High-resilience composite filling fiber material preparation device

A technology for filling fiber and preparing equipment, which is applied in the direction of mechanical material recycling, plastic recycling, recycling technology, etc. It can solve the problems of poor crushing effect of raw materials, incomplete crushing of raw materials, and large space for the crusher, and achieves compact structure and space saving. The effect of high utilization rate and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

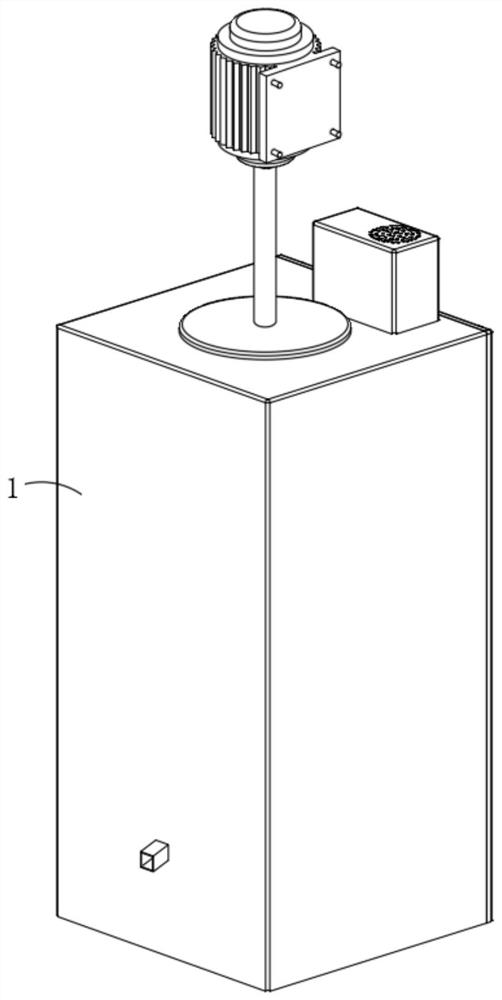

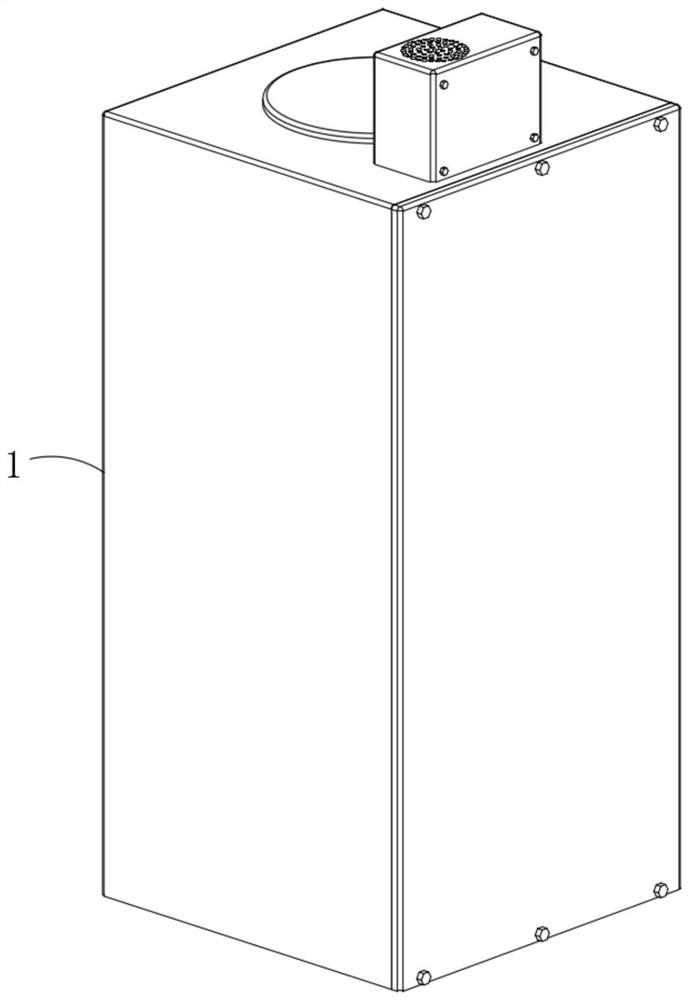

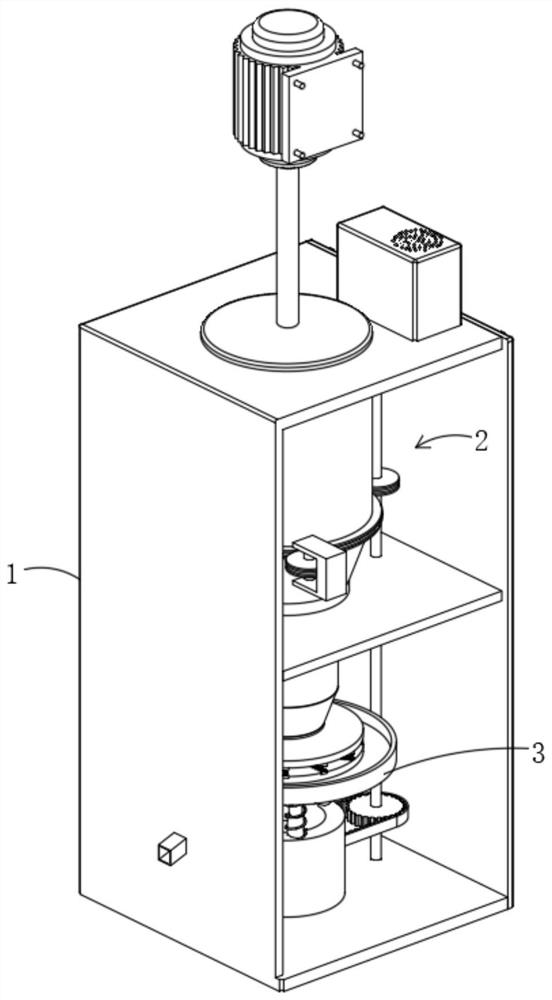

[0034] Refer Figure 1-9: High-back elastic composite filling fiber material preparation means, including a pulverizer for pulverizing regenerative polyester bottle sheet, the pulverizer comprising: pulverizing machine body 1, setting for mounting and stabilizing, pulverizing machine body 1 The top center is provided with a box cover, which is used to put the raw material. The inner portion of the pulverizer body 1 is provided with a pulverizing mechanism 2 for pulverizing the material, the pulverizing mechanism 2 includes power components, pulverizing tube 211, transfer tower 215 The mounting plate 216 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com