Wheat drying device for flour processing

A drying device and wheat technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of poor dispersion performance of wheat, affecting drying efficiency, etc., achieve excellent drying effect, improve drying uniformity, Avoid uneven drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

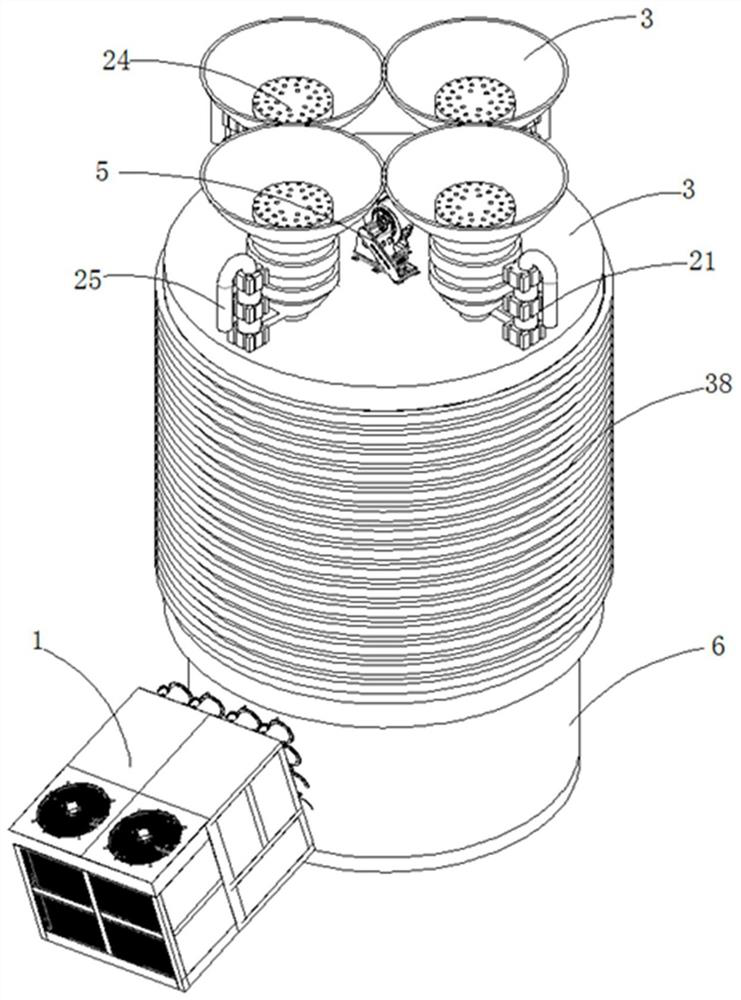

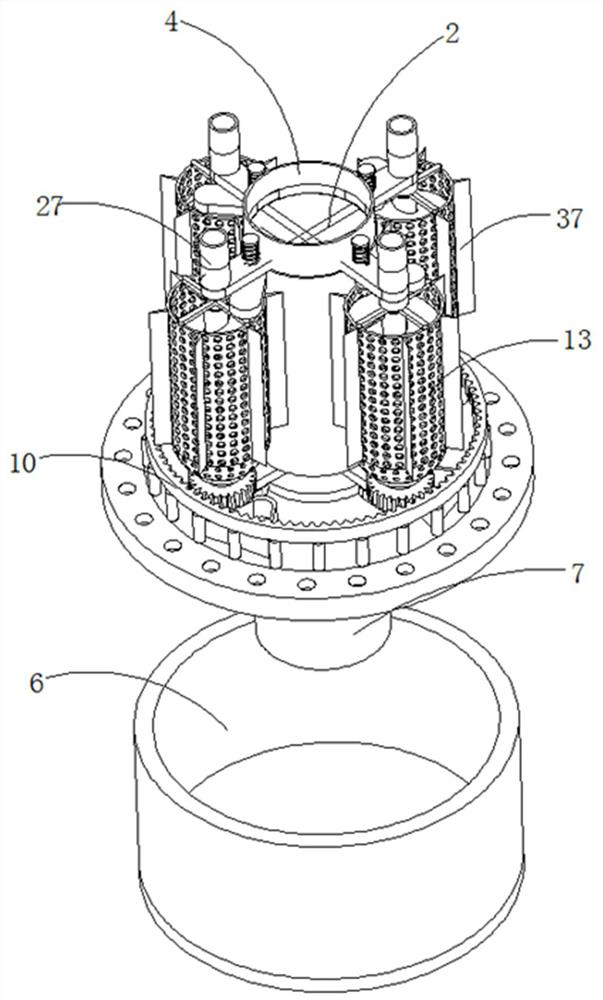

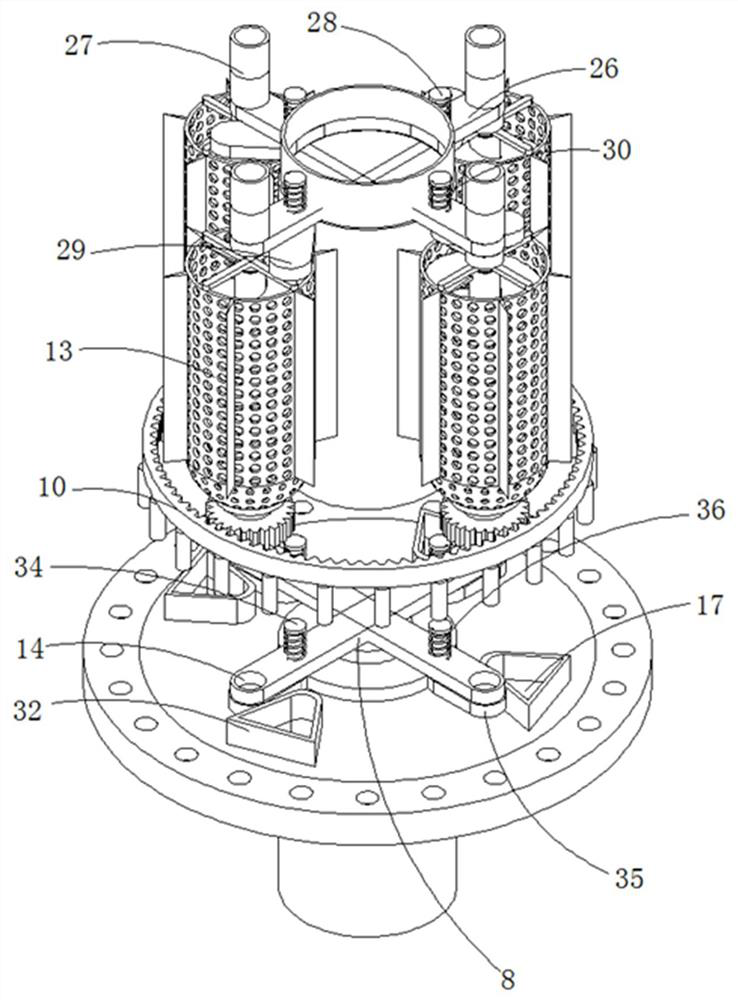

[0040] refer to Figure 1-6 , a wheat drying device for flour processing, comprising a heat pump main unit 1, a condenser extension unit 2 and a drying bin 3, the heat pump main body 1 is arranged outside the drying bin 3, and the inner cavity of the drying bin 3 is surrounded by a partition plate 4 for heating The drying chamber is formed between the inner wall of the drying chamber 3 and the partition 4, the condenser extension 2 is installed in the heating chamber, and the top of the drying chamber 3 is fixedly connected with a centrifugal fan 5 connecting the heating chamber and the drying chamber. A collection bin 6 is fixedly connected to the bottom of the collection bin 6, and a drive motor 7 is fixedly connected to the center of the bottom of the collection bin 6. The driving end of the drive motor 7 is fixedly connected with a cross drive plate 8 through a rotating shaft placed in the drying bin 3, and the cross drive The end of the plate 8 is fixedly connected with t...

Embodiment 2

[0050] refer to Figure 2-5 , a wheat drying device for flour processing, which is basically the same as that of Embodiment 1, and furthermore, the outer wall of the hollow drying cylinder 13 is fixedly connected with an air-introduction piece 37, and the air-induction piece 37 is driven while the driven gear 9 rotates. 37 rotations to evenly disperse the hot air conducted in the heating chamber to improve the uniformity of drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com