Raw material crushing equipment for feed

A raw material pulverization and equipment technology, which is applied in feed, lighting and heating equipment, heating devices and other directions, can solve the problems of difficult secondary pulverization, incomplete pulverization, and feed destruction, etc., to achieve economic benefits, improve preservation effect, Avoid the effect of dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

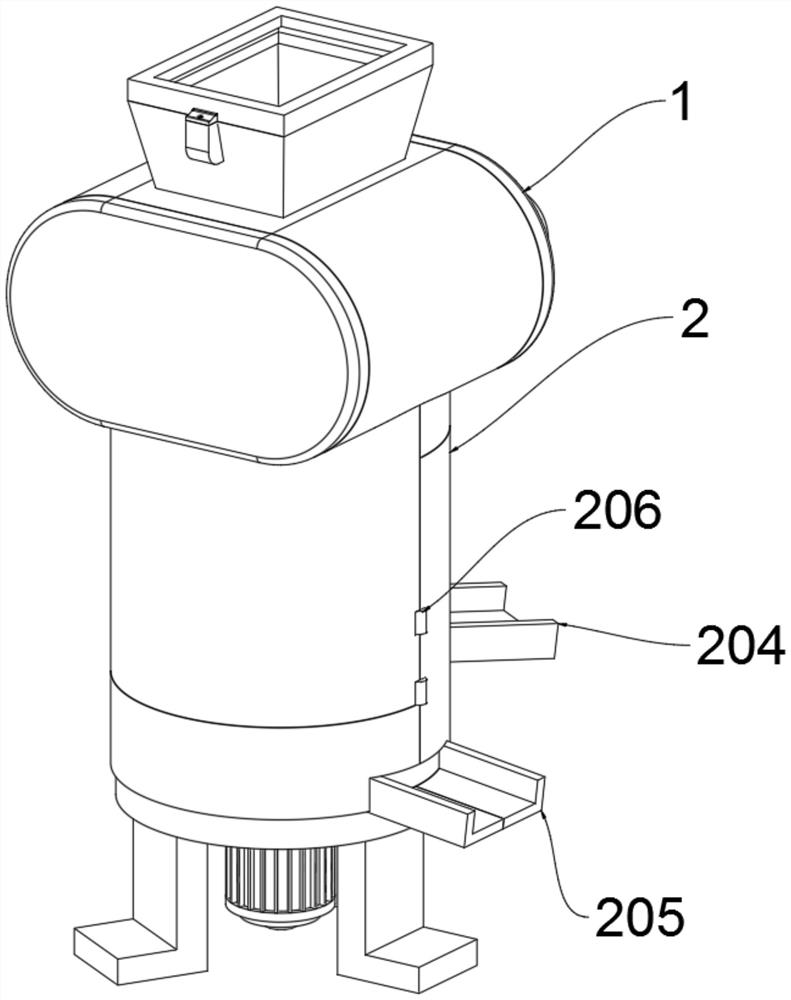

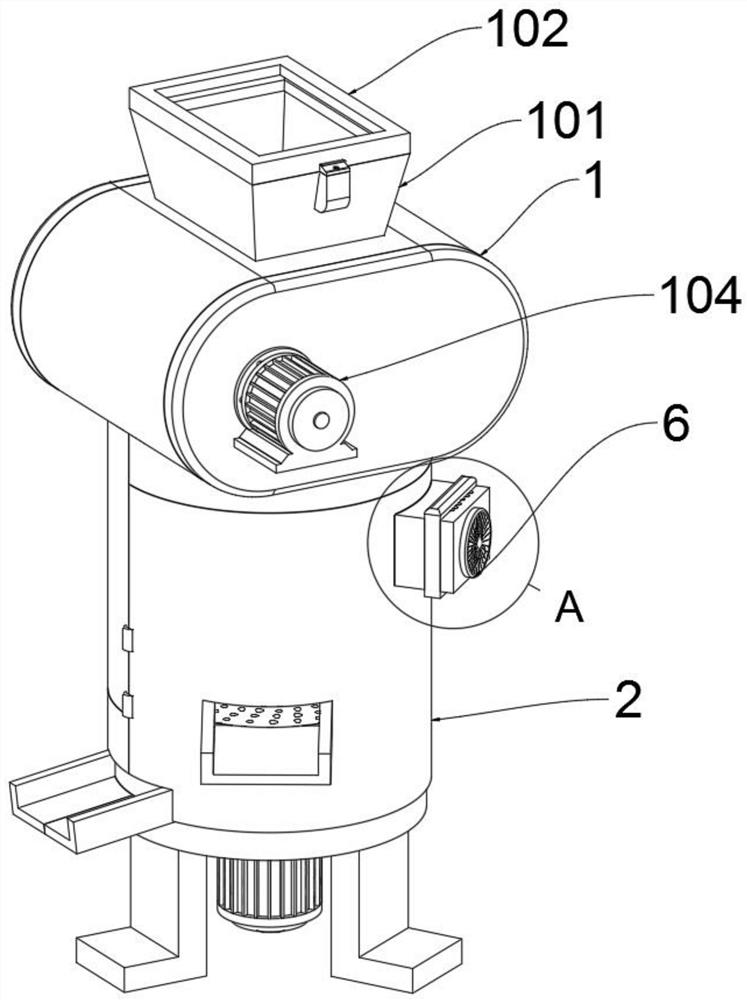

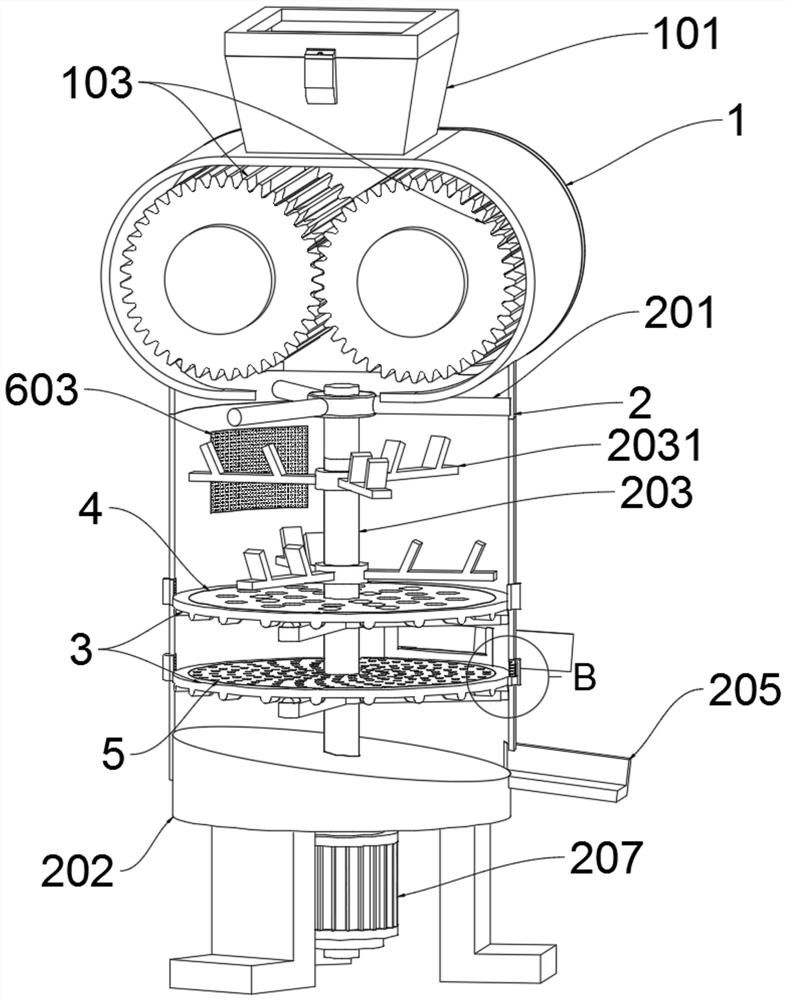

[0051] as attached figure 1 to attach Figure 8 Shown:

[0052] The invention provides a raw material crushing equipment for feed, including a crushing device 1;

[0053] The top of the crushing device 1 is provided with a feeding port 101, and two crushing shaft knives 103 engaged with each other are installed in rotation in the crushing device 1, and a first motor 104 is installed at the rear end of the crushing device 1, and the crushing shaft knife 103 is installed on the On the transmission shaft of a motor 104, a crushing device 2 is installed at the bottom of the crushing device 1;

[0054]The top of the rotating shaft 203 inside the crushing device 2 is rotatably connected to the three-jaw support plate 201, two crushing blades 2031 are installed on the rotating shaft 203, and a second motor 207 is installed at the bottom of the crushing device 2, and the second motor 207 is connected to the rotating shaft 203. The shafts 203 are connected, and the crushing device 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com