal sliding piece 55 is provided with insulating tube 56, and the outer side of insulating tube 56 is wound with resistance coil 57, and the outer side of insulating tube 56 is provided with extruding rod 58, and extruding rod 58 is far away from insulating tube 56 One side is provided with button 59.

[0033] There are two pressure rods 51 with the same specifications...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com