Patents

Literature

31results about How to "Realize intermittent discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

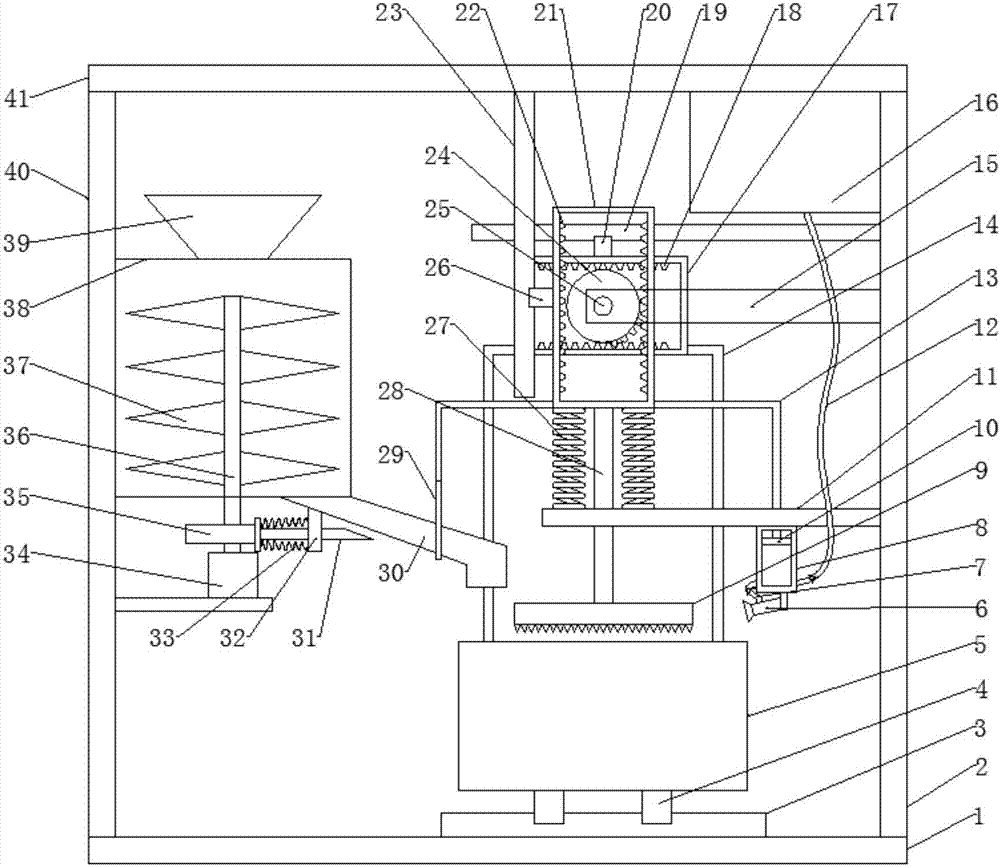

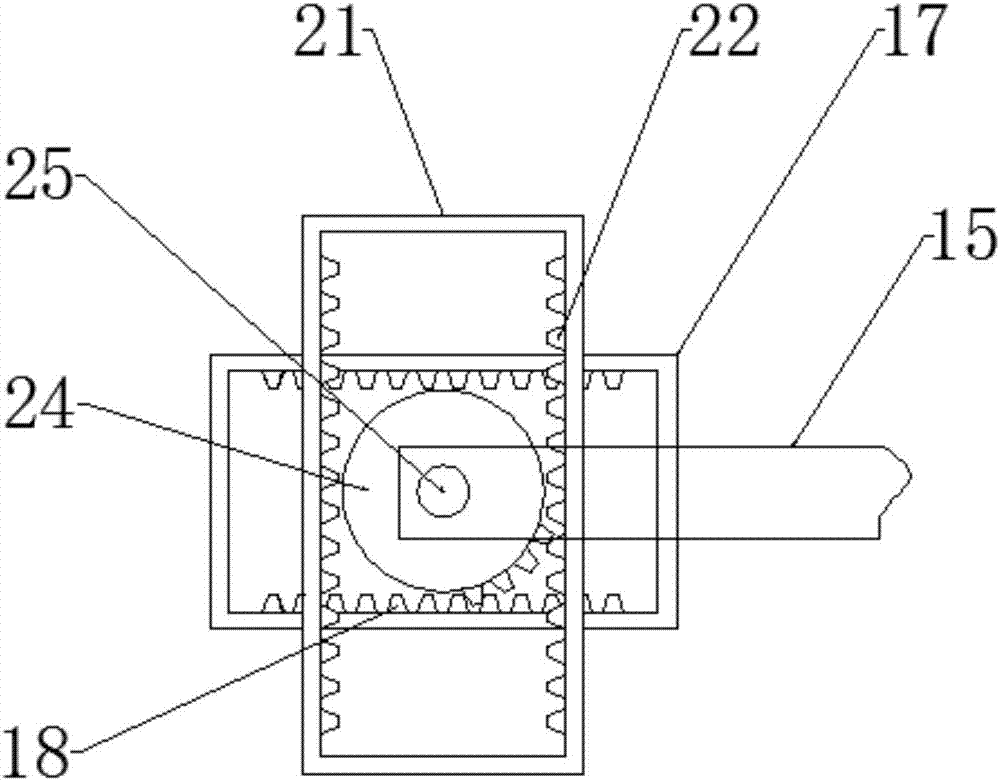

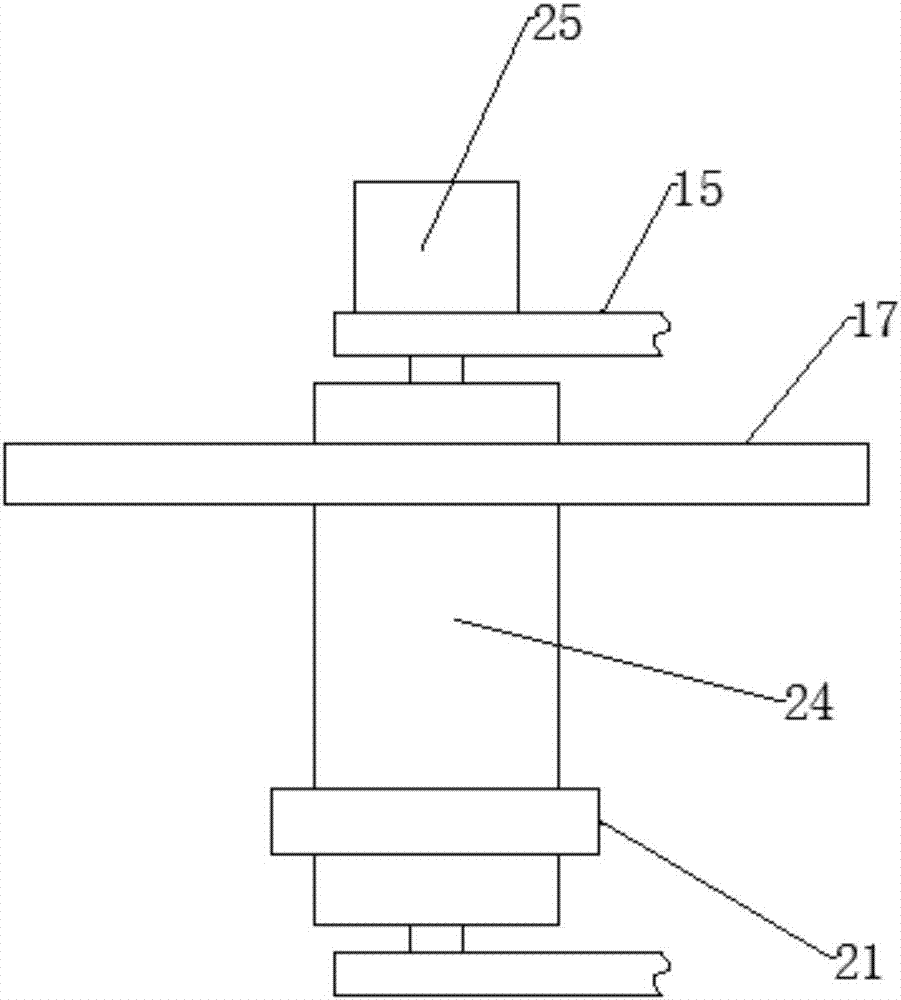

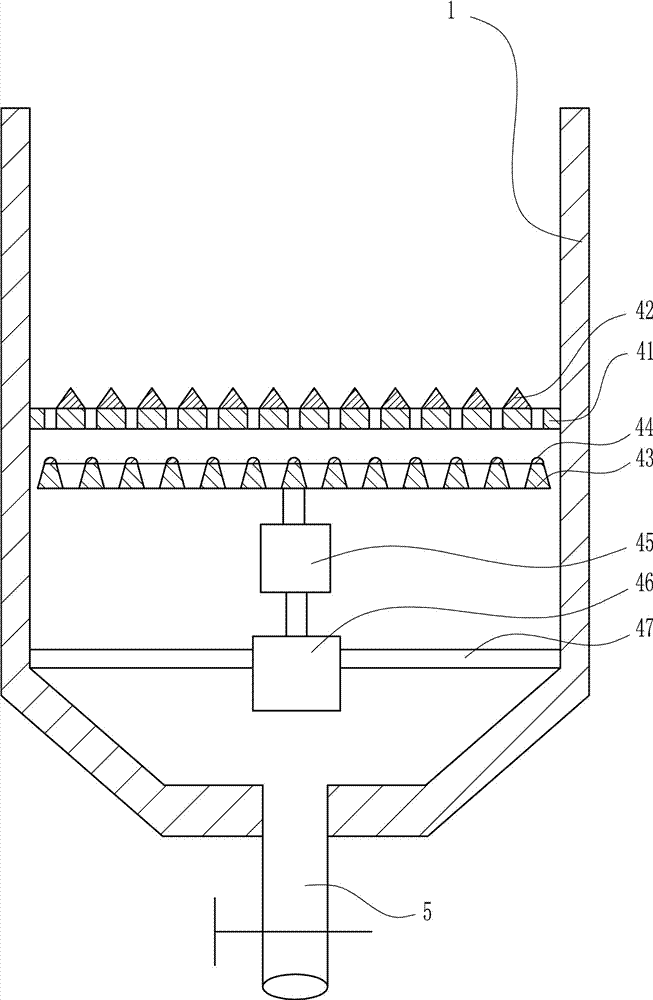

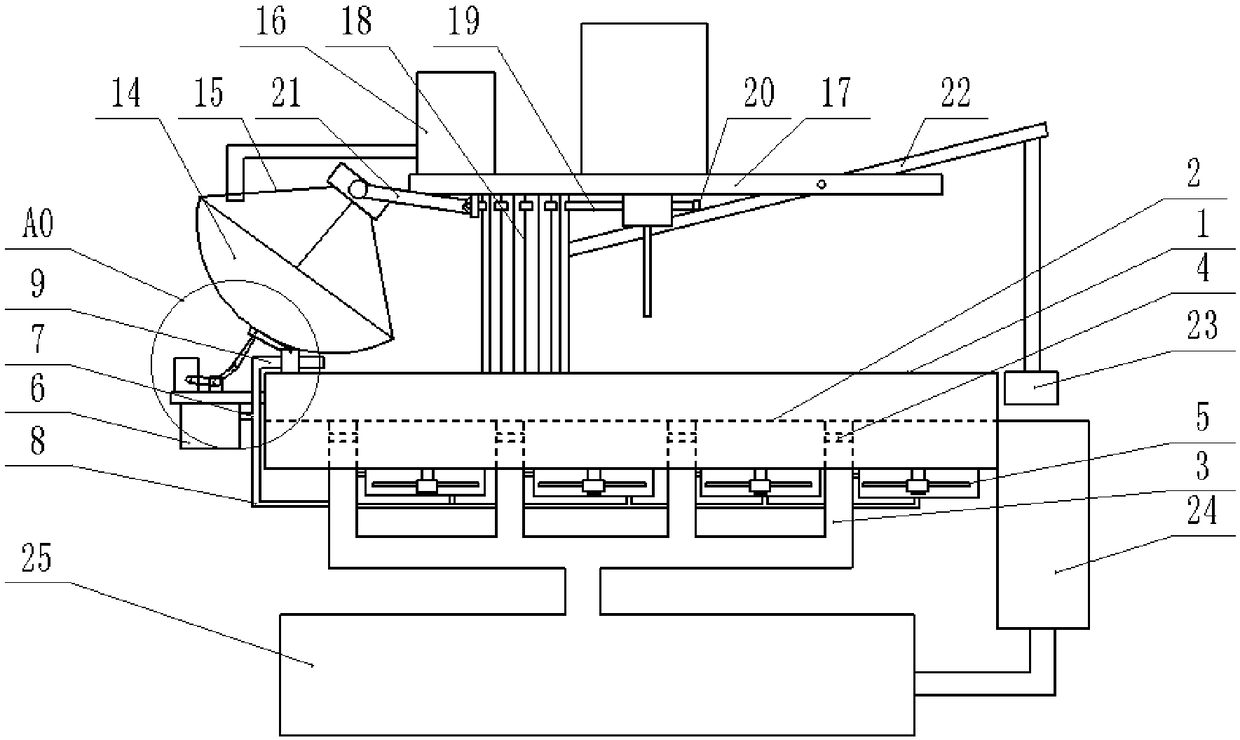

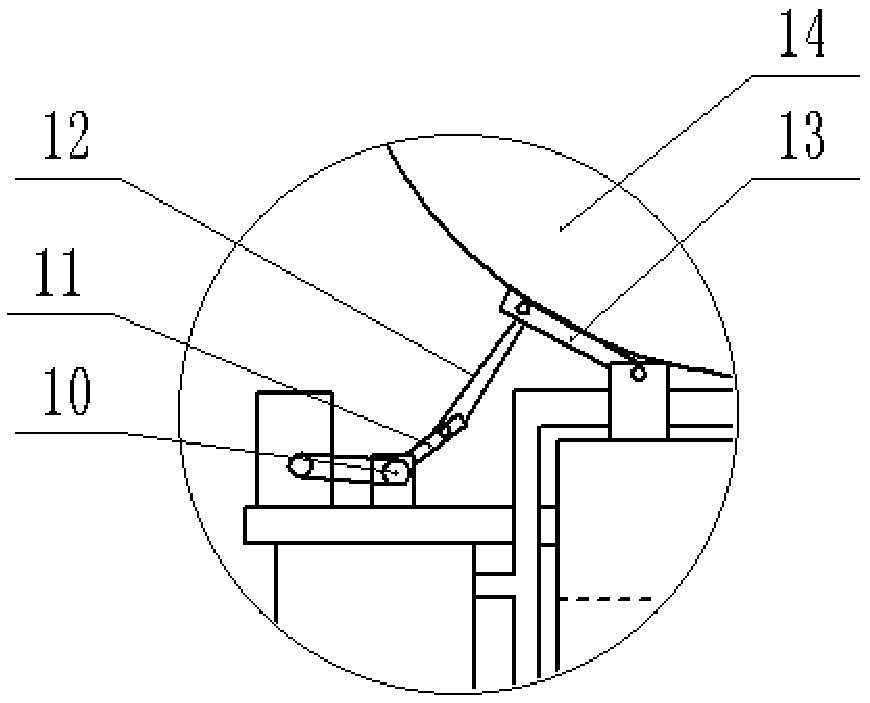

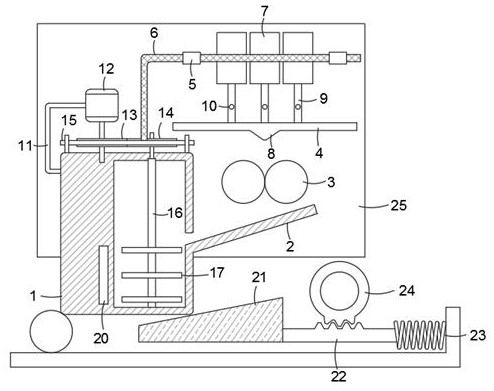

Efficient medical waste smashing and disinfecting treatment device

InactiveCN107413484AAvoid cloggingAvoid wastingMedical waste disposalGrain treatmentsDisinfectantSprayer

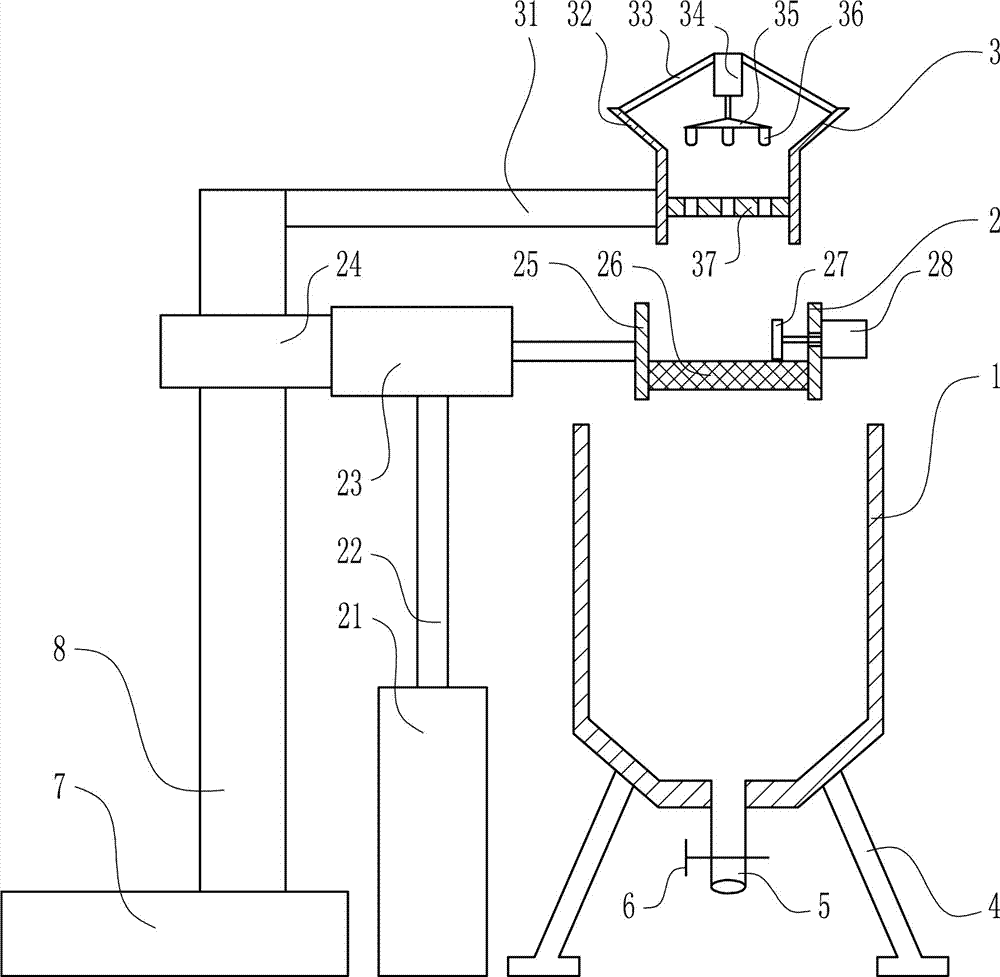

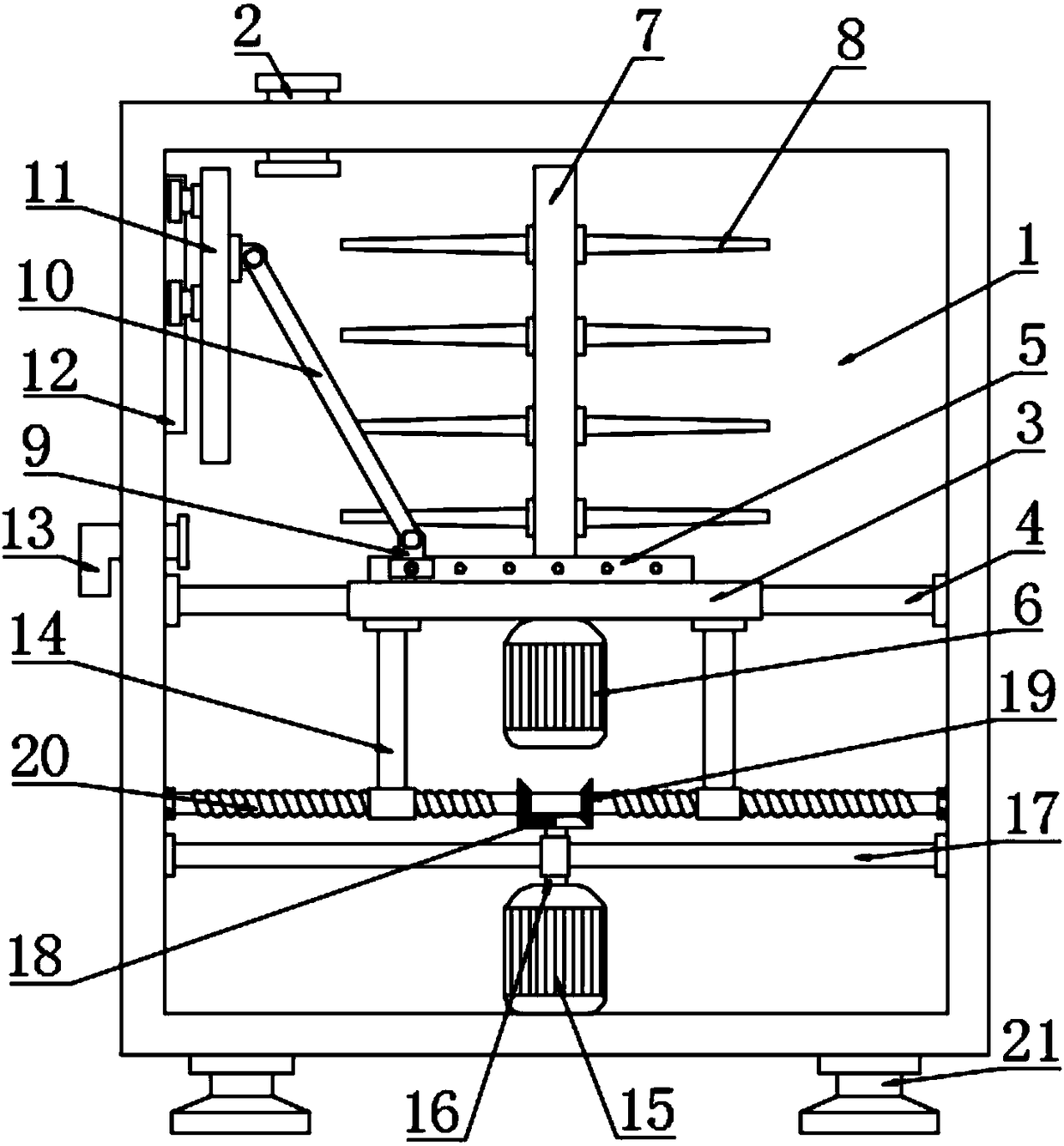

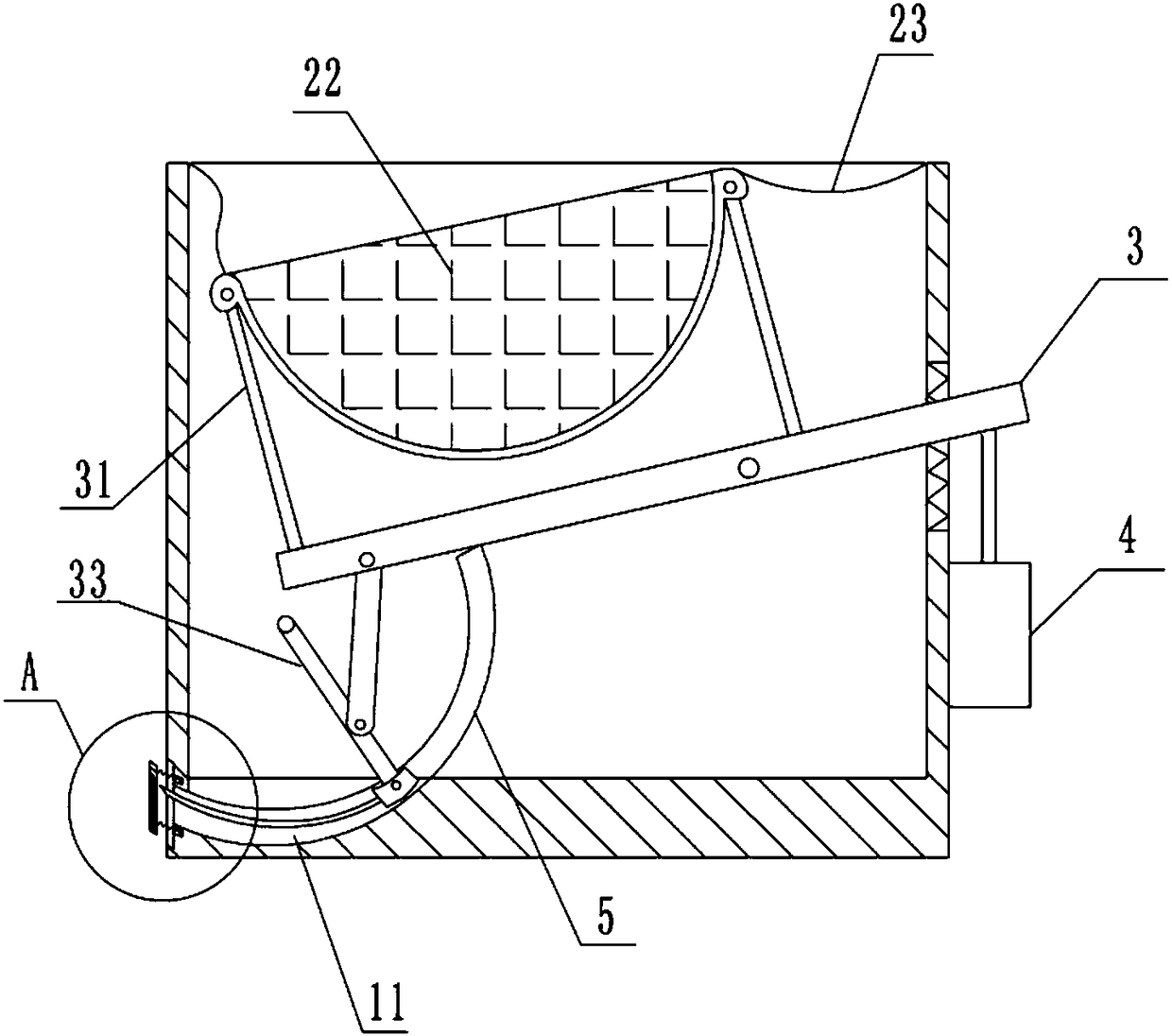

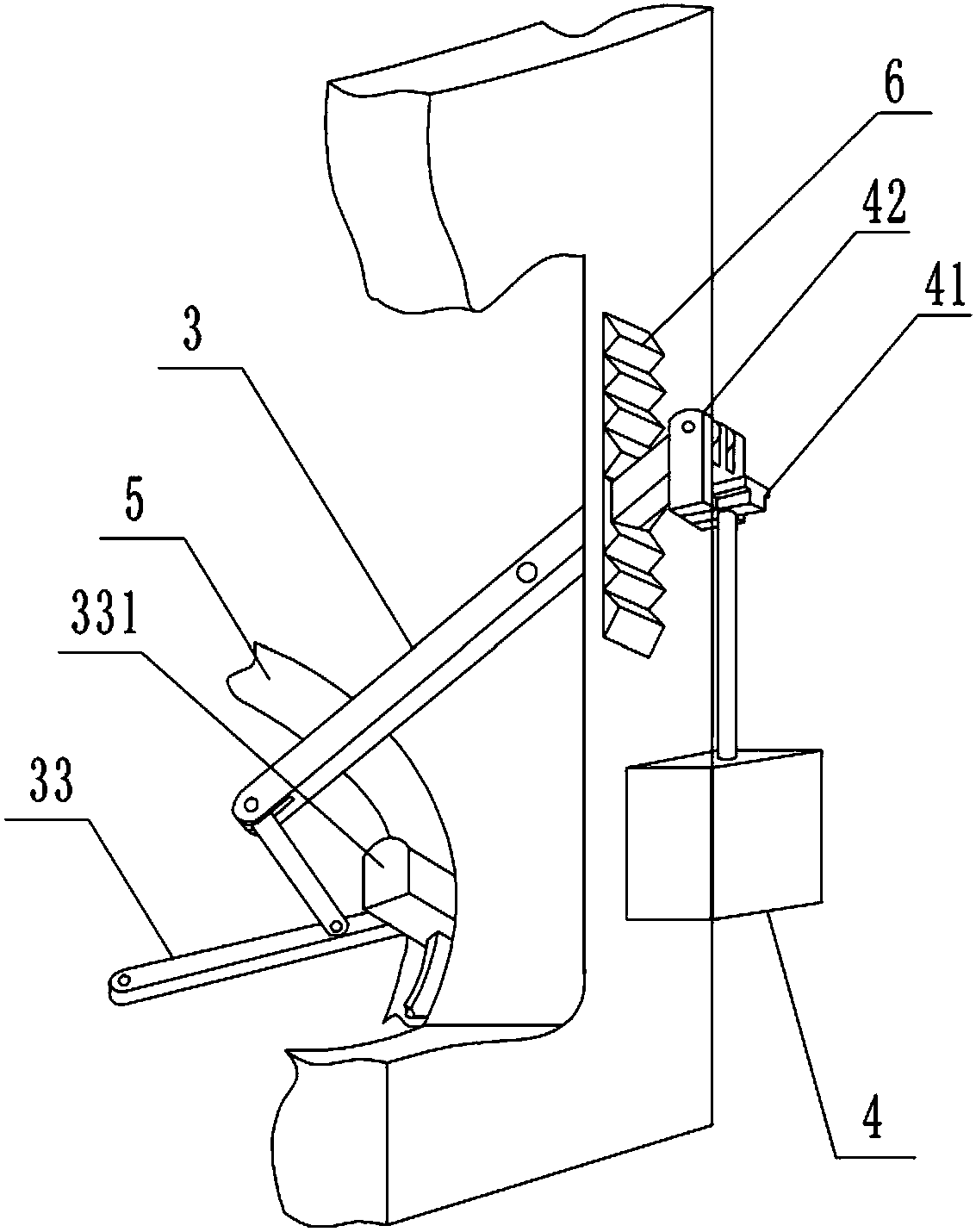

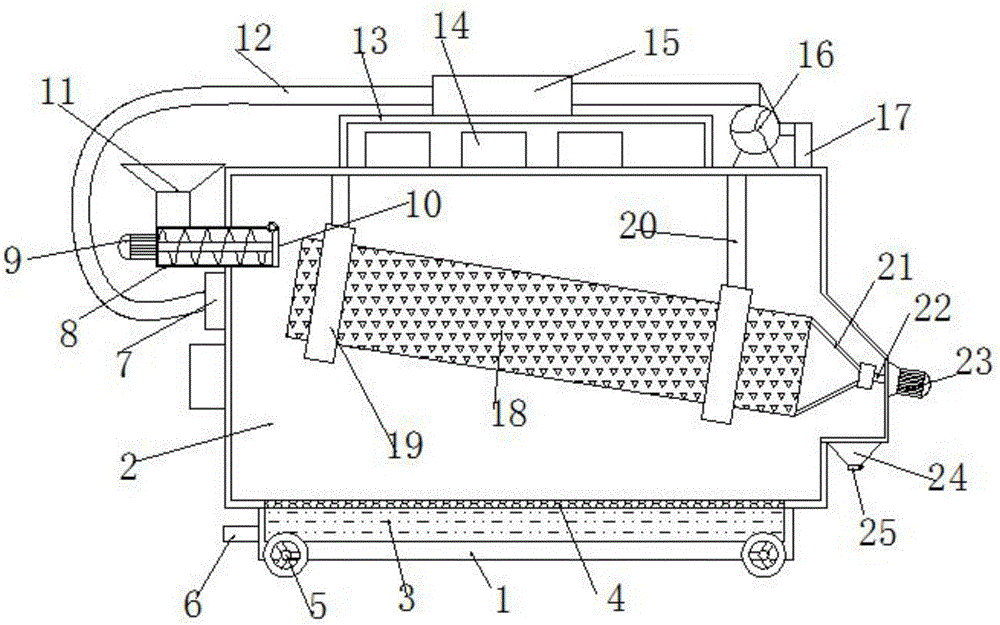

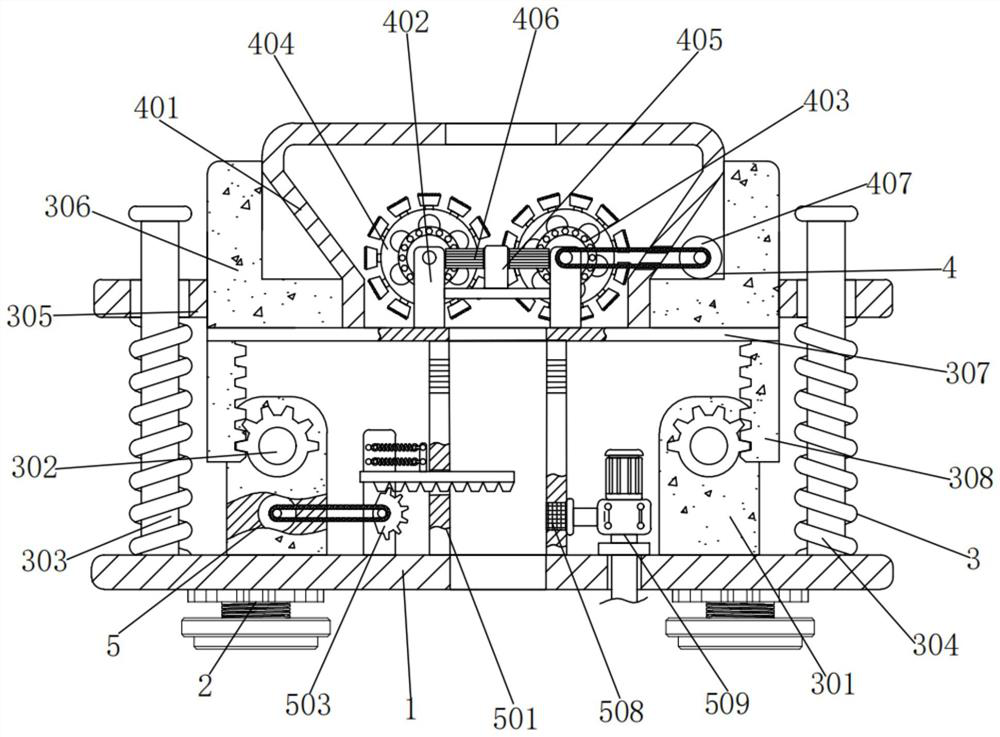

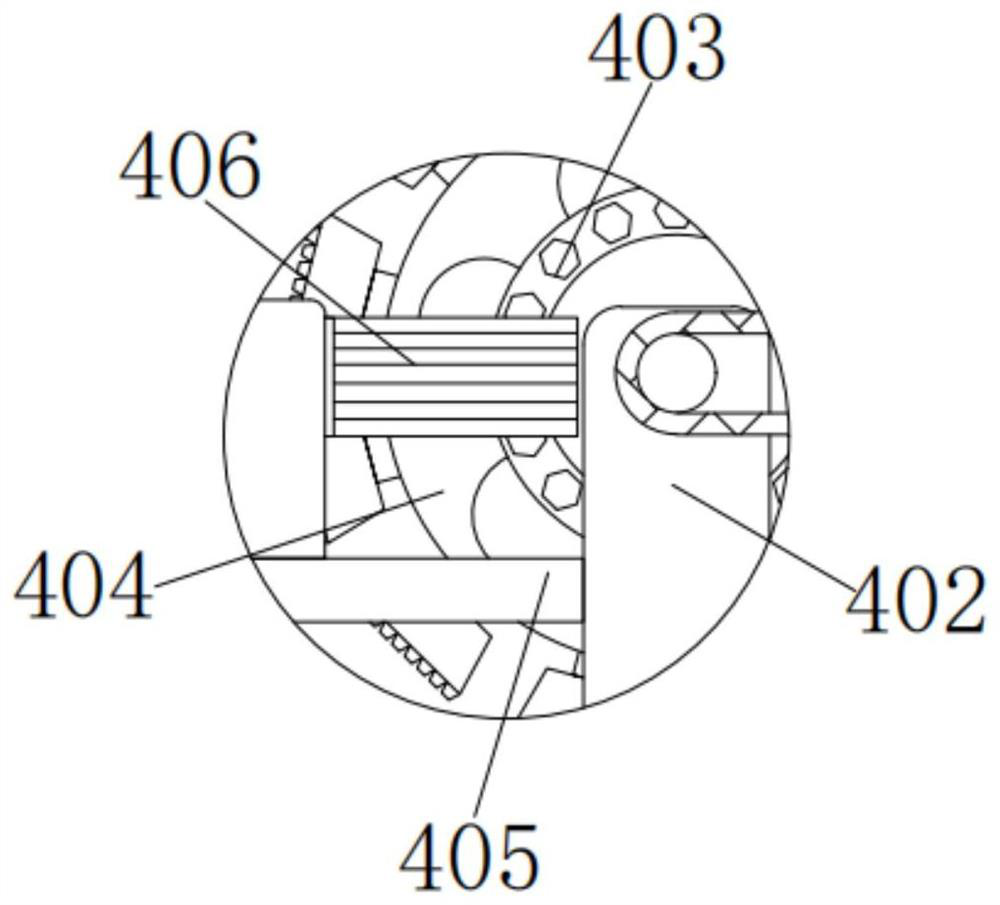

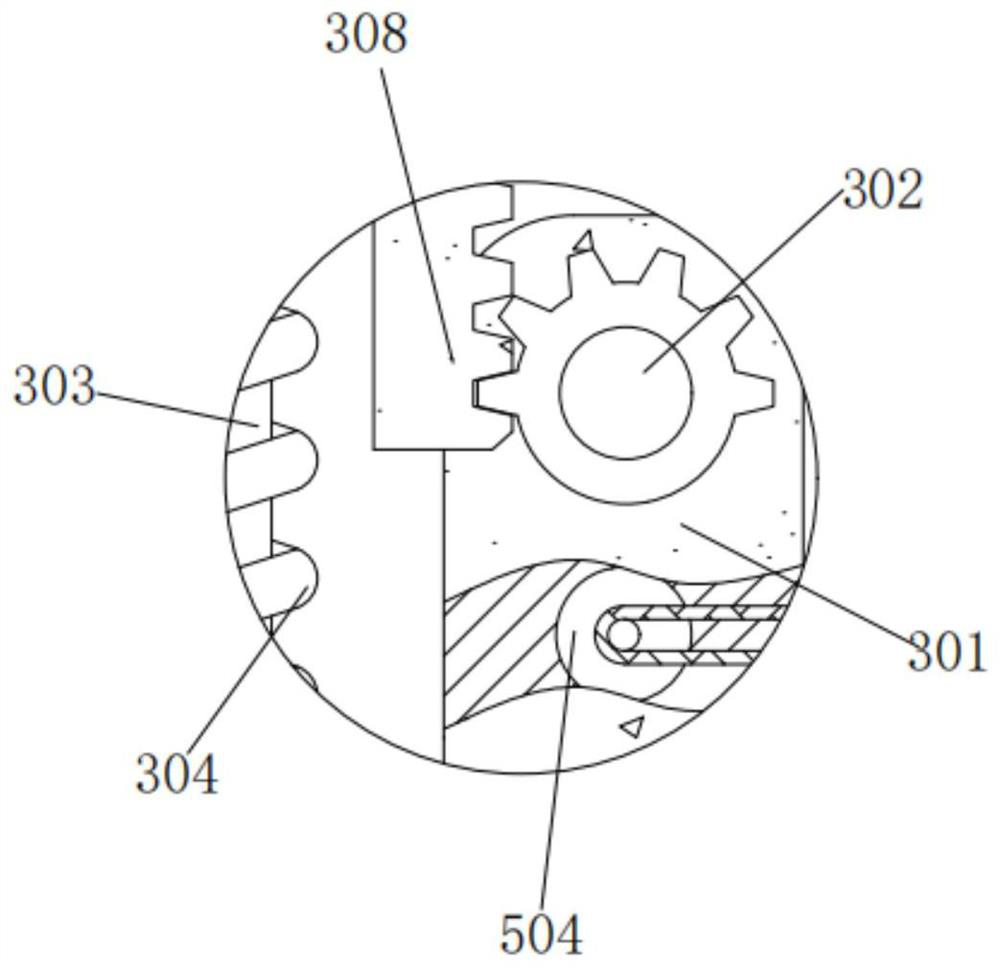

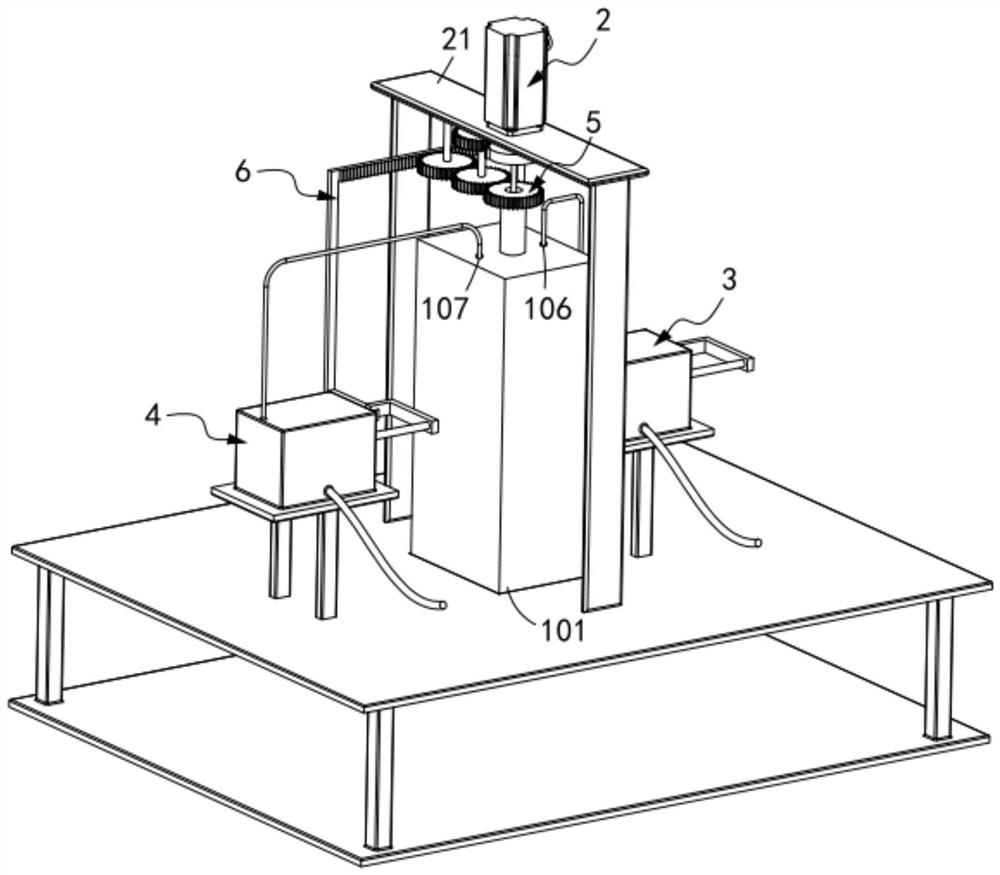

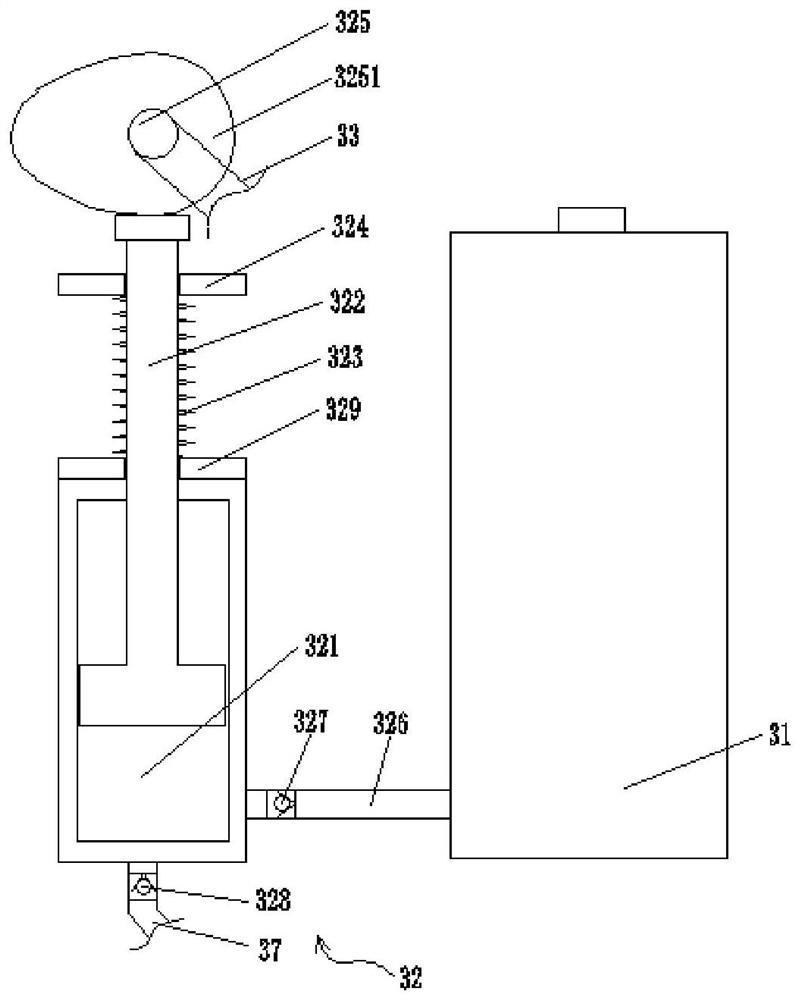

The invention discloses a high-efficiency crushing and disinfection treatment device for medical waste, which includes a bottom plate, a pre-crushing device, a secondary crushing device and a disinfection device. The pre-crushing device includes a box body, a first motor, a crushing blade, a cam and a T-shaped hammer Striker, the secondary crushing device includes a transmission mechanism, a crushing plate and a crushing frame, the transmission mechanism includes a second motor, an incomplete gear, a first rectangular frame and a second rectangular frame, and the disinfection device includes a disinfection The liquid tank, the third L-shaped rod, the piston, the cylinder body and the nozzle, the present invention is equipped with a pre-crushing device for pre-crushing medical waste, which is convenient for subsequent processes, and is equipped with a secondary crushing device for secondary crushing of medical waste , improve the crushing efficiency, and intermittently discharge materials to avoid incomplete crushing due to excessive continuous discharge. A disinfection device is provided to disinfect while crushing, so that the disinfectant can better penetrate into the interior of medical waste, improving the disinfection effect and avoiding waste. disinfectant.

Owner:宁波新材料科技城犀鸟工业设计有限公司

High-speed screening and crushing device for rare earth carbonate

The invention relates to a screening and crushing device, in particular to a high-speed screening and crushing device for rare earth carbonate. The high-speed screening and crushing device for the rare earth carbonate comprises a barrel body, a material-screening device, a material-charging device, landing legs, a discharging pipe and the like. The material-screening device is arranged above the barrel body, the material-charging device is arranged above the material-screening device, and the landing legs are arranged below the barrel body in a left-right symmetrical mode; and the upper ends of the landing legs are connected with the lower inclined wall of the barrel body in a welded mode, and the discharging pipe is arranged under the barrel body. According to the high-speed screening and crushing device for the rare earth carbonate, through the combination of the material-charging device and the material-screening device, the rare earth carbonate can be screened and crushed at a high speed, and the working efficiency is high.

Owner:安徽鑫科生物环保有限公司

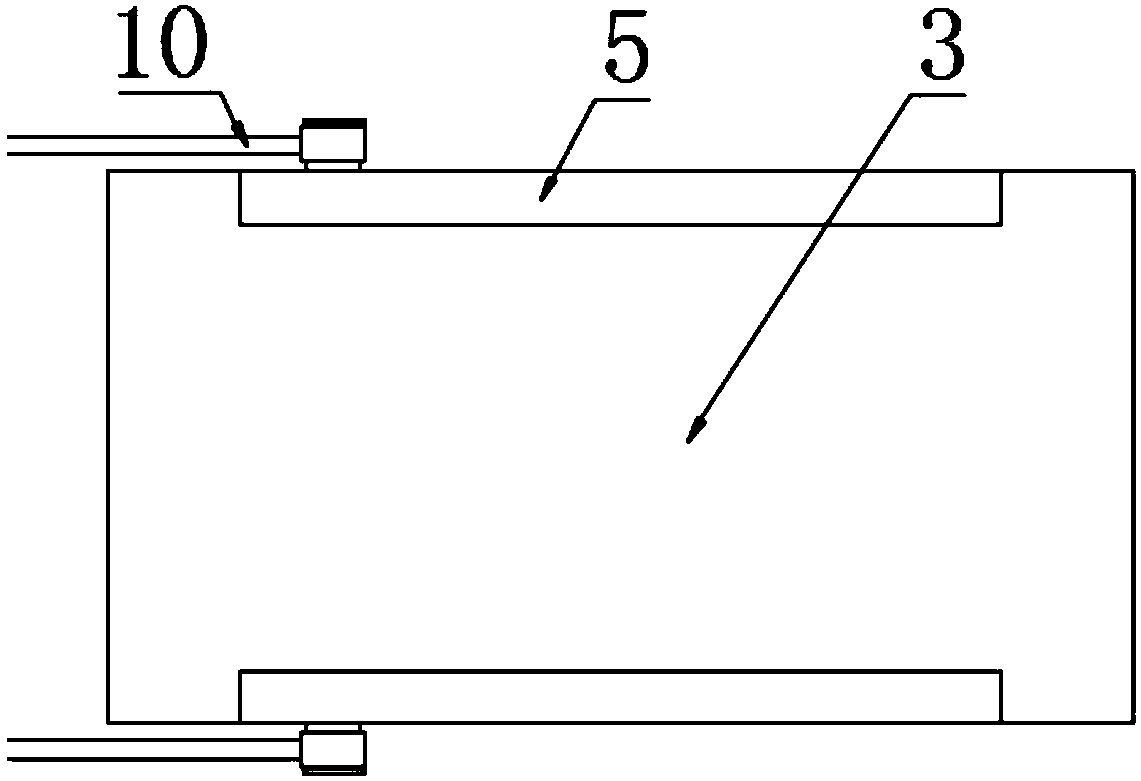

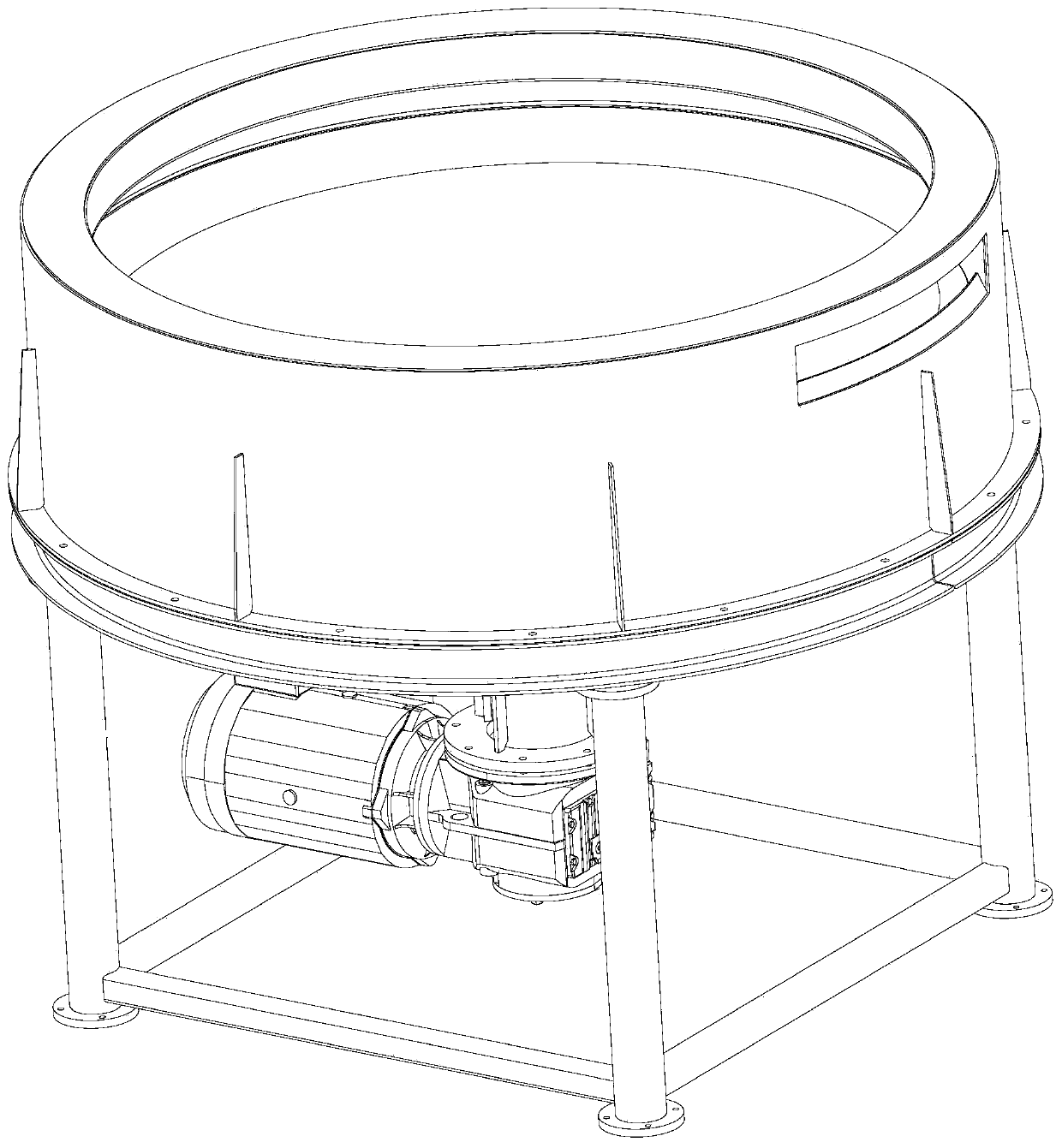

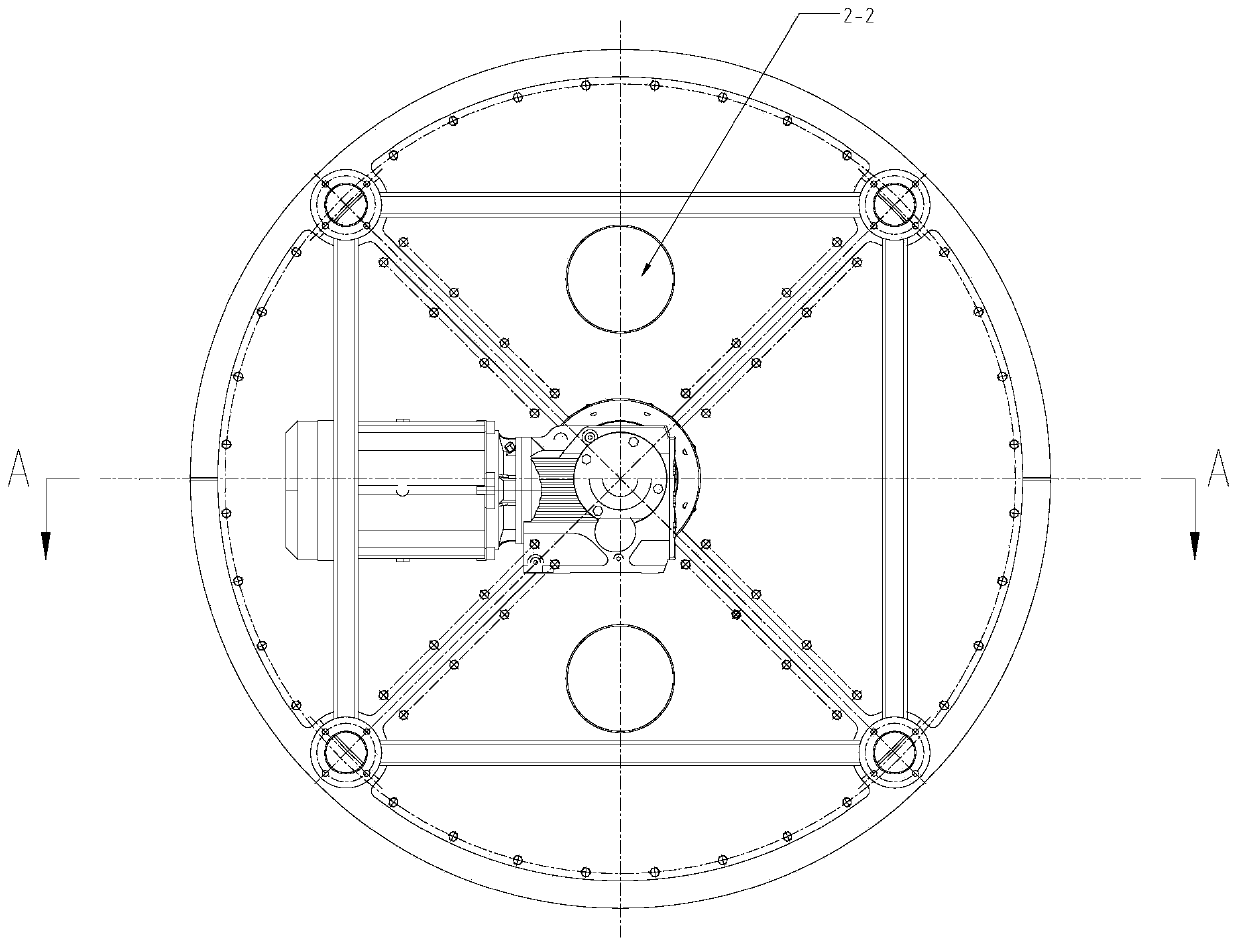

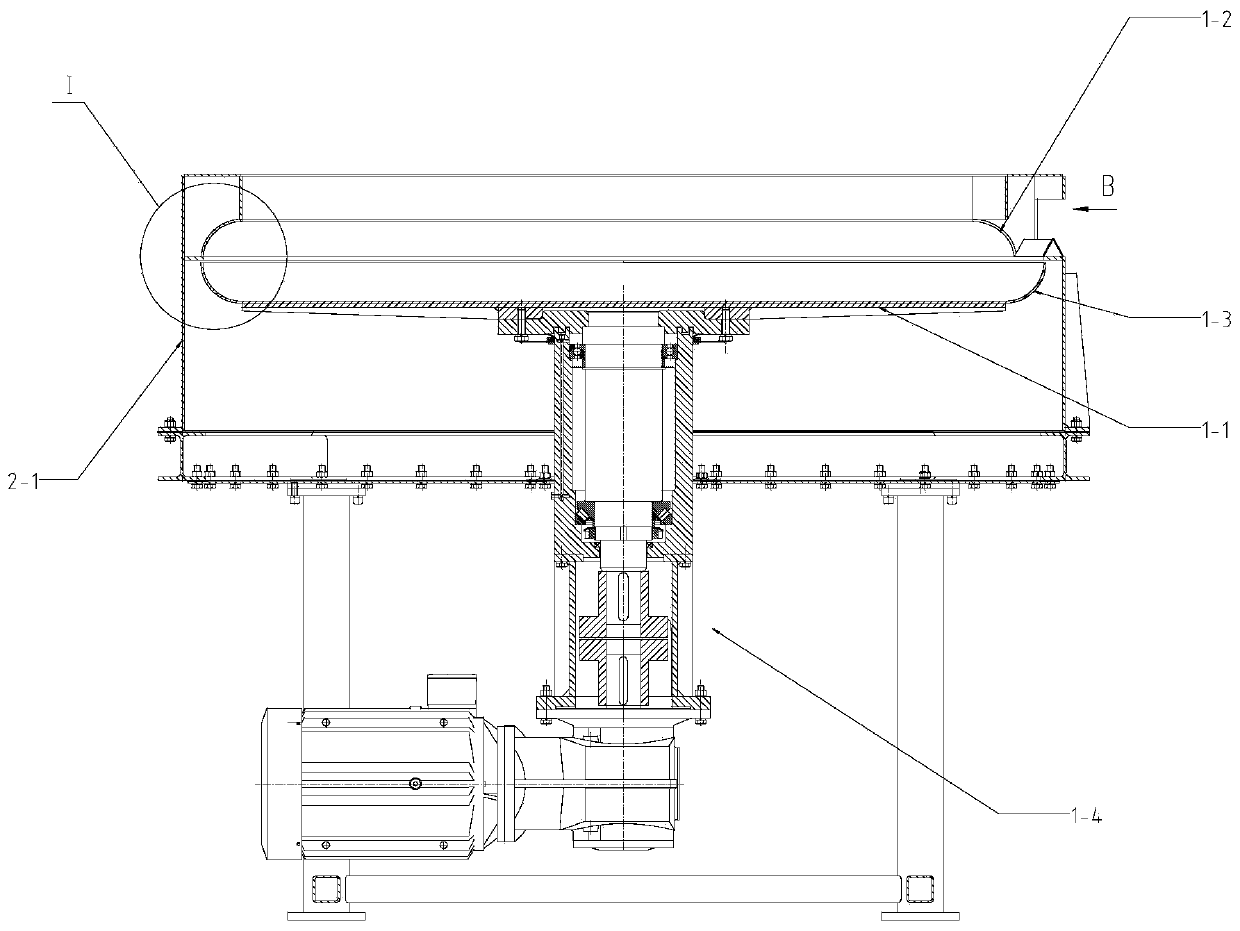

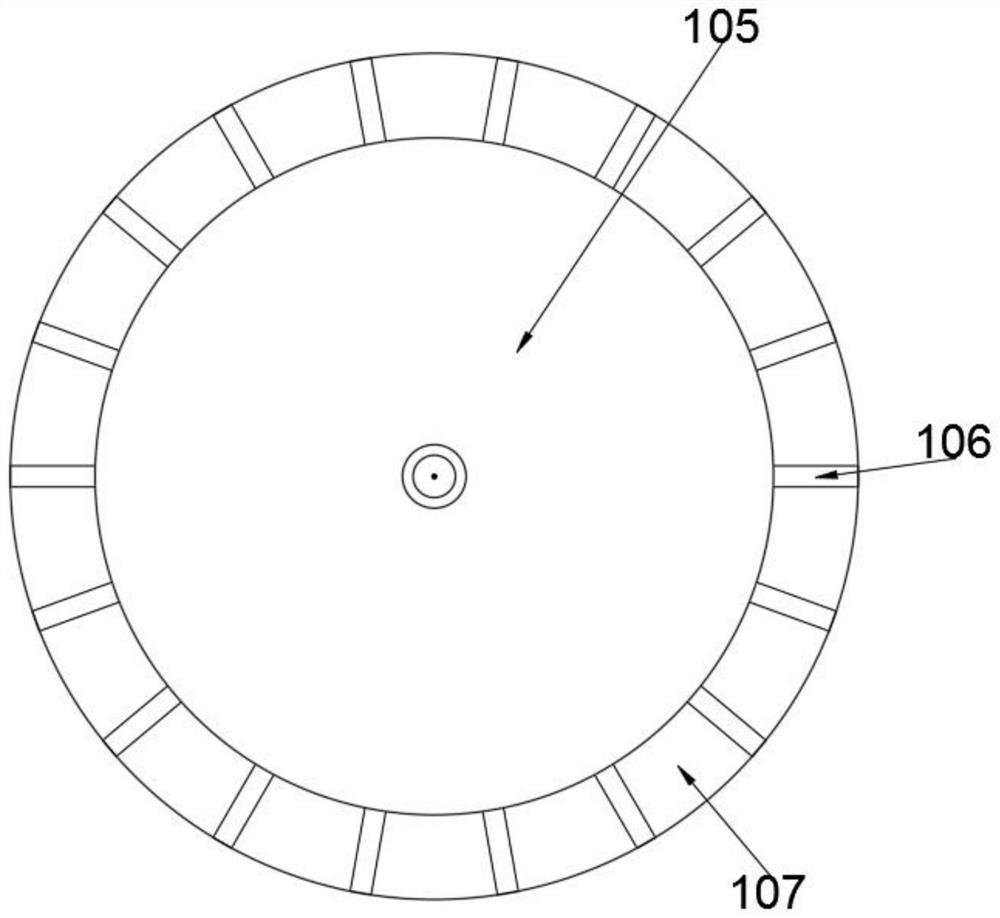

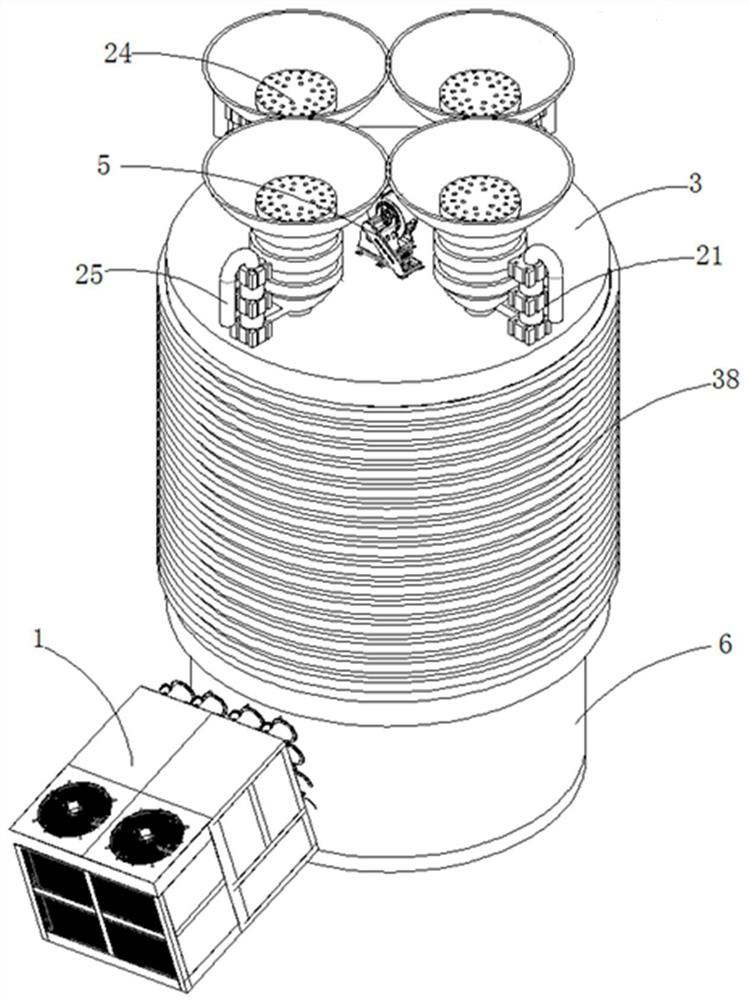

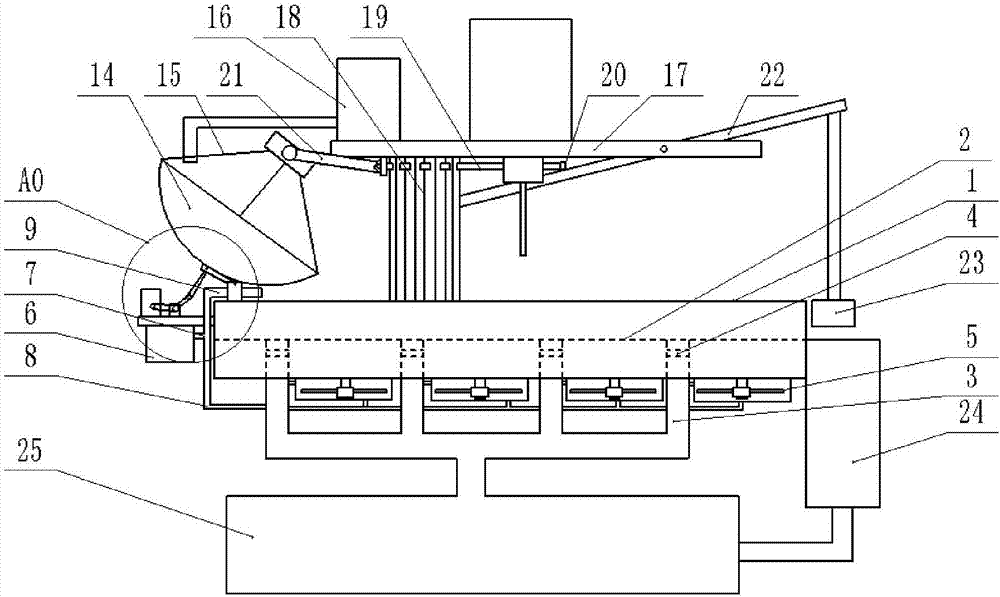

Wheat drying device for flour processing

ActiveCN112129058ARealize intermittent feeding functionAvoid uneven drying problemsSievingGas current separationAgricultural engineeringElectric machinery

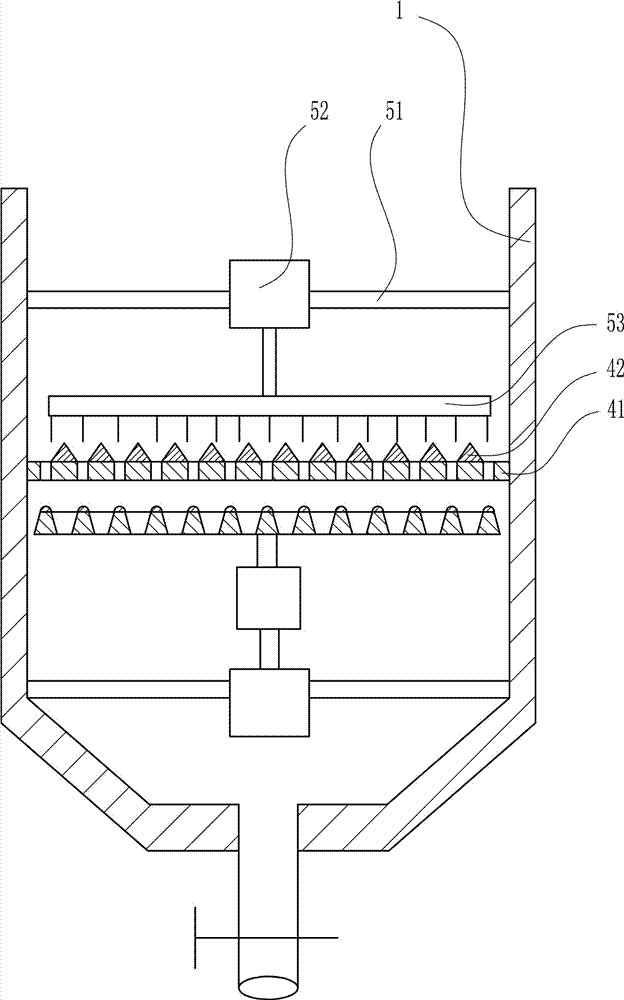

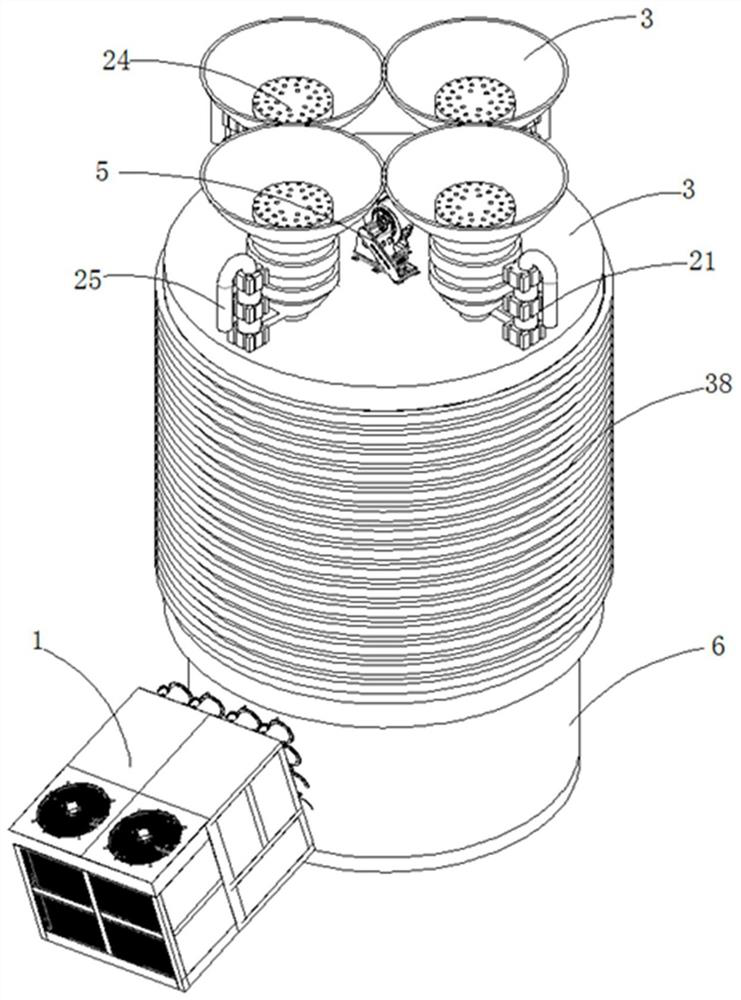

The invention discloses a wheat drying device for flour processing, and belongs to the technical field of flour processing equipment. The wheat drying device for flour processing comprises a heat pumpmain machine, a condenser auxiliary machine and a drying bin, wherein a heat pump main body is arranged on the outer side of the drying bin; a heating chamber is arranged in an inner cavity of the drying bin through a partition plate in a surrounding mode; a drying chamber is formed between the inner side wall of the drying bin and the partition plate; the condenser auxiliary machine is installedin the heating chamber; the top of the drying bin is fixedly connected with a centrifugal fan communicating with the heating chamber and the drying chamber; the bottom of the drying bin is fixedly connected with a collecting bin; the center of the bottom of the collecting bin is fixedly connected with a driving motor; the driving end of the driving motor is fixedly connected with a cross-shaped transmission plate through a rotating shaft arranged in the drying bin; and the end of the cross-shaped transmission plate is fixedly connected with a driven gear through a rotating cylinder. Accordingto the wheat drying device for flour processing provided by the invention, wheat is dispersed and dried after being screened and subjected to impurity removal, meanwhile, the dispersion performance of hot air in the drying chamber is improved, and the drying uniformity is improved.

Owner:XIAOXIAN JIAJIE FLOUR CO LTD

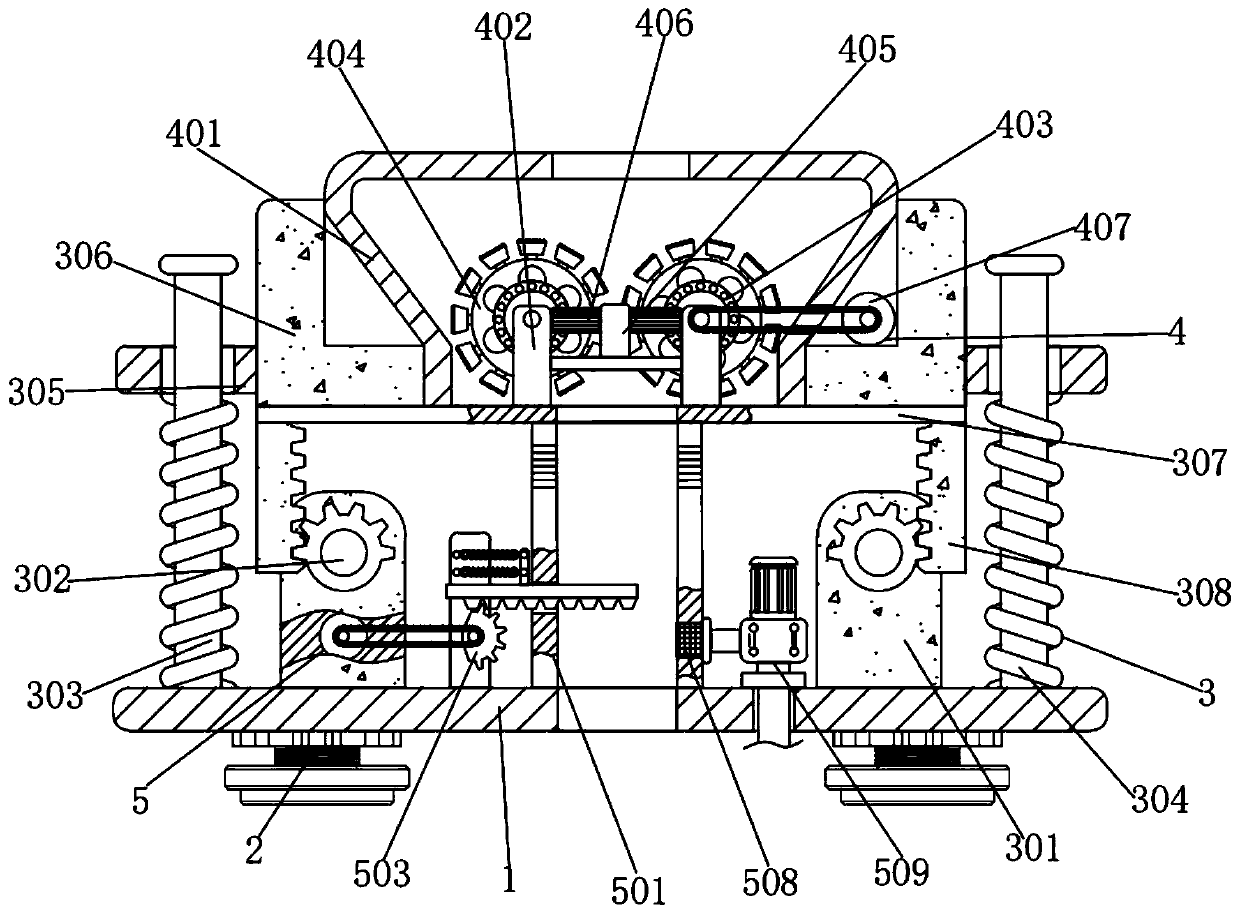

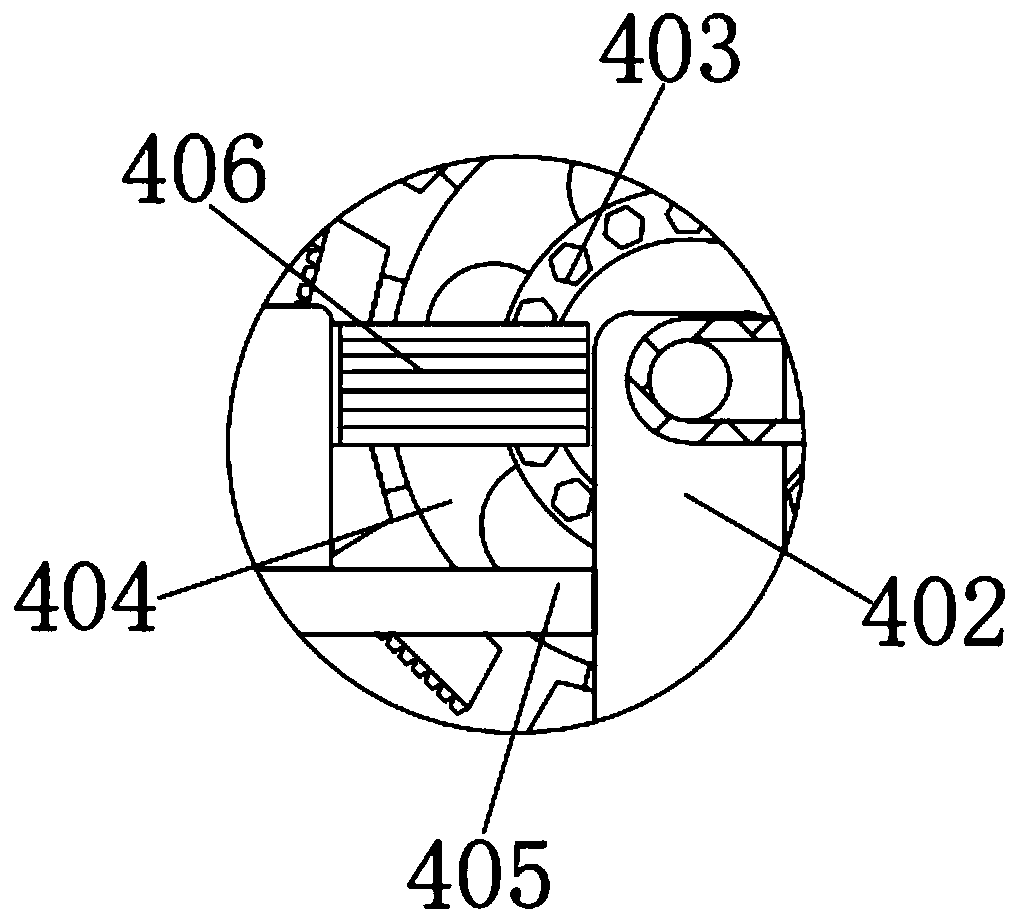

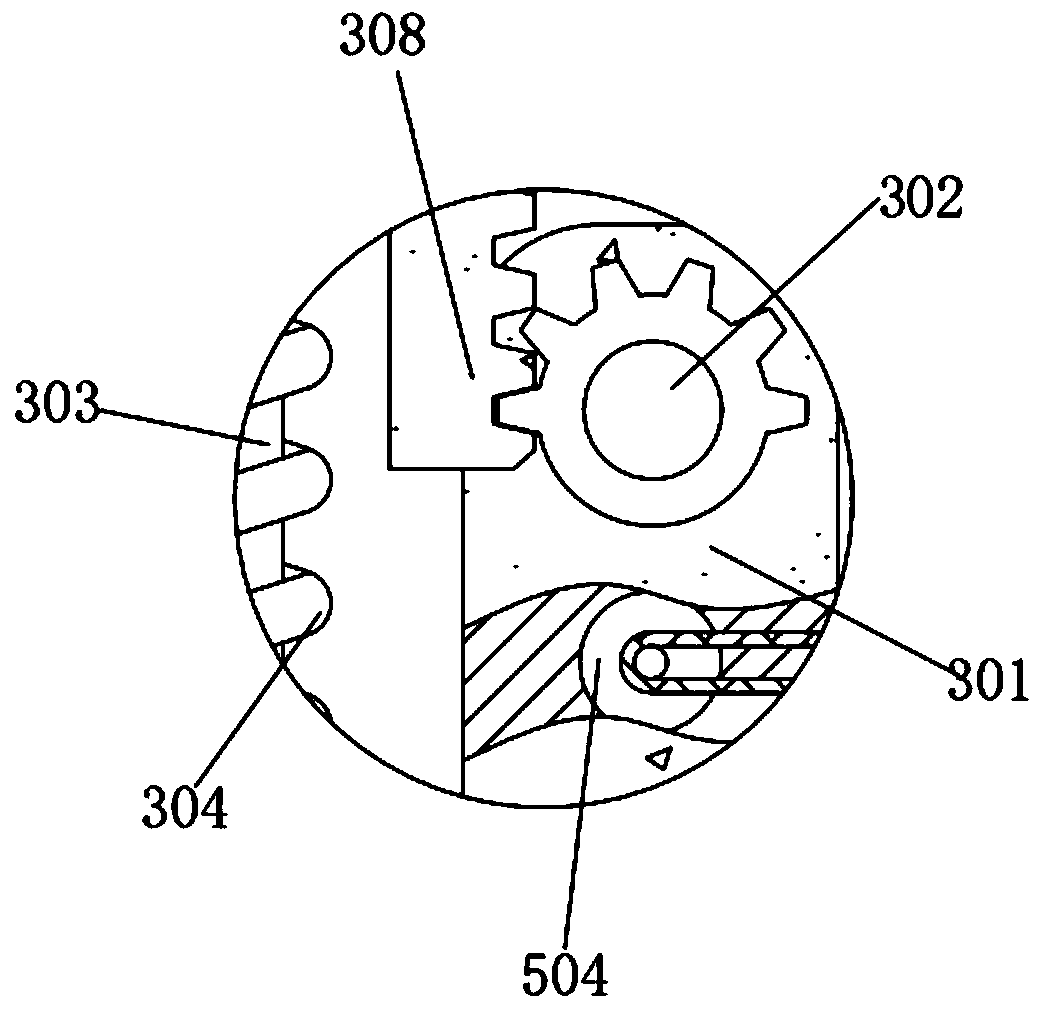

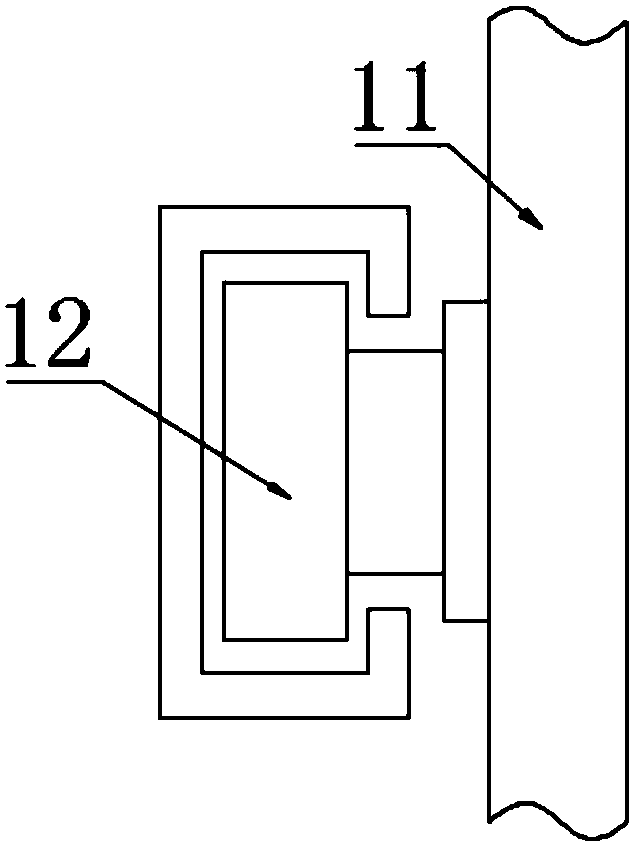

Cement smashing device

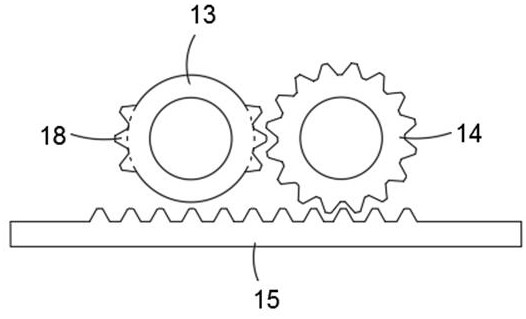

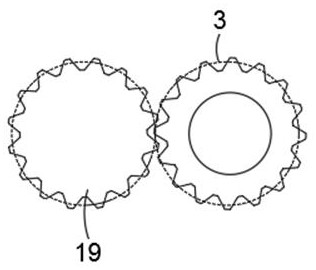

ActiveCN111151339AReduce vibrationExtended service lifeNon-rotating vibration suppressionDirt cleaningVibration amplitudeGear wheel

The invention discloses a cement smashing device comprising a first cross plate and bases fixedly connected with the lower surface of the first cross plate. A damping device is installed on the uppersurface of the first cross plate. According to the cement smashing device, by means of mutual cooperation of vertical rods, first half-ring gears, first tooth plates, second cross plates, first springs, L-shaped plates and other structures, the vibration amplitude can be lowered when the cement smashing device works, so that the service life of the cement smashing device is prolonged. By means ofmutual cooperation of a second motor, a second half-ring gear, a second toothed plate, a second spring, a pipe and other structures, a material blockage phenomenon is avoided, the work efficiency is improved and the labor cost is reduced; by means of mutual cooperation of a filtering net, a third cross plate, a pipe, a fan, the first cross plate and other structures, dust generated during smashingcan be sucked for centralized treatment, and therefore the health of operation personnel is protected.

Owner:承德冀东水泥有限责任公司

Mixing device for processing composite material

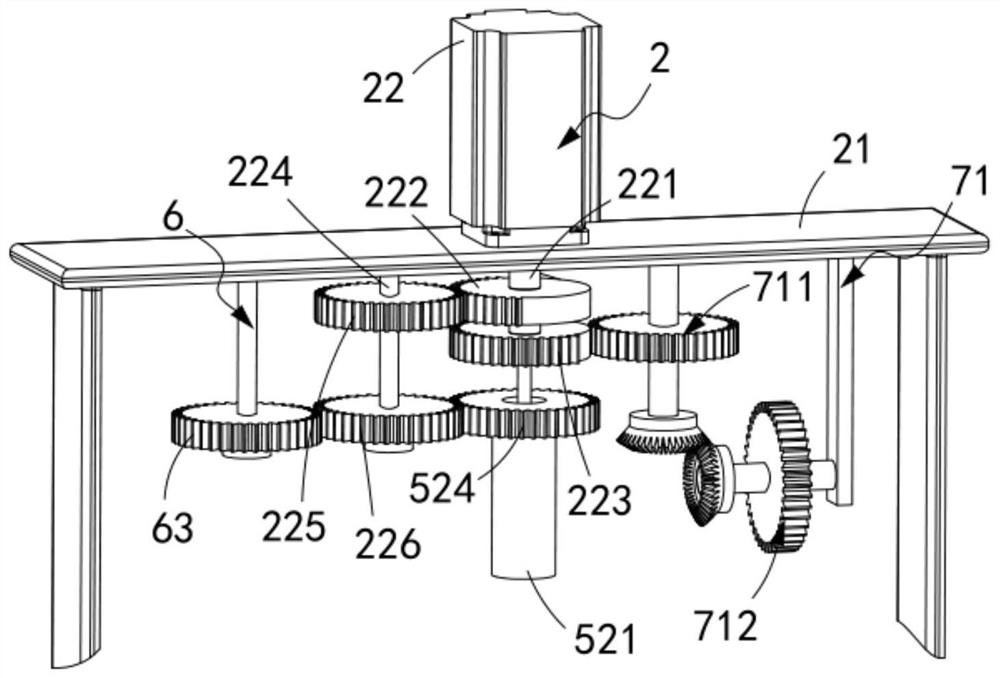

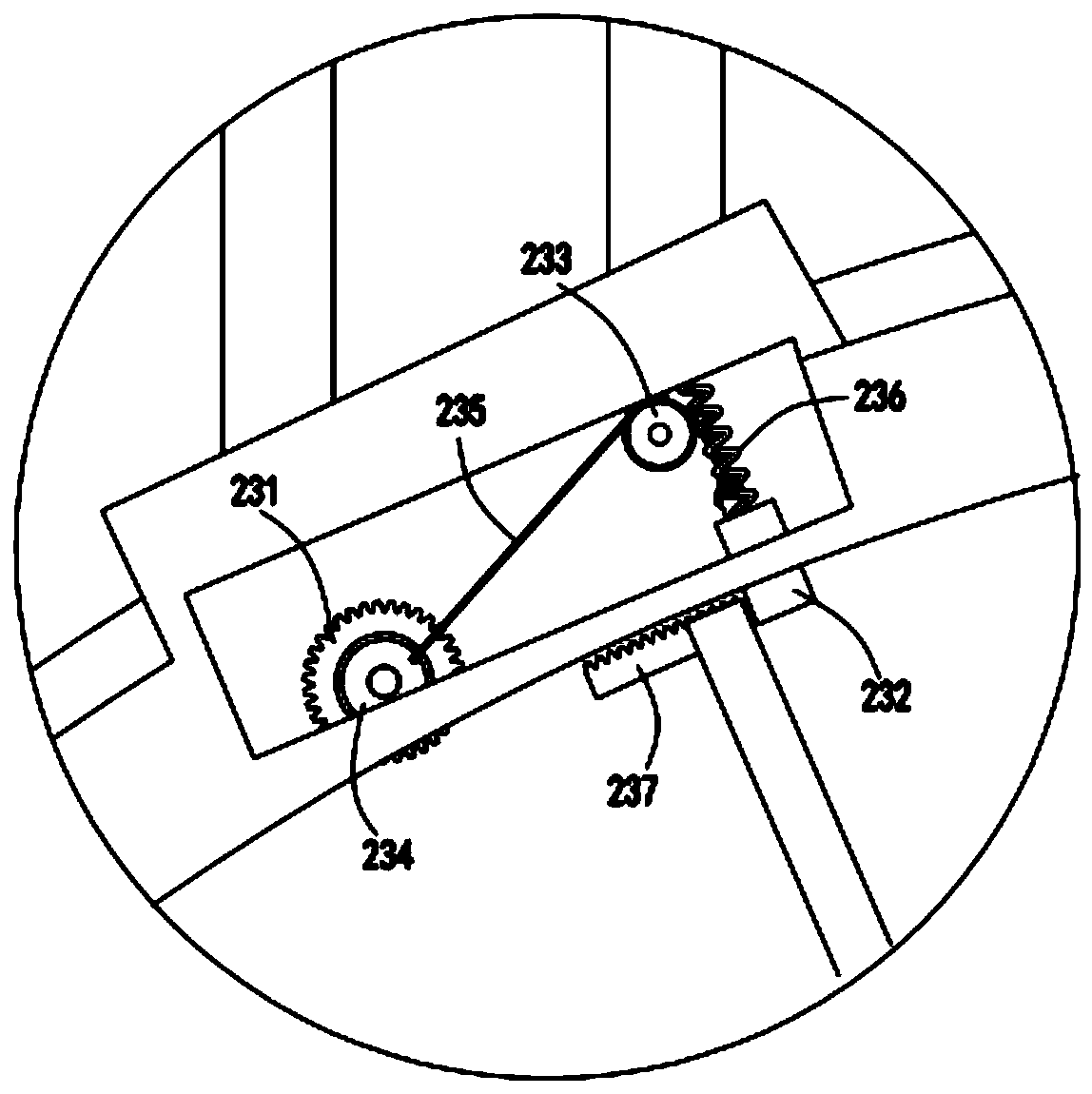

InactiveCN108607419ARealize intermittent dischargeWell mixedShaking/oscillating/vibrating mixersTransportation and packagingDrive shaftGear wheel

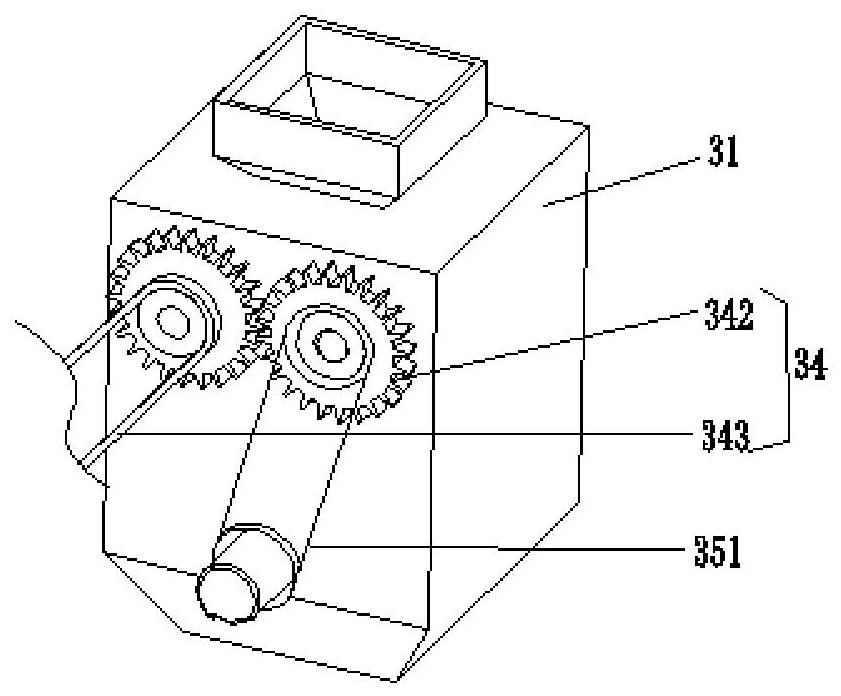

The invention discloses a mixing device for processing a composite material. A second motor is fixedly connected with the bottom of a device body; the upper part of the second motor is rotationally connected with a driving shaft; in addition, the middle part of the driving shaft sleeves a stabilizing rod; two ends of the stabilizing rod are respectively and fixedly connected with the device body;the upper end of the driving shaft is fixedly connected with a semicircular bevel gear; one bevel gear is arranged on each of two sides of the upper part of the semicircular bevel gear; besides, a toothed part of the semicircular bevel gear is meshed with one bevel gear; the bevel gears are fixedly connected with the middle part of a threaded rod. According to the device, a mixing roller rotates to drive stirring rods to rotate along for stirring and mixing the composite material inside the device body; in addition, a moving plate moving in a reciprocating left-right manner drives the mixing roller and the stirring rods to do reciprocating left-right motion and drives a sealing plate to move in a reciprocating up-down manner by a connecting rod to intermittently seal a discharge opening, and intermittent discharge of the materials is realized; by matching fixed connection of a sliding block and different pin holes, the opening and closing sizes of the discharge opening can be controlled each time, and further discharging flow of the material is controlled.

Owner:陈璐滨

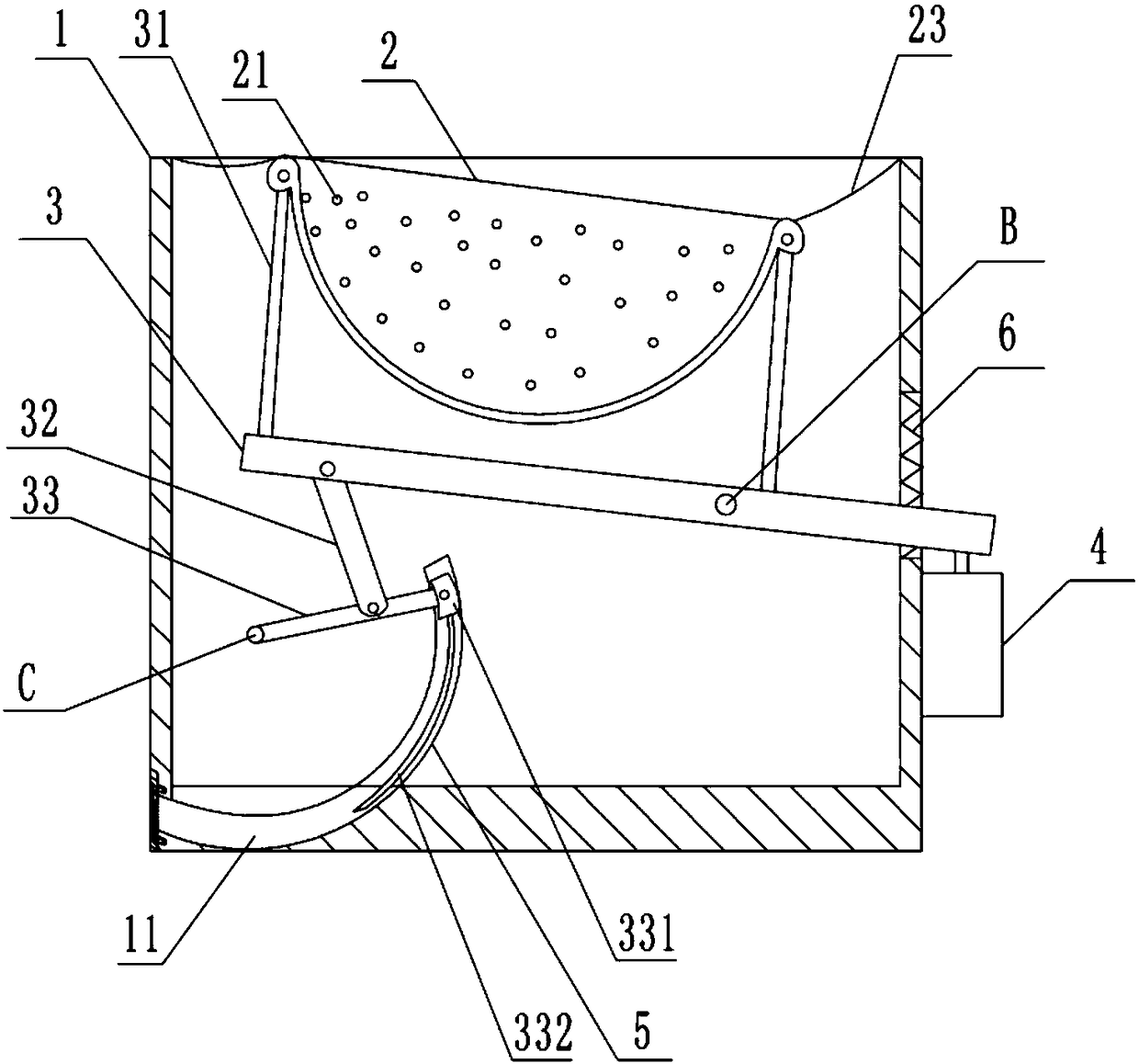

Soybean milk skin producing device

PendingCN108185016AReduce the time waiting for soy milk to boilUniform concentrationCheese manufactureFood scienceHydraulic cylinderEngineering

The invention relates to the technical field of bean curd production, in particular to a soybean milk skin producing device which comprises a filtering barrel and a filtering part. A swing rod is rotationally connected to the inner wall of the filtering barrel. One end of the swing rod is connected with a hydraulic cylinder for driving the swing rod to swing up and down. A shaking rod for being connected with the filtering part and making the filtering part swing is arranged on the swing rod. A push rod is hinged to the end, away from the hydraulic cylinder, of the swing rod. The inner wall ofthe filtering barrel is provided with a stirring rod and arc-shaped slide groove. One end of the stirring rod is rotationally connected with the inner wall of the filtering barrel. The other end of the stirring rod is provided with a slider. The slider is slidingly connected into the arc-shaped slide groove. The push rod is hinged to the side, close to the slider, of the stirring rod. An arc-shaped liquid outlet channel is arranged in the bottom face of the filtering barrel. A piston for blocking the liquid outlet channel is arranged at the liquid outlet channel. An arc-shaped rod is arrangedon the slider. A reset spring for making the piston reset is arranged on the piston. By means of the scheme, the problem that too much soybean milk is added to a pot at a time, so soybean milk cooking time is long in the prior art is solved.

Owner:贵州省三好食品开发有限公司

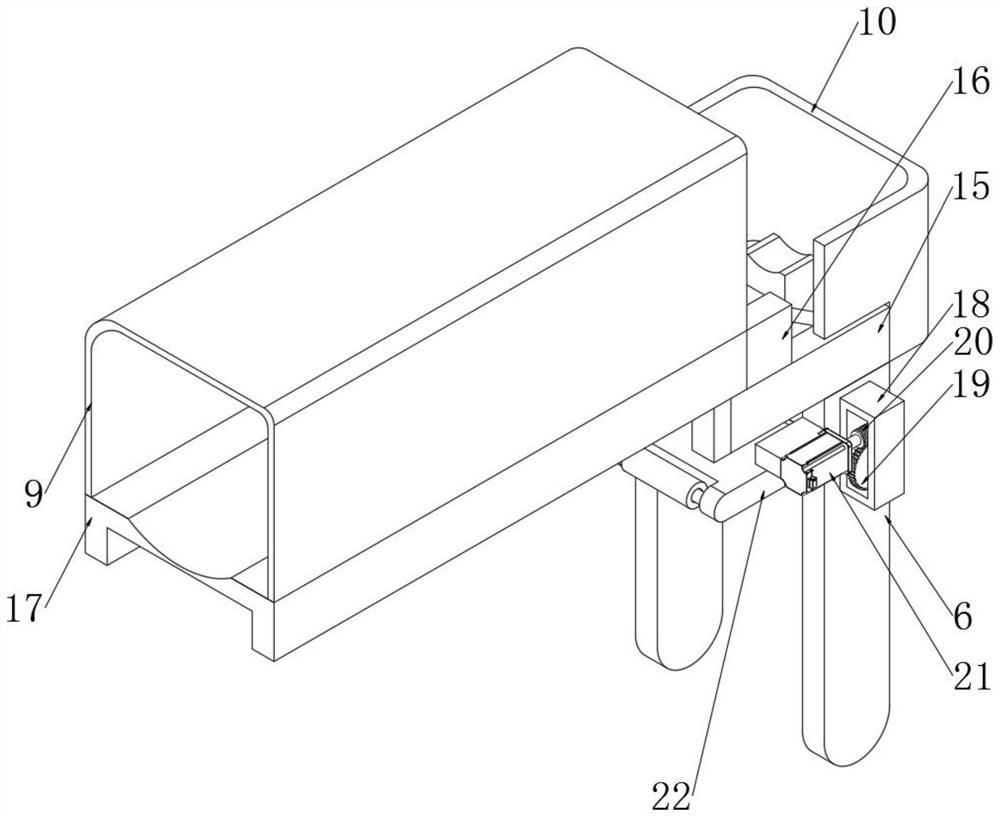

Transport trolley intermittent electrostatic discharging device

PendingCN110304002ARealize intermittent dischargeAvoid wear and tearElectric/fluid circuitLocomotivesEngineeringElectrostatic discharge

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Roller type tealeaf microwave drying machine

InactiveCN105981836AImprove sealingAvoid dischargePre-extraction tea treatmentMicrowaveElectric machinery

The invention discloses a drum-type tea microwave dryer, which comprises a base and a box body. Rollers are arranged on the left and right sides of the base, and a box body is arranged above the base. Ventilation holes are evenly distributed on the surface of the material drum. The left end of the material turning tube is higher than the right end. The ends are connected, and the left and right sides of the turning cylinder are provided with supports. The supports are connected to the inner wall of the upper side of the box through the boom. The box on the lower right side of the turning barrel is equipped with a discharge hopper. A discharge baffle is fixed, a feeding tube is provided on the upper left side of the turning cylinder, a feeding hopper is provided at the upper left end of the feeding tube, and a feeding baffle is provided at the right port of the feeding tube. The structure of the invention is simple and Reasonable, easy to carry, good drying effect, realizes heat recovery and utilization, reduces the pollution of the device to the environment, and has strong practicability.

Owner:SUQIAN HUAIHAI TECH SERVICES

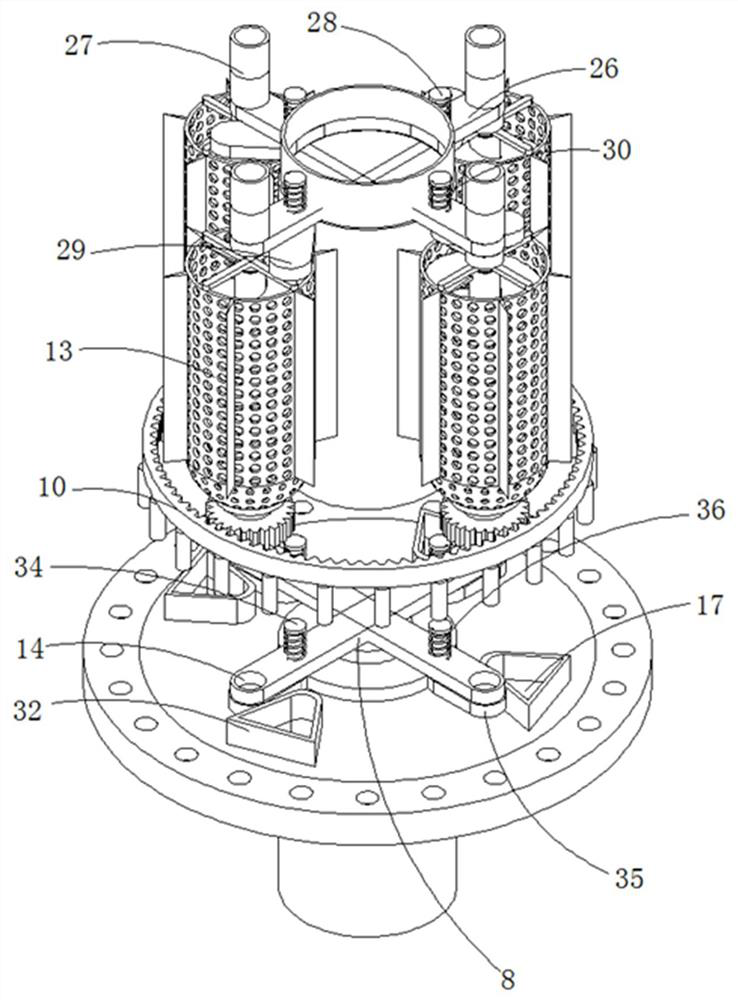

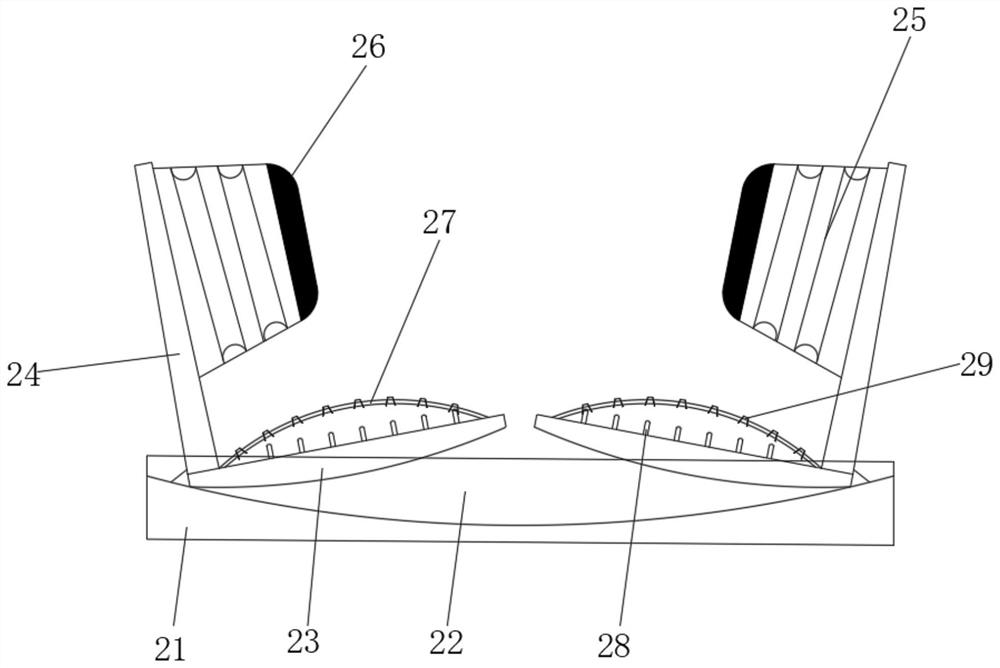

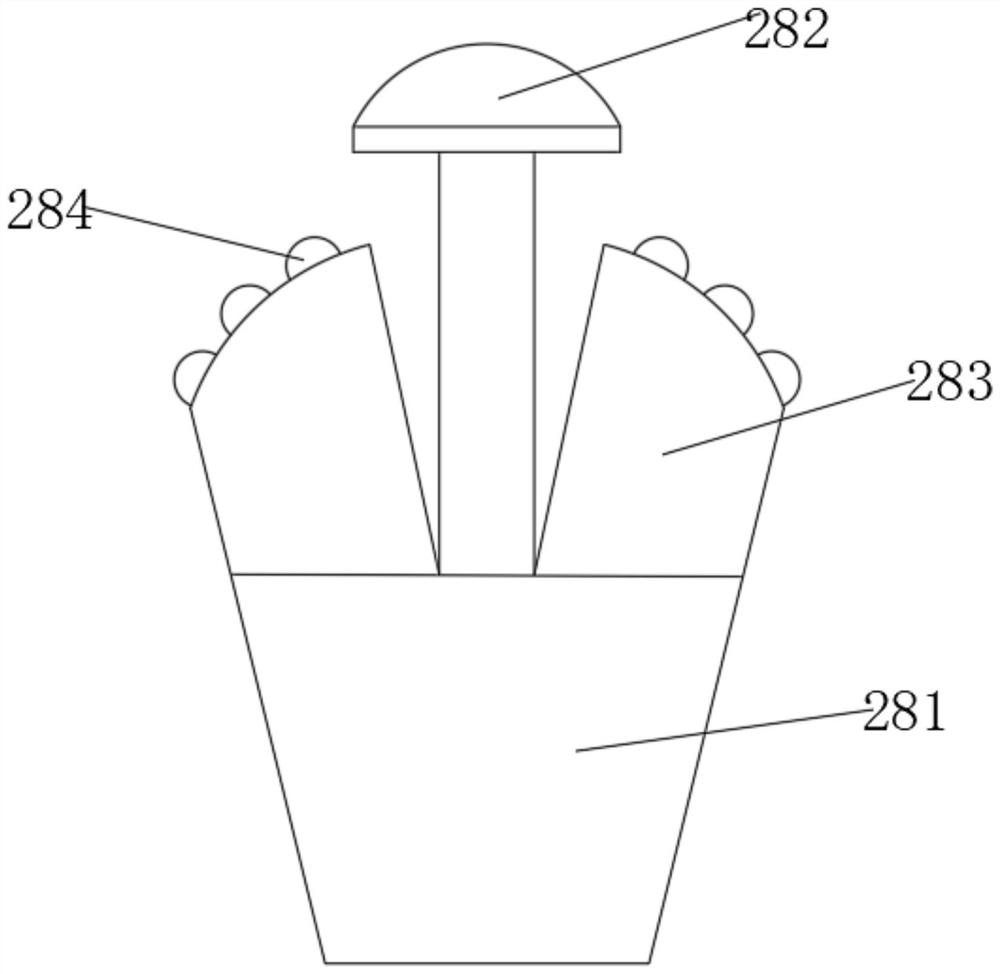

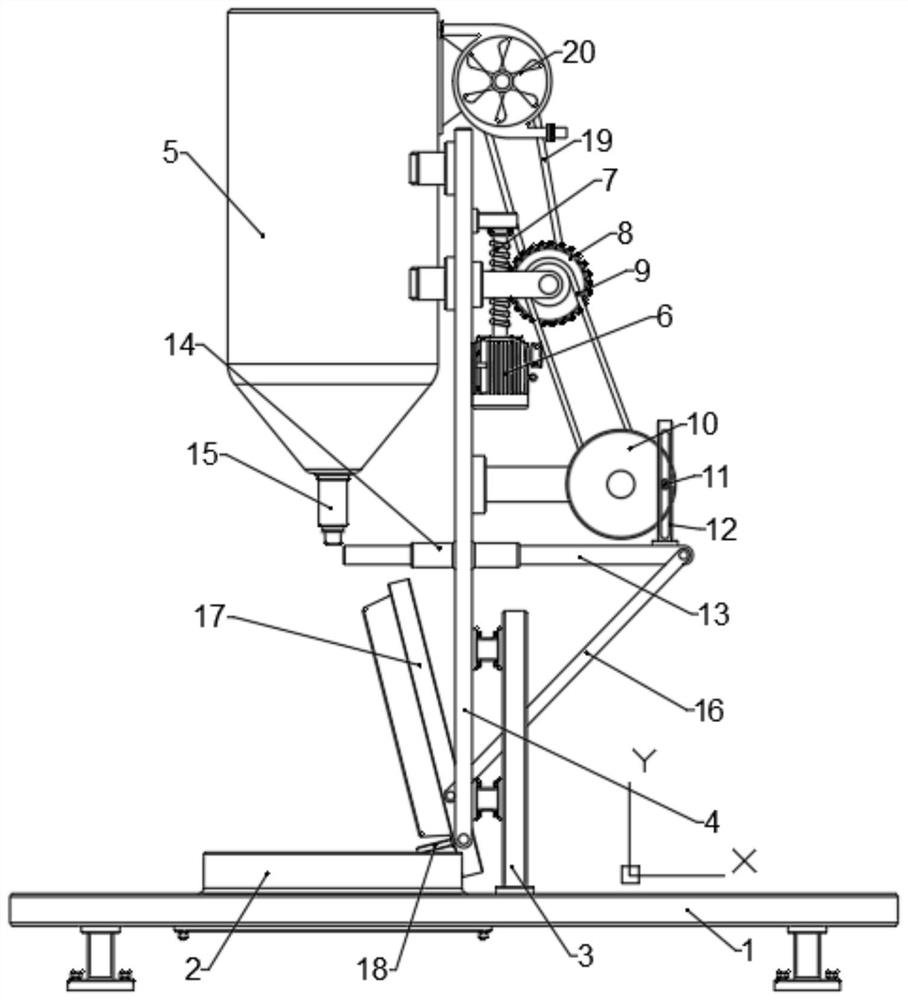

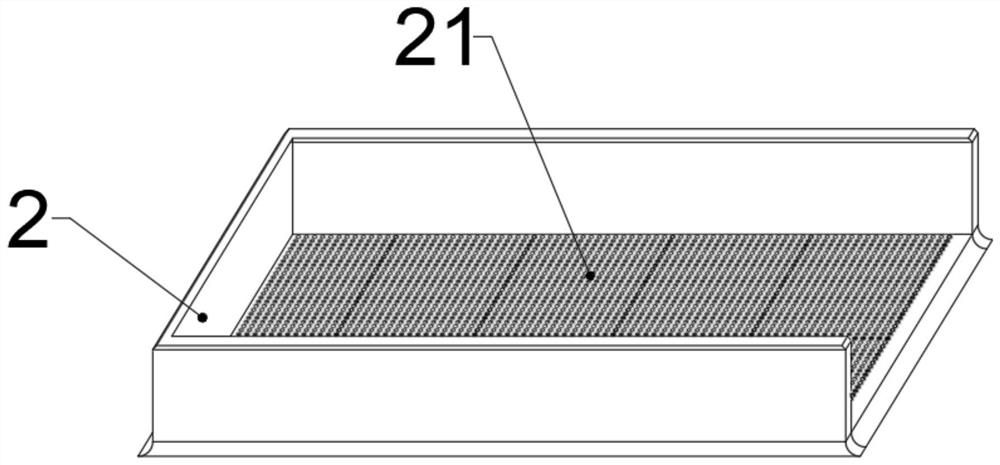

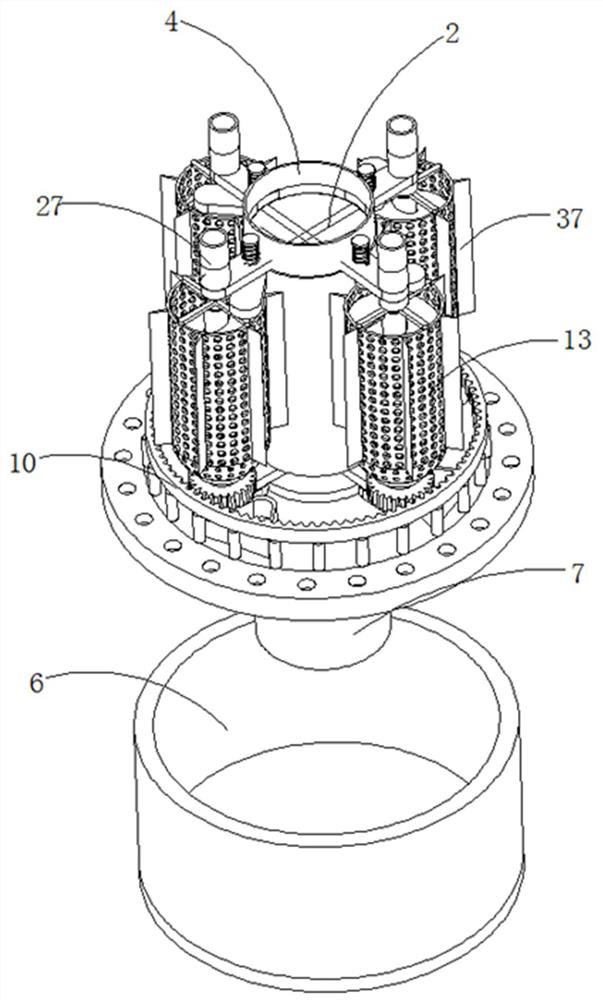

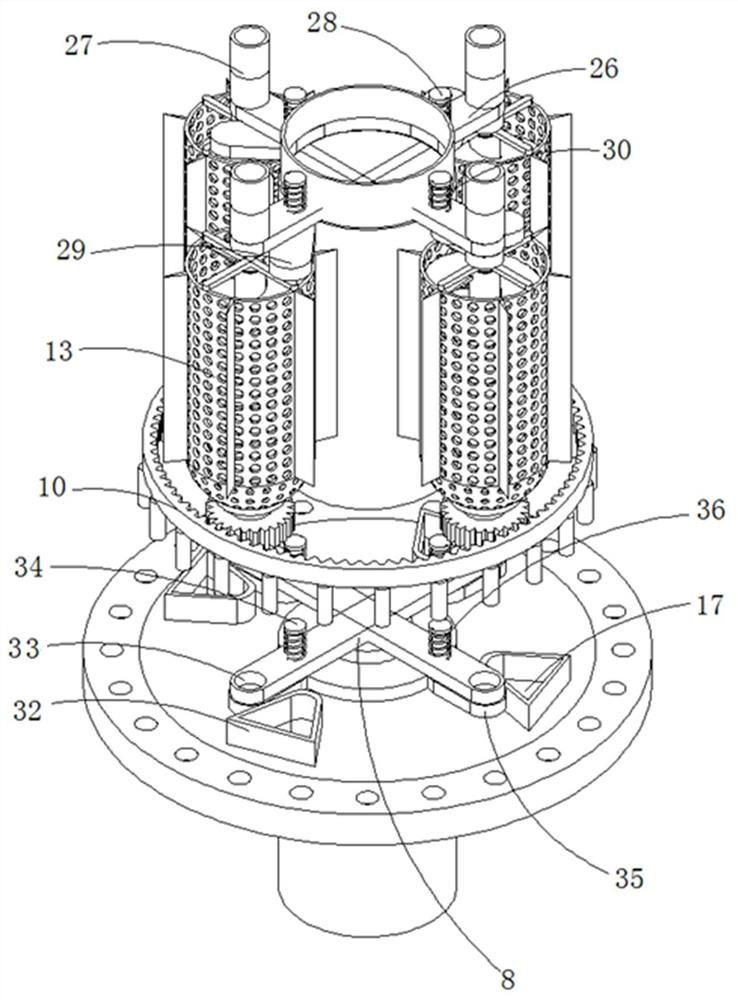

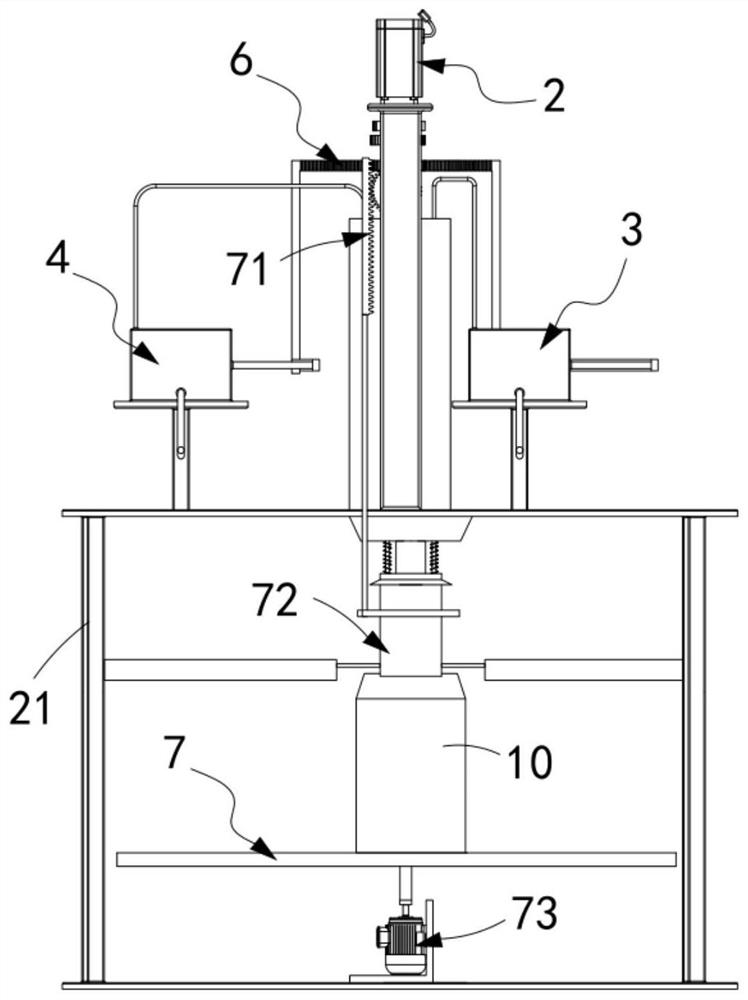

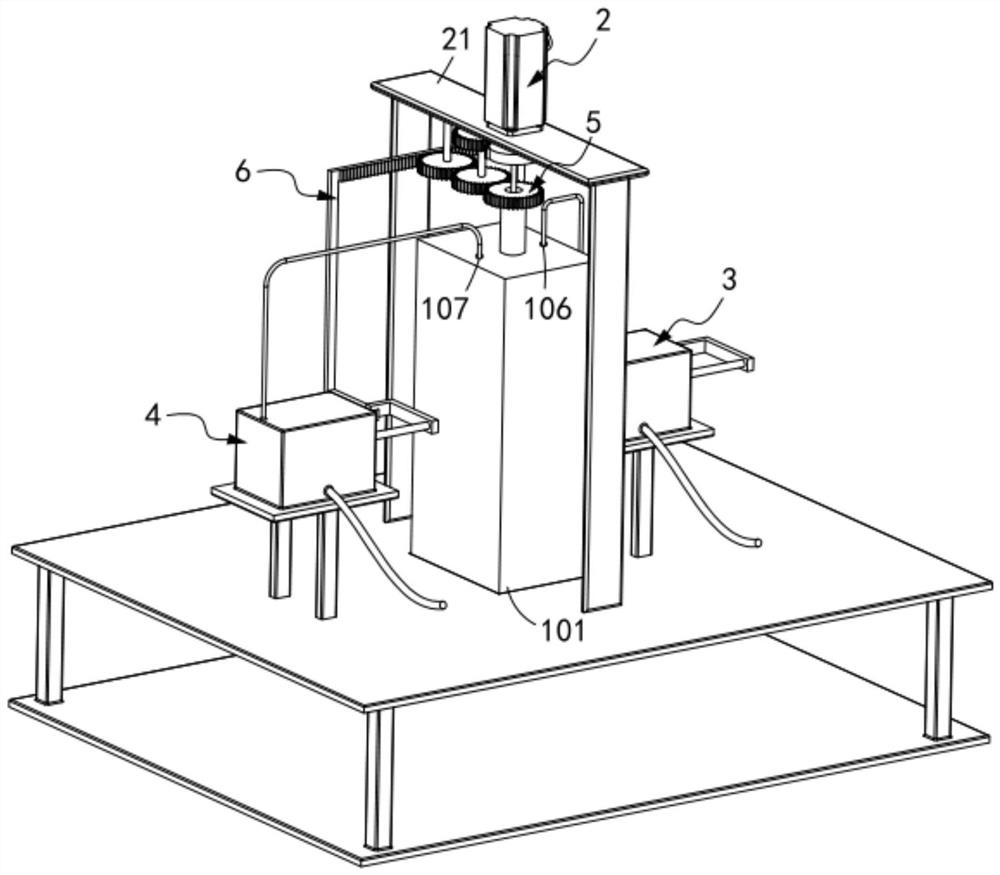

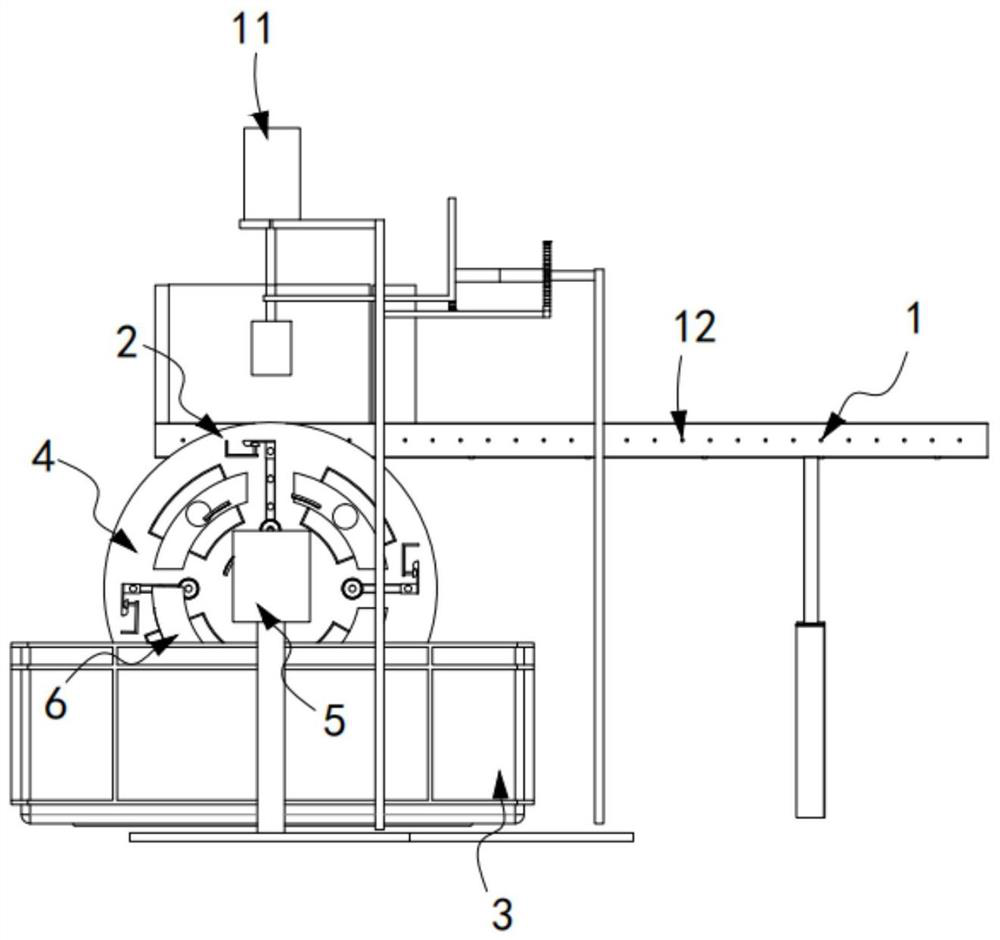

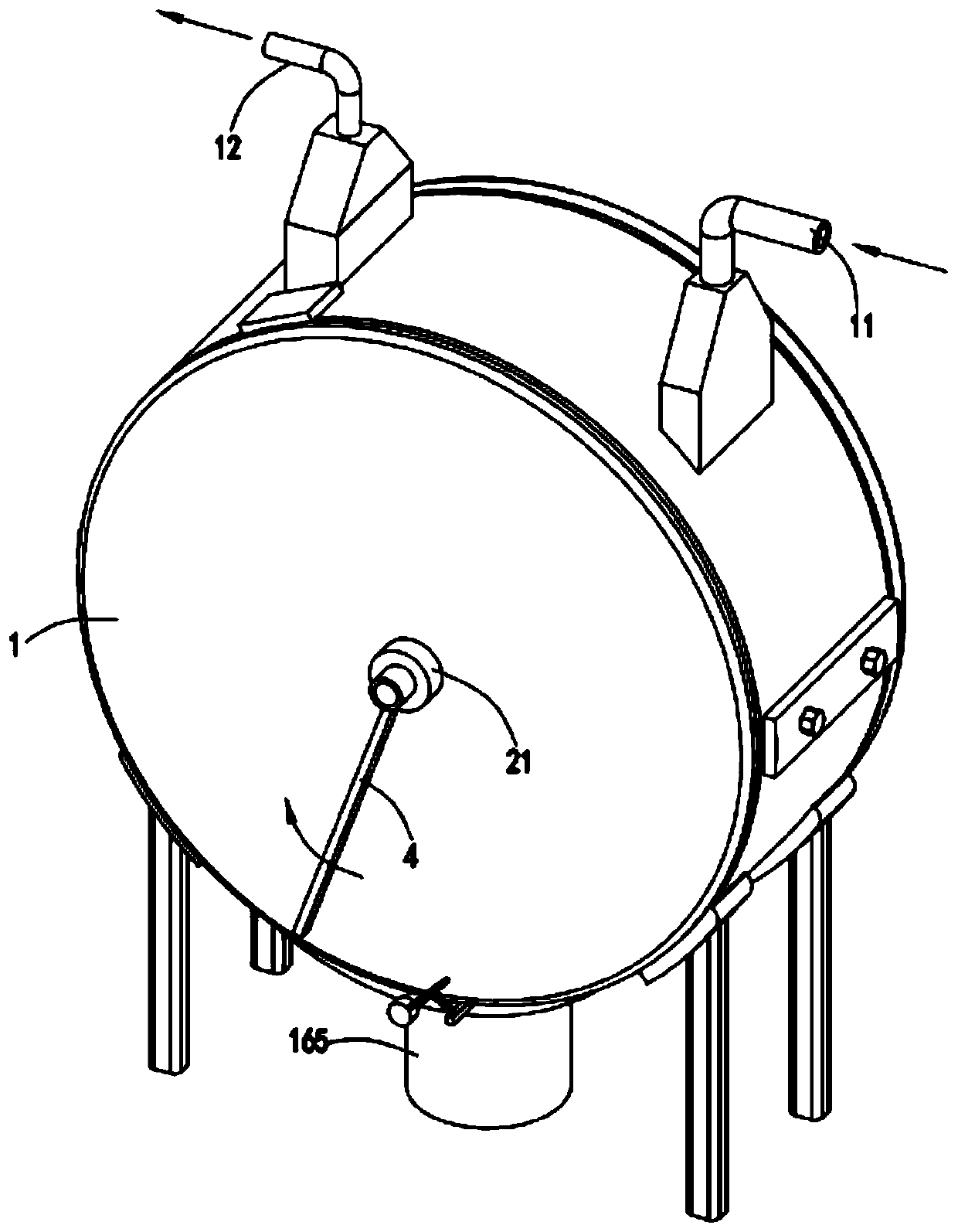

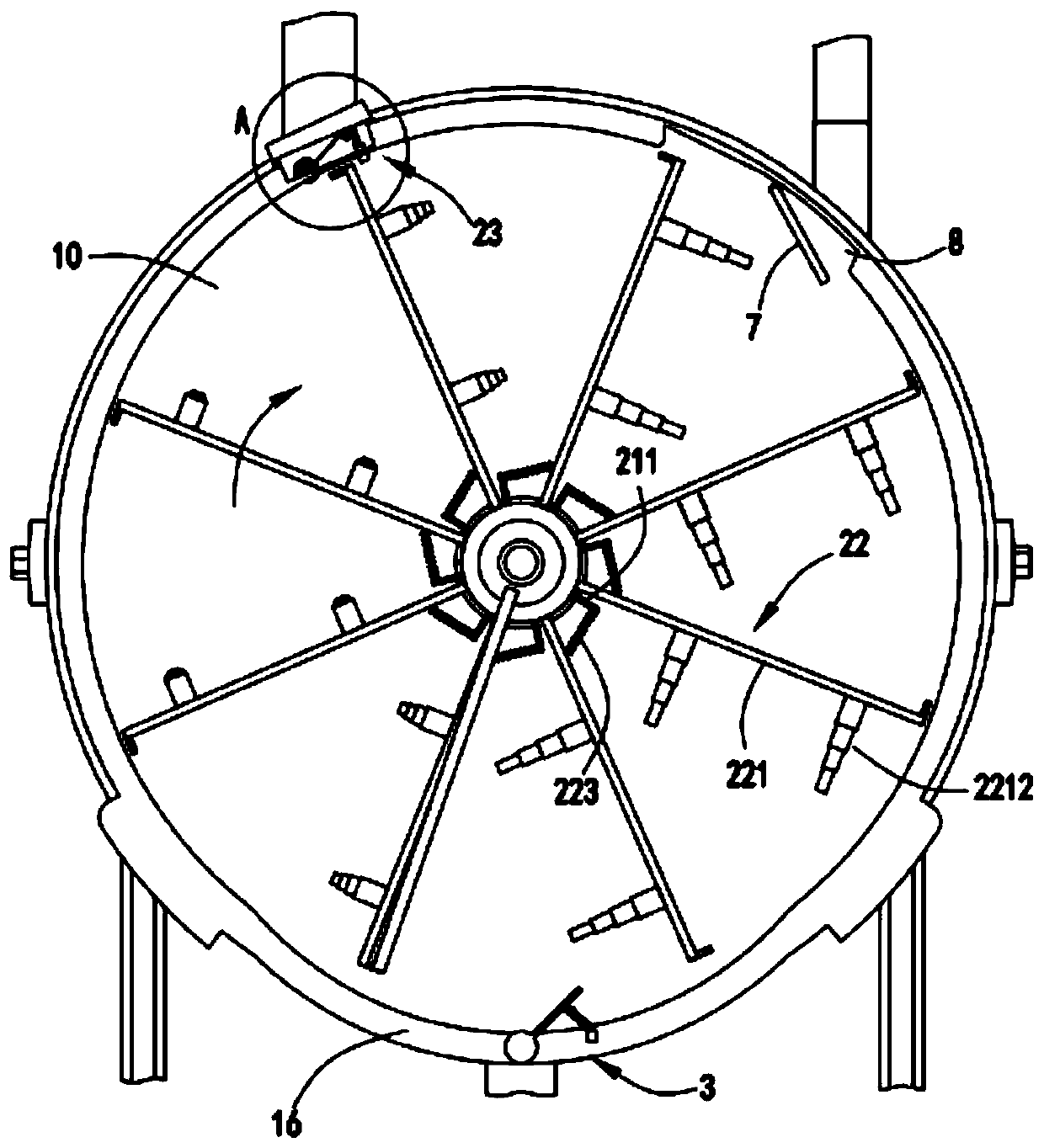

Granulation disc, granulator and granulation assistant preparation system

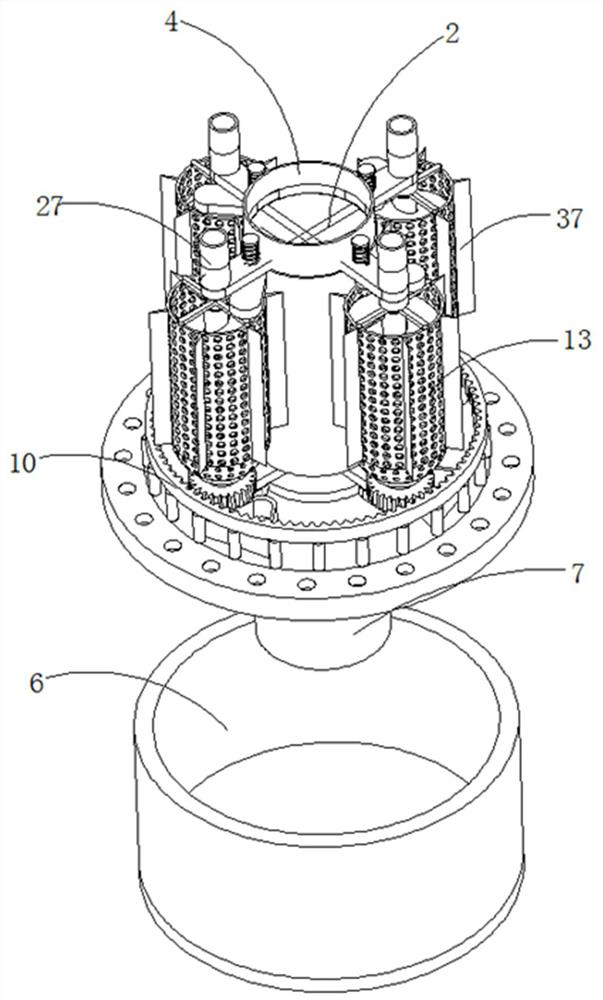

PendingCN110327843AImprove continuityRealize intermittent dischargeGranulation in rotating dishes/pansGranulation by liquid drop formationRelative motionEngineering

The invention belongs to the field of granulation, and especially relates to a granulation disc, a granulator and a granulation assistant preparation system. The edge of the granulation disc adopts a150-200 DEG arc design, the curvature radius of the arc is 8-20% of the diameter of the granulation disc, the edge of the granulation disc is divided into an upper disc and a lower disc that are relatively movable, the lower disc is connected with a transmission mechanism to make the lower disc rotate around the center point in the horizontal plane, the upper disc stands, a gap is left between theupper disc and the lower disc, and the gap is sealed with a gas. The granulation disc, the granulator and the granulation assistant preparation system which are provided by the invention can improvethe sphericity and the strength of a pressed powder.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +2

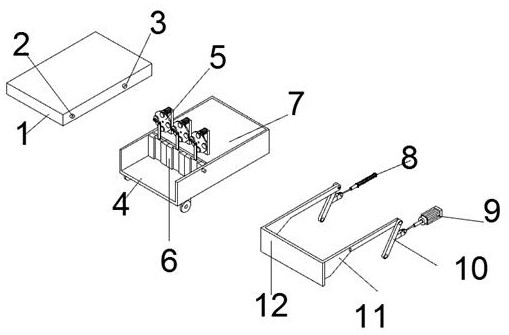

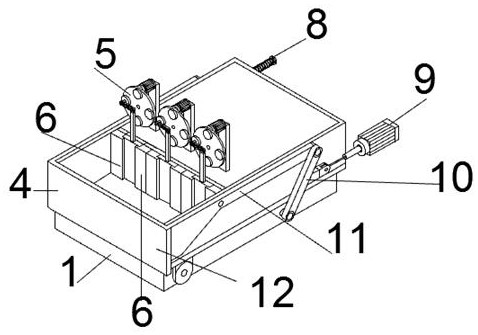

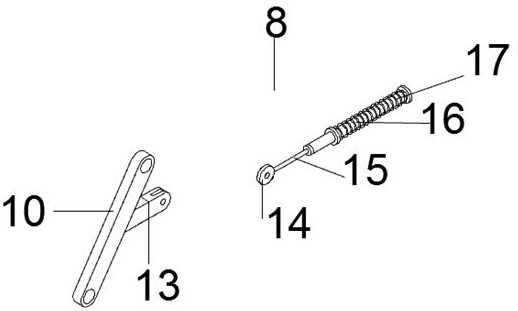

Intermittent material mixing device

PendingCN112473545AWell mixedRealize intermittent feedingRotating receptacle mixersTransportation and packagingCushioningElectric machine

The invention discloses an intermittent material mixing device which comprises a base plate, a front rotary shaft, a rear rotary shaft, a material mixing box, a material turning rotary disc, a discharging plate, a sealing plate, a cushioning supporting column, a stepping motor, a moving connecting rod, a transverse support and a front baffle; the discharging plate is arranged in a material mixingbox body, the material turning rotary disc is arranged on the upper end of the discharging plate, and discharging of the discharging plate is realized through rotation of the material turning rotary disc; the cushioning supporting column and the stepping motor are arranged on the two side of the moving connecting rod; the stepping motor is adopted to push the moving connecting rod to move, so thatopening of the front baffle and multi-angle overturning of the material mixing box are achieved, and discharging operation after material mixing is completed. According to the intermittent material mixing device, the stepping motor is adopted to push the moving connecting rod to move, the material mixing box is turned over, three kinds of materials are enabled to enter the material mixing box through pipelines, the material turning rotary disc rotates, a moving rotary rod is in linkage with a lifting connecting rod, vertical movement of a material blocking plate is achieved, intermittent discharging of the discharging plate is achieved, the front baffle is opened at the moment after the materials are mixed at the front end of the material mixing box, and the mixed materials are guided outof the material mixing box in time.

Owner:西安宝鑫自动化设备有限公司

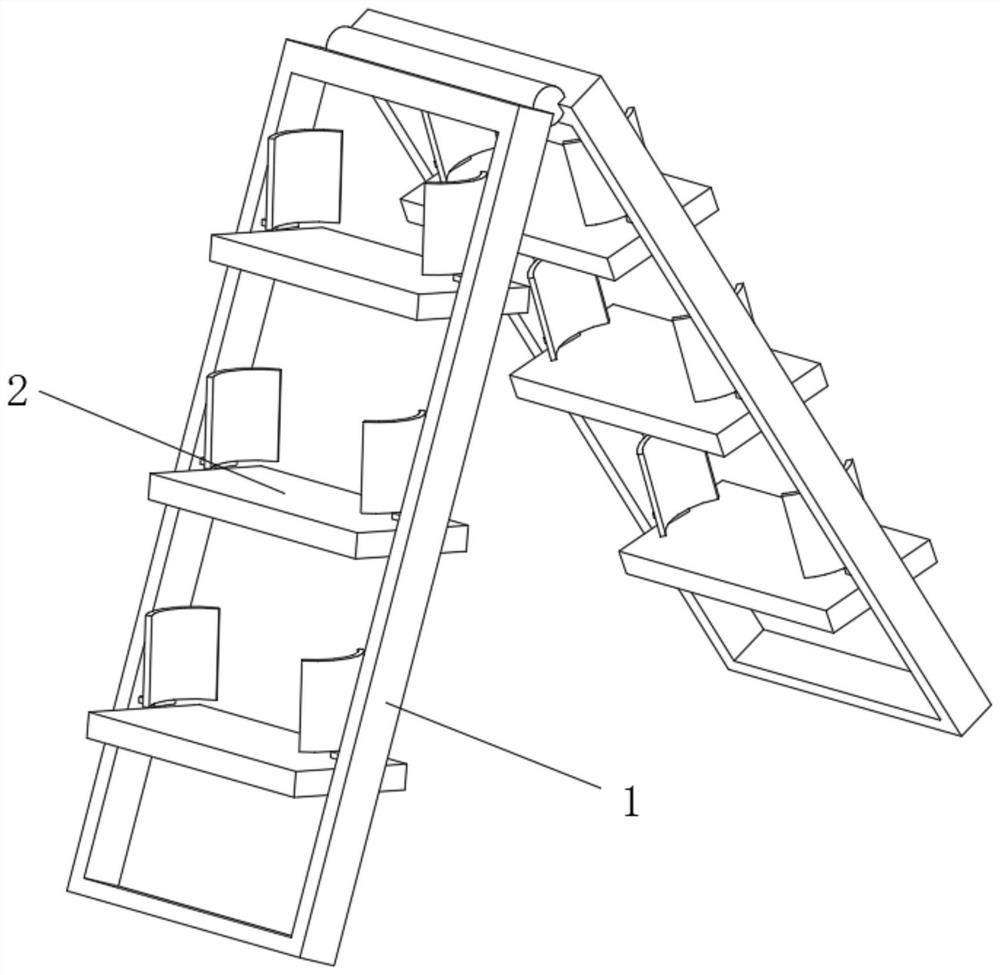

Electric power overhaul herringbone ladder

InactiveCN112681966AGuaranteed stabilityGuaranteed supportLaddersStructural engineeringMechanical engineering

The invention discloses an electric power overhaul herringbone ladder. The electric power overhaul herringbone ladder comprises a herringbone ladder frame, wherein protective pedal mechanisms are uniformly and fixedly connected to the transverse position of the herringbone ladder frame; each protective pedal mechanism comprises a bearing pedal; an adjusting storage groove is formed in the middle position of the top of each bearing pedal; supporting arc-shaped pressing plates are rotatably connected to the left side and the right side of the inner part of each adjusting storage groove; protective clamping rods are fixedly connected to the positions, close to the outer sides, of the top ends of the supporting arc-shaped pressing plates; a magnet block is fixedly connected to one end, far away from the corresponding protective clamping rod, of a corrugated sleeve frame; a protective air bag is fixedly connected to the surface of the top of each supporting arc-shaped pressing plate; limiting inserting rod assemblies are uniformly and fixedly connected to the surfaces of the top ends of the supporting arc-shaped pressing plates of the protective air bags and are located in the protective air bags; and protective conduction assemblies are uniformly arranged at the top ends of the outer parts of the protective air bags. The invention relates to the technical field of electric power. According to the electric power overhaul herringbone ladder disclosed by the invention, the phenomena that workers tread and slide are avoided, and the safety of the workers in a climbing process is protected.

Owner:张谦荣

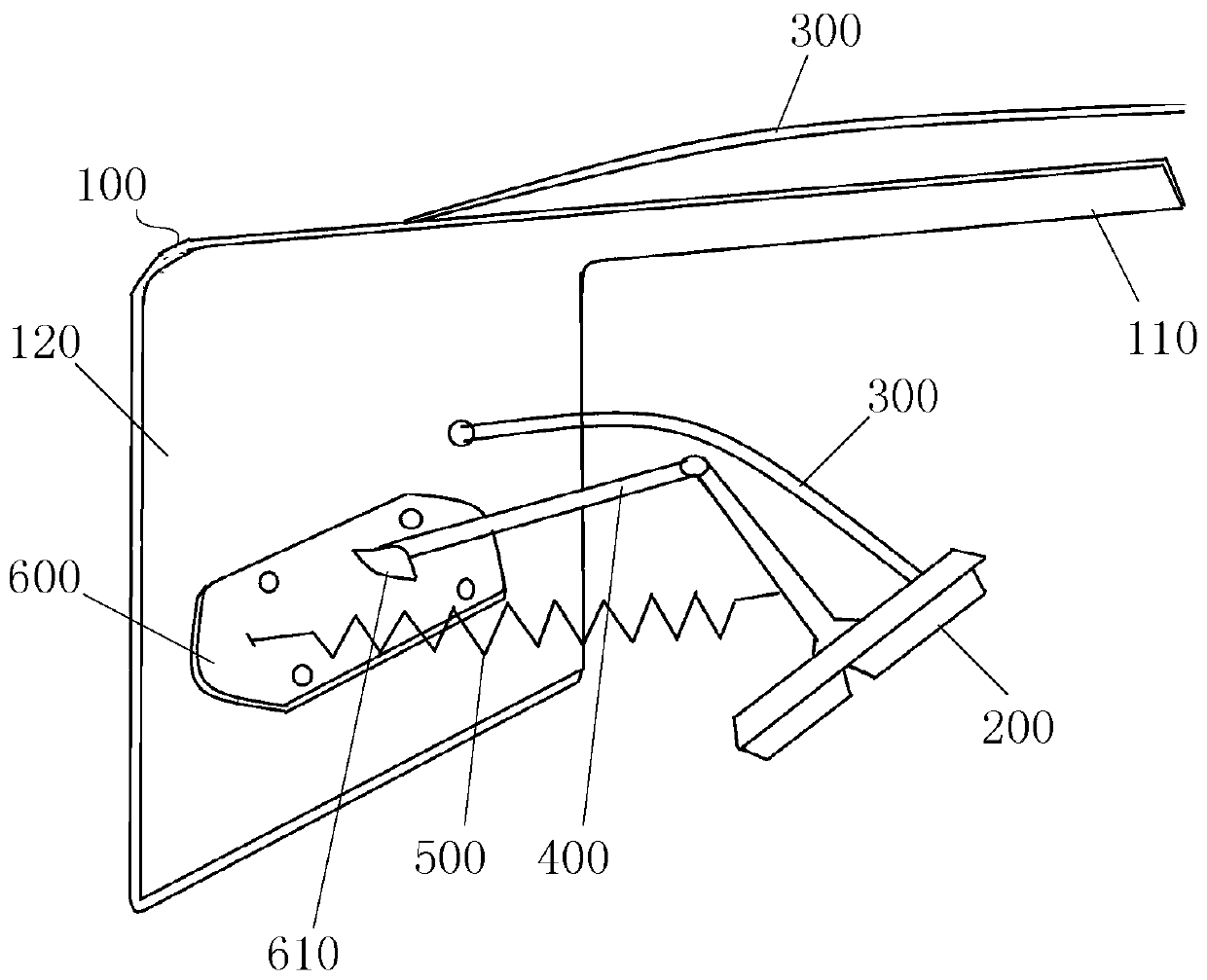

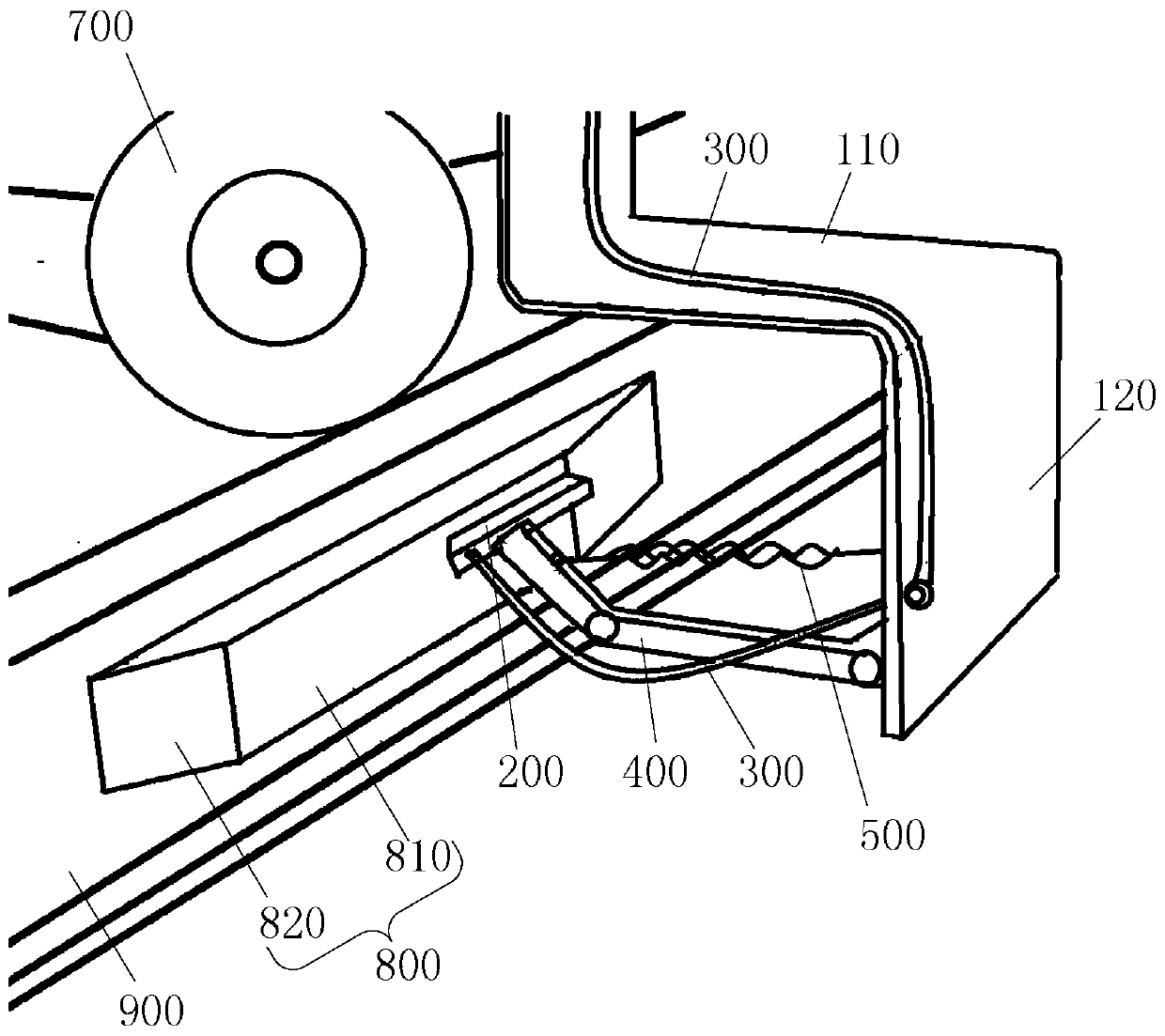

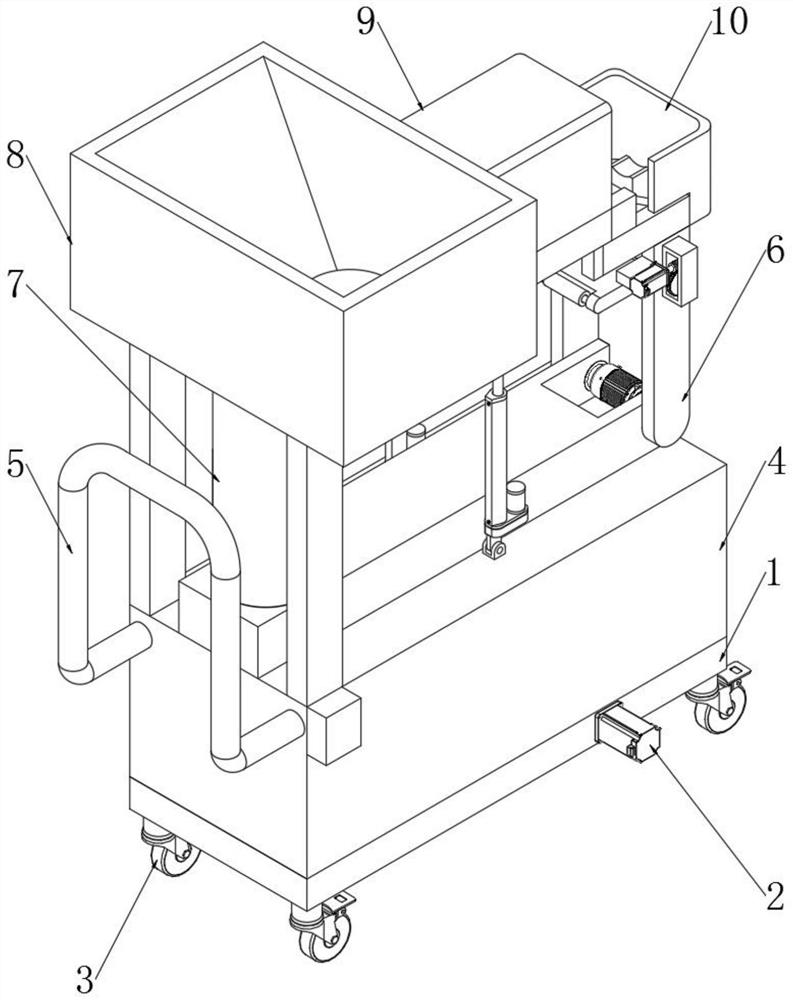

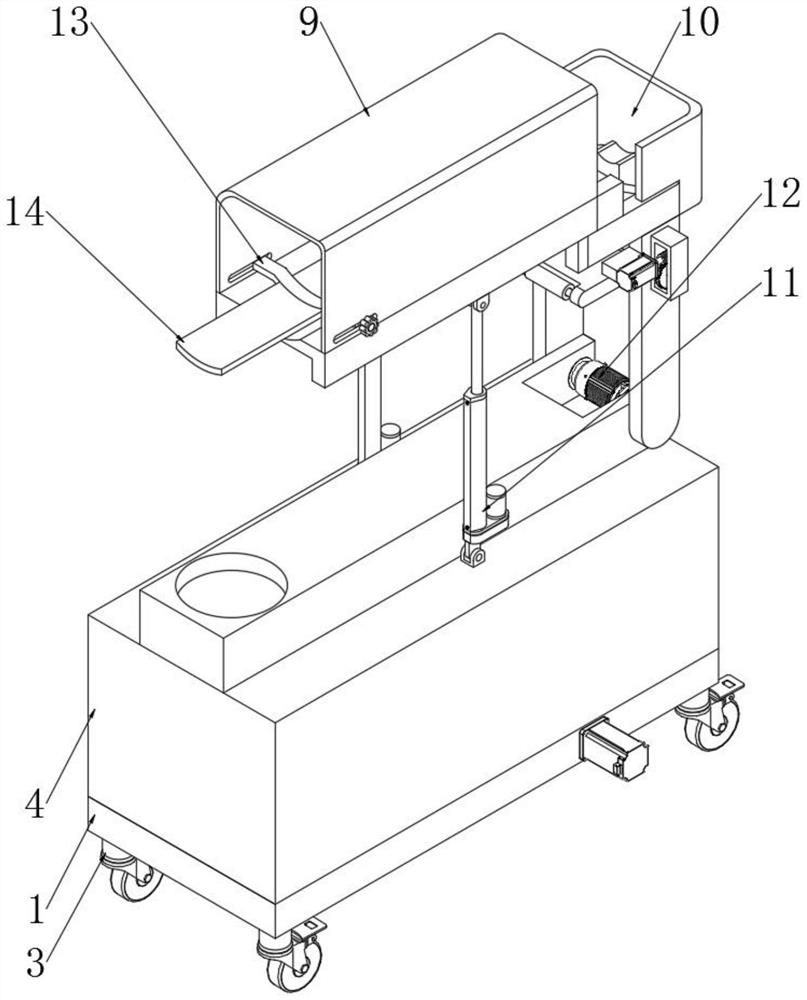

A milling machine with dust removal function

ActiveCN107984014BEffective flushing and cleaningAvoid cloggingLarge fixed membersMilling equipment detailsMedical equipmentPulp and paper industry

The invention relates to the technical field of milling machine medical equipment, and discloses a milling machine with the dust removal function. The milling machine comprises a machine table, a groove is formed in the machine table, and is connected with a discharge pipe, an opening and closing plate is arranged in the discharge plate, and is connected with a spring, the spring is connected to adischarge pipe which communicates with a negative pressure draught fan, and fan blades are arranged in the negative pressure draught fan; an air box and a rotation connection rotating shaft are arranged on the machine table, the air box is connected with a tee-joint pipe which comprises a first end, a second end and a third end, the first end is communicated with the air box, the second end is communicated with the negative pressure draught fan, the third end extends into the groove, the rotating shaft is connected with a power mechanism, a swing rod is fixedly connected to the rotating shaft, a first rod is hinged to the machine table, a concave disc is fixedly connected to the first rod, a second rod is hinged between the first rod and the swing rod, a water tank is arranged on the machine table, and is communicated with a water pipe, the water pipe extends to the position over the concave disc, and the third end is located under the concave disc. Sweeps and waste dust accumulated nthe milling machine can be treated in time.

Owner:淮安市东旭达五金粘胶制品有限公司

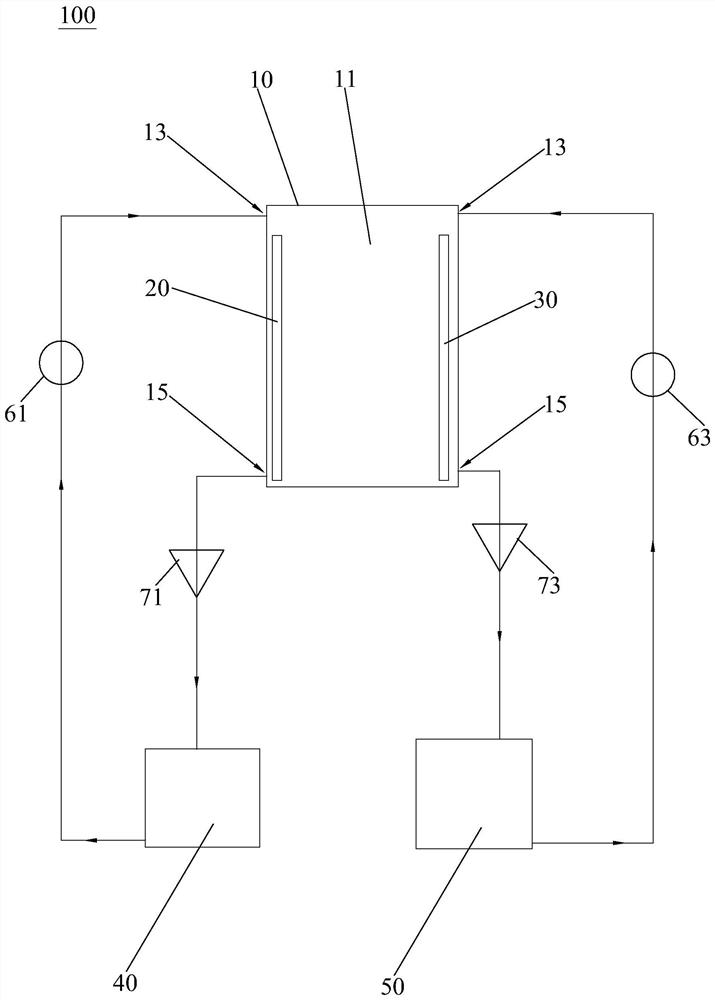

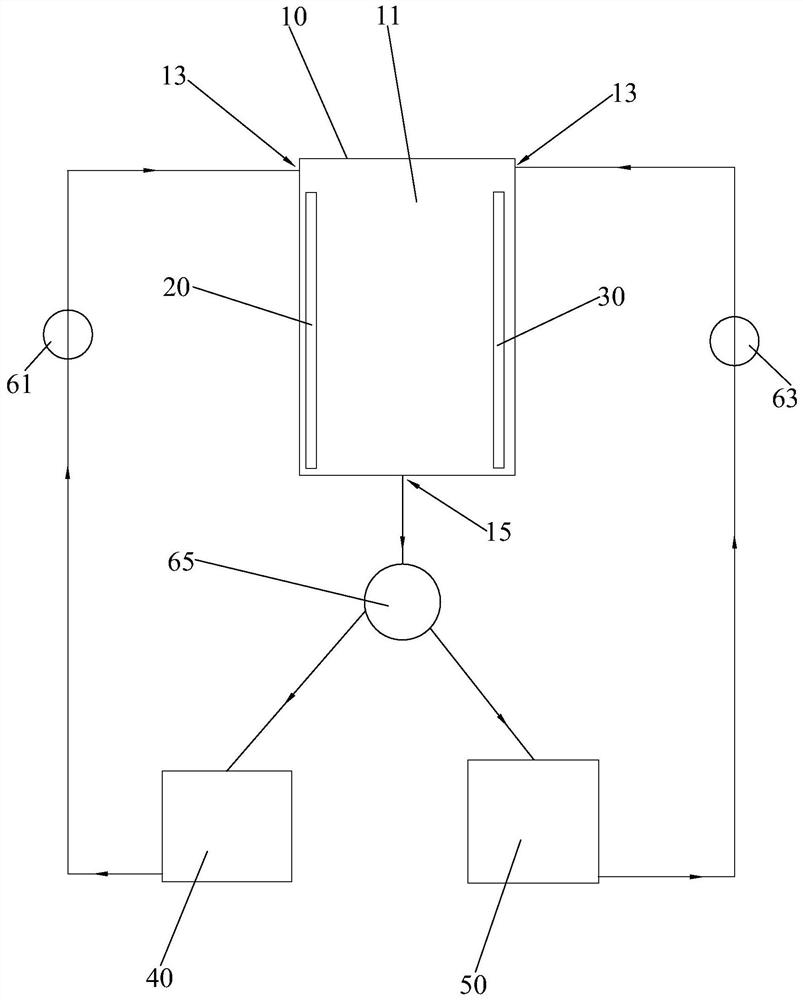

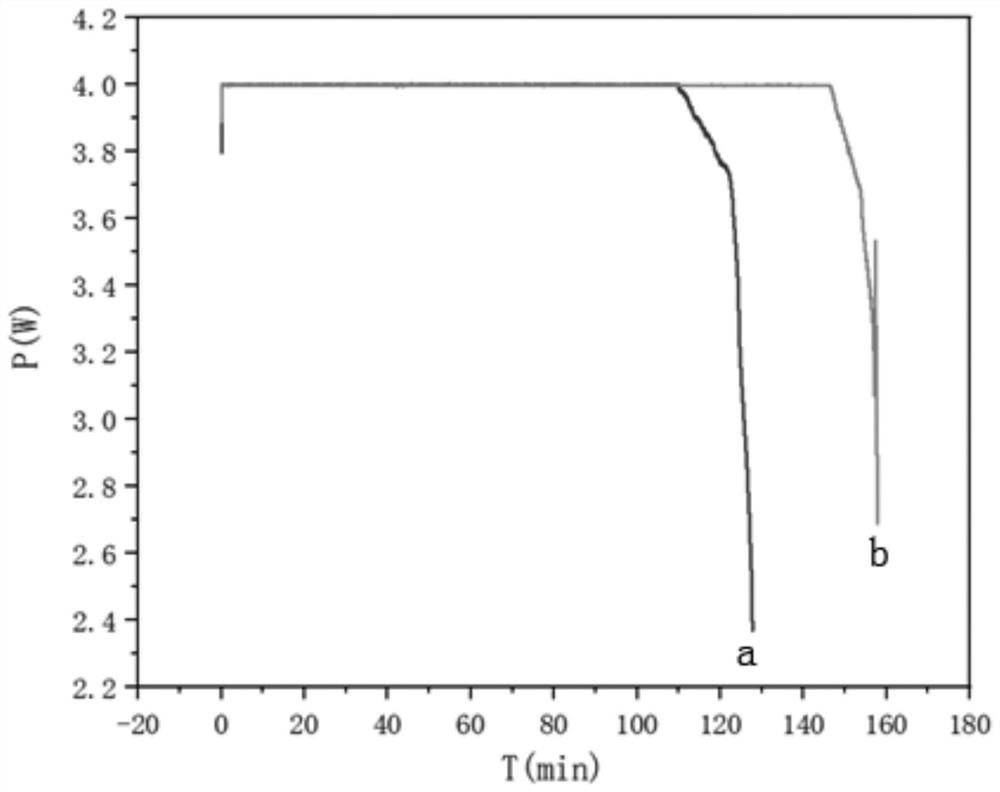

Metal-air battery capable of discharging for multiple times and implementation method

InactiveCN112164844AAvoid corrosionMultiple dischargesFuel and secondary cellsSecondary cells servicing/maintenanceElectrolytic agentElectrical battery

The invention provides a metal-air battery capable of discharging for multiple times. The battery comprises a shell, a metal electrode, an air electrode, an electrolyte tank and a cleaning liquid tank. The shell is provided with a cavity, a liquid inlet and a liquid outlet, the metal electrode and the air electrode are located in the cavity, the electrolyte tank is filled with an electrolyte, thecleaning liquid tank is filled with a cleaning liquid, and the cleaning liquid contains a corrosion inhibitor. An outlet of the electrolyte tank is communicated with the liquid inlet, an inlet of theelectrolyte tank is communicated with the liquid outlet, an outlet of the cleaning liquid tank is communicated with the liquid inlet, an inlet of the cleaning liquid tank is communicated with the liquid outlet, and the electrolyte tank and the cleaning liquid tank are operated to selectively convey electrolyte or cleaning liquid into the cavity. According to the metal-air battery, the problem of difficulty in secondary starting of the metal-air battery can be solved, and self-corrosion or corrosion of the metal electrode in the shelving process is avoided, so that intermittent discharge, repeated use and repeated discharge of the metal-air battery can be realized. The invention further provides an implementation method for multiple times of discharging of the metal-air battery.

Owner:蔚蓝(广东)新能源科技有限公司

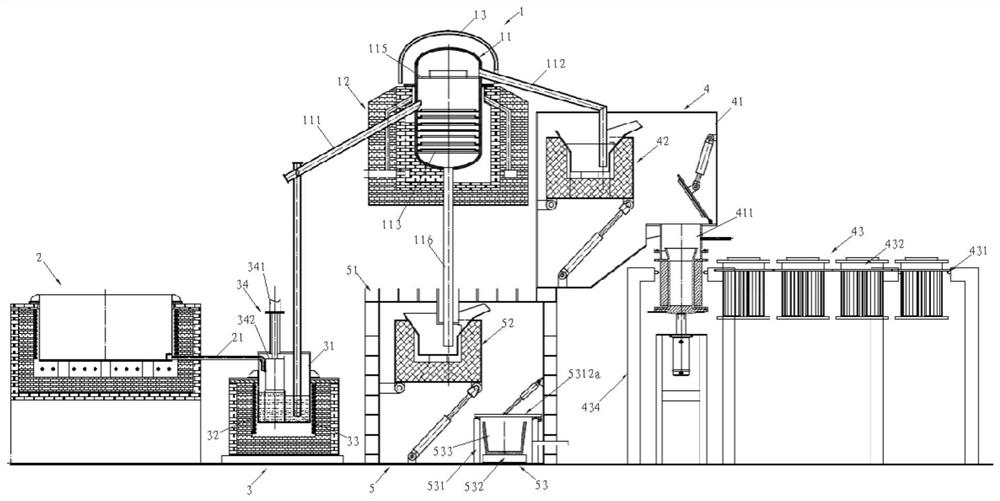

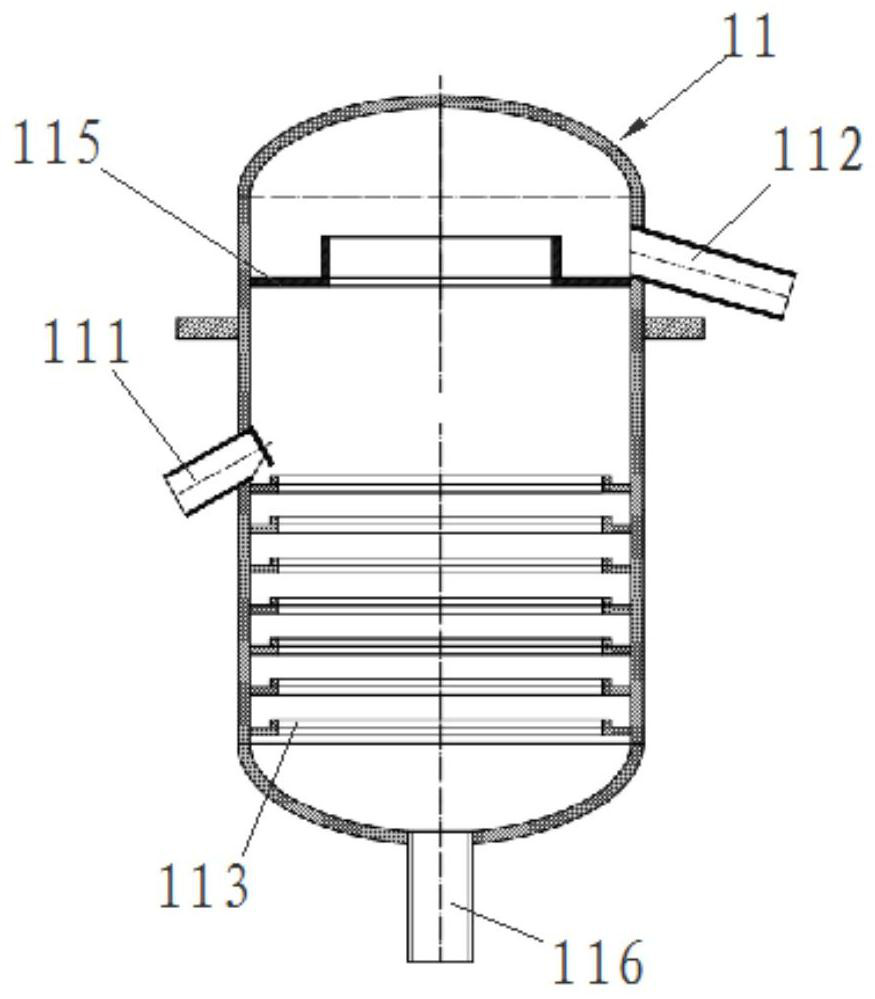

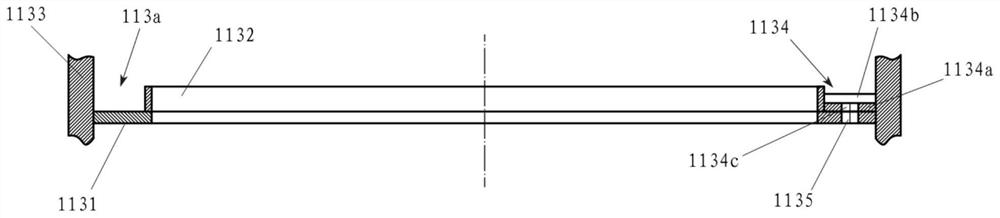

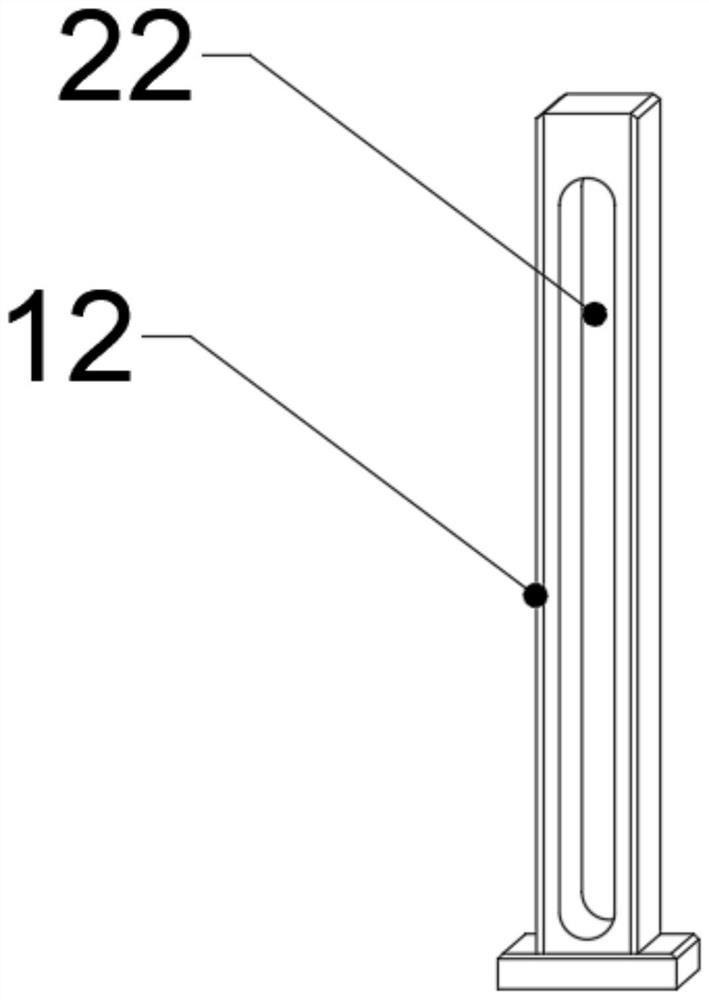

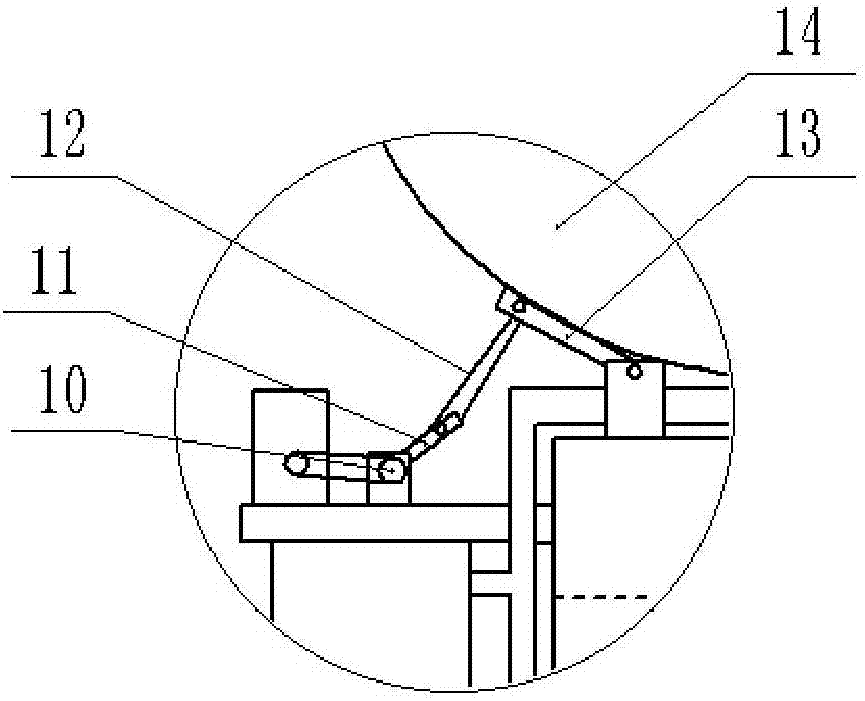

Vacuum distillation and forming device and method for extracting metal calcium from carbide slag

PendingCN113265550AImprove distillation efficiencyIncrease productivityIngot casting plantsProcess efficiency improvementSlagCarbide

The invention relates to a vacuum distillation and forming device and method for extracting metal calcium from carbide slag. The vacuum distillation device comprises a vacuum calcium distillation furnace (11) and a heating furnace seat (12) for mounting the vacuum calcium distillation furnace (11); a part of the vacuum calcium distillation furnace (11) is covered with a cooling device (13), and the rest part of the vacuum calcium distillation furnace (11) is positioned in the heating furnace seat (12); and the cooling device (13) is positioned above the heating furnace seat (12). The vacuum distillation device is high in distillation efficiency, and the production efficiency of refined calcium is greatly improved.

Owner:鄂尔多斯市欣欣宸瑞高纯材料有限公司

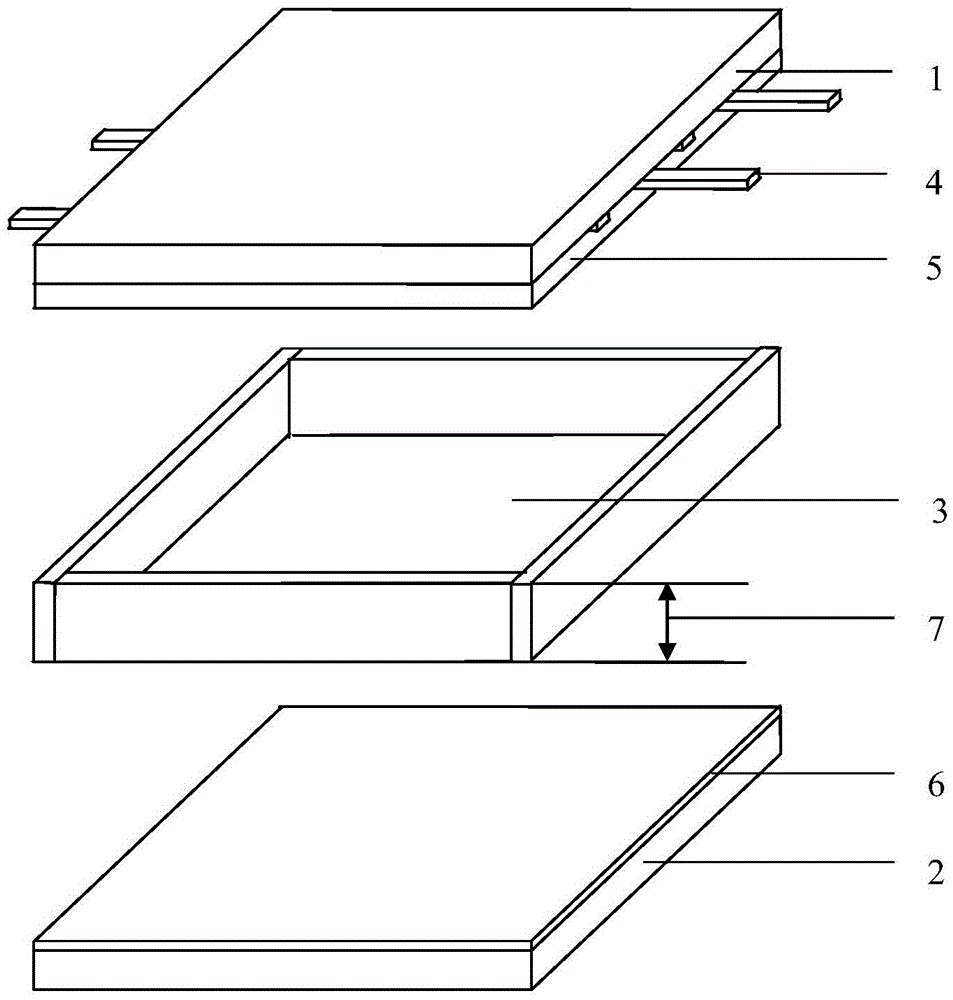

Automatic continuous plate-and-frame filter press

InactiveCN111821734ARealize intermittent dischargeAchieve the effect of automatic continuous filter pressFiltration separationControl engineeringFilter press

The invention discloses an automatic continuous plate-and-frame filter press which comprises a frame body and a fixed part fixed above the frame body, wherein a hopper is fixed above the fixed part through a vertical mounting piece; a discharging pipe is fixed to the bottom of the hopper in a penetrating mode; and a blocking assembly used for controlling the discharging pipe to be opened and closed is horizontally and movably arranged below the discharging pipe. The power structure works to simultaneously drive the blocking assembly and a pump machine to work, wherein the blocking assembly acts to enable materials in the hopper to be discontinuously discharged into the filter frame, and with the matching of the pump machine, a new material is continuously injected into the hopper accordingto the automatic continuous filter pressing device, the filter pressing piece is driven by the connecting rod to rotate back and forth to extrude materials discharged into the filter frame when the blocking assembly works, so that solid and liquid in the materials are separated, and finally, the effect of automatic continuous filter pressing is achieved.

Owner:明洋(山东)环境科技有限公司

A cement crushing device

ActiveCN111151339BReduce vibrationExtended service lifeNon-rotating vibration suppressionDirt cleaningGear wheelClassical mechanics

The invention discloses a cement crushing device, which comprises a first horizontal plate and a base, the lower surface of the first horizontal plate is fixedly connected with the base, and the upper surface of the first horizontal plate is installed with a shock absorbing device. The cement crushing device can reduce the vibration of the device during operation through the mutual cooperation between the vertical bar, the first half gear, the first tooth plate, the second horizontal plate, the first spring and the L-shaped plate. range, thereby improving the service life of the equipment, through the mutual cooperation between the second motor, the second half gear, the second tooth plate, the second spring and the pipeline, so as to prevent the occurrence of material blocking and improve the The working efficiency reduces the labor force. Through the mutual cooperation between the filter screen, point and horizontal plate, pipe, fan and the first horizontal plate, the dust generated during crushing can be absorbed and processed in a centralized manner, thus protecting the environment. Operator health.

Owner:承德冀东水泥有限责任公司

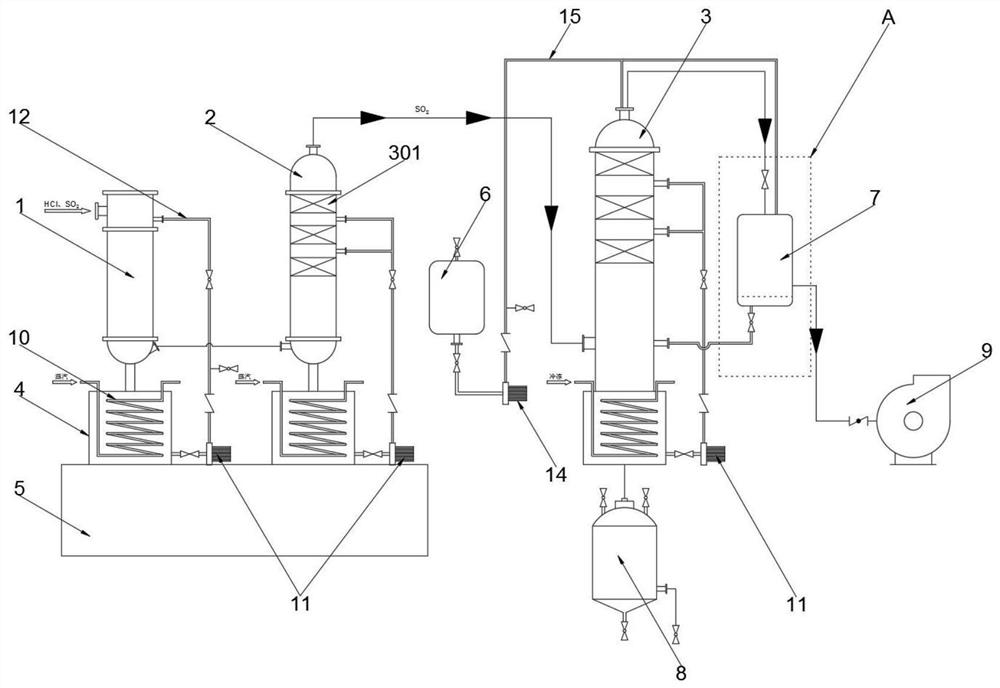

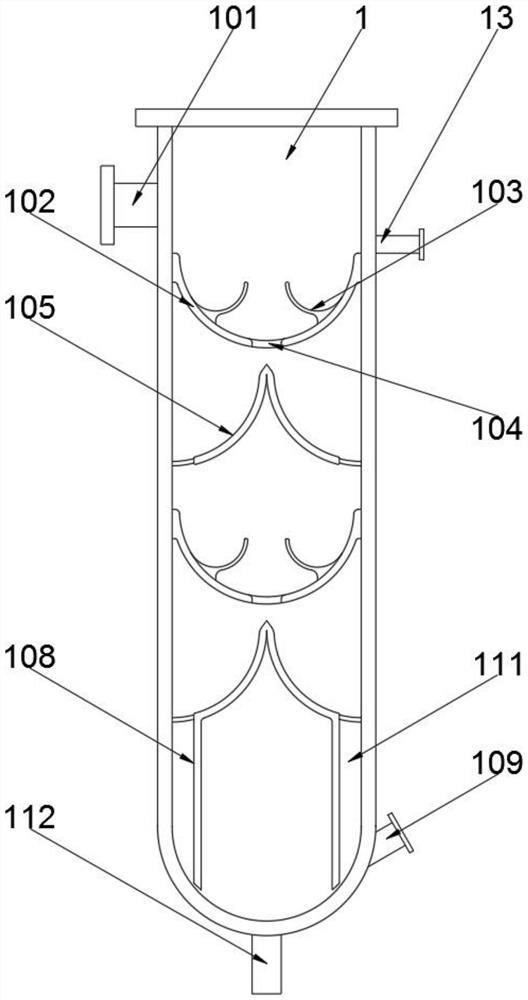

A hydrogen chloride, sulfur dioxide mixed tail gas separation device

ActiveCN112370942BAchieve mutual separationAvoid pollutionChlorine/hydrogen-chloride purificationDispersed particle separationTemperature controlSulfite salt

The invention discloses a hydrogen chloride and sulfur dioxide mixed tail gas separation device, which relates to the technical field of waste gas treatment. The mixed tail gas separation device includes a separation and absorption tower, a primary packing absorption tower and a secondary packing absorption tower, and one side of the separation and absorption tower is arranged There is a primary packing absorption tower, one side of the primary packing absorption tower is provided with a secondary packing absorption tower, a sodium sulfite filter tank is also provided below the secondary packing absorption tower, and a vacuum filter tank is provided on one side of the secondary packing absorption tower. Adsorption tank, the invention is scientific and reasonable, safe and convenient to use, the invention utilizes the different solubility of hydrogen chloride gas and sulfur dioxide gas at different temperatures, and controls the temperature of water and liquid caustic soda through the temperature control tube, so that about 30% hydrochloric acid can be obtained As a by-product, at this time, at a temperature of 50°C-65°C, the solubility of sulfur dioxide in 30% hydrochloric acid is only 0.2%, and the mutual separation of hydrogen chloride gas and sulfur dioxide gas is well realized.

Owner:江苏春江润田农化有限公司

A wheat drying device for flour processing

ActiveCN112129058BImplement the pre-screening functionRealize the filtering functionSievingGas current separationBiotechnologyElectric machinery

The invention discloses a wheat drying device for flour processing, which belongs to the technical field of flour processing equipment; a wheat drying device for flour processing, comprising a heat pump main unit, a condenser sub-unit and a drying bin. The heat pump main body is arranged outside the drying bin. The inner cavity of the drying warehouse is surrounded by a partition board to form a heating chamber. A drying chamber is formed between the inner wall of the drying chamber and the partition board. The condenser extension is installed in the heating chamber. The centrifugal fan in the chamber, the bottom of the drying bin is fixedly connected with the collection bin, and the center of the bottom of the collection bin is fixedly connected with the driving motor, and the driving end of the driving motor is fixedly connected with the cross transmission plate through the rotating shaft placed in the drying bin. The end of the transmission plate is fixedly connected with the driven gear through the rotating drum; the invention disperses and dries the wheat after screening and removing impurities, and at the same time improves the dispersion performance of the hot air in the drying chamber and improves the uniformity of drying.

Owner:XIAOXIAN JIAJIE FLOUR CO LTD

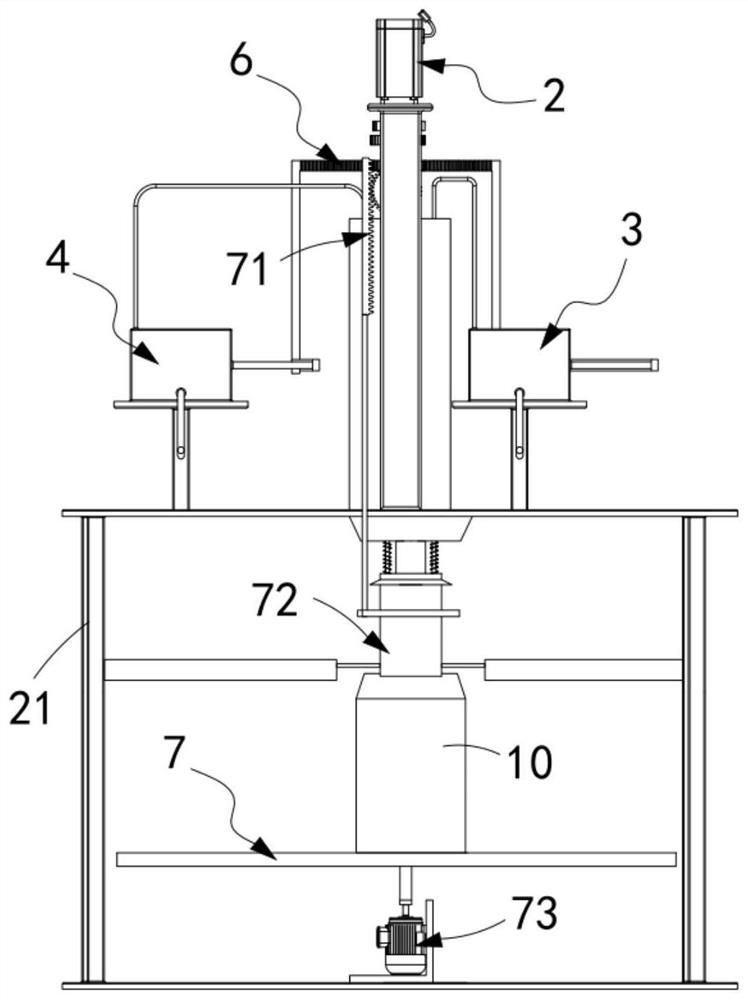

Edible oil processing discharging device

InactiveCN111825048AIncrease productivityHigh degree of automationBarrels/casks fillingFatty-oils/fats refiningProcess engineeringEdible oil

The invention relates to an edible oil processing discharging device which comprises a tank body, an insulation layer, a stem channel, a first filter screen and a second filter screen and further comprises a driving mechanism, an edible oil feeding mechanism, a decolorizing agent feeding mechanism and a stirring mechanism as well as a discharging filling mechanism, wherein a first feed inlet and asecond feed inlet communicate to the stirring mechanism, the edible oil feeding mechanism and the decolorizing agent feeding mechanism are in synchronous drive to the driving mechanism through a transmission mechanism to input edible oil and a decolorizing agent quantatively; and the discharging filling mechanism comprises a control assembly in transmission connection to the driving mechanism, alifting assembly slidably connected to the lower end of the tank body in a vertical direction and an oil bucket transmission assembly located below the tank body. The edible oil processing dischargingdevice solves the technical problem that the production efficiency is low as it is needed to control edible oil successively manually during filling because the edible oil cannot be output quantatively.

Owner:唐海红

Milling machine with dust removal function

ActiveCN107984014ARealize the control of the strength of negative pressureRealize intermittent dischargeLarge fixed membersMilling equipment detailsMedical equipmentPulp and paper industry

The invention relates to the technical field of milling machine medical equipment, and discloses a milling machine with the dust removal function. The milling machine comprises a machine table, a groove is formed in the machine table, and is connected with a discharge pipe, an opening and closing plate is arranged in the discharge plate, and is connected with a spring, the spring is connected to adischarge pipe which communicates with a negative pressure draught fan, and fan blades are arranged in the negative pressure draught fan; an air box and a rotation connection rotating shaft are arranged on the machine table, the air box is connected with a tee-joint pipe which comprises a first end, a second end and a third end, the first end is communicated with the air box, the second end is communicated with the negative pressure draught fan, the third end extends into the groove, the rotating shaft is connected with a power mechanism, a swing rod is fixedly connected to the rotating shaft, a first rod is hinged to the machine table, a concave disc is fixedly connected to the first rod, a second rod is hinged between the first rod and the swing rod, a water tank is arranged on the machine table, and is communicated with a water pipe, the water pipe extends to the position over the concave disc, and the third end is located under the concave disc. Sweeps and waste dust accumulated nthe milling machine can be treated in time.

Owner:淮安市东旭达五金粘胶制品有限公司

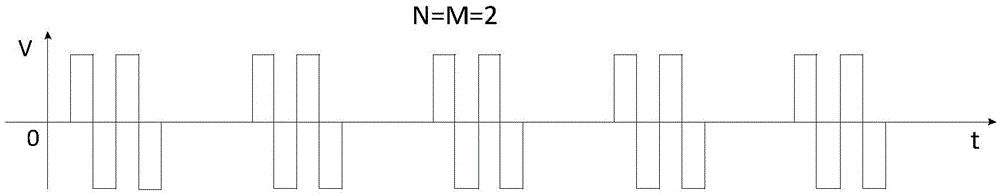

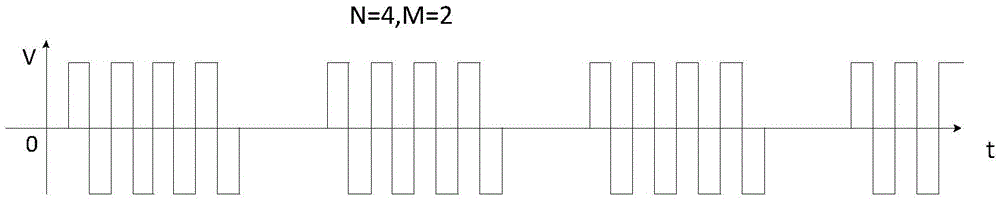

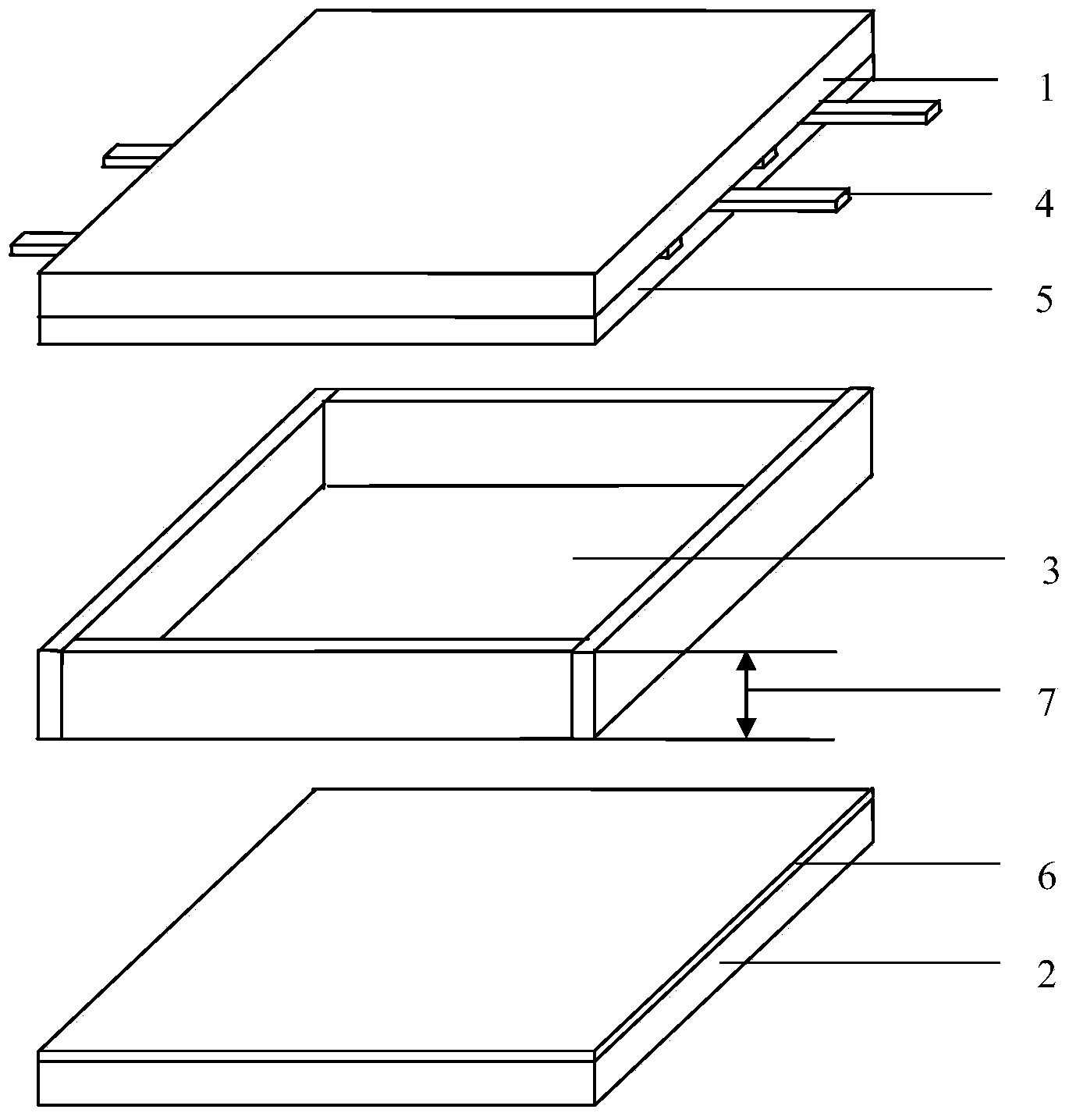

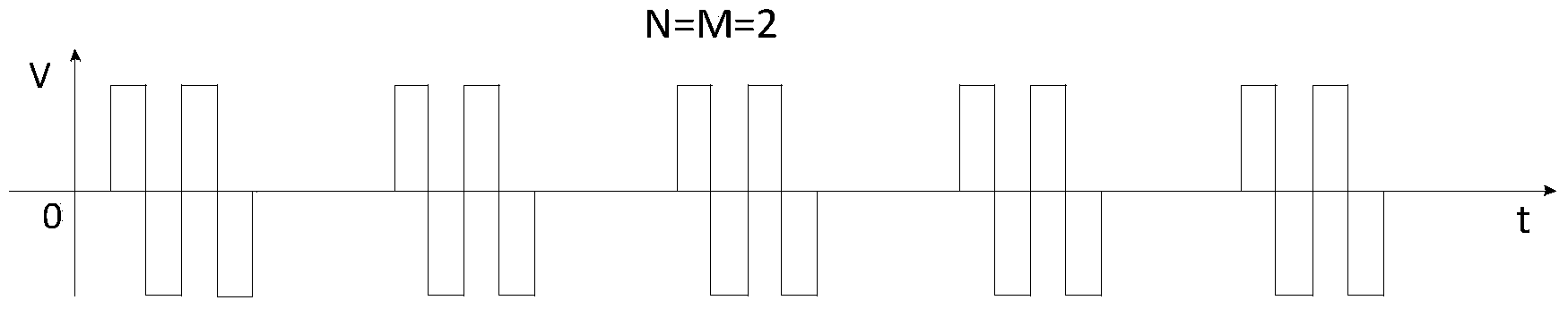

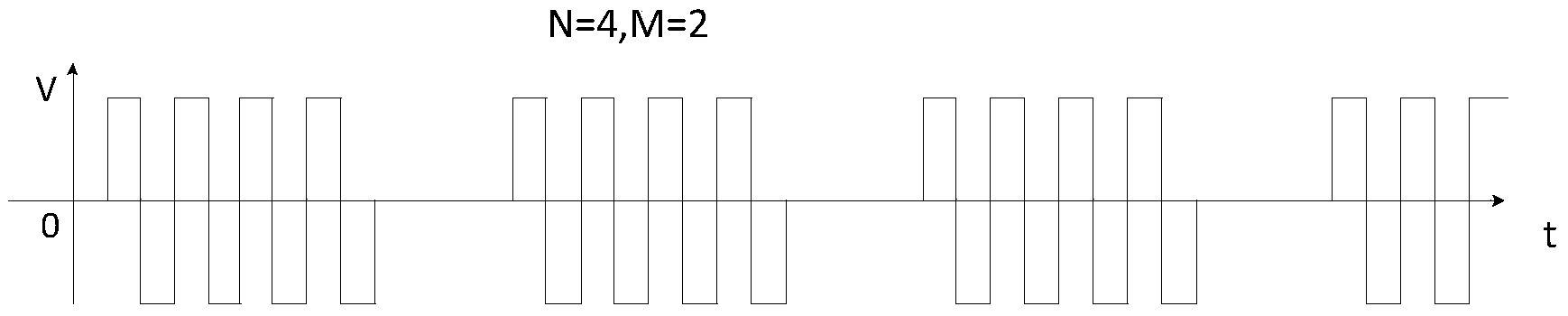

A driving method of a plasma flat panel light source

InactiveCN103687261BDoes not affect brightnessIncremental brightnessElectric lighting sourcesSingle pulse train generatorElectricityHeat losses

The invention discloses a plasma flat light source driving method. A driving signal applied to a plasma flat light source adopts a periodic signal formed by N square-wave pulses which are provided with rapid rising edges and rapid falling edges with frequency of 10-80KHZ and M low-level signals in a spacing way. The square-wave pulses are provided with the rapid rising edges and the falling edges. The plasma flat light source discharges only at the rising edges and the falling edges of the square-wave pulses and does not discharge at low levels. N is less than 5, M is less than 5 and N is greater than or equal to M. In order to improve light emission efficiency of the plasma flat light source, the invention brings forward the driving waveform adopting the mode that multiple high-level square-wave pulses and the low-level signals are arranged in the spacing way under the premise that the square-wave pulses are provided with steep rising edges so that the plasma flat light source can discharge intermittently and can emit light normally. Therefore, discharging maintenance time is reduced, electric heat loss can be greatly reduced, heat amount of a screen is reduced and light emission efficiency of the plasma flat light source is enhanced.

Owner:NANJING JIANQIAO XINGANG TECH DEV CO LTD

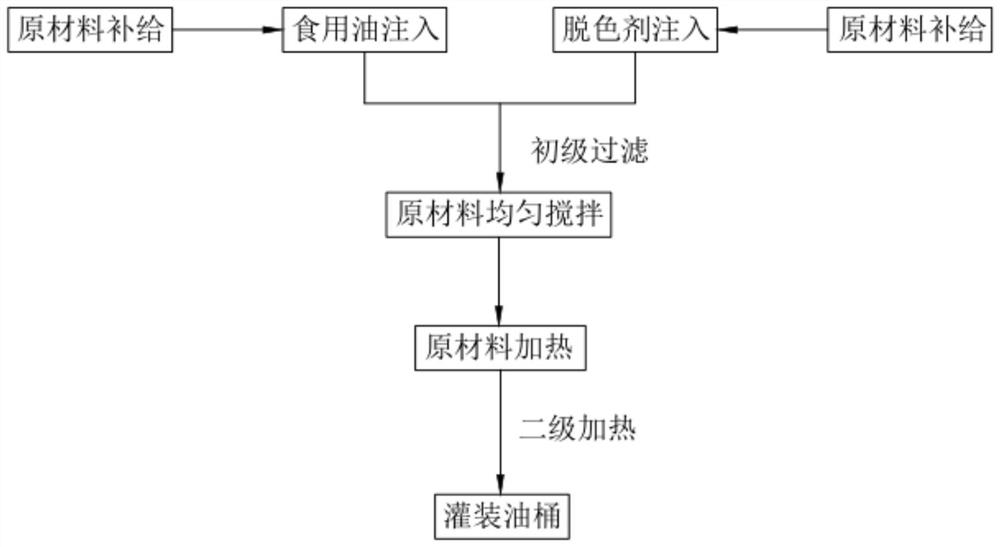

Edible oil processing and discharging technology

InactiveCN111793521AIncrease productivityHigh degree of automationBarrels/casks fillingFatty-oils/fats refiningThermodynamicsProcess engineering

The invention relates to an edible oil processing and discharging technology. The technology comprises the following steps: 1, supplying raw materials; 2, injecting edible oil; 3, injecting a decolorizing agent; 4, uniformly stirring the raw materials; 5, heating the raw materials, introducing the fully stirred mixture into a flow guide mechanism, introducing steam into a steam channel to heat thetank body, fully reacting the heated edible oil and decolorizing agent in the tank body, and outputting to the output end of a tank body through a second filter screen after a complete reaction; and6, filling an oil drum, using a driving mechanism to drive a control assembly to conduct transmission, and enabling a lifting assembly to slide downwards along the output end of the tank body and stretch into the oil drum located on the oil loading station of a rotating disc, so as to complete oil injection work. The technical problems that quantitative output of edible oil cannot be achieved, then manual sequential control is needed during filling, and the production efficiency is low are solved.

Owner:唐海红

Plasma flat light source driving method

InactiveCN103687261ADoes not affect brightnessIncremental brightnessElectrical apparatusElectric lighting sourcesElectricityWave shape

The invention discloses a plasma flat light source driving method. A driving signal applied to a plasma flat light source adopts a periodic signal formed by N square-wave pulses which are provided with rapid rising edges and rapid falling edges with frequency of 10-80KHZ and M low-level signals in a spacing way. The square-wave pulses are provided with the rapid rising edges and the falling edges. The plasma flat light source discharges only at the rising edges and the falling edges of the square-wave pulses and does not discharge at low levels. N is less than 5, M is less than 5 and N is greater than or equal to M. In order to improve light emission efficiency of the plasma flat light source, the invention brings forward the driving waveform adopting the mode that multiple high-level square-wave pulses and the low-level signals are arranged in the spacing way under the premise that the square-wave pulses are provided with steep rising edges so that the plasma flat light source can discharge intermittently and can emit light normally. Therefore, discharging maintenance time is reduced, electric heat loss can be greatly reduced, heat amount of a screen is reduced and light emission efficiency of the plasma flat light source is enhanced.

Owner:NANJING JIANQIAO XINGANG TECH DEV CO LTD

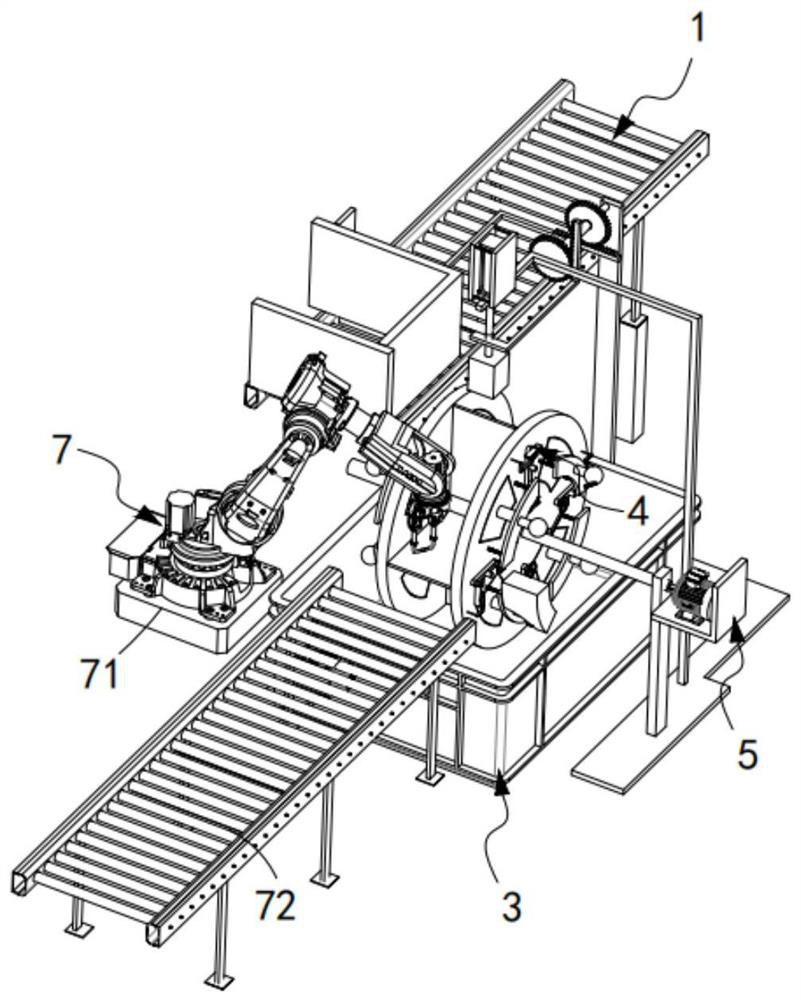

Post-processing equipment for infant wet tissue production

InactiveCN112709022AEasy to useFully contactedTextile treatment machine partsLiquid/gas/vapor removal by squeezingFiberProcess engineering

The invention relates to post-processing equipment for infant wet tissue production. The post-processing equipment comprises an input device, an electrostatic treatment device and an electrostatic liquid storage box; the electrostatic treatment device comprises a station switching mechanism, a driving mechanism, a draining mechanism and an output mechanism used for outputting the destaticized fiber clusters; the station switching mechanism is sequentially provided with a material receiving station, a pretreatment scattering station, a destaticizing station and a draining station in the transmission direction of the station switching mechanism; the draining mechanism is located on the draining station; and the station switching mechanism is provided with a plurality of sets of positioning assemblies at equal intervals in the circumferential direction, and any positioning assembly is matched with a control assembly in the circumferential rotating process to position and scatter fiber clusters. The post-processing equipment solves the technical problems that static electricity can be generated in the production process of fibers, sufficient static electricity removing work needs to be conducted on the fibers during aftertreatment, and spraying is not uniform and insufficient due to the fact that an electrostatic gun is adopted for spraying at present.

Owner:郑欢欢

A mixing and batching device for oil field development and production of viscosity reducer

ActiveCN112495287BStir wellRealize Intermittent ConnectivityTransportation and packagingMixer accessoriesReciprocating motionOil field

The invention discloses a mixing and batching device for the production of viscosity reducer for oilfield development, relates to the technical field of viscosity reducer production, and comprises a stirring tank, the lower side of the stirring tank is provided with a base, and the lower side of the stirring tank is connected with the upper side wall of the base Rotating connection, the rear side wall of the mixing tank is fixedly connected with a vertical plate, a feed inlet is opened on the side wall of the mixing tank, a deflector is connected to the feed inlet, and two vertical plates located on the upper side of the deflector are installed on the vertical plate There are two extruding rollers in contact with each other, and a horizontal material receiving plate is fixedly connected to the vertical plate, and the middle part of the horizontal material receiving plate is provided with a discharge port corresponding to the guide plate, and two guiding plates are fixedly connected to the outer wall of the vertical plate. frame, and connecting plates are slidingly arranged in the two guide frames. The invention realizes the intermittent discharge of the raw materials in the storage tank through the reciprocating motion of the storage tank driven by the connecting plate, realizes the premixed material while avoiding the difficulty of stirring caused by one-time pouring, resulting in uneven stirring, and realizes the The reciprocating rotation of the stirring shaft ensures that the raw materials are fully stirred.

Owner:胜利星科石油技术开发(山东)有限公司

Variable multi-ball exercise equipment for physical education

ActiveCN114653044AGuaranteed practice effectImprove applicabilitySport apparatusPhysical educationGear wheel

The variable multi-ball exercise equipment for physical education comprises a bottom plate, movable trundles are fixedly arranged at the four corners of the bottom end of the bottom plate, the edge side of the top end of the bottom plate is fixedly connected with the edge side of the bottom end of a supporting box, and the two sides of one end of the supporting box are fixedly connected with the two ends of a handle; electric telescopic rods are hinged to the two sides of the middle of the top end of the supporting box through movable hinges, the acting plate connected with the acting shaft acts on the stress plate, a clockwork spring in the driving box is connected with the stress shaft connected with the stress plate, and in this way, balls can be thrown out in a throwing mode; a first large gear connected with an acceleration motor is meshed with a first small gear, the first small gear is meshed with a second small gear connected with a ball serving wheel through a second large gear connected with a transmission shaft, balls can be horizontally shot in the mode, people can carry out different shooting modes according to selection of the balls, and higher applicability is achieved; and the ball practice effect of the personnel is ensured.

Owner:江西师范高等专科学校

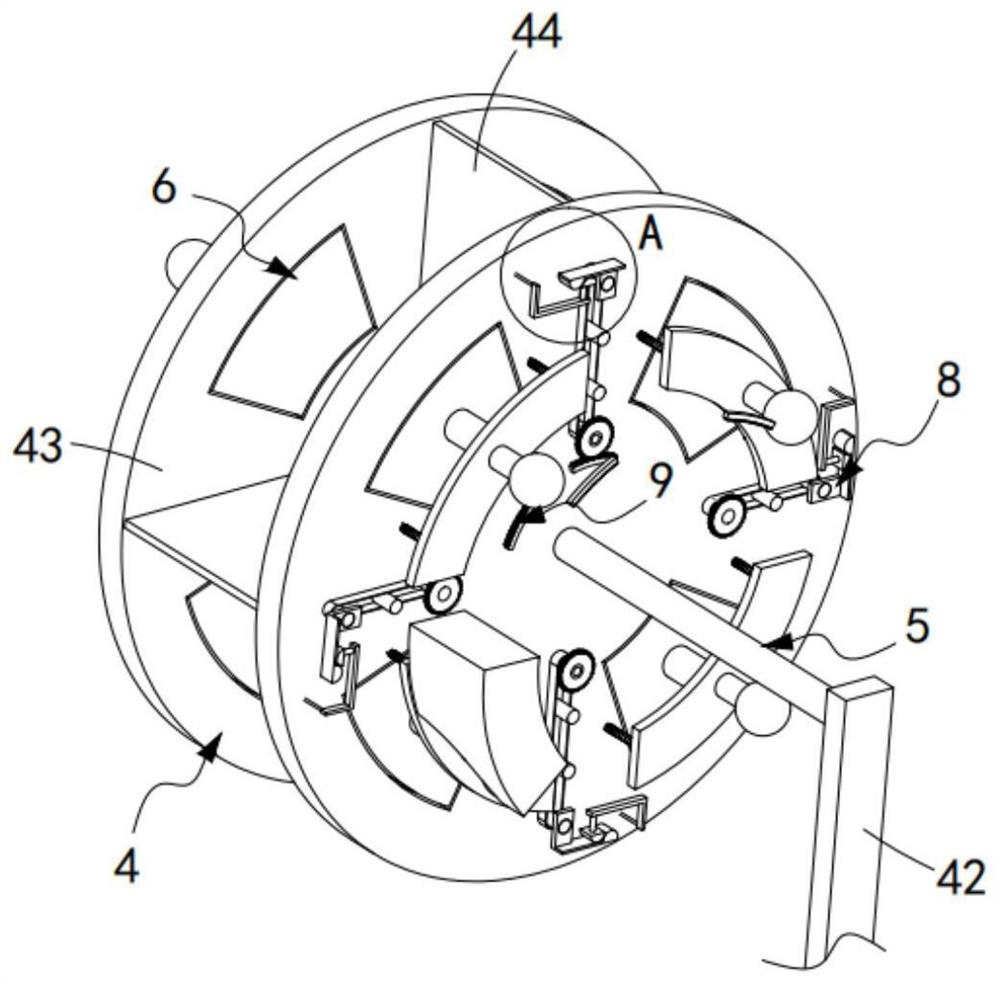

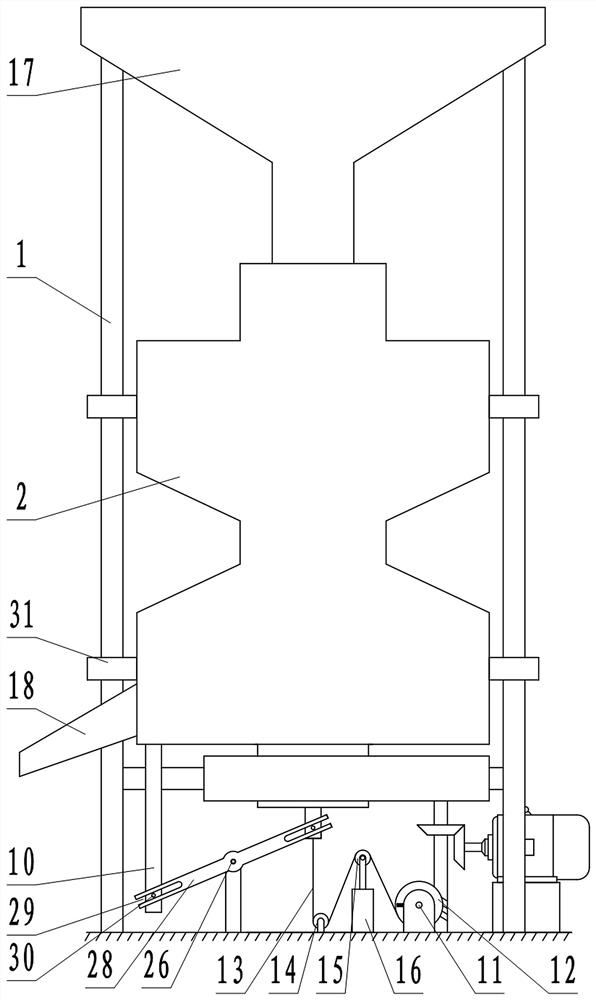

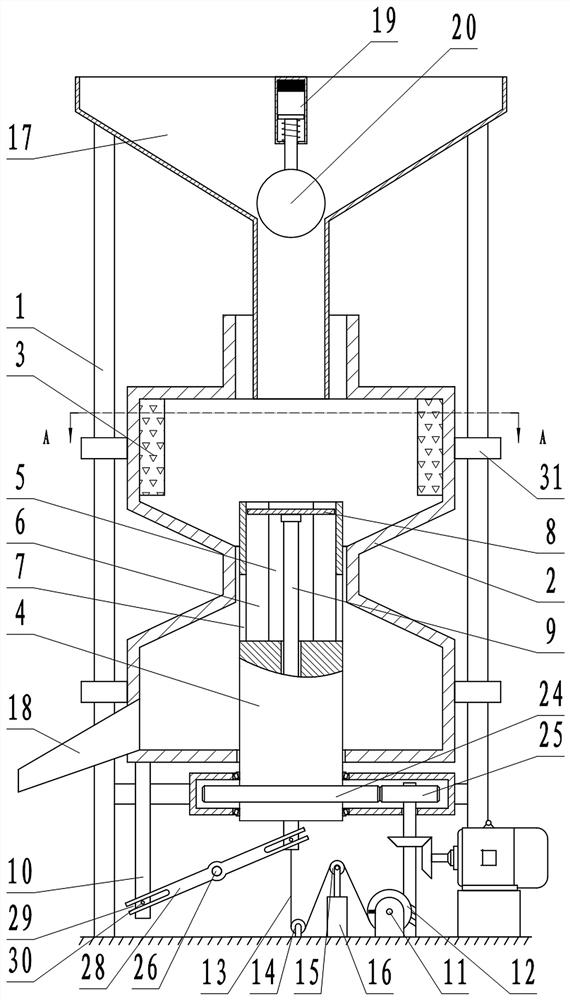

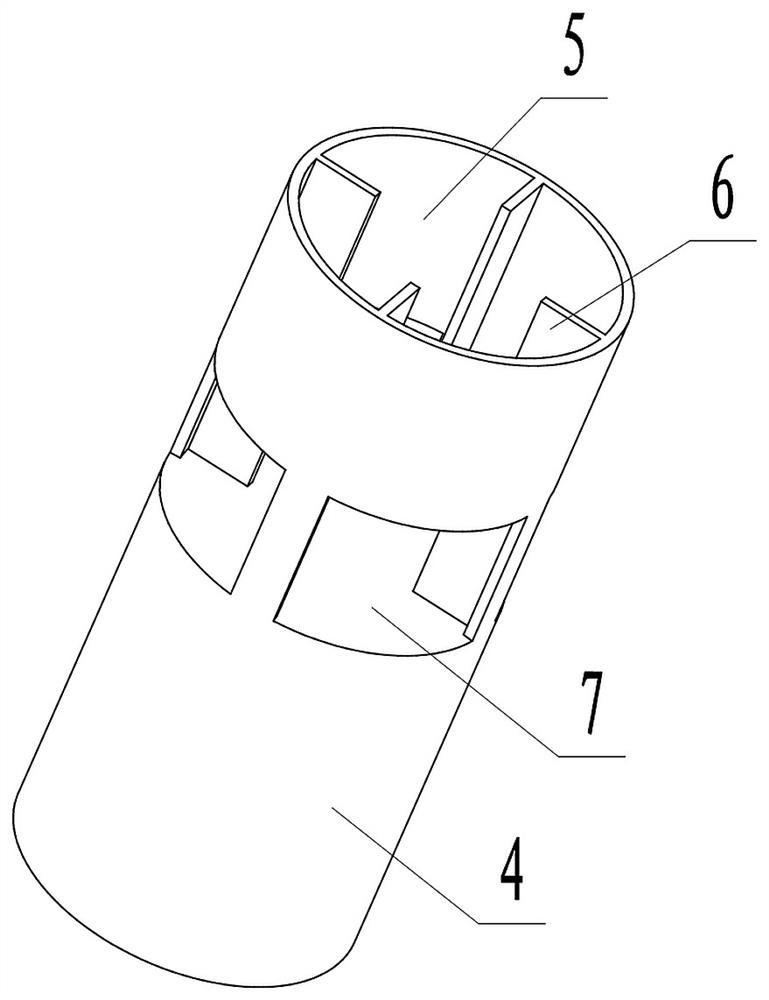

Ceramic fragment high-speed crushing device

InactiveCN112169962ARealize intermittent feedingRealize intermittent dischargeGrain treatmentsVertical edgeMechanical engineering

The invention relates to a ceramic fragment high-speed crushing device effectively solving the problems that the ceramic fragments are not easy to crush and easily damage instruments. According to thesolution technical scheme, the ceramic fragment high-speed crushing device comprises multiple supporting rods, an outer shell capable of moving up and down is installed on the supporting rods, a rotatable cylinder is arranged at the center of the outer shell, a counter bore is formed in the upper portion of the cylinder, and multiple vertical edges are evenly distributed on the circumference of the inner wall of the counter bore. Multiple through grooves penetrating through the side wall are formed in the bottom circumference of the counter bore. A push disc capable of moving up and down is installed in the counter bore, a first push rod penetrating through the cylinder is fixed to the lower end of the push disc, and a vertical second push rod is connected to the lower end of the outer shell. The first push rod and the second push rod synchronously move up and down in opposite directions, a feeding hopper is fixed above the supporting rods, the lower end of the feeding hopper is arranged in the outer shell, and a discharging passageway is arranged on the lower left portion of the outer shell. A second telescopic rod is installed in the feeding hopper, and a spherical plug is arranged on the end portion of the second telescopic rod. The ceramic fragment high-speed crushing device can sufficiently crush the ceramic fragments.

Owner:刘立超

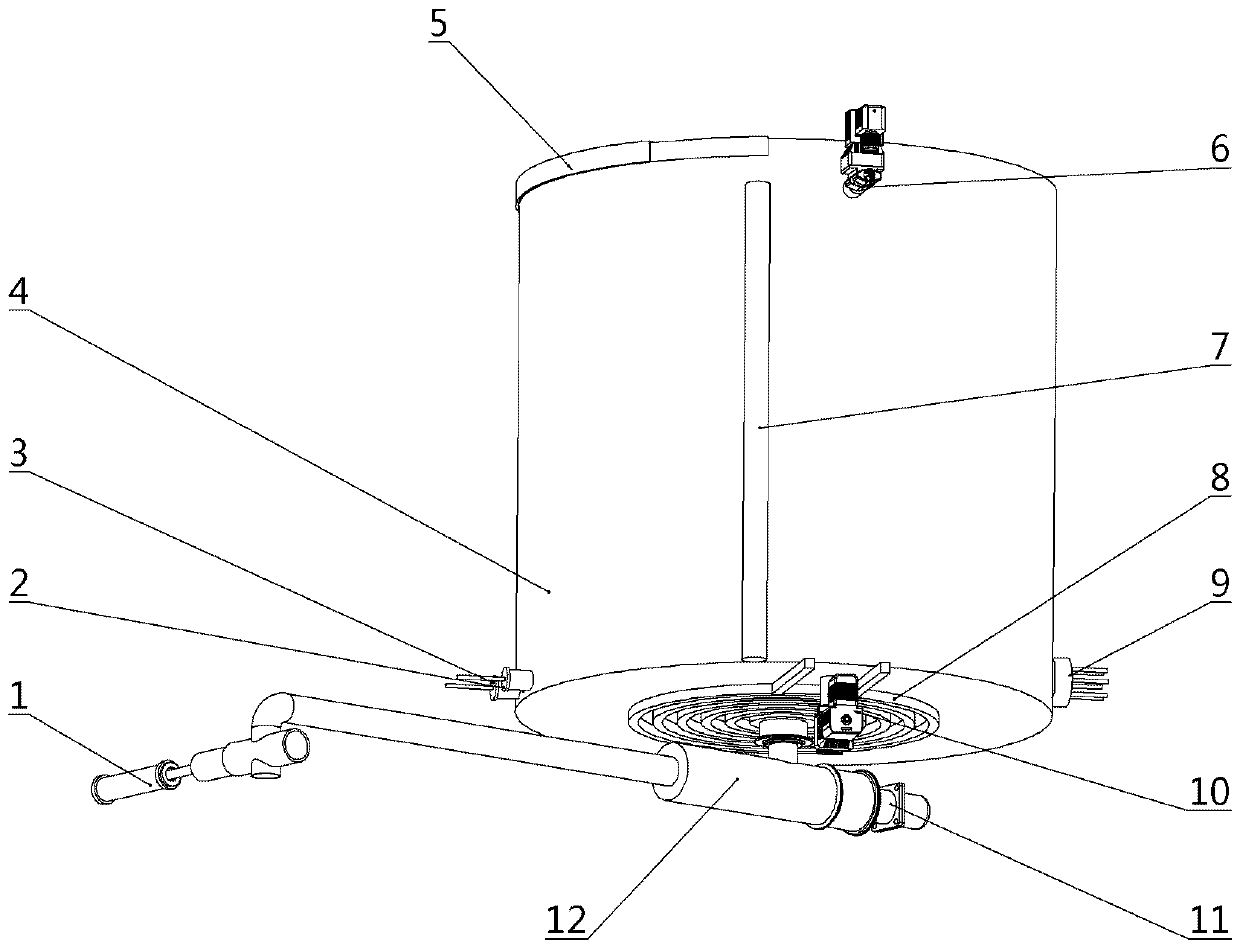

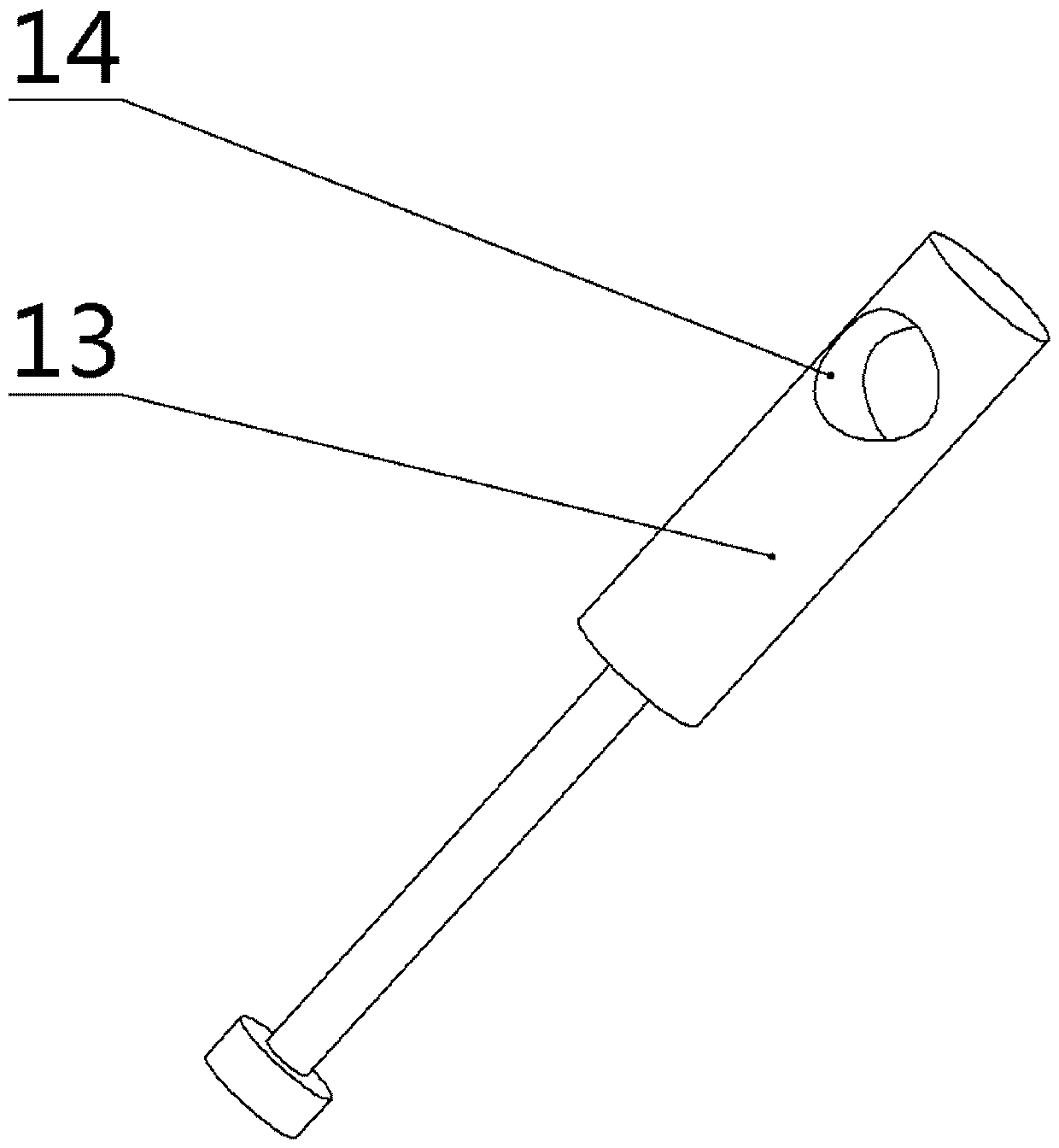

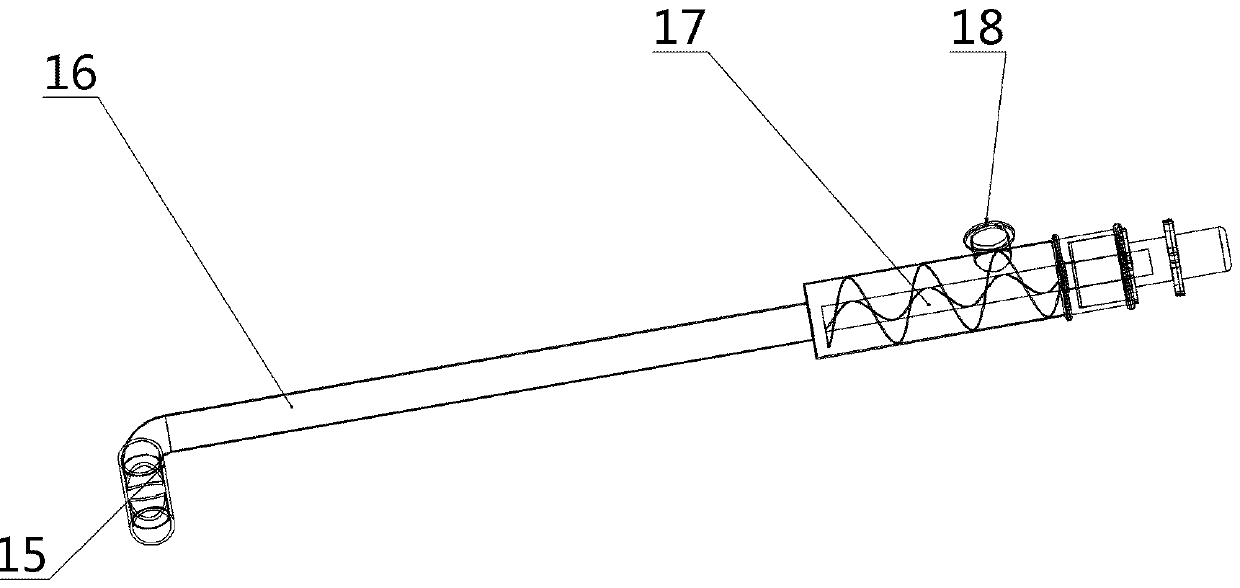

Magnetic stirring, heating and quantitative conveying selling system for retail field

The invention relates to a magnetic stirring, heating and quantitative conveying selling system for a retail field. The system comprises a water bath type heating and heat preservation cylinder, a spiral conveyor, a magnetic stirring device and a pneumatic type outlet switch. A water bath type heat preservation conveying device is located above the spiral conveyor, the spiral conveyor is horizontally placed, and a magnetic coil is located at the bottom of the water bath type heating and heat preservation cylinder; a stirrer is provided with blades and located in the center of the cylinder, andthe pneumatic type outlet switch is located in a horizontal pipe of a four-way pipe at the tail end of the spiral conveyor and is perpendicular to an outlet of the spiral conveyor; a through hole isformed in an air cylinder rod and is opposite to a pipeline at the outlet of the spiral conveyor. According to the system, magnetic stirring, heating, heat preservation and quantitative conveying of fresh porridge food in the retail field can be realized, and the invention belongs to the field of food processing and retail.

Owner:王建忠 +1

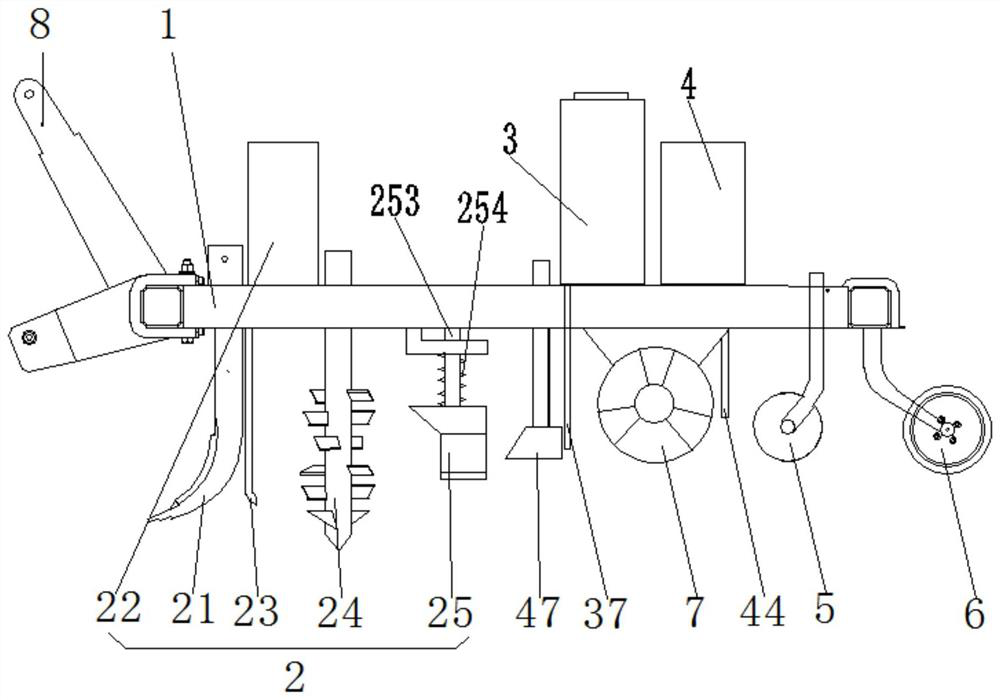

Corn no-tillage seeding and fertilizing machine

PendingCN113207332AGuaranteed not to burn seedlingsPromote germinationSpadesPloughsSeederAgricultural engineering

The invention discloses a corn no-tillage seeding and fertilizing machine, and belongs to the technical field of agricultural machinery. The corn no-tillage seeding and fertilizing machine comprises a machine frame, a deep scarification, fertilization and soil preparation mechanism, a seed and fertilizer application mechanism, a seeding mechanism, a soil covering mechanism and a pressing mechanism, and the deep scarification, fertilization and soil preparation mechanism, the seed and fertilizer application mechanism, the seeding mechanism, the soil covering mechanism and the pressing mechanism are sequentially arranged on the machine frame. The seed and fertilizer application mechanism and the seeding mechanism are correspondingly connected with a walking wheel shaft through chain transmission; a seed and fertilizer discharge pipe is arranged at the working rear end of a furrowing blade of the seeding mechanism; the fertilizer is arranged at the bottom of a seed furrow; and a seed outlet of a seed discharging pipe of the seeding mechanism is arranged behind the furrowing blade, so that the fertilizer discharged from the seed fertilizer and the sown seeds are arranged at different positions and different depths of the seed furrow. According to the corn no-tillage seeding and fertilizing machine, the fertilizer does not burn seedlings, the seeds can well absorb the fertilizer, and the germination of the seeds is facilitated.

Owner:LIAONING JIDIAN POLYTECHNIC

Oil-water separation device for vacuum pump

InactiveCN111265968AImprove cooling effectAvoid pollutionDispersed particle separationVapor condensationCooling effectEngineering

The invention relates to an oil-water separation device for a vacuum pump. The oil-water separation device comprises a separation box, and the separation box is connected with a gas inlet pipe and a gas outlet pipe; a separation mechanism is arranged in the separation box and comprises a rotating shaft and a plurality of separation assemblies, a separation space is formed between every two adjacent separation assemblies, oil-containing gas enters the separation box through the gas inlet pipe and the gas inlet, and the oil-containing gas acts on the separation assemblies located below the gas inlet to drive the rotating shaft to rotate so as to drive all the separation assemblies to rotate together; when the separation space rotates to the gas outlet along with the separation assemblies, the two adjacent separation assemblies forming the separation space gradually get close to each other, gas in the separation space is extruded out of the gas outlet, oil gas in the separation space is cooled in the rotating process, and oil-containing liquid is condensed and flows out of the bottom of the separation box. The problems that when existing equipment cools and separates exhausted gas, the cooling effect is poor, separation is insufficient, and the exhausted gas contains oil and impurities and pollutes gas are solved.

Owner:魏九宝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com