Medical chemical pharmaceutical mixer

A mixer and chemical technology, applied in mixers, mixers with rotary stirring devices, mixer accessories, etc., can solve the problems of poor mixing effect, long mixing time, and reduce particle porosity, and achieve fine mixing and stirring of materials. , Avoid mixing time, avoid the effect of incomplete crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

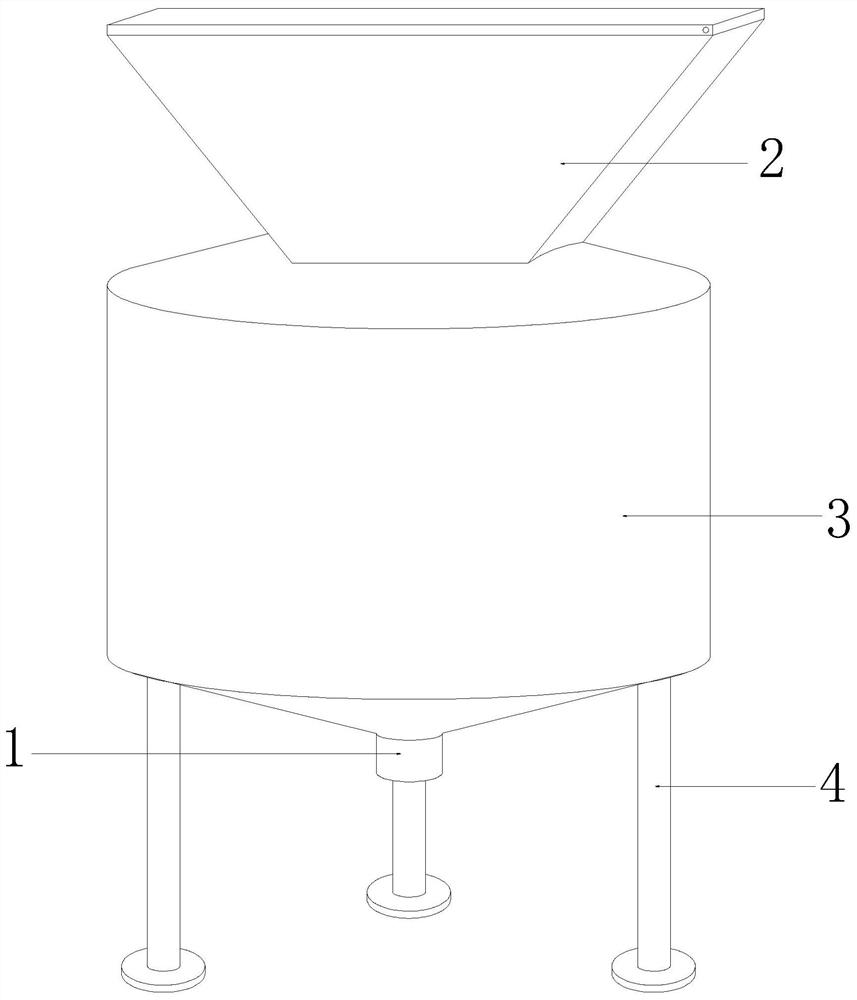

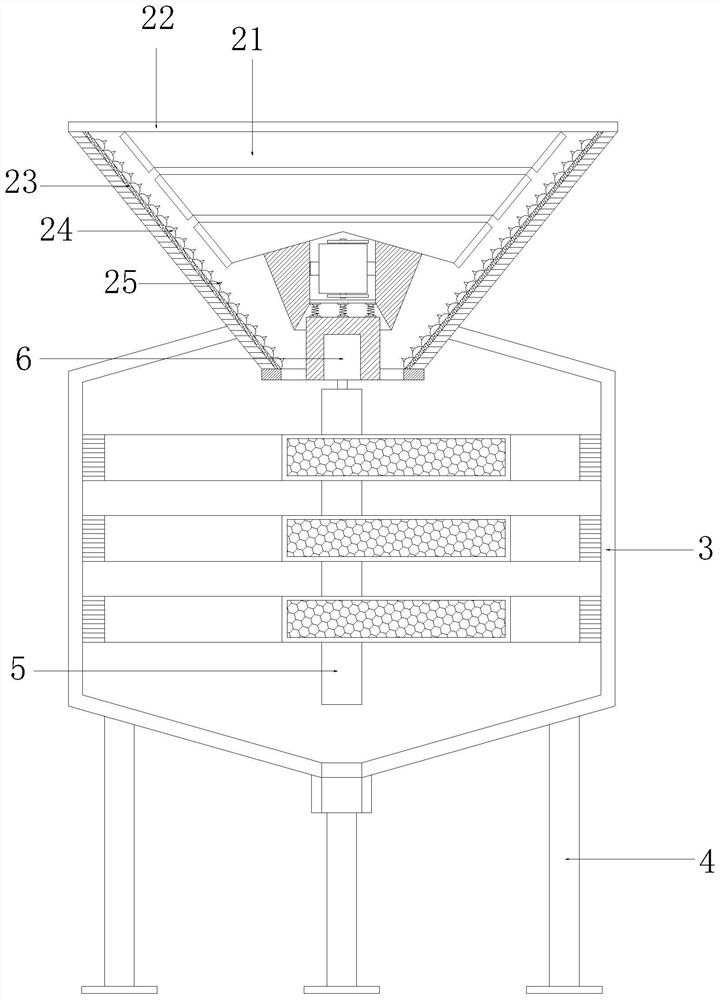

[0023] like figure 1 As shown, the present invention provides a kind of medical chemical industry pharmacy mixing machine, and its structure comprises discharge valve 1, crushing device 2, mixing cylinder 3, support column 4, mixing and agitating device 5, motor 6, and the top of described mixing cylinder 3 is installed There is a crushing device 2, and a discharge valve 1 is fixed at the center of the bottom. The three corners of the bottom surface of the mixing cylinder 3 are vertically connected with support columns 4. The inside of the mixing cylinder 3 is provided with a mixing and stirring device 5. The mixing The stirring device 5 is connected with a motor 6 installed at the bottom of the pulverizing device 2 .

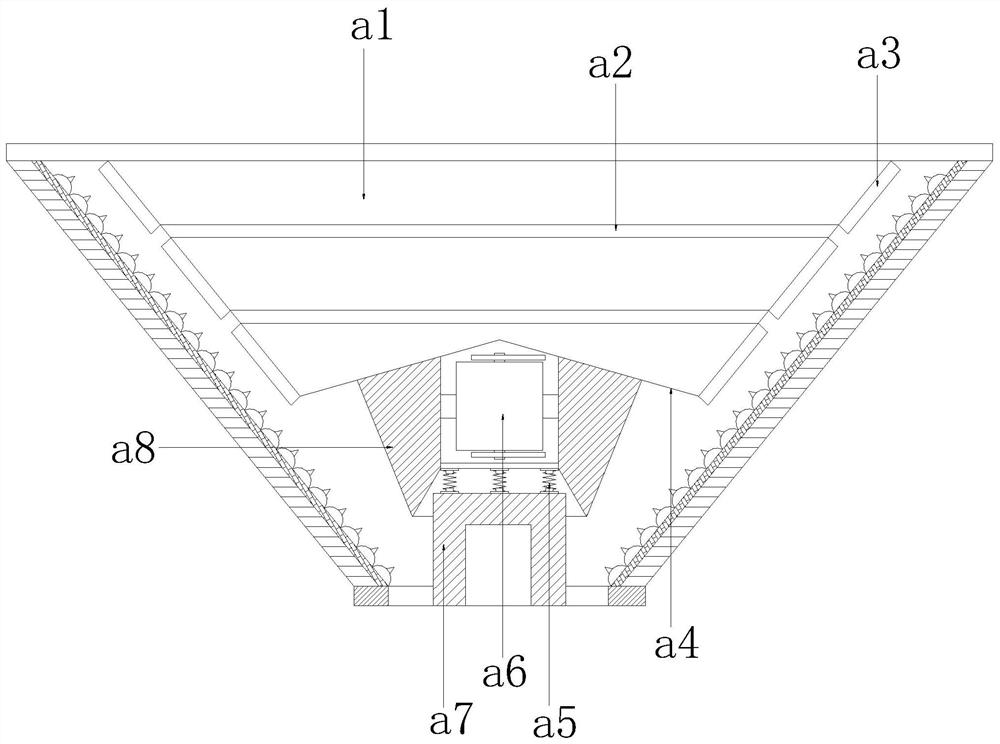

[0024] like figure 2 As shown, the crushing device 2 includes a vibration mechanism 21, a dust-proof cover 22, an isosceles trapezoidal box 23, an elastic pad 24, and spines 25, and the top hinge of the isosceles trapezoidal box 23 is connected with a dust-pr...

Embodiment 2

[0034] like figure 1 As shown, the present invention provides a kind of medical chemical industry pharmaceutical mixing machine, and its structure comprises discharge valve 1, crushing device 2, mixing cylinder 3, support column 4, mixing and agitating device 5, motor 6, and the top of described mixing cylinder 3 is installed There is a crushing device 2, and a discharge valve 1 is fixed at the center of the bottom. The three corners of the bottom surface of the mixing cylinder 3 are vertically connected with support columns 4. The inside of the mixing cylinder 3 is provided with a mixing and stirring device 5. The mixing The stirring device 5 is connected with a motor 6 installed at the bottom of the pulverizing device 2 .

[0035] like Figure 5As shown, the mixing and stirring device 5 includes a cutting blade 51, a central shaft 52, a mounting sleeve 53, a stirring blade 54, and a silicone brush 55. The top of the central shaft 52 is connected to the output shaft of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com