Station switching device for processing interior doors

A technology for station conversion and interior doors, which is applied in transmission devices, metal processing, feeding devices, etc., can solve the problems that workers need to walk around the workbench, and achieve the effect of avoiding disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

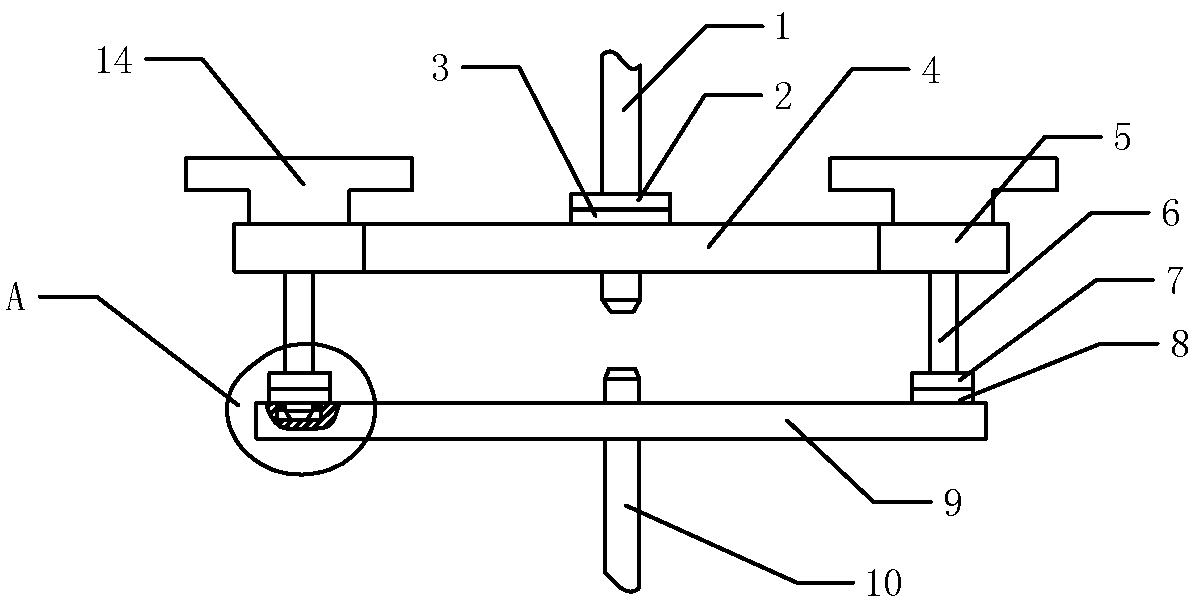

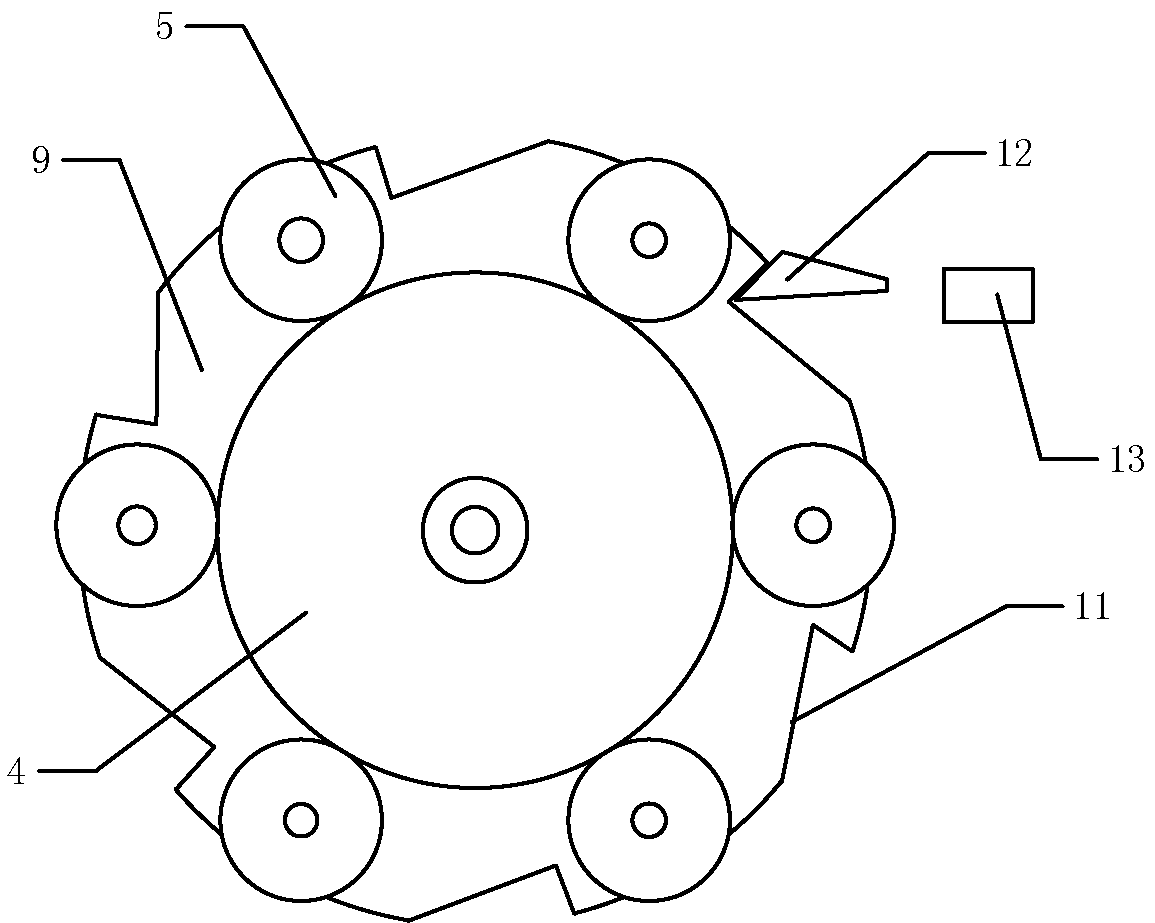

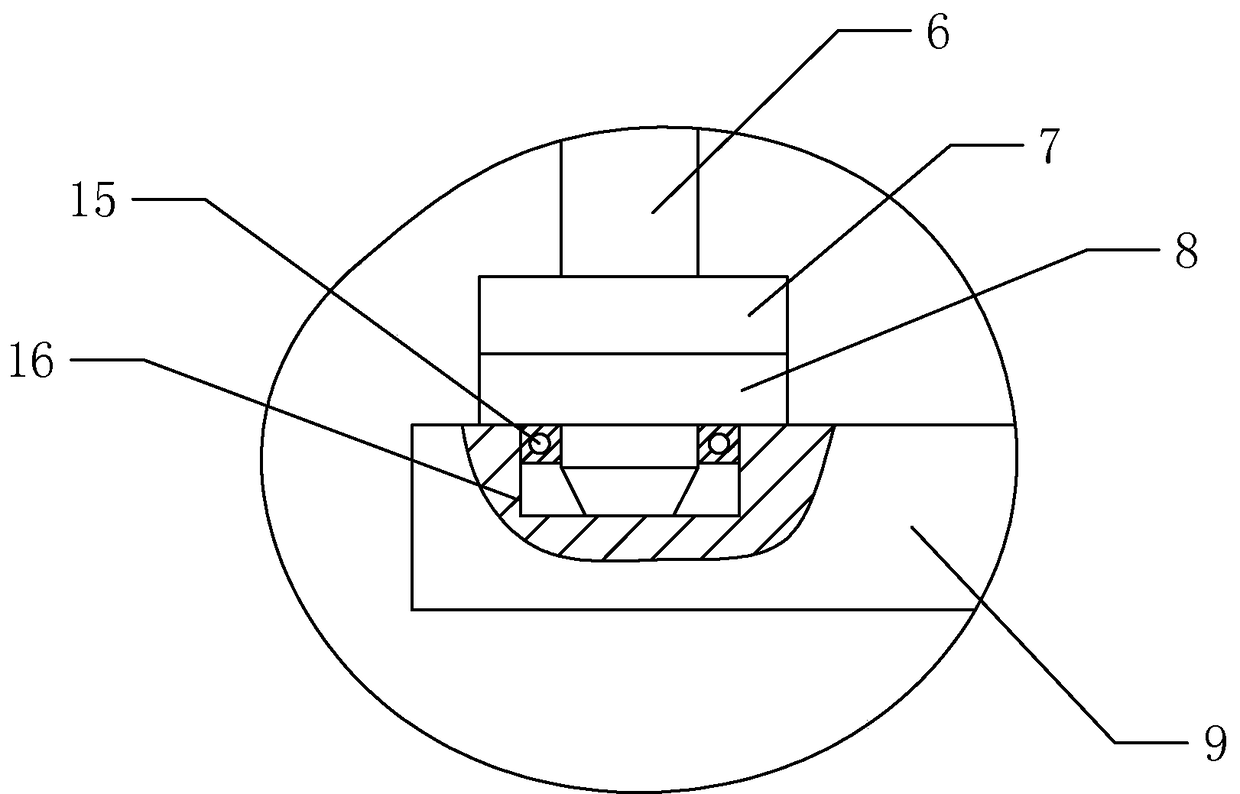

[0016] Such as figure 1 , figure 2 As shown, the station conversion device for processing indoor doors of the present invention includes a rotation shaft 1, a sun gear 4, six planetary shafts 6 and six planetary gears 5, and the sun gear 4 is empty sleeved on the rotation shaft 1 perpendicular to the ground Above, the planetary gear 5 is sleeved on the planetary shaft 6, the six planetary gears 5 are evenly distributed on the periphery of the sun gear 4 and the six planetary gears 5 are all externally meshed with the sun gear 4, and the top of the planetary gear 5 is provided with a workbench 14 , the end of the rotation shaft 1 close to the upper end surface of the sun gear 4 is provided with a first active friction plate 2, and the first active friction plate 2 is keyed to the rotation shaft 1, and the upper end surface of the sun gear 4 is provided with a first slave The moving friction plate 3 is provided with a second driven friction plate 7 on the end of the planetary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com