A kind of processing equipment of metal fireproof composite board

A technology for processing equipment and composite boards, applied in metal processing equipment, welding equipment, non-electric welding equipment, etc., to avoid mechanism damage and improve processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

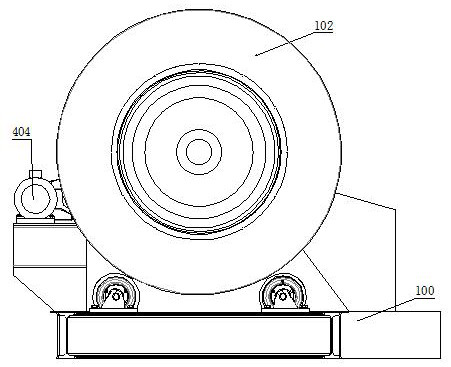

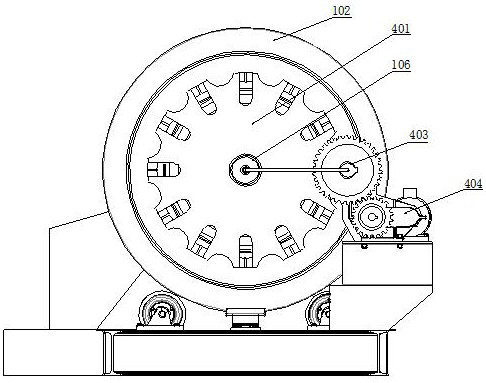

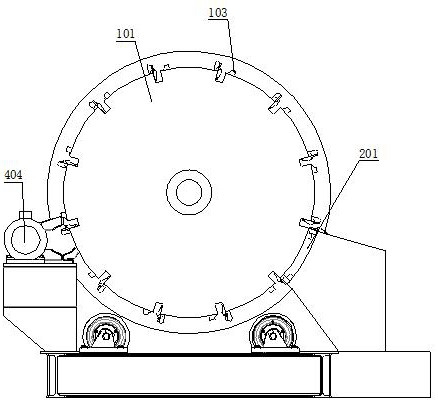

[0039] like Figure 1-Figure 12 As shown, a metal fireproof composite panel processing equipment includes a rotating body 101, the rotating body 101 is rotatably arranged on the base 100, the two ends of the rotating body 101 are provided with end covers 102, and the outer periphery of the rotating body 101 is provided with A plurality of auxiliary processing units 103 distributed in a uniform annular array, the auxiliary processing unit 103 includes a first fixed plate 104 and a first movable plate 105, the first fixed plate 104 is fixedly connected with the rotating body 101, and the first movable plate 105 passes through the first The connection between the movable shaft and the rotating body 101 in rotation;

[0040] The base 100 is also provided with a main processing unit. The main processing unit includes a main processing seat 201. The side of the main processing seat 201 close to the rotating body 101 is provided with an arc surface parallel to the outer circular surf...

Embodiment 2

[0063] like Figure 13-Figure 16 As shown, different from the first embodiment, the first movable plate 105 of the auxiliary processing unit 103 and the second movable plate 203 of the main processing unit are reset by a reset mechanism, and the reset mechanism includes a reset mechanism arranged on the first movable shaft and the second movable shaft. The second torsion spring, the base 100 is provided with a reset push block 501, and the reset push block 501 is connected to the first linear drive mechanism 502; the reset push block 501 is provided with a first piston 503 on the side close to the second movable plate 203, away from the first linear drive mechanism 502. One side of the two movable plates 203 is provided with a second piston 504. The reset push block 501 is provided with a piston cylinder that cooperates with the first piston 503 and the second piston 504. The piston cylinder is connected to an air supply pipe or a liquid supply pipe. Telescoping of a piston 50...

Embodiment 3

[0066] like Figure 17 As shown, different from Embodiment 1 and Embodiment 2, the bottom of the main processing base 201 of the main processing unit slides through the sliding rails on the connecting base 100 . With the linear drive mechanism 601 , the main machining base 201 can move along the slide rail to change the distance from the rotating body 101 .

[0067] The main machining base 201 can be kept away from the rotating body 101 by the second linear drive mechanism 601 , so that the second metal plate can be easily arranged on the main machining base 201 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com