Granulation disc, granulator and granulation assistant preparation system

A technology of granulation disc and granulation machine, which is applied in the direction of granulation of raw materials, granulation of liquid into beads, granulation in rotating disk/pot, etc., which can solve the problem of poor sphericity, reduced fluidity and difficult to meet Single kiln particle demand and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

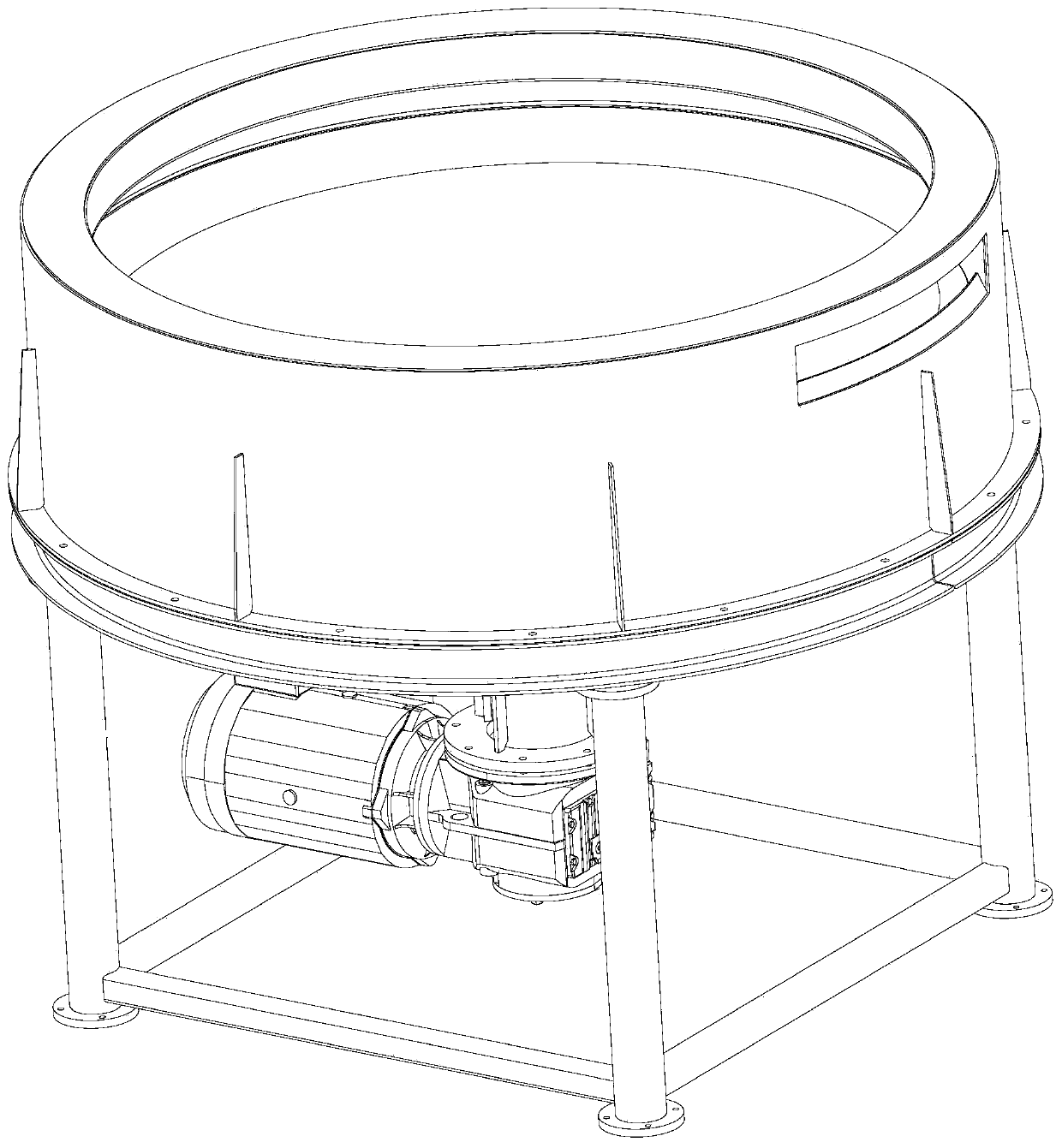

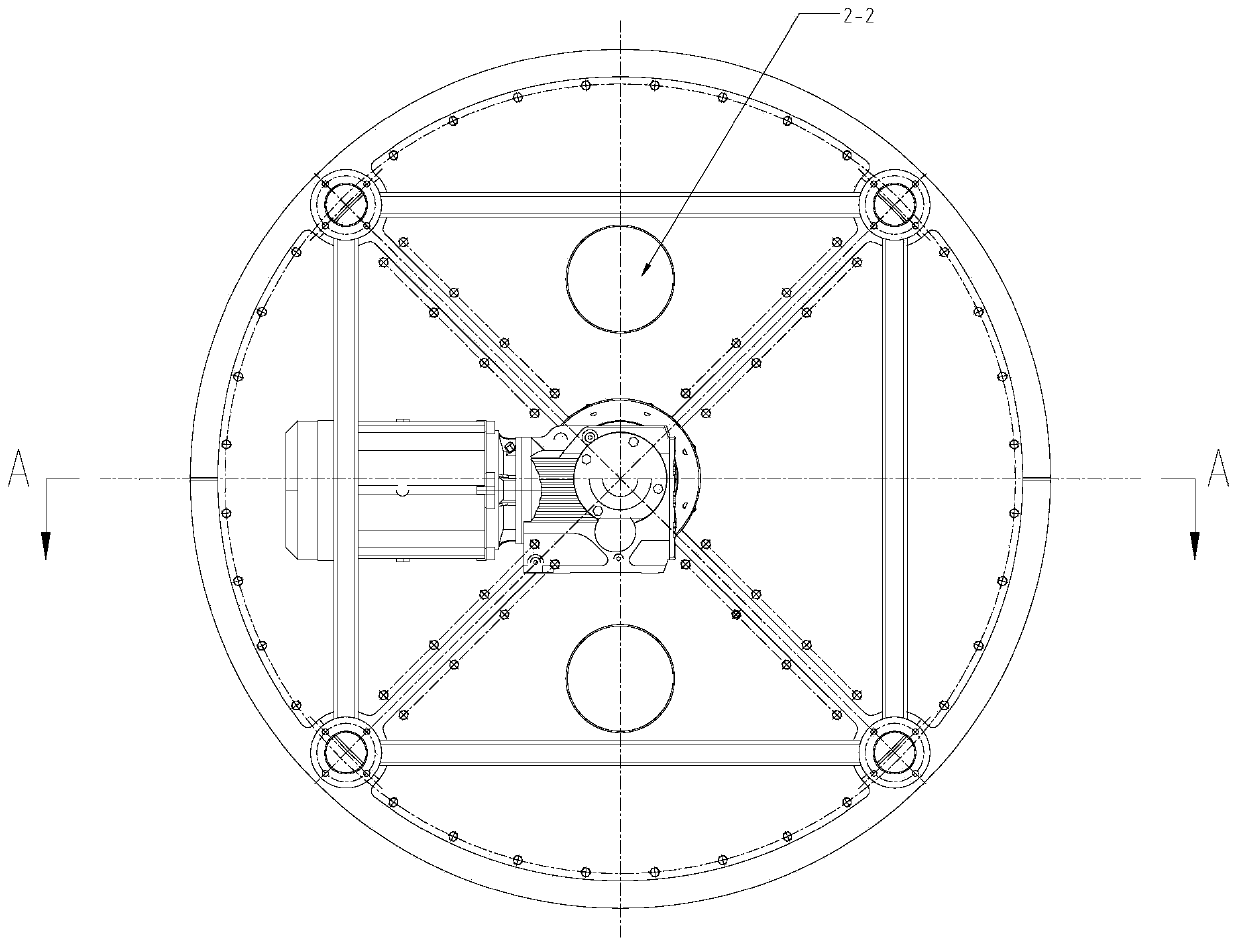

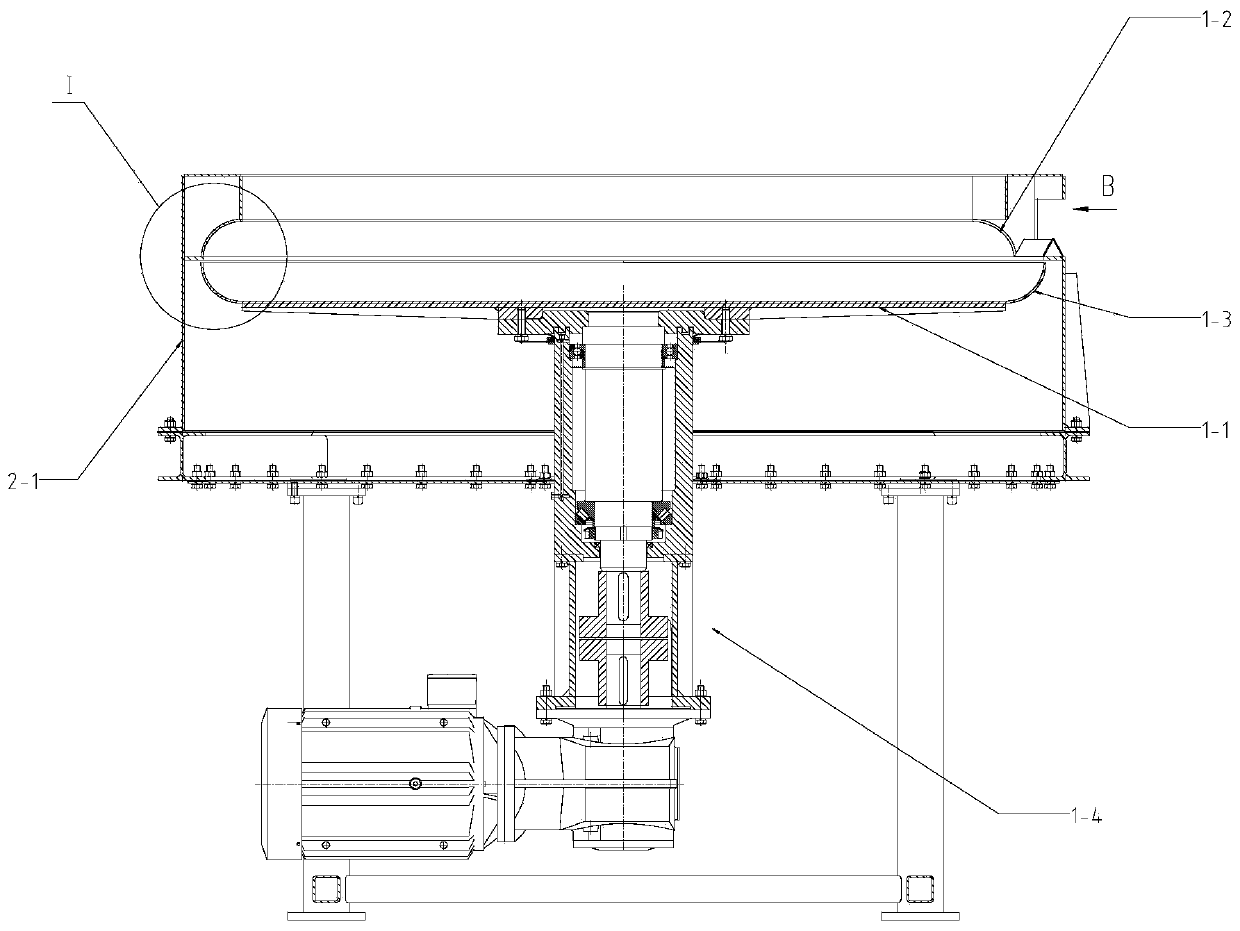

[0102] As attached to the manual Figure 1-5 As shown, a granulation disk, the edge of the granulation disk 1-1 adopts a 180° arc design, and the edge of the granulation disk is divided into a relatively movable upper disk 1-2 and a lower disk 1 -3, the lower disk is connected with the transmission mechanism 1-4, so that the lower disk rotates on the horizontal plane around its center point, the upper disk is left standing, and there is a gap between the upper disk and the lower disk, and the gap Gas-tight.

[0103] In order to improve the strength and sphericity of the pressed powder particles, the patent of the present invention adopts a special design for the internal structure of a single granulation disk in order to prolong the residence time and rolling times of the pressed powder particles in the granulation disk. The edge of the plate adopts a 180° arc design, and divides the 180° arc into upper plate and lower plate, but not limited to the equal division mode. The lo...

Embodiment 2

[0106] Further speaking, it can also be considered in the present invention, as described in the attached description figure 2 As shown, the upper plate 1-2 is installed on the frame 2-1, the lower plate is accommodated in the frame 2-1, and an air charging port 2-2 is opened on the frame outside the lower plate, so The air charging port is connected with a hot air blower through a pipeline.

[0107] The gas seal is realized by blowing hot air into the frame outside the upper plate and the lower plate with a hot air blower. The hot air blown by the blower enters the frame through the pipe. Since the drive bearing of the frame and the lower plate is mechanically sealed, it is compatible with the frame. The upper plate is also mechanically sealed, and the bulging hot air can only flow into the plate through the gap between the upper plate and the lower plate, forming a gas seal between the upper plate and the lower plate.

[0108] Another object of the present invention is to ...

Embodiment 3

[0111] As attached to the manual Figure 6-8As shown, further speaking, it can also be considered in the present invention that the top 3-1 of the granulator adopts a hemispherical design, and the top of the granulator adopts a hemispherical design, and the top curve and multi-layer material spreading The material distribution trajectory of the plate is coordinated.

[0112] The edge of the hemisphere is a 90-degree arc. The top curve matches the spreading trajectory of the multi-level spreading disc. After the powder is accelerated by pneumatic force, it is sprinkled on the rotating three-layer spreading plate. The trajectory of the powder is in the form of a parabola from the front. The top of the granulator is used for the dispersion of the powder, so the granulator The design of the top shape also adopts a 90° arc design close to a parabola, that is, the edge of the hemisphere is a 90° arc.

[0113] The top of the prilling tower adopts a hemispherical design, which coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com